Introduction

Shape Memory Alloys (SMAs) are a fascinating class of materials that can remember their original shape and return to it when heated. This unique property makes SMAs incredibly versatile and opens up possibilities for innovative applications. From medical implants to aerospace components, SMAs are revolutionizing various industries with their remarkable properties.

Understanding SMA Shape Memory Alloys

SMA alloys, such as Nitinol, undergo a phase transformation when subjected to temperature changes, allowing them to recover their original shape after deformation. This unique behavior is due to the reversible martensitic transformation within the material's crystal structure. As a result, SMA alloys have found a wide range of applications in various industries, including biomedical devices, aerospace engineering, and robotics. Their ability to remember and return to their original shape makes them ideal for use in minimally invasive medical procedures, adaptive wing designs for aircraft, and shape-changing components in robotic systems.

The Remarkable Properties of SMA Alloys

Shape memory alloys (SMAs) are a unique class of materials with remarkable properties that make them valuable in many fields. Here's why SMAs are revolutionizing various industries:

- Superelasticity and Shape Memory Effect: SMAs can undergo significant deformation and return to their original shape or "remember" a trained shape upon heat application. This enables precise control over their form, making them ideal for applications requiring adaptability.

- Excellent Strength-to-Weight Ratio: SMAs offer impressive strength while remaining lightweight. This translates to advantages in applications where weight reduction is crucial, such as aerospace and automotive engineering.

- Corrosion Resistance and Biocompatibility: SMAs demonstrate exceptional corrosion resistance, extending their lifespan and making them suitable for harsh environments. Additionally, their biocompatible nature makes them well-suited for medical devices.

- Durability and Fatigue Resistance: SMAs can withstand repeated stress and strain without fatigue. This exceptional durability ensures reliable performance over extended periods, a key factor in aerospace and medical implant applications.

In conclusion, SMAs offer a compelling combination of properties – shape memory, superelasticity, strength, and durability – making them versatile materials with the potential to transform various industries. Their ability to adapt, perform reliably, and last under demanding conditions positions SMAs at the forefront of material science advancements.

Real-World Applications of SMA Alloys

Shape memory alloys (SMAs) are a fascinating class of materials with the unique ability to return to their original shape after deformation. This property, along with their strength and adaptability, has led to a surge in their use across various industries.

Here are some of the remarkable real-world applications of SMAs:

- Medical Implants: From orthodontic braces that gently guide teeth into alignment to cardiovascular stents that keep arteries open, SMAs are transforming healthcare. Their biocompatibility and ability to conform to body temperature make them ideal for delicate medical procedures.

- Robotics and Aerospace: The ability of SMAs to exert force and change shape with precision makes them perfect for actuators in robots and critical components in aerospace vehicles. Their lightweight nature and resistance to extreme temperatures further enhance their suitability for these demanding applications.

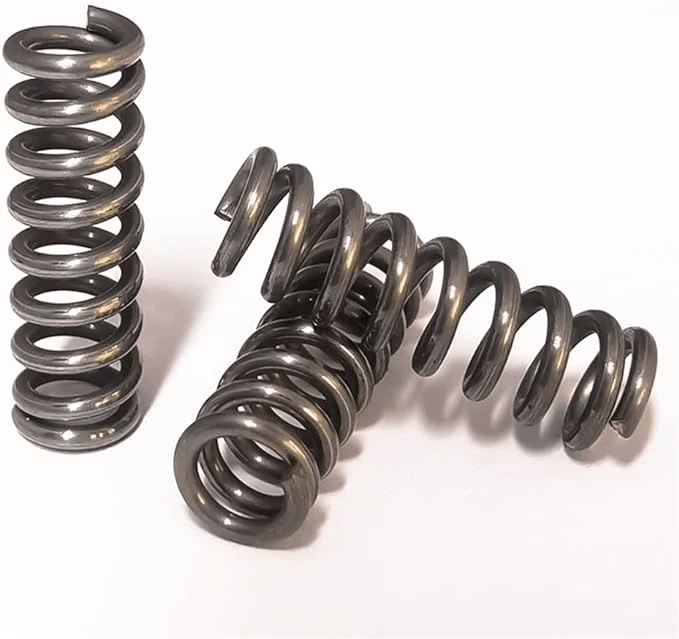

- Automotive Engineering: SMAs are finding their way into various automotive parts, including actuators, sensors, and springs. Their ability to withstand high temperatures and resist fatigue makes them ideal for engine components, exhaust systems, and safety mechanisms. This opens doors to innovative designs that improve vehicle performance and safety.

The potential of SMAs continues to be explored, with new applications always emerging. These versatile materials promise to revolutionize various fields and shape a more innovative future.

Medical Implants

Nitinol shape memory alloy in orthodontic braces has revolutionized the field of orthodontics, providing patients with a more comfortable and efficient teeth-straightening experience. SMA wire's flexibility and shape memory properties allow for gradual tooth movement, reducing discomfort and treatment time. Orthodontists are increasingly turning to SMA for its superior performance in braces.

SMA stents in cardiovascular interventions have significantly improved patient outcomes by providing a more durable and responsive solution for treating narrowed or weakened arteries. The ability of SMA stents to expand and contract based on temperature changes within the body ensures better blood flow and reduces the risk of complications. As a result, patients experience quicker recovery times and reduced chances of re-narrowing.

SMA bone plates for orthopedic surgeries offer enhanced stability and support during healing, allowing patients to regain mobility sooner than with traditional metal implants. The unique ability of the shape-memory alloy to return to its original shape after deformation makes it an ideal material for bone plates that must adapt to the body's movements. Orthopedic surgeons are increasingly relying on SMA for its reliability and biocompatibility.

Remember that SMA alloys are not just limited to medical implants – their versatility extends across various industries, making them an invaluable material for innovative solutions.

Robotics

SMA actuators are revolutionizing the field of robotics, providing precise and efficient movements for robotic arms and grippers. The unique ability of SMA shape memory alloys to return to their original shape after being deformed allows for accurate and repeatable robotic motions, making them ideal for tasks requiring high precision.

Shape memory alloy wire is a game-changer in the development of robotic exoskeletons. It offers lightweight and flexible components that can be programmed to remember specific shapes. This enables the creation of exoskeletons that seamlessly mimic natural human movements, providing assistance and support to individuals with mobility impairments.

Memory-shaped metal also makes waves in soft robotics, where flexibility and adaptability are paramount. SMA alloys are used to create soft actuators that can bend, twist, and stretch like natural muscles, opening up new possibilities for designing more lifelike and agile robotic systems.

With SMA-shaped memory alloys at the forefront of technological advancements in robotics, the future looks bright for innovative applications across various industries.

Aerospace

SMA components in aircraft engines are revolutionizing the aerospace industry, providing lightweight and durable solutions for critical engine parts. The shape memory alloy wire is used to enhance engine efficiency and performance, ensuring smoother operations and reduced maintenance needs. With SMA technology, aircraft engines are becoming more reliable and cost-effective.

SMA sheet technology in deployable space structures is enabling the development of innovative and adaptable designs for spacecraft and satellites. The memory-shaped metal allows for compact storage during launch and deployment into large-scale structures once in space, providing flexibility and versatility in space missions. With its groundbreaking capabilities, SMA sheet technology is reshaping the future of space exploration.

SMA wire in adaptive aerospace systems transforms how aircraft adapt to changing conditions during flight. Aerospace systems can make real-time adjustments to optimize performance and safety by utilizing shape memory alloy wire. This cutting-edge technology is enhancing aircraft agility and responsiveness, setting new standards for aviation excellence.

Remember that SMA shape memory alloys are at the forefront of innovation across various industries, including aerospace. Their remarkable properties are reshaping the possibilities for engineering solutions in various applications. As we continue to push boundaries with SMA technology, we can expect even more groundbreaking advancements that will redefine what's possible in aerospace engineering.

Automotive

Regarding automotive safety systems, SMA shape memory alloys are revolutionizing the industry. These remarkable materials are used in everything from seat belts to airbag deployment systems, providing a level of reliability and performance that traditional materials can't match. SMA wire is particularly popular in automotive control systems, offering precise and efficient actuation for various functions within the vehicle. Additionally, SMA additive manufacturing is making waves in the production of automobile parts, allowing for complex geometries and enhanced performance.

Shape Memory Alloy for Sale in Automotive SafetySystems

In automotive safety, SMA-shaped memory alloys are game-changers. Their unique ability to return to a predetermined shape after deformation makes them ideal for critical components such as seat belt buckles and airbag release mechanisms. The resilience and durability of SMAs ensure that these safety systems perform reliably under extreme conditions, providing peace of mind for drivers and passengers alike.

SMA Wire in Automotive Control Systems

SMA wire has found its way into various automotive control systems, offering precise actuation and control over critical functions within the vehicle. From throttle control to transmission shifting, these shaped memory alloy wires provide smooth and efficient operation while withstanding the rigors of constant use. The result is improved performance and longevity for essential automotive components.

SMA Additive Manufacturing in Automobile Parts

SMA additive manufacturing has opened up new possibilities in producing automobile parts. This innovative technology allows for creating complex geometries that were previously unattainable with traditional manufacturing methods. As a result, automobile parts made from SMAs exhibit enhanced performance characteristics, contributing to overall vehicle efficiency and reliability.

Using SMA additive manufacturing in automobile parts also allows for producing lighter and stronger components, improving fuel efficiency and overall performance. This technology enables the customization of parts to meet specific design requirements, resulting in a more streamlined and efficient manufacturing process. With the ability to create intricate designs and structures, SMA additive manufacturing offers automobile manufacturers a competitive edge in producing high-quality, reliable vehicles.

Consumer Electronics

SMA shape memory alloys have revolutionized the consumer electronics industry, offering innovative solutions for smart eyewear frames, wearable technology, and consumer electronic gadgets. The versatility of SMAs allows for precise and durable components that enhance user experience and product performance.

SMA in Smart Eyewear Frames

Smart eyewear frames made with shape memory alloy wire provide a lightweight, flexible design that ensures a comfortable fit for users. The unique properties of SMAs allow the frames to return to their original shape even after being bent or twisted, making them ideal for everyday use. In addition, the durability of SMAs makes them resistant to corrosion and wear, ensuring a longer lifespan for the eyewear frames. This means users can rely on smart eyewear frames to maintain their shape and functionality, even with frequent use.

SMA in Wearable Technology

Integrating shape-memory alloy in wearable technology, such as fitness trackers and smartwatches, creates durable and resilient devices that can withstand constant movement and usage. The flexibility of SMAs allows for seamless integration into various wearable products, ensuring reliability and longevity. Additionally, using SMAs in wearables provides a lightweight yet sturdy construction, making these devices comfortable to wear for extended periods without sacrificing durability. This makes them ideal for athletes and individuals with active lifestyles who require robust, long-lasting technology to support their daily activities.

Shape-Memory Alloy in Consumer ElectronicGadgets

Shape memory alloy (SMA) additive manufacturing is revolutionizing the creation of intricate components for consumer electronics. This technology offers several advantages, making gadgets more durable, precise, and user-friendly.

Here's how SMA additive manufacturing is transforming consumer electronics:

- Enhanced Durability and Precision: By using SMAs, manufacturers can create intricate components that are highly resistant to wear and tear. This translates to longer-lasting and more reliable electronic devices.

- Superior Performance: The unique properties of SMAs allow for the creation of components that can adapt and respond to different conditions, potentially leading to improved functionality and performance in consumer electronics.

- Increased User Comfort: SMAs can be designed to conform to a user's grip or body heat, enhancing the comfort and ergonomics of electronic devices.

As consumer demand for innovative and high-performing electronics continues to rise, SMA additive manufacturing is poised to play a key role in shaping the future of this industry.

The Versatility of SMA Shape Memory Alloys

SMA shape memory alloys have revolutionized various industries with their remarkable properties. The ability of shape memory alloy wire to return to its original shape after deformation has made it a game-changer in medical implants, robotics, aerospace, automotive, and consumer electronics. As the demand for innovative materials grows, the future of SMA in innovative applications looks promising.

The versatility of SMA shape memory alloys extends beyond just temperature responsiveness. These alloys can also be engineered to respond to other stimuli, such as stress or magnetic fields, opening up even more possibilities for their use in various industries. With the ability to tailor their behavior to specific conditions, SMAs are paving the way for innovative applications in robotics, automotive engineering, and consumer electronics. The adaptability and customizability of these alloys make them a highly sought-after material for companies looking to push the boundaries of what is possible in their respective industries.

The Future of SMA in Innovative Applications

As technology advances, the future of SMA in innovative applications looks bright. With ongoing research and development efforts, new uses for SMAs are being discovered regularly. The potential for growth and expansion in this field is limitless, from enhanced automotive safety systems to more efficient robotic exoskeletons. Furthermore, the medical industry is also exploring using SMAs in minimally invasive surgical tools, allowing for more precise and less invasive procedures. This could revolutionize certain surgeries, leading to better patient outcomes and shorter recovery times.

GEE SMA: Pioneering Nitinol Shape Memory Alloys

At GEE SMA, we are pioneering Nitinol shape memory alloys for a wide range of industries and applications. Our commitment to innovation and quality ensures that our SMAs meet the highest standards and deliver exceptional performance in real-world scenarios.

With their incredible properties and diverse applications, SMA shape memory alloys will continue to play a pivotal role in shaping the future of various industries.