Introduction

Nitinol, a unique alloy of nickel and titanium, is widely used in medical devices due to its superelastic and shape memory properties. This versatile material is known for its ability to return to its original shape after deformation, making it ideal for a variety of applications in the medical field. Nitinol is mainly used for manufacturing stents, orthopedic devices, and guidewires due to its flexibility and durability.

What is Nitinol and Where is it Used?

Nitinol, also known as Shape Memory Alloy (SMA), is a combination of nickel and titanium that exhibits remarkable properties such as shape memory and superelasticity. It finds extensive use in various medical devices due to its unique characteristics.

How is Nitinol Used in Medical Devices?

Nitinol's exceptional properties make it an ideal material for medical devices such as stents, orthopedic implants, and guidewires. Its superelasticity allows these devices to withstand deformation without permanent damage.

What is Nitinol Mainly Used For?

Nitinol is mainly utilized in the production of stents, orthopedic implants, and guidewires due to its flexibility, durability, and ability to adapt to the body's natural movements.

Understanding Nitinol Medical Devices

Nitinol medical devices are made from a unique alloy of nickel and titanium, known for its shape memory and superelastic properties. This allows the devices to return to their original shape after deformation, making them ideal for various medical applications. Nitinol is primarily used in minimally invasive procedures due to its flexibility and biocompatibility, making it a popular choice in the medical industry.

The Science Behind Nitinol

The unique properties of nitinol are a result of its crystal structure, which allows it to undergo significant deformation and still return to its original shape when exposed to heat or stress. This makes it an ideal material for medical devices that need to be inserted into the body and then expanded or contracted as needed. In addition, nitinol is also biocompatible, meaning it is well-tolerated by the human body and does not cause adverse reactions. This further enhances its suitability for use in medical implants and devices, as it reduces the risk of complications for patients.

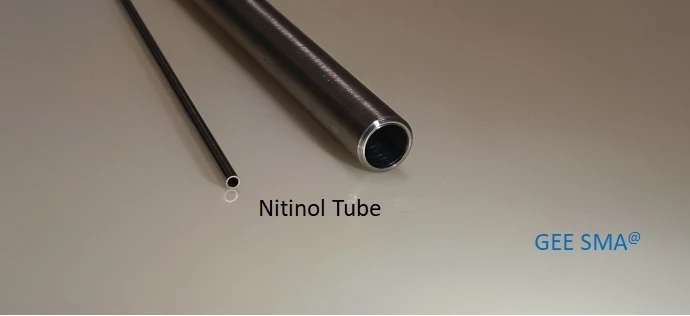

Nitinol Components

Nitinol components are often used in medical devices such as stents, guidewires, and orthopedic implants. These components are designed to provide flexibility and durability while maintaining their shape memory properties, ensuring they can withstand the stresses of being inside the human body. The super elastic nature of Nitinol allows for easy insertion and removal of medical devices, reducing trauma to the patient's body during procedures. Additionally, Nitinol's biocompatibility makes it an ideal material for long-term implantation, as it minimizes the risk of adverse reactions or rejections within the body.

Nitinol's Super Elastic Solution

One of the key benefits of nitinol is its superelasticity, which allows it to undergo large deformations without permanent damage. This property is crucial in medical devices where flexibility and resilience are essential for successful treatment outcomes.

GEE SMA specializes in the production of high-quality nitinol materials and components that are tailored to meet specific customer needs. With a focus on enhancing product quality and addressing customer requirements swiftly, GEE SMA is at the forefront of advancing nitinol technology in the medical industry.

The Benefits of Nitinol Medical Devices

Maximizing Performance

Nitinol medical devices are designed to maximize performance, offering superior strength and resilience for a wide range of applications. Whether used in stents, orthopedic devices, or guidewires, Nitinol's unique properties ensure optimal functionality and reliability in medical settings.

Nitinol's flexibility and durability make it an ideal choice for medical devices that need to withstand the rigors of everyday use. Its ability to bend and flex without losing its shape or strength ensures that devices made from Nitinol can adapt to the body's natural movements without compromising their performance. This flexibility also allows for easier insertion and placement during medical procedures, making Nitinol a top choice for healthcare professionals.

Flexibility and Durability

One of the key benefits of Nitinol medical devices is their exceptional flexibility and durability. This allows for easy insertion and manipulation within the body, while also ensuring long-term performance and resistance to wear and tear, making them ideal for use in various medical procedures. Additionally, the flexibility of Nitinol devices allows for minimally invasive procedures, reducing patient discomfort and recovery time. Furthermore, the durability of these devices means fewer replacements are needed, leading to cost savings for both healthcare providers and patients.

Enhanced Patient Experience

Nitinol medical devices contribute to an enhanced patient experience by providing minimally invasive treatment options with reduced recovery times. The flexibility and biocompatibility of Nitinol allow for comfortable implantation, leading to improved outcomes and overall satisfaction for patients.

Nitinol medical devices also offer the advantage of being highly durable, providing long-lasting solutions for patients. This means fewer follow-up procedures and a reduced need for additional interventions, ultimately saving time and resources for both patients and healthcare providers. Additionally, the unique properties of Nitinol allow for customized treatment options, ensuring that each patient receives personalized care tailored to their specific needs.

Nitinol in Practice: Medical Applications

Nitinol is widely used in medical devices, particularly in stents, orthopedic devices, and guidewires. Nitinol's unique properties make it an ideal material for these applications, as it offers flexibility, durability, and biocompatibility.

Nitinol in Stents

Nitinol is used in stents due to its super elastic solution, which allows the stent to be compressed and inserted into the body without losing its original shape. This property is crucial for ensuring that the stent can expand and keep the blood vessels open once inside the body.

Nitinol's super elastic solution also makes it an ideal material for orthopedic devices such as bone plates, screws, and wires. Its ability to return to its original shape after deformation allows these devices to withstand the stresses and strains of the body's movement without breaking or causing discomfort. Additionally, Nitinol's biocompatibility ensures that it can safely remain within the body without causing adverse reactions or complications. This makes it a valuable resource for orthopedic surgeons looking for reliable and durable materials for their patients' implants.

Nitinol in Orthopedic Devices

In orthopedic devices, such as bone plates and screws, nitinol components provide flexibility and strength. This allows for better fixation of fractures and ensures that the devices can withstand the stresses placed on them within the body.

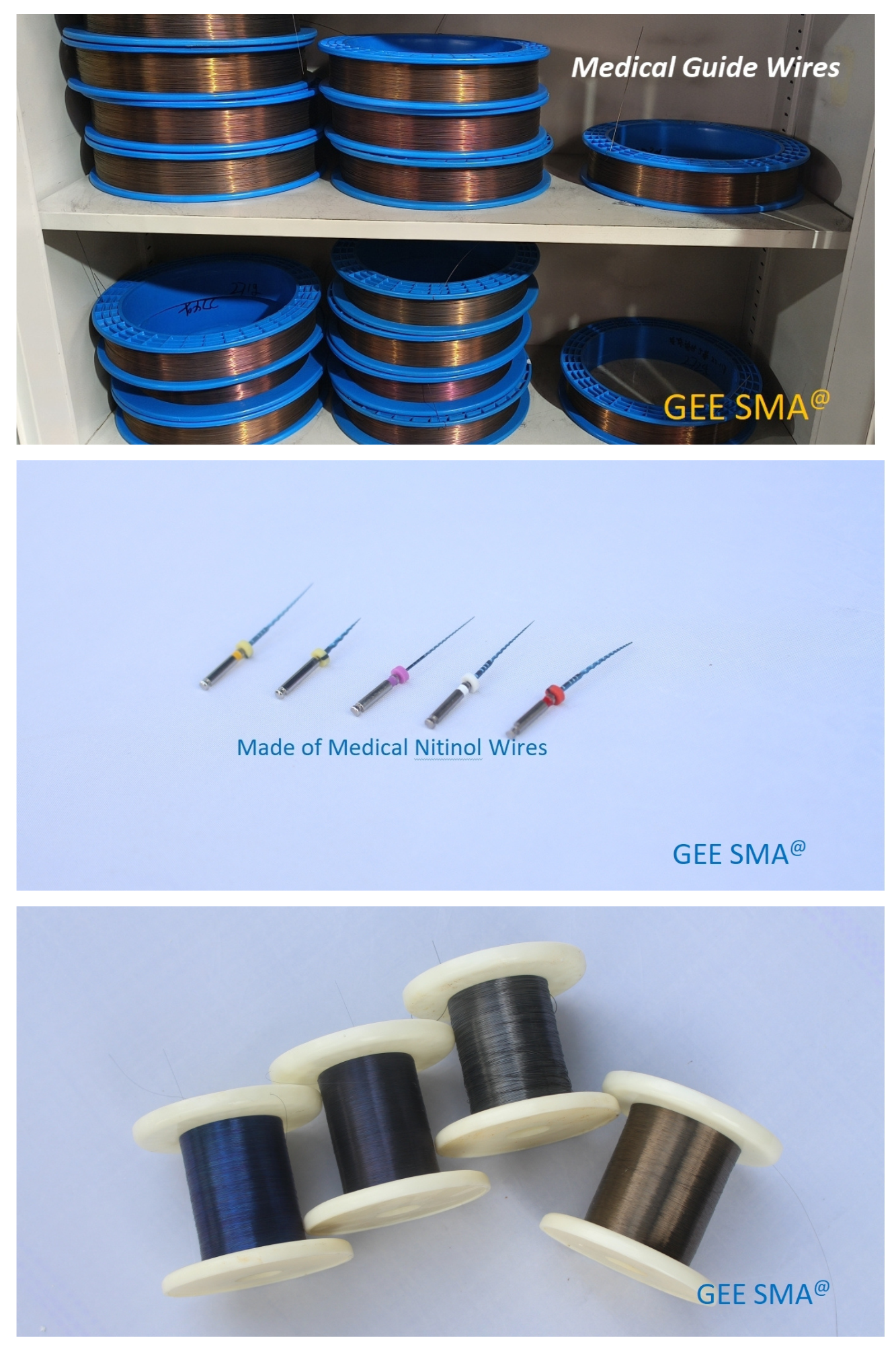

Nitinol is also commonly used in guidewires for medical procedures, thanks to its unique combination of flexibility and shape memory. This allows the guidewire to navigate through the body's intricate pathways with ease, while still being able to return to its original shape after use. As a result, nitinol guidewires are essential tools for surgeons performing minimally invasive procedures, as they provide reliable support and maneuverability during delicate operations.

Nitinol in Guidewires

Nitinol guidewires are used in minimally invasive procedures due to their shape memory properties. They can navigate through tortuous pathways within the body and then return to their original shape once they reach their destination, providing precise guidance for medical interventions.

Safety and Effectiveness of Nitinol in the Human Body

Nitinol medical devices have been proven to be safe and effective in the human body, with a long track record of successful use in various medical applications. The unique properties of Nitinol, such as its super elastic solution and flexibility, make it an ideal material for use in implants and other medical devices.

Is Nitinol Safe in the Human Body?

Numerous studies have demonstrated the biocompatibility of Nitinol, confirming that it is safe for use within the human body. Its corrosion resistance and ability to withstand bodily fluids make it an excellent choice for long-term implantation without adverse effects on surrounding tissues.

Long-term Performance

Nitinol's durability and resistance to wear and tear ensure its long-term performance within the human body. This is particularly important for medical devices such as stents, where reliability over extended periods is crucial for patient health and safety. The ability of Nitinol to maintain its shape memory and superelasticity over time allows for consistent performance in maintaining blood flow through stents, reducing the risk of blockages and potential complications. Additionally, Nitinol's biocompatibility ensures that it can remain in the body without causing adverse reactions or tissue irritation, further contributing to positive patient outcomes.

Patient Outcomes

Patients who have received Nitinol-based medical devices have reported positive outcomes, with reduced recovery times and improved overall quality of life. The flexibility and biocompatibility of Nitinol contribute to better patient experiences during and after medical procedures.

Furthermore, the advanced shape memory alloy (SMA) technology used in Nitinol-based medical devices has allowed for more precise and minimally invasive procedures, leading to reduced trauma and scarring for patients. This has resulted in a higher level of patient satisfaction and a quicker return to normal activities. The ability of Nitinol to adapt to the body's natural movements also contributes to a more comfortable experience for patients during recovery, further enhancing their overall well-being. Overall, the use of GEE SMA in advancing Nitinol technology has significantly improved patient outcomes and recovery processes.

The Role of GEE SMA in Advancing Nitinol Technology

GEE SMA is at the forefront of producing high-quality Nitinol Shape Memory Alloys for medical devices. Our expertise lies in crafting materials and components that maximize the performance and safety of nitinol medical devices, ensuring they meet the stringent requirements of the healthcare industry.

Crafting High-Quality Materials

GEE SMA specializes in creating top-notch Nitinol materials that are essential for manufacturing medical devices. Our dedication to quality ensures that our materials meet the highest standards, providing reliability and durability for a wide range of applications in the healthcare sector.

Tailoring Nitinol Functional Materials

We understand the diverse needs of our customers when it comes to nitinol medical devices. That's why we offer tailored solutions to meet specific requirements, whether it's flexibility, shape memory, or superelasticity. Our ability to customize functional materials ensures that our clients can achieve optimal results in their medical device designs.

Our team of experts is dedicated to providing swift customer response, ensuring that our clients receive the personalized attention and support they deserve. We understand that time is of the essence in the medical device industry, and our commitment to efficient communication and problem-solving sets us apart. Whether it's addressing specific concerns or making adjustments to meet changing requirements, we are always ready to go the extra mile for our customers.

Swift Customer Response

At GEE SMA, we prioritize swift customer response to ensure that our clients receive the support they need promptly. Our team is dedicated to addressing customer inquiries, providing technical assistance, and delivering solutions efficiently. We are committed to being a reliable partner for all nitinol-related needs in the medical device industry.

In addition to our commitment to swift customer response, we also prioritize ongoing communication and feedback from our clients. We understand the importance of staying connected with our customers to ensure that their needs are consistently met and exceeded. By actively seeking input and suggestions, we can continue to improve our services and provide the highest level of support in the industry.

Conclusion

Nitinol medical devices have revolutionized the healthcare industry, offering unparalleled flexibility, durability, and performance. GEE SMA is at the forefront of advancing Nitinol technology, specializing in crafting high-quality materials and components. By swiftly addressing customer requirements and tailoring Nitinol functional materials to meet unique needs, GEE SMA is committed to enhancing product quality and ensuring the safety and effectiveness of Nitinol medical devices.

Enhancing Product Quality

GEE SMA's dedication to crafting high-quality Nitinol materials and components ensures that medical devices meet the highest standards of performance and safety. By employing advanced manufacturing techniques and stringent quality control measures, GEE SMA consistently delivers products that exceed industry benchmarks for excellence.

Furthermore, GEE SMA is committed to continuous improvement in product quality. This dedication is evidenced by the company's investment in research and development to explore new techniques and technologies that can further enhance the performance and safety of medical devices. By staying at the forefront of innovation, GEE SMA ensures that its products not only meet but exceed customer expectations.

Addressing Customer Requirements

GEE SMA understands the diverse needs of its customers in the medical device industry. By actively engaging with clients to understand their specific requirements, GEE SMA can tailor Nitinol solutions that align with their unique applications, ensuring optimal functionality and patient outcomes.

Meeting Unique Customer Needs

With a focus on innovation and customization, GEE SMA is committed to meeting the unique needs of its customers. By offering personalized solutions that cater to specific design specifications and performance requirements, GEE SMA empowers medical device manufacturers to create cutting-edge products that enhance patient care.

By collaborating closely with medical device manufacturers, GEE SMA ensures that each customized solution is tailored to meet the exact needs of the client. This collaborative approach allows for a deep understanding of the unique challenges and goals of each project, leading to innovative and effective solutions. As a result, medical device manufacturers can confidently deliver products that not only meet but exceed the expectations of healthcare providers and patients.