Introduction

Nitinol, a unique alloy of nickel and titanium, possesses remarkable properties that make it a valuable material in various fields, particularly in the medical industry. Its superelasticity, shape memory effect, and biocompatibility have led to diverse applications in medical devices. This versatile material has revolutionized the way medical procedures are performed and has significantly improved patient outcomes.

Understanding the Properties of Nitinol

The properties of nitinol that set it apart from other materials include its superelasticity, allowing it to return to its original shape after deformation; its shape memory effect, enabling it to revert to a predetermined shape when subjected to heat; and its biocompatibility with human tissues and fluids. These properties make nitinol an ideal choice for manufacturing medical devices such as stents, guidewires, and orthodontic archwires.

Exploring the Applications of Nitinol

In the medical field, nitinol is widely used for producing minimally invasive surgical tools and implants due to its unique properties. It is utilized in stents for treating narrowed or weakened arteries, guidewires for navigating through blood vessels during surgeries, and orthodontic archwires for correcting dental misalignments. These applications demonstrate the versatility of nitinol in addressing various medical needs.

The Diverse Uses of Nitinol in Medical Field

The properties of nitinol play a crucial role in enhancing patient care by providing durable yet flexible materials for medical devices that can withstand high stress and strain within the body's environment. Additionally, these materials contribute to improved patient comfort during recovery. The diverse uses of nitinol in the medical field highlight its significance as an innovative material that continues to drive advancements in healthcare technology.

Properties of Nitinol

Nitinol, a nickel-titanium alloy, possesses three unique properties that make it highly valuable in medical applications. Firstly, its superelasticity allows it to return to its original shape after being deformed, making it ideal for stents and guidewires. Secondly, its shape memory effect enables it to revert to a predetermined shape when exposed to heat or stress, perfect for self-expanding stents and orthodontic archwires. Lastly, its biocompatibility and corrosion resistance make it safe for use in the human body without causing adverse reactions or degradation.

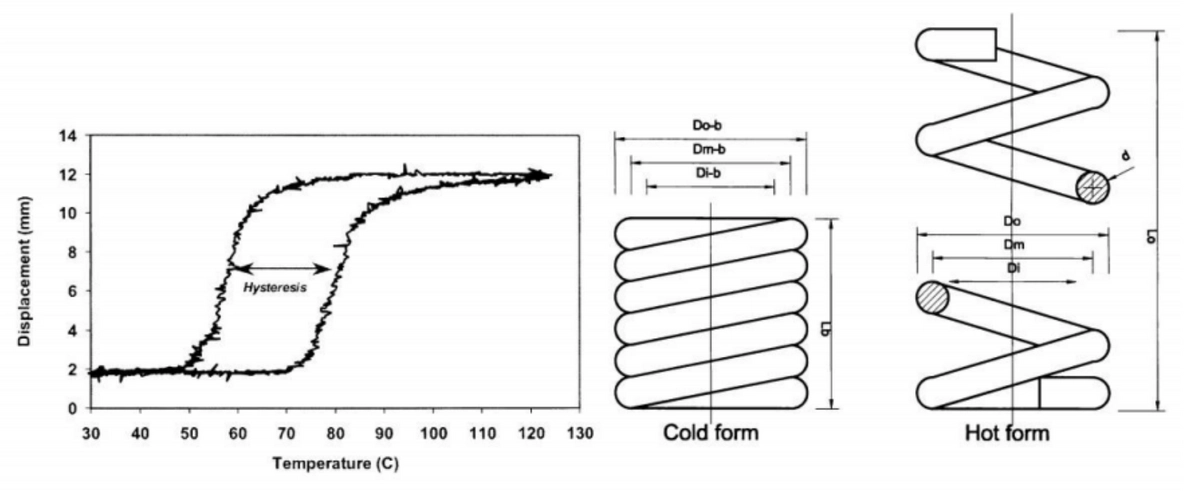

Superelasticity and Shape Memory Effect

The superelasticity of nitinol allows it to withstand high levels of strain without permanent deformation, making it suitable for devices that need to bend or flex within the body. Additionally, its shape memory effect means that nitinol components can be compressed into a smaller form for insertion into the body and then expand back to their original shape once in position. These properties are crucial in the design of minimally invasive medical devices such as stents and guidewires.

The superelasticity and shape memory effect of nitinol also contribute to its longevity and durability within the body. This allows medical devices made from nitinol to maintain their structural integrity over time, reducing the need for frequent replacements or interventions. As a result, patients can benefit from longer-lasting treatments and reduced risk of complications, ultimately improving their quality of life.

Biocompatibility in Medical Devices

Nitinol's biocompatibility ensures that it does not trigger an immune response or cause harm when implanted within the body, making it an ideal material for medical devices such as stents and orthodontic wires. This property allows patients to benefit from these devices without experiencing adverse reactions or complications post-implantation.

Corrosion Resistance in Body Environments

The corrosion resistance of nitinol is essential for ensuring the longevity and reliability of medical implants within the body's harsh chemical environment. This property prevents degradation of the material over time, maintaining the structural integrity of devices like stents and guidewires for extended periods.

The unique composition of nitinol allows for exceptional flexibility and shape memory, making it an ideal material for medical devices that need to withstand the body's constant movement and pressure. This flexibility ensures that implants like stents can adapt to the body's natural movements without causing discomfort or complications for the patient. Additionally, the shape memory of nitinol allows devices to return to their original form after being deformed during insertion, ensuring proper functionality once in place.

Applications of Nitinol in Medical Devices

Nitinol's unique properties make it a versatile material for various medical applications. Its superelasticity allows stents to be compressed and inserted into blood vessels, then expand to their original shape. This makes it ideal for stent delivery systems, providing a reliable solution for treating cardiovascular diseases.

Stents and Stent Delivery Systems

Nitinol's shape memory effect is crucial in the design of stents, as it enables them to return to their original shape once they are deployed in the body. This property ensures that the stent will effectively open up narrowed arteries and restore blood flow, providing a life-saving treatment for patients with heart conditions. Additionally, its biocompatibility ensures that the material won't cause adverse reactions or rejection by the body.

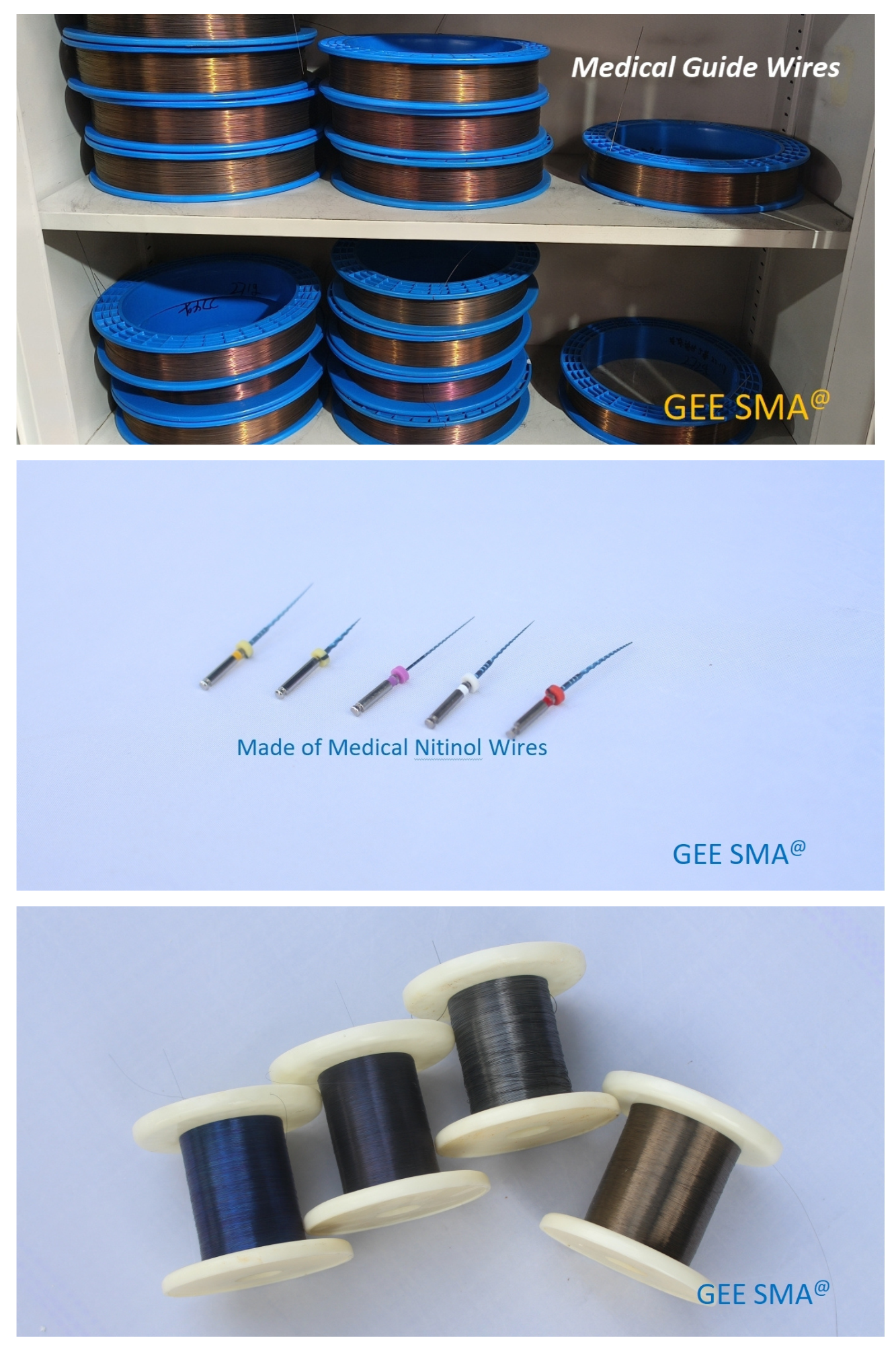

Guidewires for Minimally Invasive Surgery

In minimally invasive surgery, nitinol guidewires are used to navigate through delicate pathways within the body with ease due to their flexibility and kink resistance. The superelasticity of nitinol allows these guidewires to bend without permanent deformation, ensuring precise navigation during procedures such as angioplasty or endovascular surgery.

In addition to their flexibility and kink resistance, nitinol guidewires are also known for their high tensile strength, allowing them to withstand the forces exerted during minimally invasive procedures. This durability ensures that the guidewires can safely navigate through the body without the risk of breakage or damage, providing both patients and medical professionals with peace of mind. Furthermore, the radiopacity of nitinol makes these guidewires visible under fluoroscopy, aiding in their precise placement and enhancing their overall effectiveness in guiding surgical instruments.

Orthodontic Archwires for Dental Braces

Orthodontic archwires made from nitinol are not only more comfortable for patients, but they also offer greater durability and longevity compared to traditional materials. This means fewer visits to the orthodontist for adjustments, saving time and inconvenience for both patients and practitioners. Additionally, the flexibility and resilience of nitinol archwires contribute to a more efficient orthodontic treatment process, ultimately leading to quicker and more effective results.

Advantages of Nitinol in Medical Industry

Nitinol's unique properties make it an ideal material for a wide range of medical applications. Its flexibility and durability allow for long-term use in devices such as stents and guidewires, providing reliable support without compromising patient safety. Additionally, its ability to withstand high stress and strain makes it suitable for use in minimally invasive surgical procedures, where precision and resilience are critical for successful outcomes. Furthermore, the enhanced patient comfort and quicker recovery associated with Nitinol-based medical devices make them a preferred choice among healthcare professionals.

Flexibility and Durability for Long-Term Use

The remarkable flexibility and durability of nitinol make it well-suited for long-term use in various medical devices. Its superelasticity allows it to withstand repeated bending and twisting without losing its original shape, making it an excellent choice for applications that require prolonged support within the body. This property is particularly valuable in stent design, where the device must maintain its structural integrity while adapting to the natural movements of the body's vessels.

Ability to Withstand High Stress and Strain

Nitinol's ability to withstand high stress and strain is crucial in medical applications where the material must endure significant mechanical forces without failing. This unique property enables nitinol-based guidewires to navigate through tortuous blood vessels during minimally invasive surgeries with precision and reliability, ensuring successful treatment outcomes while minimizing patient discomfort.

Enhanced Patient Comfort and Recovery

The enhanced patient comfort associated with nitinol-based medical devices contributes to quicker recovery times and improved overall outcomes. The biocompatibility of nitinol ensures that these devices are well-tolerated by the body, reducing the risk of adverse reactions or complications post-procedure. As a result, patients experience less discomfort during treatment, leading to faster recovery periods and better overall satisfaction with their healthcare experience.

Innovations and Developments in Nitinol Technology

Nitinol, a unique nickel-titanium alloy, possesses remarkable properties that make it ideal for various medical applications. One of the most notable properties of nitinol is its superelasticity, allowing it to return to its original shape after being deformed. This property is crucial in medical devices such as stents, where the material needs to expand and contract within the body without losing its shape. Another key property is its shape memory effect, enabling it to revert to a predetermined shape when subjected to heat or stress. This feature is utilized in orthodontic archwires for dental braces, providing patients with a comfortable and effective treatment.

GEE SMA's Contribution to Nitinol Advancements

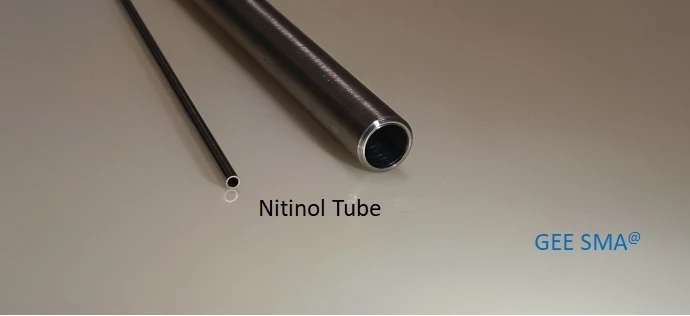

GEE SMA has been at the forefront of advancing nitinol technology, contributing significantly to the development of high-quality nitinol materials and components. Through extensive research and innovation, GEE SMA has enhanced the mechanical properties of nitinol, making it more durable and resilient for medical applications. Their contributions have led to the creation of cutting-edge nitinol-based medical devices that improve patient outcomes and quality of care.

Crafting High-Quality Nitinol Materials and Components

GEE SMA's expertise lies in crafting top-notch nitinol materials and components that meet the stringent requirements of the medical industry. Their meticulous manufacturing processes ensure that the nitinol products exhibit superior biocompatibility, corrosion resistance, and flexibility essential for long-term use within the human body. By consistently delivering high-quality materials, GEE SMA has earned a reputation as a trusted partner for medical device manufacturers worldwide.

Tailoring Nitinol Functional Materials for Unique Customer Needs

In response to diverse customer needs, GEE SMA specializes in tailoring nitinol functional materials with specific attributes required for various medical applications. Whether it's customizing stents with precise expansion capabilities or developing guidewires with exceptional flexibility, GEE SMA leverages its technical expertise to create bespoke solutions that address unique challenges in healthcare settings.

Conclusion

Nitinol is poised to revolutionize the field of medical innovations with its unique properties and versatile applications. The shape memory effect, superelasticity, and biocompatibility of nitinol make it an ideal material for a wide range of medical devices, from stents to orthodontic archwires. As the demand for high-quality nitinol materials continues to grow, GEE SMA remains committed to ensuring product quality and tailoring materials to meet the specific needs of our customers.

The Future of Nitinol in Medical Innovations

With ongoing advancements in nitinol technology, the future looks bright for its role in medical innovations. As researchers and engineers continue to explore the full potential of nitinol, we can expect to see even more groundbreaking applications in areas such as minimally invasive surgery, cardiovascular interventions, and orthopedics. The unique properties of nitinol will undoubtedly play a crucial role in shaping the future landscape of medical devices.

GEE SMA's Commitment to Product Quality

At GEE SMA, our commitment to product quality is unwavering. We understand the critical importance of precision and reliability when it comes to medical devices, which is why we prioritize stringent quality control measures throughout our manufacturing process. By upholding the highest standards for our nitinol materials and components, we aim to provide healthcare professionals with the confidence they need to deliver exceptional care to their patients.

Tailoring Nitinol Materials to Meet Customer Needs

As customer needs continue to evolve, so too does our approach at GEE SMA. We recognize that each application of nitinol comes with its own set of unique requirements, which is why we are dedicated to customizing our materials and components accordingly. Whether it's adjusting mechanical properties or fine-tuning surface finishes, we are committed to tailoring our nitinol solutions in order to exceed customer expectations.