Introduction

Nitinol Shape Memory Alloys, also known as SMA, are revolutionizing the field of robotics actuators. These innovative components are being widely used in the development of advanced robotic systems, owing to their unique properties and capabilities. Nitinol's ability to remember its original shape and return to it when heated makes it an ideal material for creating efficient and powerful actuators in robotics.

Understanding Nitinol Shape Memory Alloys

Nitinol For Robots is paving the way for cutting-edge advancements in robotics technology, with its remarkable shape memory properties. These alloys can undergo deformation and then revert to their original shape when subjected to temperature changes, making them ideal for creating versatile actuators that mimic human muscle movement in robots.

Nitinol shape memory alloys are revolutionizing the field of robotics by providing a solution to the limitations of traditional actuators. With the ability to revert to their original shape, these alloys enable robots to perform a wide range of movements with precision and efficiency. This opens up new possibilities for the development of robots that can navigate complex environments and interact with objects in a more human-like manner.

Nitinol Components in Robotics

Actuators built from Nitinol have highest power, offering superior performance and precision in robotic movement. From linear actuators to artificial actuators for exoskeletons, Nitinol components are being integrated into a wide range of robotic systems to enhance their functionality and efficiency.

Nitinol components are also known for their durability and resilience, making them ideal for use in robotic systems that require long-term reliability. This allows robotic devices to operate consistently without the need for frequent maintenance or replacement of parts, ultimately reducing downtime and increasing productivity. Additionally, the high energy efficiency of Nitinol actuators contributes to cost savings and environmental sustainability, making them a preferred choice for modern robotic applications.

Advantages of Nitinol Robotics Actuators

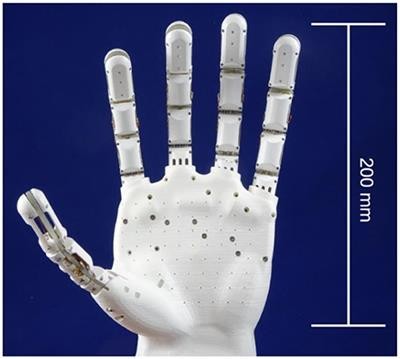

Nitinol Finger Actuator is a game-changer in robotics, providing unparalleled precision and control in robotic movement. These durable and long-lasting actuators not only improve the efficiency of robots but also contribute to the overall durability and longevity of robotic systems. Furthermore, the use of Nitinol actuators reduces the need for frequent maintenance and replacement, saving both time and resources for robot operators. In addition, their compact size allows for more intricate and agile robotic designs, opening up new possibilities for applications in various industries.

GEE SMA: Leader in Nitinol Production

GEE SMA has established itself as a leader in the production of high-quality Nitinol materials for robotics actuators. With state-of-the-art manufacturing processes, they ensure that their Nitinol components meet the stringent requirements of the robotics industry. Their expertise in crafting Nitinol for robots has set them apart as the go-to supplier for cutting-edge actuators.

Crafting High-Quality Nitinol Materials

GEE SMA's commitment to crafting high-quality Nitinol materials is evident in their rigorous quality control measures and precision manufacturing techniques. Their dedication to excellence ensures that the actuators used in robotics are reliable, durable, and capable of delivering optimal performance. This attention to detail has solidified their reputation as a trusted provider of Nitinol components for robots.

GEE SMA's dedication to customer satisfaction is reflected in their ability to tailor Nitinol components to meet specific needs. By working closely with clients, they are able to understand the unique requirements of each robotics application and customize their materials accordingly. This personalized approach ensures that the Nitinol components not only meet industry standards but also exceed the expectations of their customers, setting them apart as a leader in the field.

Tailoring Nitinol Components to Customer Needs

One of GEE SMA's key strengths lies in their ability to tailor Nitinol components to meet specific customer needs in robotics actuators. Whether it's custom shapes, sizes, or performance requirements, they work closely with clients to deliver bespoke solutions that align with their unique specifications. This personalized approach has earned them praise for their flexibility and responsiveness in catering to diverse robotics applications.

Furthermore, GEE SMA's expertise in Nitinol components extends to their ability to optimize the material's shape memory and superelasticity to meet the unique demands of robotics actuators. This means that their tailored solutions not only fit specific size and shape requirements but also deliver exceptional performance under varying conditions. By staying at the forefront of Nitinol technology, GEE SMA ensures that their customers receive cutting-edge solutions that push the boundaries of what is possible in robotics applications.

Addressing Customer Requirements Swiftly

GEE SMA prides itself on its agility and responsiveness when it comes to addressing customer requirements for Nitinol components used in robots' actuators. Their streamlined processes and efficient communication channels enable them to swiftly adapt to changing demands and deliver solutions within tight timelines. This proactive approach has positioned them as a preferred partner for robotic actuator needs.

GEE SMA's commitment to customer satisfaction extends beyond just meeting requirements for Nitinol components. Their team of experts goes the extra mile to understand the specific needs and challenges of their clients, allowing them to offer tailored solutions that address unique use cases and performance demands. This personalized approach not only ensures customer satisfaction but also fosters long-term partnerships built on trust and reliability.

Nitinol For Robots: The Future of Actuators

Nitinol For Robots is revolutionizing the field of robotics actuators with its cutting-edge technology. The Nitinol Linear Actuator (2 way) is a game-changer, providing precise and efficient movement for robotic applications. This innovative actuator allows for seamless back-and-forth motion, making it ideal for a wide range of robotic functions.

Nitinol Linear Actuator (2 way)

The Nitinol Linear Actuator (2 way) is at the forefront of robotics actuators, offering unparalleled versatility and control. Its unique two-way shape memory alloy design enables smooth and accurate linear movement, making it an indispensable component in advanced robotic systems. With Nitinol For Robots, the future of actuators in robotics is brighter than ever.

The Nitinol Linear Actuator (2 way) is not only versatile and precise, but it also offers exceptional durability, making it a reliable choice for long-term use in robotic systems. Its ability to seamlessly transition between two different shapes allows for greater flexibility in movement, giving robots the agility they need to perform a wide range of tasks with efficiency and accuracy. As robotics technology continues to advance, the Nitinol Linear Actuator (2 way) is poised to play an increasingly vital role in shaping the future of automation and artificial intelligence.

Shape Memory Alloy as an Artificial Actuator for Exoskeletons

Nitinol's Shape Memory Alloy serves as an artificial actuator for exoskeletons, enhancing strength and flexibility in robotic exosuits. This groundbreaking application of Nitinol components opens up new possibilities for exoskeleton technology, allowing for seamless integration with human movement and superior performance in various environments.

Furthermore, Nitinol's Shape Memory Alloy offers the highest power actuators for exoskeletons, providing unparalleled strength and durability for robotic exosuits. This cutting-edge technology allows for seamless integration with human movement, enabling exoskeletons to mimic natural motion with precision and efficiency. As a result, users can experience enhanced mobility and functionality in a wide range of environments, from industrial settings to medical rehabilitation facilities.

Highest Power Actuators with Nitinol

Actuators built from Nitinol have set a new standard for power and efficiency in robotics. With unmatched strength and durability, these high-power actuators are capable of handling the most demanding tasks with ease. From heavy lifting to precise manipulation, Nitinol components are paving the way for next-generation robotics actuators.

With Nitinol For Robots leading the charge, the future of actuators in robotics is taking a giant leap forward. As the demand for more advanced and efficient robotic systems grows, Nitinol components are poised to play a pivotal role in shaping the next generation of robotics technology.

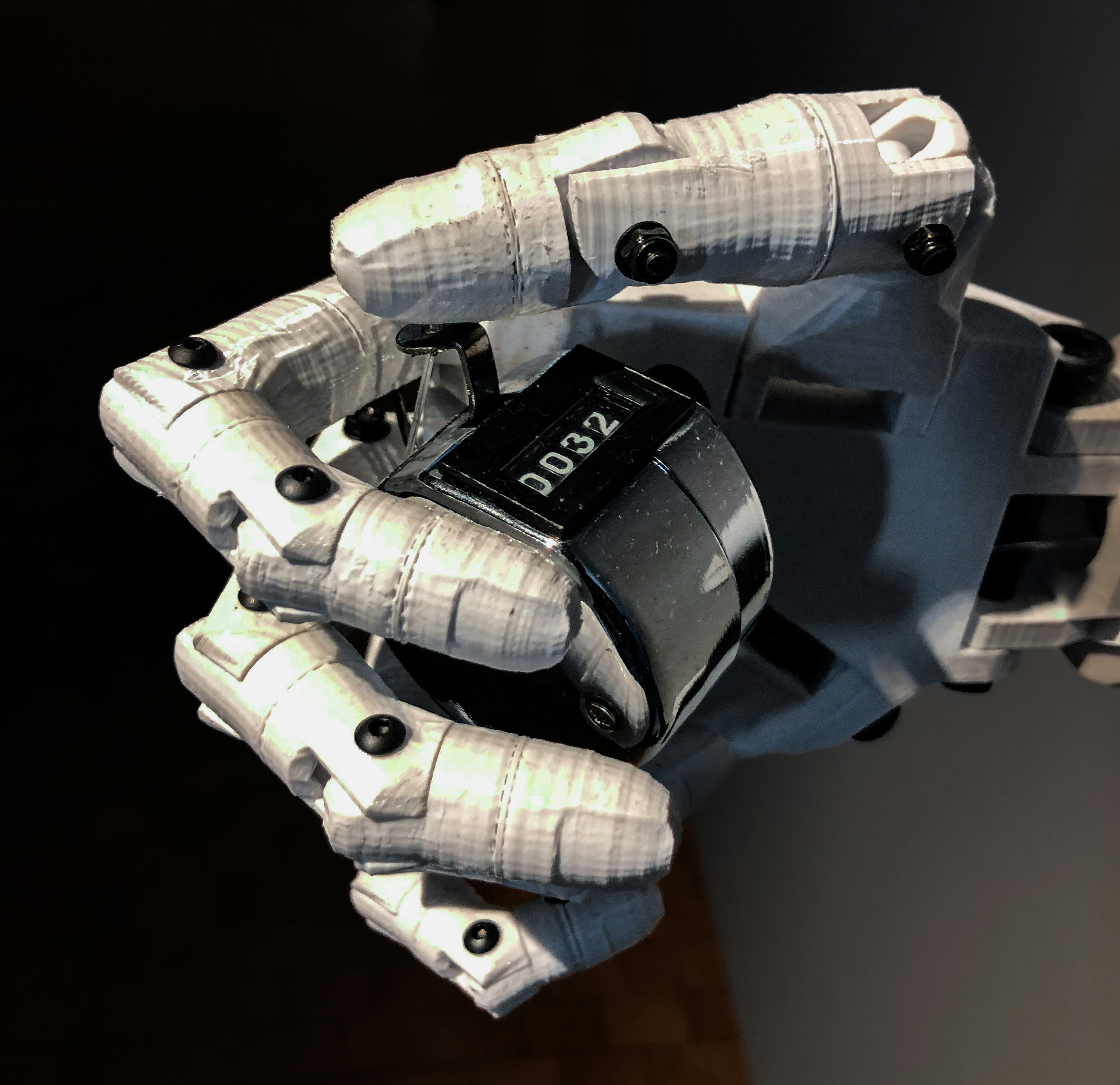

Nitinol Finger Actuator: A Game-Changer in Robotics

Nitinol finger actuators are revolutionizing robotics with their precision and control, allowing for intricate movements and manipulation. These actuators, built from Nitinol, provide enhanced efficiency in robotic movement, enabling robots to perform tasks with greater accuracy and speed. Moreover, the durability and longevity of Nitinol actuators ensure sustained performance over extended periods, making them an indispensable component in the field of robotics.

Precision and Control with Nitinol Actuators

Nitinol finger actuators offer unparalleled precision and control in robotics, allowing for delicate and intricate movements. This level of accuracy is crucial in various applications such as surgical robots or assembly line automation, where precise actions are required to perform complex tasks with utmost accuracy.

Nitinol finger actuators are also known for their durability and longevity, making them a cost-effective solution for robotics. Their ability to withstand repetitive movements and high stress environments ensures that they can maintain their precision and control over time, reducing the need for frequent maintenance or replacement. This makes them an ideal choice for industries looking to streamline their operations and minimize downtime.

Enhanced Efficiency in Robotic Movement

The integration of Nitinol linear actuators (2 way) and shape memory alloy as artificial actuators for exoskeletons has significantly enhanced the efficiency of robotic movement. These advanced components allow robots to move more fluidly and swiftly, optimizing their performance across a wide range of tasks.

The durability and longevity of Nitinol actuators also contribute to the enhanced efficiency of robotic movement. With the ability to withstand repetitive use and extreme conditions, these advanced components ensure that robots can maintain their peak performance over an extended period. This reliability is essential for applications in industries such as manufacturing, healthcare, and logistics, where robots are required to operate continuously with minimal downtime.

Durability and Longevity of Nitinol Actuators

Actuators built from Nitinol have the highest power among all available options, making them ideal for demanding robotic applications that require robust performance. Furthermore, the durability and longevity of Nitinol components ensure that robots equipped with these actuators can operate consistently over extended periods without compromising on their functionality.

In addition, Nitinol actuators are known for their high energy efficiency, allowing robots to operate for longer periods without draining excessive power. This makes them an excellent choice for applications where energy conservation is a priority, such as in remote or autonomous robotic systems. The ability of Nitinol actuators to maintain their performance over time also contributes to their cost-effectiveness, as they require minimal maintenance and replacement compared to other actuator options.

Conclusion

Nitinol For Robots has revolutionized the field of robotics actuators with its cutting-edge technology and unmatched performance. The use of Nitinol Linear Actuator (2 way) and Shape Memory Alloy as an Artificial Actuator for Exoskeletons has paved the way for more efficient and powerful robotic movements. Actuators built from Nitinol have the highest power, providing unparalleled strength and precision in robotic operations.

The Role of Nitinol in Robotics Advancement

Nitinol Components have played a pivotal role in advancing robotics by offering superior quality materials that enhance the overall performance of robotic systems. With Nitinol Finger Actuator, precision and control are taken to new heights, ensuring seamless and accurate movements in various applications.

Leveraging Nitinol Components for Efficient Robotics

By leveraging Nitinol components, robotics engineers can achieve greater efficiency and reliability in their designs. The durability and longevity of Nitinol actuators make them an ideal choice for long-term use, reducing maintenance costs and downtime.

By leveraging Nitinol components, robotics engineers can achieve greater efficiency and reliability in their designs. The durability and longevity of Nitinol actuators make them an ideal choice for long-term use, reducing maintenance costs and downtime. Additionally, the unique shape memory properties of Nitinol allow for precise and repeatable movements, enhancing the overall performance of robotic systems. This level of precision is essential for tasks that require delicate manipulation or intricate motions, giving Nitinol actuators a clear advantage over traditional components.

Future of Robotics Actuators: Nitinol's Dominance

As we look to the future, it is evident that Nitinol's dominance in robotics actuators will only continue to grow. With ongoing advancements in material science and engineering, Nitinol For Robots is set to lead the way in shaping the next generation of highly efficient and powerful robotic systems.

With the increasing demand for robots in various industries, Nitinol's unique properties make it an ideal choice for actuators. Its shape memory and superelasticity allow for precise and responsive movements, making it perfect for intricate tasks in robotics. As the technology continues to evolve, we can expect to see even more innovative uses of Nitinol in robotic systems, further solidifying its dominance in the field.