Introduction

Nickel-titanium shape memory alloy, also known as memory metal nitinol, is a revolutionary material that has gained widespread attention for its unique properties. This alloy can remember its original shape and return to it when heated, making it a game-changer in various industries.

Understanding Nickel Titanium Shape Memory Alloy

The nickel titanium shape memory alloy, or nitinol, is a type of metal shape memory alloy that exhibits the extraordinary ability to recover its initial shape after deformation. This remarkable characteristic has led to its use in various innovative applications.

Nitinol's unique properties make it ideal for use in medical devices, such as stents and orthodontic wires. Its ability to return to its original shape allows for minimally invasive procedures and reduces the risk of complications during surgery. Nitinol's biocompatibility and corrosion resistance make it a safe and reliable choice for medical applications.

Applications of Nickel Titanium Shape Memory Alloy

From biomedical devices to aerospace components, nickel titanium shape memory alloy's applications are diverse and far-reaching. Its flexibility and durability make it ideal for industries seeking advanced materials with unique properties.

Nickel titanium shape memory alloy is also widely used to manufacture eyeglass frames and orthodontic wires. Its ability to return to its original shape after being deformed allows for comfortable and long-lasting wear, making it a popular choice for those needing corrective eyewear or dental appliances. The flexibility of this alloy also ensures a snug fit, reducing the need for frequent adjustments and replacements, ultimately saving time and money for both manufacturers and consumers.

Benefits of Using Nickel Titanium Shape Memory Alloy

Nickel-titanium shape memory alloy (NiTi) is a remarkable material with unique properties that have revolutionized various industries. Here are some of the key benefits of using NiTi:

- Shape Memory Effect: NiTi can be deformed and "remember" its original shape when exposed to a specific temperature or external stimulus. This allows for the creation of intricate designs that can be compressed for easier insertion and then regain their original form within the body or at the desired location.

- Superelasticity: NiTi exhibits incredible elasticity, able to withstand significant deformation without permanent damage. This property makes it ideal for applications requiring flexibility and resilience, such as orthodontic wires and cardiovascular stents.

- Biocompatibility: NiTi is well-tolerated by the human body, making it a highly sought-after material for medical devices like implants and surgical instruments.

- Durability: NiTi is resistant to corrosion and wear, ensuring long-lasting performance in demanding environments.

- Versatility: With its unique properties, NiTi finds applications in various fields, including aerospace, medicine, consumer goods, and more.

NiTi's potential seems endless, offering innovative solutions across diverse industries thanks to its remarkable shape memory, superelasticity, biocompatibility, and durability.

The unique properties of nickel-titanium shape memory alloy also make it an ideal choice for medical devices and implants. Its biocompatibility and ability to withstand the harsh conditions inside the human body make it a reliable material for surgical instruments, stents, and other medical applications. This versatility has revolutionized medicine, allowing for more effective and longer-lasting treatments for patients.

What is Nickel Titanium Shape Memory Alloy?

Nickel titanium shape memory alloy, also known as memory metal nitinol, is a unique type of metal shape memory alloy that can remember its original shape and return to it when heated. This remarkable property makes it incredibly versatile and useful in various industries.

Definition of Nickel Titanium Shape Memory Alloy

Nickel titanium shape memory alloy, or nitinol, is a type of shape memory alloy composed of roughly equal parts nickel and titanium. This unique combination gives nitinol its distinctive properties, allowing it to return to its original shape after being deformed when exposed to heat.

Nickel titanium shape memory alloy, or nitinol, is a type of shape memory alloy composed of roughly equal parts nickel and titanium. This unique combination gives nitinol its distinctive properties, allowing it to return to its original shape after being deformed when exposed to heat. The ability of nitinol to remember and recover its original shape makes it an ideal material for various applications in industries such as medical devices, aerospace, and robotics. Its flexibility and durability make it a popular choice for intricate designs and complex mechanisms.

Composition of Nickel Titanium Shape Memory Alloy

The composition of nickel titanium shape memory alloy typically consists of approximately 50% nickel and 50% titanium. This specific blend of metals gives nitinol its remarkable ability to undergo significant deformation at low temperatures and revert to its original form when heated.

The unique composition of nickel titanium shape memory alloy also contributes to its superelasticity, making it highly resistant to permanent deformation. This makes nitinol ideal for applications requiring repetitive bending or shaping, such as medical devices and robotics. Additionally, the combination of nickel and titanium gives the alloy excellent corrosion resistance, further expanding its potential uses in various industries.

Properties of Nickel Titanium Shape Memory Alloy

One of the most fascinating properties of nickel titanium shape memory alloy is its superelasticity, which allows it to undergo large deformations without permanent damage. Additionally, nitinol exhibits excellent corrosion resistance and biocompatibility, making it suitable for various industrial applications.

Moreover, nickel titanium shape memory alloy has the unique ability to return to its original shape after deforming, making it ideal for applications requiring precise and reliable performance. This property allows nitinol to be used in medical devices such as stents and orthodontic wires, where the material can adapt to the body's movements without causing discomfort or complications. The shape memory effect of nitinol also makes it a valuable material for actuators and sensors in various engineering fields.

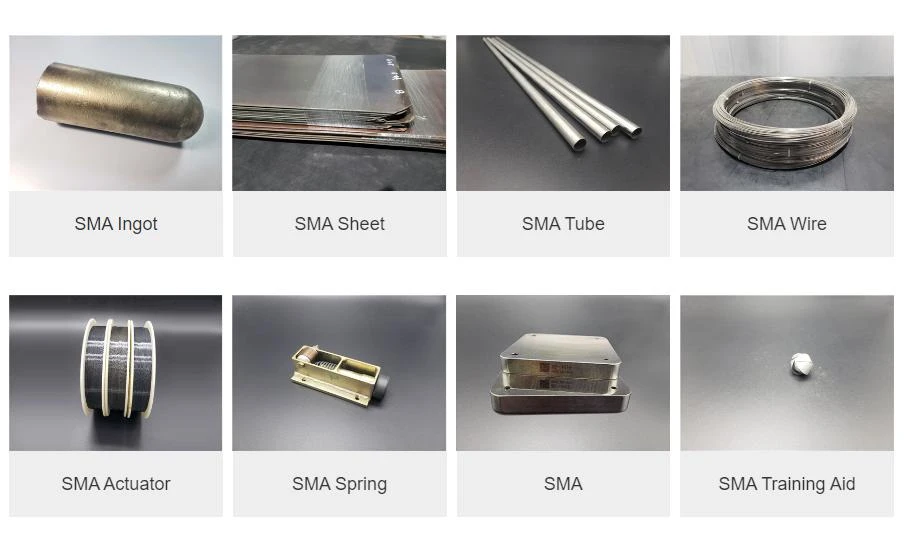

Advantages of Using GEE SMA's Nitinol Alloys

GEE SMA's nitinol alloys offer exceptional flexibility and durability, making them ideal for various applications. Their unique properties allow for repeated deformation and recovery without permanent damage, ensuring long-lasting performance in various industries.

Flexibility and Durability of GEE SMA's Nitinol Alloys

GEE SMA's nitinol alloys are known for their remarkable flexibility, allowing them to undergo significant deformation and return to their original shape when subjected to heat or mechanical force. This flexibility makes them suitable for applications requiring intricate shapes or movements, such as medical devices and aerospace components. Additionally, the durability of these alloys ensures reliable performance over extended periods, reducing the need for frequent replacements.

Unique Applications Enabled by GEE SMA's Nitinol Alloys

The exceptional properties of GEE SMA's nitinol alloys enable unique applications that would be challenging or impossible with other materials. These alloys have been utilized in minimally invasive medical devices, such as stents and guidewires, where their shape memory capabilities allow for compact delivery systems that expand to their intended shape once deployed within the body. In addition, they have found use in actuators for robotics and adaptive structures in aerospace engineering, showcasing the versatility of these advanced materials.

Customization Options for GEE SMA's Nitinol Alloys

GEE SMA offers customization options for their nitinol alloys, allowing clients to tailor the material properties to specific application requirements. This customization may involve adjusting the transition temperatures or fine-tuning mechanical properties to achieve optimal performance in diverse environments. By providing tailored solutions, GEE SMA empowers industries to harness the full potential of shape memory alloy nitinol to address complex engineering challenges.

GEE SMA's expertise in customization extends to developing unique nitinol alloy compositions that cater to specific industry needs. Whether enhancing corrosion resistance, improving fatigue life, or optimizing biocompatibility, GEE SMA can tailor nitinol alloys to meet the most demanding application requirements. This level of customization enables industries to push the boundaries of what is possible with shape memory alloys, opening up new opportunities for innovation and advancement in various fields.

Is Titanium Nickel Free?

Exploring the Nickel-Free Properties of Nitinol Alloys

Nitinol alloys have gained significant attention due to their unique properties, but one drawback is the presence of nickel, which can cause allergic reactions in some individuals. As a result, there has been a growing interest in exploring nickel-free alternatives to nitinol alloys. Researchers and manufacturers are actively investigating the possibility of replacing nickel with other elements without compromising the desirable characteristics of nitinol alloys. This pursuit has led to promising developments in creating nickel-free nitinol alloys that could expand their potential applications while addressing concerns related to nickel allergies.

Comparing Nitinol Alloys with Traditional Nickel Alloys

Nitinol alloys have the distinct advantage of remembering their original shape and returning to it after deformation. Traditional nickel alloys do not possess this unique property, making nitinol alloys a preferred choice for applications where shape memory is essential. Nitinol alloys also offer superior flexibility and durability, further setting them apart from traditional nickel alloys.

Furthermore, nitinol alloys exhibit excellent biocompatibility, making them ideal for medical devices such as stents and orthodontic wires. This is a significant advantage over traditional nickel alloys, which may cause allergic reactions in some individuals. The health benefits of using nickel-free nitinol alloys in medical applications cannot be overstated, as they provide patients a safer and more comfortable experience.

Health and Environmental Benefits of Nickel-Free Nitinol Alloys

One of the most significant advantages of nitinol alloys is their nickel-free properties. This makes them an ideal choice for medical devices and implants, as they eliminate the risk of allergic reactions or toxicity associated with nickel exposure. Furthermore, using nickel-free nitinol alloys aligns with environmental regulations and sustainability initiatives, making them a responsible choice for various industries.

Now that we've explored the unique properties and advantages of nickel titanium shape memory alloy, let's delve into its diverse range of applications in various industries.

Applications of Nickel Titanium Shape Memory Alloy

Medical Industry Applications of Nickel Titanium Shape Memory Alloy

One of the most significant applications of nickel titanium shape memory alloy in the medical industry is orthodontic wires, whose unique properties allow for gentle and continuous tooth movement. Additionally, it is used in stents for treating cardiovascular diseases due to its ability to adapt to the shape of blood vessels. Furthermore, it is utilized in minimally invasive surgical instruments, benefiting from its flexibility and biocompatibility.

Aerospace Industry Applications of Nickel Titanium Shape Memory Alloy

In the aerospace industry, nickel titanium shape memory alloy finds applications in actuation systems for aircraft wings and engine components. Its ability to withstand extreme temperatures and return to its original shape makes it ideal for actuators that control various functions within an aircraft. Moreover, it is used in deployable structures such as antennas and solar arrays due to its lightweight and durable nature.

Automotive Industry Applications of Nickel Titanium Shape Memory Alloy

Within the automotive industry, nickel titanium shape memory alloy is utilized in various components such as actuators for engine valves and exhaust systems. Its ability to withstand high temperatures and repetitive motion makes it suitable for these applications, contributing to improved fuel efficiency and reduced emissions. Additionally, it is used in safety systems such as airbag deployment mechanisms due to its reliability and rapid response capabilities.

Remember that when considering nickel titanium shape memory alloy applications across different industries, GEE SMA's Nitinol Alloys offer unparalleled flexibility, durability, and customization options that cater to specific requirements within each sector.

Partner with GEE SMA for High-Quality Nitinol Alloys

Exploring the Versatility of Nickel Titanium Shape Memory Alloy

Nickel titanium shape memory alloy, also known as Nitinol, is a remarkable material with the unique ability to return to a predetermined shape when subjected to heat. This exceptional property has led to its widespread use in various medical, aerospace, and automotive industries. Due to its biocompatibility and superelasticity, Nitinol is used for minimally invasive surgical procedures, such as stents and guidewires. Nitinol is utilized in actuators and landing gear components in the aerospace industry for its lightweight and durable nature. Additionally, in the automotive sector, Nitinol finds applications in engine components and safety systems for its ability to withstand high temperatures and harsh conditions.

When sourcing high-quality nitinol alloys, partnering with GEE SMA is the best choice. Their expertise in producing flexible and durable nitinol alloys and their customization options make them a leading provider in the industry. With GEE SMA, you can be assured of top-notch nitinol alloys for your specific applications.

Embracing the Future of Shape Memory Alloys

As we look ahead, the future of shape memory alloys like nickel titanium holds immense promise. With ongoing research and development efforts, new applications and advancements are continually being discovered. Embracing these innovative materials will pave the way for groundbreaking solutions across diverse fields. Furthermore, the unique properties of shape memory alloys make them ideal for medical devices, such as stents and orthodontic wires. Their ability to return to a predetermined shape after deformation allows for minimally invasive procedures and improved patient outcomes.