Introduction

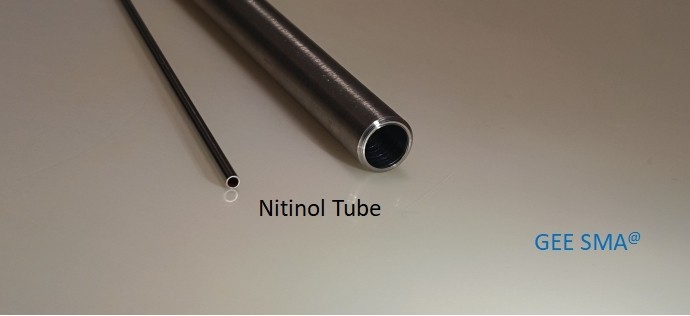

In the fast-paced world of healthcare, medical Niti alloy guide wires play a crucial role in various medical procedures. These guide wires are made from Nitinol shape memory alloys, known for their remarkable flexibility and durability. As a leading manufacturer, GEE SMA has revolutionized the industry with their high-quality Niti alloy guide wires, offering unparalleled benefits to healthcare providers and patients alike.

Understanding the Importance of Medical Niti Alloy Guide Wires

Medical Niti alloy guide wires are essential tools used in a wide range of medical procedures, including cardiovascular interventions, urology, and orthopedic surgeries. These guide wires provide the necessary support and navigation for other medical devices during minimally invasive procedures, ensuring precision and safety for patients.

Exploring the Benefits of GEE SMA's Nitinol Shape Memory Alloys

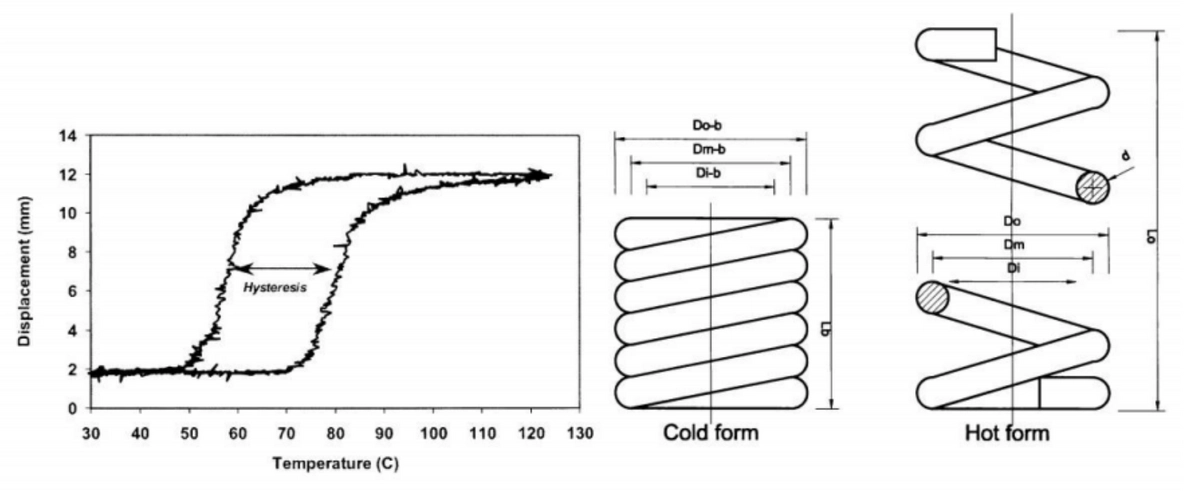

GEE SMA's Nitinol shape memory alloys offer exceptional properties that make them ideal for crafting medical Niti alloy guide wires. Their unique ability to return to a predetermined shape after deformation allows for greater maneuverability within the body's intricate anatomical structures, resulting in improved procedural outcomes and patient comfort.

Key Characteristics of Niti Alloy Guide Wires

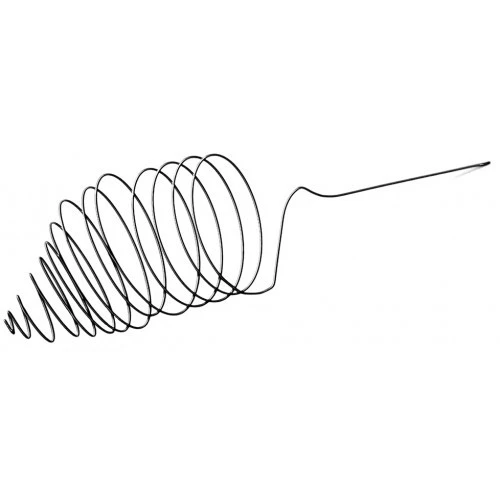

Niti alloy guide wires boast remarkable characteristics such as superelasticity and kink resistance, making them highly reliable during complex medical interventions. With diameters as small as 0.1mm or 0.15mm, these tensile nitinol medical guide wires can navigate through narrow passages with ease, ensuring minimal trauma to surrounding tissues.

The Basics of Niti Alloy Guide Wires

Niti alloy guide wires, also known as nitinol guidewires, are essential tools used in various medical procedures for navigating through the body's intricate pathways. These wires are made from Nitinol Shape Memory Alloys (SMA), a unique material that allows them to return to their original shape after being deformed, making them ideal for use in minimally invasive surgeries and other medical interventions.

What are Medical Niti Alloy Guide Wires?

Medical Niti alloy guide wires are thin, flexible wires used by healthcare professionals to access and navigate through the body's complex network of blood vessels and organs during surgical procedures. These guide wires play a crucial role in guiding other medical devices such as catheters and stents to the targeted areas within the body, ensuring precise placement and successful treatment outcomes.

The Impact of Nitinol Shape Memory Alloys in Healthcare

Nitinol shape memory alloys have revolutionized the field of healthcare by providing medical professionals with highly flexible and durable materials for crafting guide wires that can withstand bending, twisting, and stretching without losing their structural integrity. This has significantly improved the accuracy and safety of various medical procedures, leading to better patient outcomes and faster recovery times.

Applications of Niti Alloy Guide Wires in Medical Procedures

Niti alloy guide wires have a wide range of applications across different medical specialties, including cardiology, radiology, urology, and neurology. In urology, for example, specialized guide wires made from Nitinol SMA are used for navigating through the urinary tract to diagnose and treat conditions such as kidney stones or ureteral strictures. These versatile tools have become indispensable in modern medicine due to their reliability and precision.

Properties and Composition of Niti Alloy Guide Wires

Understanding the Unique Properties of Nitinol

Nitinol, a type of shape memory alloy, is renowned for its remarkable properties, including superelasticity and shape memory. This allows Niti alloy guide wires to be flexible yet resilient, making them ideal for navigating through complex anatomical structures with minimal trauma.

The Role of GEE SMA in Crafting High-Quality Niti Alloy Guide Wires

GEE SMA plays a pivotal role in the production of high-quality Niti alloy guide wires by leveraging their expertise in working with Nitinol materials. Their advanced manufacturing processes ensure precision and consistency, resulting in guide wires that meet stringent medical standards for performance and safety.

Key Components of Niti Alloy Guide Wires

Niti alloy guide wires are composed of Nitinol wire with diameters as small as 0.1mm to 0.15mm, allowing for precise maneuverability during medical procedures such as urological interventions. These tensile nitinol medical guide wires are designed to provide optimal support and control while minimizing patient discomfort.

Advancements and Innovations in Niti Alloy Guide Wires

In recent years, there has been significant evolution in Niti alloy guide wire technology, with advancements in materials and manufacturing processes. These developments have led to the creation of high-performance medical niti alloy guide wires that offer enhanced flexibility and durability, making them ideal for a wide range of medical procedures.

Evolution of Niti Alloy Guide Wire Technology

The evolution of Niti alloy guide wire technology has seen a shift towards the use of advanced nitinol shape memory alloys, such as those developed by GEE SMA. These alloys exhibit excellent superelasticity and shape memory properties, allowing for precise navigation through complex anatomical structures during medical procedures. This has greatly improved the safety and efficacy of using guide wires in various clinical settings.

GEE SMA's Commitment to Enhancing Product Quality

GEE SMA is committed to enhancing the quality of medical niti alloy guide wires by leveraging cutting-edge manufacturing techniques and stringent quality control measures. By employing state-of-the-art production processes, GEE SMA ensures that its guide wires meet the highest standards for tensile strength, flexibility, and biocompatibility, thus providing healthcare professionals with reliable tools for their practice.

Tailoring Niti Alloy Guide Wires to Meet Customer Requirements

One notable trend in the field of medical niti alloy guide wires is the customization of products to meet specific customer requirements. Healthcare providers are increasingly seeking guide wires with unique characteristics tailored to their individual needs, such as ultrafine 0.1mm or 0.15mm diameter nitinol wires for delicate procedures in urology or other specialized fields.

With a focus on delivering innovative solutions that address evolving clinical demands, companies like GEE SMA are driving progress in the application and development of NiTi alloys for medical use. As a result, the future holds great promise for further advancements in medical niti alloy guide wire technology that will continue to improve patient outcomes across diverse healthcare settings.

Clinical Applications of Niti Alloy Guide Wires

The Role of Niti Alloy Guide Wires in Minimally Invasive Procedures

Nitinol guide wires are instrumental in minimally invasive procedures, allowing for precise navigation through the body's intricate pathways. These flexible and durable wires are used to access hard-to-reach areas with minimal disruption, making them essential tools in procedures such as angioplasty and endovascular surgery.

Nitinol guide wires are also crucial in the field of neurosurgery, where delicate and precise navigation is essential. These wires allow surgeons to access deep-seated brain tumors and other neurological conditions with minimal trauma to surrounding tissues, reducing the risk of complications and speeding up recovery times for patients. Additionally, the flexibility of Niti alloy guide wires enables them to maneuver through narrow and winding pathways within the brain, providing neurosurgeons with the accuracy and control they need during complex procedures.

Implications of Niti Alloy Guide Wires in Surgical Interventions

In surgical interventions, Niti alloy guide wires play a crucial role in guiding catheters and other medical devices to targeted locations within the body. Their unique shape memory properties allow them to navigate tortuous anatomical structures with ease, enabling surgeons to perform complex procedures with enhanced accuracy and safety.

In addition to their navigational capabilities, Niti alloy guide wires also offer the benefit of reduced trauma to the patient during surgical interventions. Their flexibility and durability allow for smoother insertion and movement within the body, minimizing tissue damage and discomfort. This ultimately contributes to improved patient outcomes and shorter recovery times, making Niti alloy guide wires a valuable tool in modern surgical practice.

Patient Benefits and Outcomes with Niti Alloy Guide Wires

Patients benefit from the use of Niti alloy guide wires due to reduced trauma, shorter recovery times, and decreased risk of complications associated with traditional open surgeries. These advanced guide wires contribute to improved patient outcomes by enabling less invasive treatment options while maintaining high levels of precision and efficacy.

Furthermore, Niti alloy guide wires are designed to be highly flexible and durable, allowing for easier navigation through the body's intricate pathways. This flexibility reduces the risk of damage to surrounding tissues and organs, leading to a smoother recovery process for patients. Additionally, the use of Niti alloy guide wires often results in smaller incisions, further minimizing the potential for scarring and post-operative discomfort.

Future Trends and Developments in Niti Alloy Guide Wires

As the demand for minimally invasive procedures continues to rise, the industry is witnessing significant innovations in Niti Alloy Guide Wire technology. These advancements aim to enhance flexibility, kink resistance, and trackability of medical Niti alloy guide wires, ultimately improving patient outcomes and procedural success rates.

Industry Innovations in Niti Alloy Guide Wire Technology

The ongoing progress of NiTi alloys has led to the development of ultra-fine 0.1mm and 0.15mm Medical Nitinol Wires, offering exceptional tensile strength and shape memory properties. These advancements have expanded the applications of Niti wire in urology, cardiology, neurology, and other medical specialties, revolutionizing the way medical procedures are performed.

The development of ultra-fine 0.1mm and 0.15mm Medical Nitinol Wires has not only expanded the applications of Niti wire in various medical specialties but has also allowed for more precise and minimally invasive procedures. These ultra-fine wires provide exceptional maneuverability, allowing physicians to navigate through intricate anatomical structures with ease. As a result, patients can benefit from reduced trauma, shorter recovery times, and improved overall outcomes.

GEE SMA's Efforts in Addressing Unique Customer Needs

GEE SMA is at the forefront of addressing unique customer needs by customizing Niti alloy guide wires to meet specific clinical requirements. Their commitment to crafting high-quality nitinol materials ensures that healthcare professionals have access to reliable and tailored solutions for their patients' diverse medical conditions.

The Ongoing Evolution of Nitinol Functional Materials and Components

The evolution of Nitinol functional materials and components continues to drive advancements in medical device technology. With ongoing research and development efforts focused on enhancing the performance and durability of nitinol guide wires, we can expect further improvements in patient care and treatment outcomes.

As research and development efforts continue to focus on improving the performance and durability of nitinol guide wires, we can anticipate advancements in the design and manufacturing processes. These improvements may lead to guide wires that are not only more flexible and kink-resistant but also more cost-effective to produce. Additionally, ongoing innovation in nitinol functional materials could pave the way for the development of new medical devices with enhanced capabilities and reduced risks for patients.

Conclusion

Exploring the Enduring Impact of Niti Alloy Guide Wires

Niti alloy guide wires have revolutionized medical procedures, offering flexibility and durability for various applications. From urology to minimally invasive surgeries, the enduring impact of Niti wires is undeniable in improving patient outcomes and advancing healthcare practices. The unique properties of Niti alloy, including its shape memory and superelasticity, make it an ideal material for guide wires, allowing for precise navigation through complex anatomical structures with minimal trauma to the patient. Additionally, the biocompatibility of Niti alloy reduces the risk of adverse reactions, further enhancing its value in medical interventions.

Leveraging GEE SMA's Expertise in Crafting High-Quality Nitinol Materials

GEE SMA has been at the forefront of crafting high-quality nitinol materials, including 0.1mm and 0.15mm medical nitinol wire, ensuring tensile strength and reliability for medical niti alloy guide wires. Their expertise has set a benchmark for quality and innovation in the industry.

GEE SMA's commitment to excellence in crafting nitinol materials extends beyond just meeting industry standards. Their dedication to research and development has led to the creation of innovative nitinol alloys that offer superior flexibility and kink resistance, setting a new standard for guide wire performance. By continuously pushing the boundaries of what is possible with nitinol materials, GEE SMA is shaping the future of guide wire technology, ensuring that medical professionals have access to the most advanced tools for minimally invasive procedures.

Embracing the Future of Niti Alloy Guide Wire Technology

As the industry continues to evolve, there is a growing focus on enhancing the application and progress of NiTi alloys, paving the way for even smaller and more precise medical nitinol wire designs that cater to specific clinical needs. Embracing these advancements will undoubtedly shape the future of healthcare. With the ability to create finer and more flexible guide wires, medical professionals will have improved maneuverability within the body, leading to more accurate and successful procedures. Additionally, the development of nitinol wire technology opens up possibilities for minimally invasive surgeries, reducing recovery times and overall patient discomfort.