Introduction

Nitinol flat wire, also known as shape memory alloy, is a revolutionary material with incredible potential. Its unique properties and versatility make it a game-changer in various industries. As we delve into the power of nitinol alloys, we uncover endless possibilities for innovation and progress. Let's explore the future of shape memory alloys and how they are reshaping the way we perceive materials.

The Potential of Nitinol Flat Wire

Nitinol flat wire is a remarkable material that exhibits shape memory and superelasticity, making it ideal for various applications. Its ability to return to a predetermined shape after deformation sets it apart from conventional materials, opening up new avenues for creativity and problem-solving.

Nitinol flat wire's unique properties make it an ideal choice for medical devices, such as stents and guidewires. Its superelasticity allows these devices to withstand deformation during insertion and return to their original shape once in place, providing better patient outcomes and reducing the need for additional procedures. This opens up new possibilities for minimally invasive surgeries and improved patient care.

Understanding the Power of Nitinol Alloys

The impressive properties of nitinol alloys, such as its biocompatibility, corrosion resistance, and high fatigue endurance, make it an attractive choice for various industries. Its flexibility and durability set it apart from other materials, offering unparalleled performance in demanding environments.

Nitinol alloys are also known for their shape memory properties, allowing them to return to their original shape after being deformed. This unique characteristic makes nitinol alloys ideal for applications such as medical devices, requiring intricate and precise movements. Additionally, the ability of nitinol alloys to exert significant force upon heating or cooling further expands their potential uses in various industries.

Exploring the Future of Shape Memory Alloys

As technology advances, so does the potential for shape memory alloys like nitinol flat wire. With ongoing research and development, we constantly uncover new ways to harness its capabilities and integrate it into cutting-edge innovations that will shape our future. One exciting area of exploration is in the field of medical devices, where nitinol flat wire is being used to create minimally invasive tools and implants that can adapt to the body's natural movements. This opens up possibilities for safer and more effective treatments, revolutionizing the way we approach healthcare.

The Wonders of Nitinol Flat Wire

Nitinol flat wire is a marvel of modern engineering, boasting unique properties that set it apart from traditional materials. With its exceptional shape memory and superelasticity, nitinol flat wire can undergo significant deformation and return to its original shape when heated, making it ideal for various innovative applications.

The Unique Properties of Nitinol

Nitinol is a special metal alloy known for its unique properties that make it valuable in many fields. Here's a closer look at what makes Nitinol stand out:

- Shape Memory: Nitinol possesses an impressive shape memory effect. No matter how bent, twisted, or compressed, it can effortlessly return to its original form when exposed to heat. This makes Nitinol ideal for applications where a material needs to be flexible for initial placement but then regain its original shape.

- Superelasticity: Nitinol exhibits remarkable superelasticity, allowing it to withstand significant deformation without permanent damage. This means it can be bent or pulled far out of shape and spring back perfectly. This superelasticity makes Nitinol incredibly durable and reliable for various demanding applications.

In conclusion, Nitinol's unique combination of shape memory and superelasticity makes it a versatile material with many potential applications in medicine, aerospace, and many other industries.

Applications of Nitinol Flat Wire in Various Industries

The versatility of nitinol flat wire has led to its widespread use across diverse industries. From medical devices like stents and orthodontic wires to actuators in robotics and aerospace components, the adaptability of nitinol alloy has revolutionized the way we approach technological advancements. Its unique properties have also made it indispensable in consumer electronics, automotive engineering, and everyday household items.

The adaptability of nitinol flat wire has also made it a crucial component in the field of sports equipment, particularly in high-performance gear like archery bows, fishing rods, and golf clubs. The unique properties of nitinol allow for enhanced flexibility and durability, providing athletes with equipment that can withstand rigorous use while delivering optimal performance. This has significantly improved the quality and longevity of sports gear, ultimately benefiting athletes and enthusiasts alike.

Advantages of Nitinol Shape Memory Alloys

Nitinol shape memory alloys are revolutionizing various fields due to their unique properties. Here's why nitinol is becoming a material of choice:

- Versatility for intricate mechanisms: Nitinol can maintain precise shapes under varying conditions, making it ideal for delicate mechanisms like microactuators and medical implants.

- Biocompatible and corrosion-resistant: Nitinol is safe for long-term implantation in the human body due to its biocompatibility and corrosion resistance, ensuring patient safety and comfort.

- Exceptional fatigue resistance: Nitinol can withstand repeated use without degrading in performance. This makes them ideal for critical medical applications like stents and guidewires where reliability is essential.

- Perfect for minimally invasive surgery: Nitinol's ability to return to its original shape after deformation makes it perfect for minimally invasive surgical tools, providing precision and control during procedures.

Nitinol's unique combination of properties makes it a valuable material for various applications, from intricate devices to life-saving medical implants.

Crafting Nitinol Flat Wire

Nitinol flat wire is a revolutionary material with unparalleled potential, and understanding the production process of nitinol alloys is crucial to harnessing its power. The creation of nitinol flat wire begins with the precise combination of nickel and titanium in a controlled environment, resulting in a unique crystalline structure that gives it its remarkable properties. This process involves intricate heating and cooling cycles to achieve the desired shape memory effect, making it a fascinating material.

The Production Process of Nitinol Alloys

The production process of nitinol alloys involves a meticulous blend of science and craftsmanship. The alloy's composition must be precisely controlled to ensure the desired shape memory effect and superelasticity are achieved. Once the alloy is formed, it undergoes a series of heat treatments to set its shape memory properties, allowing it to return to its original form after deformation. This complex process requires expertise and precision, making nitinol flat wire a marvel of modern engineering.

Quality Control Measures for Nitinol Flat Wire

Quality control measures for nitinol flat wire are imperative to ensure consistency and reliability in its performance. Every batch of nitinol alloy undergoes rigorous testing for mechanical properties, dimensional accuracy, and surface quality to meet industry standards. Additionally, non-destructive testing methods such as ultrasonic inspection are employed to detect any internal defects that could compromise the integrity of the flat wire. These stringent quality control measures guarantee that nitinol flat wire meets the highest standards for various applications.

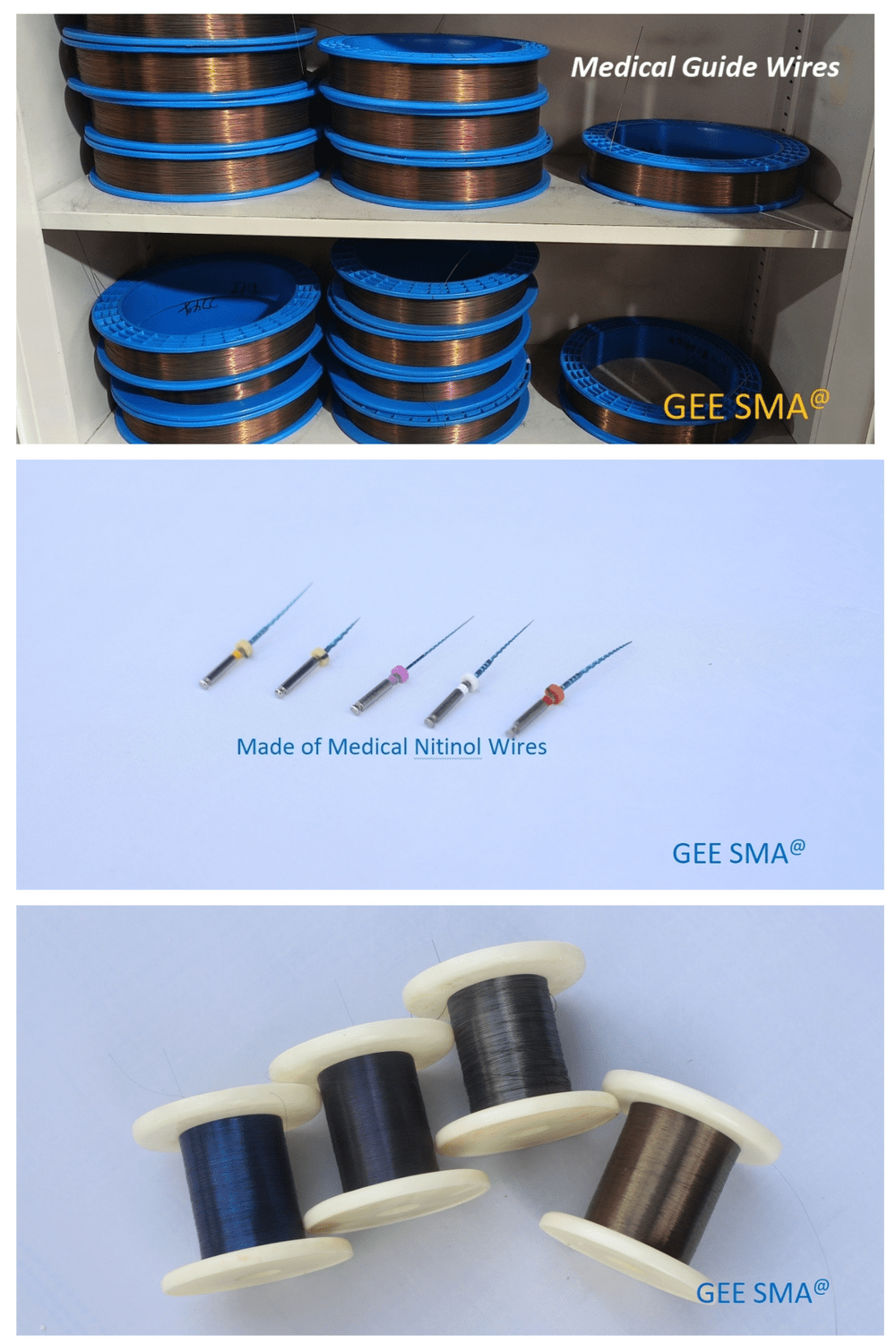

GEE SMA: Leading the Way in Nitinol Alloy Fabrication

GEE SMA stands at the forefront of nitinol alloy fabrication, leveraging cutting-edge technology and expertise to produce premium-quality nitinol flat wire. With state-of-the-art facilities and a team of skilled professionals, GEE SMA ensures that every step of the production process is meticulously executed to deliver superior nitinol alloys tailored to specific requirements. Their commitment to innovation and excellence makes them an industry leader in crafting high-performance nitinol materials.

Innovative Uses of Nitinol Flat Wire

Cutting-edge Technologies Utilizing Nitinol Alloys

Nitinol flat wire has revolutionized the field of robotics, with its unique shape memory properties allowing for the development of advanced robotic actuators and sensors. The flexibility and durability of nitinol wire make it an ideal material for creating intricate, high-performance robotic components that can adapt to changing conditions.

Medical and Healthcare Applications of Nitinol Shape Memory Alloys

In the medical industry, nitinol flat wire has been instrumental in developing minimally invasive surgical tools and devices. Its superelasticity and biocompatibility make it a perfect choice for applications such as stents, orthodontic wires, and guidewires, where precision and reliability are crucial for patient care.

Nitinol Flat Wire in Aerospace and Engineering Projects

In aerospace and engineering, nitinol alloys are being used to create innovative solutions such as adaptive wing structures in aircraft and deployable solar arrays in space missions. The ability of nitinol flat wire to return to its original shape after being deformed under certain conditions makes it a game-changer in designing lightweight, efficient aerospace components.

Now that we've explored some cutting-edge uses of nitinol alloys, let's delve into how these applications are shaping the future across various industries.

Nitinol Flat Wire: A Sustainable Choice

Environmental Benefits of Nitinol Alloys

Nitinol alloys offer several environmental advantages due to their unique properties. These advantages make them a sustainable choice for many industries.

Here are some key benefits:

- High Recyclability: Nitinol can be easily recycled and reused numerous times, minimizing waste and resource consumption.

- Low Energy Consumption: The production process for nitinol alloys requires less energy than other materials, reducing the overall carbon footprint.

- Extended Lifespan: Nitinol possesses exceptional durability and can withstand harsh environments, leading to fewer replacements and a lower environmental impact.

In conclusion, nitinol alloys are an eco-friendly choice due to their recyclability, low energy consumption during production, and extended lifespan.

Longevity and Durability of Nitinol Flat Wire

The longevity and durability of nitinol flat wire make it an ideal choice for long-term use in different applications. Its shape memory properties ensure that the wire retains its original form even after multiple uses, reducing the need for frequent replacements and minimizing waste.

Nitinol's Contribution to Sustainable Development

Nitinol, a unique nickel-titanium alloy, is playing a vital role in advancing sustainable development through its innovative applications in various fields:

- Revolutionizing Healthcare: Nitinol stents and orthodontic wires offer minimally invasive procedures, improving patient outcomes and reducing waste compared to traditional methods.

- Greening Aviation: Lightweight and durable Nitinol components in aircraft increase fuel efficiency, leading to lower emissions for a more sustainable aviation industry.

- Enhancing Efficiency in Engineering: Nitinol's shape memory allows for creating energy-efficient actuators and valves, optimizing industrial processes while minimizing energy consumption and waste.

By enabling these advancements, Nitinol demonstrates its significant potential to drive sustainable development across multiple sectors..

GEE SMA: Your Partner in Nitinol Innovation

Nitinol flat wire is truly a marvel of modern engineering, with its unique properties and versatile applications making it an indispensable material in various industries. Embracing the potential of nitinol flat wire means unlocking a world of possibilities for innovation and cutting-edge technologies. Whether in healthcare, aerospace, or engineering projects, harnessing the power of nitinol alloys opens the door to groundbreaking advancements and sustainable solutions. And with GEE SMA as your partner in nitinol innovation, you can stay at the forefront of this exciting field.

Embracing the Potential of Nitinol Flat Wire

Nitinol flat wire's shape memory properties and superelasticity make it an ideal choice for various applications, from minimally invasive medical devices to intricate aerospace components. Embracing the potential of nitinol flat wire means embracing innovation and pushing the boundaries of what is possible in materials science and engineering. Furthermore, the biocompatibility of nitinol makes it suitable for use in medical implants, such as stents and guidewires, offering a versatile solution for healthcare professionals. Additionally, its fatigue resistance and corrosion resistance ensure long-term reliability in demanding environments, making it an attractive option for critical applications in various industries.

Harnessing the Power of Nitinol Alloys

The power of nitinol alloys lies in their ability to return to a predetermined shape when subjected to heat or stress, making them invaluable for creating self-actuating mechanisms and adaptive structures. From robotics to automotive engineering, harnessing the power of nitinol alloys opens up new avenues for efficiency and performance.

As a leading manufacturer and supplier of nitinol flat wire, GEE SMA is committed to driving innovation and excellence in shape memory alloys. With our expertise and dedication to quality, we are proud to be your partner in realizing the full potential of nitinol alloys across diverse industries.