Introduction

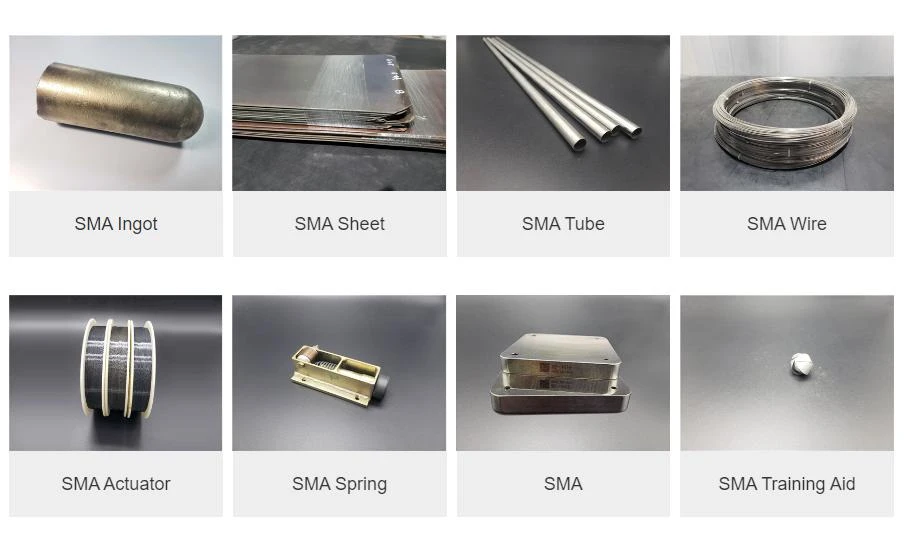

When it comes to cutting-edge manufacturing, NiTiFe wires are a game-changer. These innovative materials offer unparalleled strength and flexibility, making them essential for various industries. At GEE SMA, we specialize in producing top-quality NiTiFe wires that meet the highest standards of excellence.

Understanding NiTiFe Wires

NiTiFe wires, also known as N, iTiFe, are shape-memory alloys with remarkable properties such as superelasticity and shape-memory effect. These unique characteristics allow the wires to return to their original shape after deformation, making them ideal for a wide range of applications in manufacturing.

NiTiFe wires are highly versatile and can be used in various manufacturing processes. Their ability to return to their original shape after deformation makes them perfect for medical devices, automotive components, and aerospace engineering applications. This versatility allows manufacturers to use NiTiFe wires in multiple ways, reducing the need for different materials and streamlining production processes.

Advantages of NiTiFe Wires in Manufacturing

NiTiFe wires, a type of shape-memory alloy, are transforming the manufacturing landscape. These innovative materials boast a unique combination of properties that enhance efficiency, precision, and durability in various production processes.

Here's how NiTiFe wires are revolutionizing manufacturing:

- Superior Strength and Flexibility: NiTiFe wires can withstand high stress without permanent deformation. This exceptional resilience allows for intricate designs and precise movements in manufacturing equipment, improving production accuracy.

- Excellent Corrosion Resistance: NiTiFe wires excel in harsh industrial environments. Their corrosion resistance ensures they maintain their structural integrity and functionality over time, minimizing the need for replacements and maintenance, ultimately reducing downtime and costs.

- High Fatigue Resistance: NiTiFe wires can endure repeated stress cycles without degradation. This remarkable property extends their lifespan and cost-effectiveness in demanding manufacturing applications.

NiTiFe wires offer a compelling combination of strength, flexibility, corrosion resistance, and fatigue resistance, making them a valuable asset for manufacturers seeking to optimize their production processes.

GEE SMA: Your Source for Quality NiTiFe Wires

At GEE SMA, we are a leading provider of top-quality NiTiFe wires. Our expertise and commitment to excellence ensure that our customers receive the finest materials that meet their specific needs and exceed industry standards.

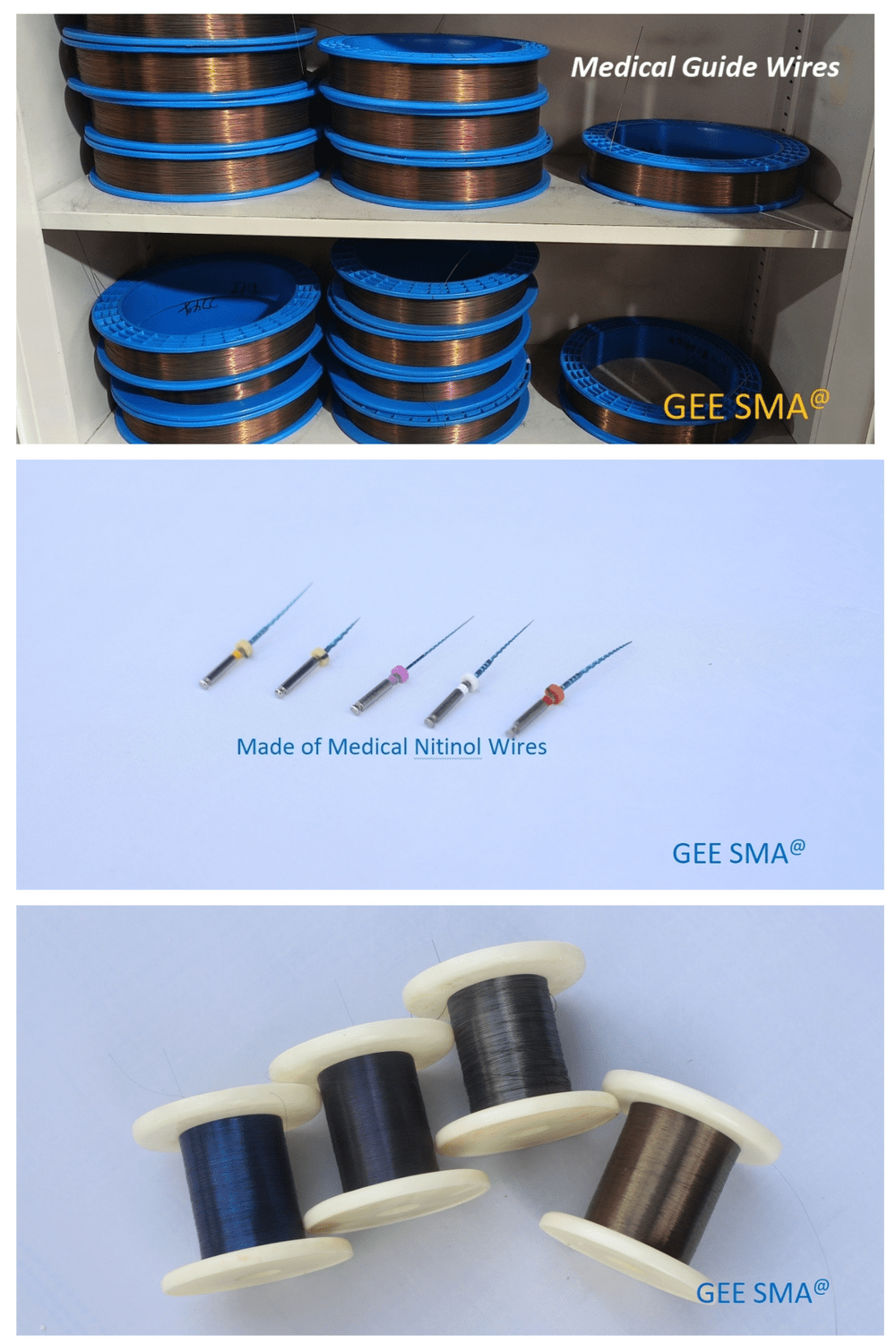

Our NiTiFe wires are known for their exceptional strength, flexibility, and resistance to corrosion, making them ideal for a wide range of applications in the medical, aerospace, and automotive industries. Whether you need wires for orthodontic braces, surgical instruments, or engine components, our NiTiFe wires are designed to deliver superior performance and durability. With GEE SMA as your trusted source for quality NiTiFe wires, you can be confident that you are getting the best materials.

The Power of NiTiFe Wires

NiTiFe wires are renowned for their superior strength and flexibility, making them a top choice in various manufacturing applications. Their unique composition allows for high tensile strength and remarkable elasticity, providing unmatched durability and resilience in demanding conditions. This makes NiTiFe wires an invaluable asset in producing components that require strength and flexibility.

Superior Strength and Flexibility

NiTiFe wires are engineered to withstand extreme pressure and tension without compromising their structural integrity. This exceptional strength, combined with their inherent flexibility, enables them to be utilized in a wide range of applications where traditional materials fall short. From aerospace engineering to medical device manufacturing, NiTiFe wires offer a level of performance unmatched by conventional materials.

NiTiFe wires offer superior strength and flexibility and contribute to enhanced production efficiency. Their ability to withstand extreme pressure and tension means they can be used in high-stress environments without the risk of structural failure, leading to increased productivity and reduced downtime. With NiTiFe wires, manufacturers can streamline their production processes and achieve higher output levels, ultimately improving their bottom line.

Enhanced Efficiency in Production

Using NiTiFe wires in manufacturing significantly enhances efficiency by streamlining production and reducing material waste. Their ability to maintain shape memory allows for precise shaping and forming without excessive tooling or post-processing, leading to faster production cycles and reduced lead times. This efficiency improves productivity and contributes to cost savings for manufacturers.

Applications in Various Industries

NiTiFe wires are revolutionizing various industries with their unique properties. Here's why they're becoming increasingly important:

- Unmatched Versatility: NiTiFe wires can be shaped into intricate components like springs, actuators, sensors, and connectors. This makes them ideal for a wide range of applications across diverse sectors.

- Strength and Flexibility: These innovative wires can withstand high stress without permanent deformation yet remain flexible for intricate designs.

- Shape Memory Magic: NiTiFe wires can "remember" their original shape and return to it after deformation, adding a new dimension to functionality.

As technology continues to evolve, the demand for NiTiFe wires will surge, solidifying their place as a key driver of innovation across multiple fields.

NiTiFe Wires in Action

NiTiFe wires are revolutionizing the manufacturing industry with their incredible versatility and performance. N, iTiFe, and NiTiFe tube coupling systems are widely used to create durable and efficient connections in various applications. These innovative coupling systems provide a reliable solution for joining tubes and pipes in the automotive, aerospace, and medical equipment manufacturing industries.

NiTiFe, NiTiFe Tube Coupling

The N, iTiFe, and NiTiFe tube coupling technology utilizes shape-memory alloys to create a secure, leak-proof connection between tubes. This advanced system allows for easy installation and removal while maintaining a tight seal under extreme conditions. With the ability to withstand high pressures and temperatures, these couplings are ideal for critical applications where reliability is paramount.

The N, iTiFe, and NiTiFe tube coupling technology is a game-changer in the industry, offering a level of reliability and performance that is unmatched by traditional coupling methods. By harnessing the unique properties of shape-memory alloys, these couplings provide a secure and leak-proof connection that can withstand the harshest conditions. This innovative system ensures easy installation and removal and minimizes the risk of maintenance issues, making it a cost-effective solution for critical applications.

SMA Shape Memory Alloy

Shape memory alloy (SMA) is at the core of NiTiFe wire technology, providing exceptional flexibility and resilience. Its unique properties allow it to return to its original shape after deformation, making it perfect for applications that require precise movements or adjustments. From robotics to biomedical devices, SMAs are driving innovation across diverse industries.

Shape Memory Alloy Wire

Shape memory alloy wires offer unmatched performance in strength, durability, and shape memory effect. These wires can be easily shaped into complex forms and revert to their original configuration when temperature or stress changes activate them. As a result, they are widely used in actuators, sensors, and other critical components that demand reliable performance under challenging conditions.

The Benefits of Using NiTiFe Wires

NiTiFe wires offer a perfect combination of lightweight and durability, making them ideal for various applications. Their unique composition allows for easy handling and installation while providing exceptional strength and resilience in various manufacturing processes.

Lightweight and Durable Materials

The use of NiTiFe wires in manufacturing offers lightweight and durable materials and opens up opportunities for innovative design and functionality. With the ability to retain their shape after deformation, these shape-memory alloys allow for creating products with unique features such as self-healing properties or adaptive structures. This presents exciting possibilities for industries such as aerospace, automotive, and medical devices, where advanced materials can lead to groundbreaking advancements in technology and performance.

Shape-Memory Alloy Innovations

NiTiFe wires are at the forefront of shape-memory alloy innovations, allowing for the creation of products with unique properties such as flexibility and shape-memory capabilities. This opens up new possibilities for designing components that adapt to specific requirements, leading to innovative solutions in various industries.

NiTiFe wires are revolutionizing product design and maximizing efficiency in manufacturing processes. By incorporating these shape-memory alloy wires into components, manufacturers can reduce the number of parts needed for assembly, streamlining production and minimizing waste. This results in cost savings and improved productivity, making NiTiFe wires a game-changer for the manufacturing industry.

Maximizing Efficiency in Manufacturing Processes

By incorporating NiTiFe wires into manufacturing processes, businesses can maximize efficiency by streamlining production and reducing waste. These wires' superior strength and flexibility enable seamless integration into automated systems, resulting in smoother operations and higher output.

Using NiTiFe wires in manufacturing saves costs through reduced maintenance and downtime. These wires are highly durable and resistant to wear and tear, leading to fewer replacements and repairs. This translates to lower business expenses and a more reliable production line, ultimately improving the bottom line.

Application of NiTiFe Wires in Manufacturing

NiTiFe wires, with their remarkable properties, are revolutionizing the manufacturing industry. N, iTiFe, and NiTiFe Tube coupling are examples of how these wires change the game. The SMA shape memory alloy and shape memory alloy wire also make waves, offering unmatched flexibility and strength for various applications.

Memory Shape Metal

The memory-shape metal capabilities of NiTiFe wires allow for tailored components that can adapt to unique manufacturing needs. Whether it's intricate medical devices or precision engineering parts, these wires can be shaped and reshaped without losing their original form, making them invaluable assets in modern manufacturing processes.

The memory-shaped metal capabilities of NiTiFe wires offer a level of flexibility and adaptability that is unmatched in traditional manufacturing materials. This means that manufacturers can easily and precisely create highly specialized components for a wide range of industries, from aerospace to automotive. The ability to shape and reshape these wires without compromising their original form opens up possibilities for innovative and efficient manufacturing processes.

Tailored Components for Unique Needs

NiTiFe wires are revolutionizing the manufacturing industry by offering unparalleled customization and performance. Here's how they can benefit your business:

- Unmatched Flexibility: NiTiFe wires can be shaped and reshaped to meet specific requirements, creating highly customized components that traditional methods can't achieve.

- Exceptional Durability: These wires are built to last. They boast superior strength and corrosion resistance, which is ideal for demanding industry applications.

- Precision and Efficiency: NiTiFe wires enable the creation of intricate components with unmatched precision, streamlining manufacturing processes and boosting overall efficiency.

By leveraging the unique properties of NiTiFe wires, manufacturers can gain a significant edge in today's competitive market. Embrace the future of manufacturing with NiTiFe – the key to tailored solutions and exceptional performance.

GEE SMA's Expertise in NiTiFe Wire Production

GEE SMA is at the forefront of NiTiFe wire production, offering expertise and innovation that drive the industry forward. With a commitment to quality and cutting-edge technology, GEE SMA is leading the way in harnessing the potential of NiTiFe wires for manufacturing excellence.

With their memory-shaped metal capabilities and tailored components for unique needs, NiTiFe wires are transforming manufacturing processes across various industries. GEE SMA's expertise ensures that these revolutionary materials are utilized to their full potential, paving the way for a future where efficiency and innovation go hand in hand.

The Future of NiTiFe Wires

NiTiFe wires are revolutionizing the manufacturing industry, offering unparalleled strength, flexibility, and efficiency. As demand for innovative materials grows, the future of NiTiFe wires looks promising, with endless possibilities for applications across various sectors.

As technology advances, the potential uses for NiTiFe wires are limitless. From aerospace to medical devices, these shape-memory alloy wires pave the way for groundbreaking innovations and improved product performance. With their ability to return to a predetermined shape after being deformed, NiTiFe wires are revolutionizing minimally invasive medical procedures. Their flexibility and durability make them ideal for surgical instruments and implants, leading to faster recovery and improved patient outcomes.

GEE SMA: Your Partner in Manufacturing Efficiency

GEE SMA is committed to providing top-quality NiTiFe wires that meet the highest industry standards. With our expertise in shape-memory alloys and tailored components, we are dedicated to helping manufacturers enhance their production processes and achieve optimal efficiency. By harnessing the potential of NiTiFe wires, we offer innovative solutions that improve product performance and reliability. Our team works closely with manufacturers to understand their needs and develop customized wire solutions that streamline manufacturing operations and reduce production costs. With GEE SMA as your partner, you can expect cutting-edge materials that elevate your manufacturing efficiency.

Harnessing the Potential of NiTiFe Wires

By partnering with GEE SMA, manufacturers can access the expertise and resources needed to integrate NiTiFe wires into their products effectively. Our team of specialists can guide the best practices for utilizing these innovative materials, ensuring that your company stays at the forefront of technological advancements. With our support, you can confidently embrace the potential of NiTiFe wires and differentiate your offerings in the market.