Introduction

Welcome to the fascinating world of Nitinol wire spring, a remarkable material with unique properties that make it highly sought after in various industrial applications. From its shape memory to superelasticity, Nitinol spring has revolutionized the way we approach industrial efficiency and precision.

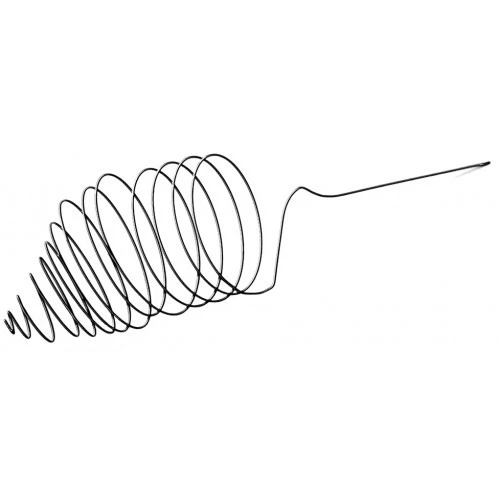

Understanding Nitinol Wire Spring

Nitinol spring, also known as Memory or Muscle Wire, is a type of Nickel Titanium Spring that exhibits remarkable properties such as shape memory and superelasticity. This allows the wire to return to its original shape after being deformed, making it ideal for a wide range of industrial applications.

Applications of Nitinol in Industry

The versatility of Nitinol spring has led to its widespread use in various industries, including medical devices, aerospace engineering, automotive components, and consumer electronics. Its ability to retain precision and memory in every coil makes it an invaluable material for achieving efficiency in industrial processes.

Importance of Efficiency in Industrial Applications

Efficiency is crucial in industrial applications as it directly impacts productivity and cost-effectiveness. The use of Nitinol spring enables manufacturers to enhance product quality, achieve cost efficiency, and overcome industry-specific challenges with innovative solutions.

By harnessing the power of Nitinol wire spring and understanding its unique properties, industries can unlock new possibilities for innovation and adaptation. Let's explore the activation process of nitinol wire and how GEE SMA specializes in crafting high-quality materials tailored to meet specific industrial needs.

The Unique Properties of Nitinol Wire Spring

Nitinol wire spring is renowned for its exceptional properties, including shape memory and superelasticity. This unique material can remember its original shape and return to it when heated, making it ideal for various industrial applications. In addition, its superelasticity allows it to withstand significant deformation without permanent damage, offering unmatched durability and reliability.

Shape Memory and Superelasticity

Nitinol wire spring's shape memory property allows it to revert to its pre-deformed shape when heated above its transformation temperature, providing a reliable and efficient solution for industrial applications requiring precise movement or force. Its superelasticity enables the material to endure substantial strain without permanent deformation, making it an ideal choice for high-stress environments where resilience is crucial.

Nitinol's unique combination of shape memory and superelasticity makes it a standout material for a wide range of applications. Whether it's in medical devices, aerospace components, or automotive systems, Nitinol wire spring's ability to return to its original shape after deformation is a game-changer. This precision in movement allows for intricate and delicate operations to be carried out with ease, making it an invaluable asset in various industries. Additionally, its superelasticity ensures that the material can withstand significant strain without succumbing to permanent damage, providing resilience in high-stress environments.

Precision and Memory in Every Coil

Each coil of the Nitinol spring possesses precision and memory, ensuring consistent performance in various industrial settings. This remarkable attribute allows for the reliable execution of specific movements or functions, contributing to enhanced efficiency and productivity in industrial processes.

Furthermore, the Nitinol spring's precision and memory also contribute to its durability and longevity, making it a cost-effective solution for industrial applications. With the ability to maintain its shape and performance over time, the Nitinol spring reduces the need for frequent replacements or repairs, saving both time and money for businesses. This reliability ensures continuous operation without interruptions, leading to improved overall efficiency in industrial processes.

Advantages of Using Nitinol Spring in Industrial Applications

The advantages of using Nitinol springs in industrial applications are numerous. From their ability to maintain precise shapes under varying conditions to their exceptional durability and resistance to fatigue, these springs offer unparalleled performance benefits. Their unique properties make them an ideal choice for industries seeking efficient solutions that deliver long-term value.

Additionally, Nitinol springs are known for their superelasticity, allowing them to undergo significant deformation and still return to their original shape. This unique property makes them highly versatile and suitable for a wide range of industrial applications where flexibility and resilience are essential. Whether used in medical devices, automotive components, or aerospace equipment, Nitinol springs provide the reliability and performance needed to meet demanding requirements.

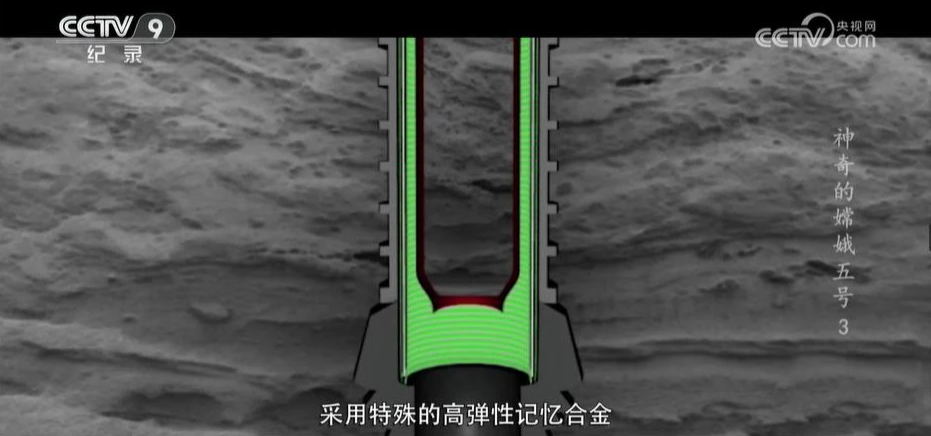

Activating Nitinol Wire for Industrial Use

How do you activate nitinol wire?

Activating nitinol wire involves a process called training, where the wire is deformed at a specific temperature and then cooled to lock in the new shape. This allows the wire to return to its original shape when heated, showcasing its unique shape memory properties.

After the training process, nitinol wire can be activated by applying heat to the wire, causing it to return to its original shape. This unique property makes nitinol wire ideal for a wide range of applications, from medical devices like stents and guidewires to robotics and actuators. The ability to activate and control the shape memory properties of nitinol wire has led to innovative breakthroughs in various industries, making it a highly sought-after material for engineers and designers.

GEE SMA's Expertise in Crafting Nitinol Shape Memory Alloys

GEE SMA specializes in crafting high-quality Nickel Titanium Springs with precision and memory in every coil. Our team of experts ensures that each Nitinol Spring is meticulously designed and manufactured to exhibit superior shape memory and superelasticity, making it ideal for various industrial applications.

Furthermore, GEE SMA's expertise extends to customizing Nitinol materials to meet the unique industrial needs of our clients. Our team works closely with customers to understand their specific requirements and then utilizes our advanced manufacturing capabilities to tailor Nitinol alloys accordingly. Whether it's adjusting the shape memory properties or fine-tuning the superelasticity, we have the knowledge and skills to deliver bespoke solutions that precisely match the demands of various industrial applications.

Tailoring Nitinol Materials to Meet Unique Industrial Needs

At GEE SMA, we understand that different industries have distinct requirements for Nitinol materials. That's why we offer customization options to tailor our Nitinol functional materials and components according to the unique needs of our customers, ensuring maximum efficiency and performance in their specific industrial applications. Our team of experts works closely with clients to understand their specific challenges and goals, allowing us to develop custom solutions that address their unique needs. Whether it's a specialized Nitinol wire spring for the medical industry or a custom shape memory alloy component for aerospace applications, we have the expertise and flexibility to deliver tailored solutions that exceed expectations.

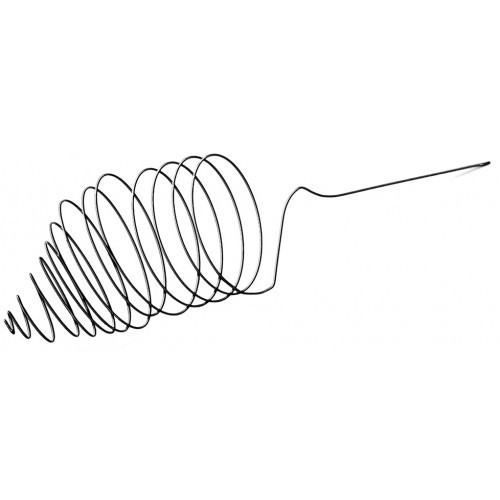

Maximizing Efficiency with Nitinol Wire Spring

Nitinol wire spring is a versatile component used in various industrial applications, providing the necessary flexibility and resilience to support mechanical movements and absorb shock. The function of a wire spring is to store mechanical energy and release it when needed, making it an essential part of many industrial systems.

Enhancing product quality with Nitinol springs involves leveraging their unique properties such as shape memory and superelasticity, ensuring consistent performance and durability. By utilizing Nitinol springs, manufacturers can achieve higher precision and reliability in their products, ultimately leading to improved customer satisfaction and brand reputation.

Achieving cost efficiency with Nitinol in industrial applications is possible due to its exceptional durability and longevity. Despite the initial investment, the long-term benefits of using Nitinol springs outweigh the costs associated with frequent maintenance or replacement of traditional spring materials. This makes Nitinol a cost-effective solution for various industrial needs.

Overcoming Challenges with Nitinol Wire Spring

What are the disadvantages of nitinol?

Nitinol wire spring offers numerous advantages, but it also comes with a few limitations. One of the main drawbacks is its relatively high cost compared to traditional materials. Additionally, nitinol's superelasticity and shape memory properties can be challenging to control during manufacturing processes, requiring specialized expertise and equipment.

One other limitation of nitinol is its susceptibility to corrosion, which can affect its long-term durability and performance. This means that additional protective coatings or treatments may be necessary to ensure the material's reliability in certain applications, adding to the overall cost and complexity of using nitinol. Furthermore, the unique properties of nitinol can make it difficult to join with other materials, potentially limiting its versatility in certain engineering designs and manufacturing processes. As a result, engineers and manufacturers need to carefully consider these factors when deciding whether to use nitinol for a specific application.

Addressing Industry-Specific Challenges with Nitinol Materials

Despite its limitations, GEE SMA specializes in addressing industry-specific challenges with nitinol materials. Our team of experts has extensive experience in tailoring nitinol components to meet the unique needs of various industrial applications. Whether it's precision medical devices or high-performance aerospace components, we have the capability to customize nitinol materials for specific industry requirements.

In addition to our expertise in customizing nitinol materials for specific industry requirements, GEE SMA prides itself on its swift response to customer needs. Our team understands the importance of agility and flexibility in meeting the demands of various industries. Whether it's a tight deadline for a medical device prototype or a sudden change in aerospace component specifications, we are committed to providing quick and efficient solutions to our clients.

GEE SMA's Swift Response to Customer Requirements

At GEE SMA, we understand the importance of swift response to customer requirements. Our dedicated team works closely with clients to ensure that their needs are met promptly and efficiently. From custom designs to quick turnaround times, we prioritize customer satisfaction and aim to exceed expectations in every aspect of our service.

Our team at GEE SMA stays ahead of the curve by keeping a pulse on future trends and innovations in Nitinol spring applications. By staying informed about the latest developments in materials science and engineering, we are able to offer cutting-edge solutions that meet the evolving needs of our customers. This proactive approach allows us to anticipate and adapt to industry changes, ensuring that our clients receive the most advanced and effective products available.

Future Trends and Innovations in Nitinol Spring Applications

Evolving Industrial Uses of Nitinol Wire Spring

As technology advances, the industrial uses of nitinol wire spring continue to evolve. From medical devices to aerospace engineering, the versatility and unique properties of nitinol make it an ideal material for a wide range of applications. As industries seek more efficient and reliable solutions, the demand for nitinol springs is expected to grow exponentially in the coming years.

With the increasing focus on sustainable and eco-friendly practices, nitinol wire springs are being integrated into renewable energy technologies such as wind turbines and solar panels. The unique shape memory and superelasticity properties of nitinol make it an ideal material for improving the efficiency and durability of these energy systems. As the demand for renewable energy solutions continues to rise, the incorporation of nitinol into advanced industrial technologies is poised to play a significant role in driving innovation and sustainability.

Incorporating Nitinol into Advanced Industrial Technologies

The integration of nitinol into advanced industrial technologies is revolutionizing manufacturing processes and product design. With its shape memory and superelasticity, nitinol springs are being incorporated into smart materials, actuators, and sensors, enabling the development of innovative products with enhanced functionality and performance. As industries embrace automation and smart technologies, the demand for nitinol in advanced industrial applications is set to soar.

The increasing use of nitinol in advanced industrial technologies is driving a wave of innovation in product design and manufacturing. As companies seek to stay ahead in an increasingly competitive market, the unique properties of nitinol are providing them with the tools to create cutting-edge products that meet the demands of modern consumers. From medical devices to aerospace components, the versatility of nitinol is opening up new possibilities for industries across the board.

GEE SMA's Commitment to Innovation and Adaptation

At GEE SMA, we are committed to driving innovation and adaptation in the field of nitinol spring applications. Our dedicated team continuously explores new possibilities for utilizing nitinol in various industrial sectors, working closely with clients to understand their specific needs and challenges. By staying at the forefront of technological advancements, we aim to lead the way in shaping the future of nitinol applications across diverse industries.

With our expertise in crafting high-quality nickel titanium springs with precision and memory in every coil, GEE SMA is well-positioned to drive innovation in evolving industrial uses of nitinol wire spring while meeting industry-specific challenges head-on.

Conclusion

Nitinol wire spring technology is revolutionizing industrial efficiency, offering unparalleled versatility and precision in various applications. GEE SMA's expertise in crafting high-quality Nitinol Spring materials ensures the activation of nitinol wire to meet specific industrial needs, overcoming any potential disadvantages. The function of a wire spring is maximized with Nitinol's shape memory and superelasticity, enhancing product quality and achieving cost efficiency in industrial settings.

Harnessing the Power of Nitinol in Industrial Efficiency

GEE SMA's commitment to innovation and adaptation ensures that the power of Nitinol is harnessed for maximum industrial efficiency. With its unique properties and activation process, Nitinol wire spring technology offers superior performance, making it an indispensable component in various industrial applications.

The Versatility of Nitinol in Industrial Settings

Nitinol's versatility shines through its precision and memory in every coil, making it suitable for a wide range of industrial settings. From aerospace to medical devices, the adaptability of Nickel Titanium Spring allows for seamless integration into advanced technologies, ensuring optimal performance across diverse industries.

Embracing the Potential of Nitinol Wire Spring Applications

As industries evolve, so do the uses of Nitinol wire spring technology. GEE SMA is at the forefront of incorporating Nitinol into advanced industrial technologies, ensuring that customers can embrace the full potential of this innovative material for their specific applications. With its unique shape memory and superelastic properties, Nitinol wire springs offer unparalleled flexibility and durability, making them ideal for a wide range of industrial applications. From medical devices to aerospace components, Nitinol wire springs are revolutionizing how industries approach design and engineering challenges. By harnessing the potential of Nitinol, GEE SMA is empowering businesses to push the boundaries of what's possible in their respective fields.