Introduction

Nitinol, also known as memory metal, is a fascinating alloy with unique shape memory properties that allow it to return to its original shape when heated. This remarkable material has found diverse applications across various industries, from the medical field to aerospace engineering. But the burning question remains - is nitinol expensive?

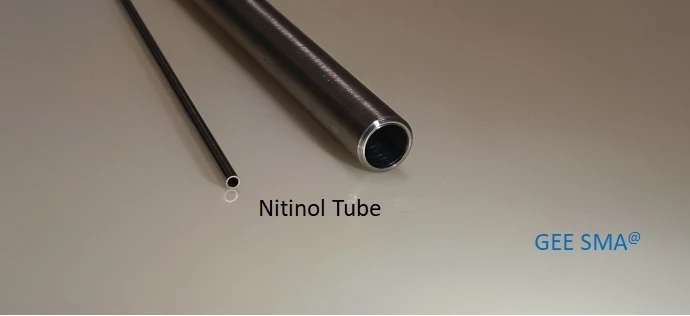

Understanding Nitinol Metal

Nitinol is a nickel-titanium alloy that exhibits superelasticity and shape memory effect, making it a highly sought-after material in the manufacturing world. Its ability to remember its original form after being deformed sets it apart from other metals and opens up a world of possibilities for innovative designs and products.

Exploring Nitinol Applications

From minimally invasive medical devices to intricate aerospace components, nitinol's versatility has made it an indispensable material in various applications. Its unique properties have led to breakthroughs in stents, orthodontic wires, actuators, and more, revolutionizing industries with flexibility and reliability.

Is Nitinol Expensive?

The cost of nitinol can vary depending on factors such as purity, shape memory properties, and manufacturing processes. While it may be pricier than traditional alloys, the benefits of using nitinol often outweigh the initial investment. Finding reputable nitinol manufacturers offering competitive quality is key to maximizing its value.

What is Nitinol?

Nitinol, a shape memory alloy, is a unique metal that remembers its original shape when heated. This remarkable property makes it ideal for a wide range of applications in various industries. Whether in the medical field, engineering, or aerospace, the versatility of nitinol makes it a sought-after material.

The Composition of Nitinol

Nitinol is a nickel-titanium alloy that exhibits superelasticity and shape memory properties. It typically consists of approximately 55% nickel and 45% titanium, although the composition varies depending on the specific application requirements. This combination of metals gives nitinol its distinctive characteristics, which set it apart from other materials.

Nitinol's unique composition of nickel and titanium allows it to exhibit superelasticity, meaning it can undergo significant deformation and return to its original shape when the stress is removed. This property makes nitinol ideal for applications such as medical stents and orthodontic wires, where flexibility and resilience are crucial. In addition, the shape memory properties of nitinol enable it to "remember" its original shape and return to it when subjected to a specific stimulus, making it highly versatile in various industries.

Nitinol Shape Memory Properties

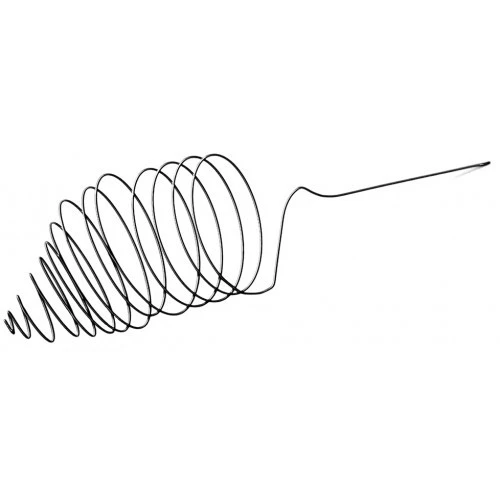

One of the most fascinating aspects of nitinol is its ability to return to its original shape after being deformed at lower temperatures and revert to its memorized shape when heated above a certain temperature, known as the transformation temperature. This unique property allows for innovative designs and applications across different industries.

Nitinol's shape memory properties have revolutionized the medical device industry, allowing for the creation of minimally invasive surgical tools that can be inserted into the body in a compact form and then expand to their original shape once inside. This has led to less invasive procedures, faster recovery times, and improved patient outcomes. Additionally, nitinol's ability to withstand repeated deformation without fatigue makes it an ideal material for applications in orthodontic wires, stents, and other implantable devices.

GEE SMA's Expertise in Nitinol

As one of the leading manufacturers specializing in nitinol alloys, GEE SMA has extensive expertise in producing high-quality nitinol materials tailored to meet specific customer needs. With state-of-the-art manufacturing processes and stringent quality control measures, GEE SMA ensures that its nitinol products meet industry standards and exceed customer expectations.

Additionally, GEE SMA understands the importance of cost-effectiveness in nitinol applications. By optimizing its manufacturing processes and sourcing high-quality raw materials, GEE SMA is able to offer competitive pricing without compromising on the quality of its nitinol products. This cost-efficiency makes GEE SMA a top choice for customers looking to incorporate nitinol into their products without breaking the bank.

The Cost of Nitinol

Nitinol, a unique alloy with shape memory properties, is renowned for its versatility and durability. When it comes to pricing, several factors come into play. The cost of nitinol is influenced by the purity of the metal, manufacturing processes, and market demand. As a result, nitinol can be more expensive than traditional metals due to its specialized properties and production methods.

Factors Affecting Nitinol Pricing

Nitinol, a nickel-titanium alloy known for its shape memory and superelasticity, offers remarkable advantages for various applications. However, its unique properties also contribute to a higher cost than other metals. Here's a breakdown of the key factors that influence nitinol pricing:

- Raw Material Costs: Nickel and titanium, the primary elements in nitinol, experience price fluctuations based on global market demands and supply chains. An increase in their cost directly impacts the overall price of nitinol.

- Manufacturing Complexity: Producing nitinol involves specialized processes like melting, shaping, and heat treatment. These intricate steps require specialized equipment and expertise, leading to higher production costs than simpler materials.

- Processing and Shaping Complexity: The desired shape and properties of nitinol components (wire, sheet, tubing) necessitate specific processing techniques. More intricate shaping or achieving precise functional characteristics can increase manufacturing costs.

- Quality of Raw Materials: Higher purity nitinol offers superior shape memory and superelasticity. Nitinol with rigorous testing and certifications to ensure these properties will naturally command a higher price due to its guaranteed performance and reliability.

- Manufacturer Expertise: Reputable manufacturers with a proven track record of producing high-quality nitinol might command a premium compared to lesser-known suppliers. However, the consistency and reliability of their product, along with their technical support, can justify the higher cost.

- Market Demand and Supply: Similar to any commodity, the price of nitinol fluctuates based on supply and demand. Increased demand or limited supply can drive prices up, while a surplus in the market can lead to lower costs.

Comparing Nitinol to Other Alloys

When comparing nitinol to other alloys such as stainless steel or titanium, it's important to note that while nitinol may be more expensive upfront, its unique properties often make it a cost-effective choice in the long run. Its shape memory capabilities and superelasticity set it apart from traditional metals, offering unparalleled performance in various applications.

Affordable Nitinol Manufacturers

Despite its reputation as a premium alloy, affordable nitinol manufacturers provide high-quality products at competitive prices. These manufacturers leverage advanced technologies and streamlined processes to offer cost-effective solutions without compromising on quality or performance. Partnering with reputable manufacturers who understand the nuances of working with this memory metal is crucial.

With careful consideration of these factors and strategic sourcing from reliable manufacturers like GEE SMA, which specializes in nitinol alloys, the question of whether nitinol is expensive can be answered effectively by making informed decisions based on specific application requirements and long-term benefits rather than upfront costs alone.

Nitinol Applications

Medical Industry Usage

Nitinol's unique properties make it a game-changer in the medical field. Its shape memory and superelasticity allow for the creation of stents that can expand and contract within the body, reducing the need for multiple surgeries. Additionally, its biocompatibility and resistance to corrosion make it ideal for implants, such as orthodontic wires and bone anchors.

Engineering and Aerospace Applications

In the engineering and aerospace industries, nitinol is used in actuators, sensors, and various other components due to its ability to return to its original shape after deformation. This makes it perfect for applications like self-deploying structures in space missions or adaptive wing designs in aircraft. Its durability and resilience also make it a preferred choice for critical components in these fields.

In addition to its use in actuators and sensors, nitinol's unique properties also make it ideal for medical devices such as stents and guidewires. Its superelasticity and shape memory allow these devices to be inserted into the body in a compact form and then expand to their original shape once inside, reducing the invasiveness of medical procedures. This has revolutionized minimally invasive surgery and has significantly improved patient outcomes.

Advantages of Nitinol in Various Industries

The advantages of nitinol extend beyond just the medical, engineering, and aerospace sectors. Its unique properties have led to innovative uses in areas such as robotics, automotive technology, and even consumer goods like eyeglass frames. The versatility of nitinol has opened up endless possibilities for industries looking to improve performance while reducing costs.

Remember that when considering nitinol applications in your industry or project, it's essential to work with reputable manufacturers who understand the complexities of this memory metal alloy. By doing so, you can ensure that you are getting high-quality nitinol products that meet your specific needs while staying within budget constraints.

Nitinol Shape Memory Alloys

Understanding Shape Memory Properties

Nitinol shape memory alloys have the remarkable ability to remember and recover their original shape after being deformed, making them ideal for various applications. This unique property is due to a phase transformation between austenite and martensite structures, allowing the material to undergo significant deformation and then return to its original form when subjected to a specific stimulus.

Nitinol shape memory alloys are highly versatile and find applications in various industries such as medical devices, aerospace, automotive, and robotics. Their ability to return to their original shape makes them suitable for use in stents, orthodontic wires, actuators, and other components that require precise and reliable shape memory properties. This unique characteristic sets Nitinol apart from other materials and has led to its widespread adoption in critical applications where dimensional stability is essential.

GEE SMA's Premium Nitinol Alloys

GEE SMA specializes in producing premium nitinol alloys that exhibit exceptional shape memory properties, ensuring reliable performance in demanding environments. Their expertise in manufacturing high-quality nitinol materials has made them a trusted supplier for industries such as medical devices, aerospace, and engineering, where precision and reliability are paramount.

GEE SMA's commitment to excellence extends beyond the production of premium nitinol alloys. Their team of experienced engineers and metallurgists work closely with clients to tailor nitinol components to their unique needs, ensuring that each product meets the specific requirements of the application. This personalized approach sets GEE SMA apart in the industry, allowing them to deliver custom solutions that optimize performance and efficiency for their customers.

Tailoring Nitinol Components to Unique Needs

One of the key advantages of nitinol alloys is their versatility in being tailored to meet specific requirements for different applications. GEE SMA offers custom fabrication services to create nitinol components that address unique design challenges, providing solutions that maximize the material's shape memory capabilities while meeting the exact specifications of their clients.

In addition to creating custom nitinol components, GEE SMA also offers expertise in material selection and design optimization. This means that clients can benefit from the company's deep knowledge of nitinol alloys and their unique properties, ensuring that the final product not only meets their specifications but also performs optimally in its intended application. By leveraging this expertise, clients can have confidence in the reliability and functionality of their nitinol components.

Conclusion

Nitinol is a fascinating metal alloy with incredible shape memory properties, making it a valuable material for various industries. When sourcing Nitinol, it's essential to consider factors such as quality, reliability, and cost-effectiveness. Look for reputable nitinol manufacturers with expertise in producing high-quality alloys at competitive prices.

Tips for Sourcing Nitinol

When looking for nitinol manufacturers, prioritize those with a proven track record of delivering top-notch alloys. Consider their experience in the industry and the range of products they offer. Additionally, seek out suppliers who are transparent about their pricing and can provide customized solutions to meet your specific needs.

Exploring Nitinol's Versatility

Nitinol's versatility extends across multiple sectors, from medical devices to engineering and aerospace applications. Its unique properties make it an ideal choice for intricate components that require precise shape memory capabilities. By exploring the diverse applications of nitinol, you can uncover innovative ways to leverage its potential in your projects.

Making Informed Decisions on Nitinol Purchases

Understanding the factors that influence nitinol pricing is crucial for making informed purchasing decisions. While nitinol may initially seem expensive, its long-term benefits often outweigh the upfront costs. By evaluating its durability and performance advantages, you can justify the investment in this remarkable memory metal. Additionally, considering the potential cost savings from reduced maintenance and replacement needs can further demonstrate the value of choosing nitinol for your applications. Moreover, taking into account the unique shape memory and superelasticity properties of nitinol can open up innovative design possibilities, leading to enhanced product performance and differentiation in the market.