Introduction

Nitinol metal, a fascinating material with unique properties, has revolutionized various industries. From its shape memory effect to superelasticity, Nitinol has become a game-changer in medical and engineering applications. Let's delve into the world of Nitinol and uncover its countless possibilities.

Understanding Nitinol Metal

Nitinol metal, also known as nickel titanium, is a type of shape memory alloy that exhibits extraordinary flexibility and resilience. Comprised of nearly equal parts nickel and titanium, Nitinol can return to its original shape when heated after being deformed at lower temperatures.

Exploring Nitinol's Unique Properties

What makes Nitinol truly remarkable is its shape memory effect and superelasticity. These distinctive properties allow it to be bent or deformed at low temperatures and recover its original shape when exposed to heat. This unique characteristic has led to various innovative applications across different industries.

Applications of Nitinol Metal

Nitinol's versatility has made it indispensable in various fields, including medicine, aerospace, automotive engineering, and consumer electronics. Its ability to remember shapes makes it ideal for medical devices like stents and orthodontic wires, while its superelasticity is perfect for applications requiring flexibility and durability.

What Is Nitinol Metal?

Nitinol metal, also known as shape memory alloy, is a unique material that can return to a predetermined shape when heated. This remarkable property has made it popular in various industries, from medical devices to aerospace engineering.

Definition of Nitinol Metal

Nitinol metal is a type of shape memory alloy composed of nickel and titanium in roughly equal atomic percentages. The name Nitinol is derived from its composition: Ni for nickel, Ti for titanium, and nol for Naval Ordnance Laboratory, where it was first developed.

Nitinol alloy exhibits the unique property of shape memory, meaning it can be deformed at one temperature and then return to its original shape when heated. This makes it an ideal material for various applications, from medical devices such as stents and guidewires to eyeglass frames and orthodontic wires. The ability to "remember" its original shape also allows Nitinol to exert a constant force over a wide range of temperatures, making it invaluable in engineering and manufacturing processes.

Composition of Nitinol Alloy

Nitinol alloy typically comprises 55-56% nickel and 44-45% titanium. This specific combination gives Nitinol unique properties such as superelasticity and the ability to remember its original shape after deformation.

The unique composition of Nitinol alloy also gives it excellent corrosion resistance, making it suitable for medical devices and implants. This corrosion resistance allows Nitinol to maintain its integrity and performance even when exposed to bodily fluids and other harsh environments within the body. As a result, Nitinol has become a popular choice for applications such as stents, guidewires, and orthodontic wires due to its ability to withstand the demanding conditions within the human body.

Unique Properties of Nitinol

Nitinol possesses two key properties that set it apart from other materials: shape memory effect and superelasticity. The shape memory effect allows Nitinol to return to its original shape after deforming, while superelasticity enables it to undergo large reversible deformations without permanent damage.

Remember, when it comes to understanding what Nitinol metal is all about, the key lies in its unique composition and remarkable properties that have made it an invaluable material across various industries.

Nitinol’s Shape Memory Alloys (SMA)

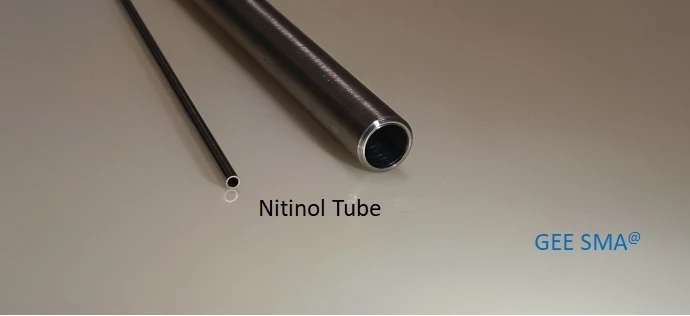

Nitinol’s Shape Memory Alloys, or SMAs, are a specialty of GEE SMA. With their extensive knowledge and experience in working with nitinol, they have mastered crafting high-quality nitinol materials that exhibit exceptional shape memory properties. Whether for medical devices, aerospace applications, or consumer products, GEE SMA excels at tailoring nitinol components to meet unique needs.

GEE SMA's Expertise in Nitinol

GEE SMA's expertise in nitinol is unmatched, making them the go-to source for anyone seeking top-notch nitinol materials. Their team of experts understands the intricacies of this unique metal and can provide valuable insights and solutions for any project requiring shape memory alloys. From consultation to production, GEE SMA offers comprehensive support every step of the way.

GEE SMA's expertise in nitinol extends beyond the technical aspects of the material. Their team is also well-versed in its practical applications, allowing them to offer real-world advice and solutions that go beyond theoretical knowledge. Whether it's developing new prototypes or troubleshooting existing designs, GEE SMA can provide hands-on support to ensure the success of any nitinol project.

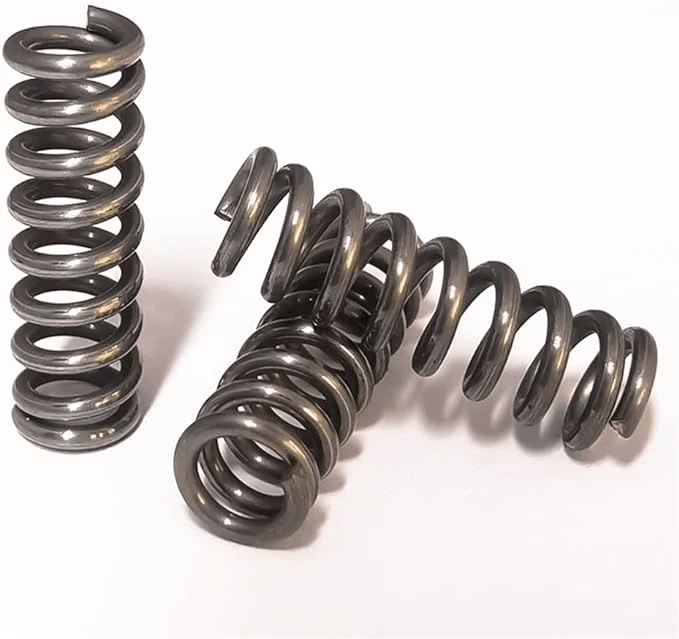

Crafting High-Quality Nitinol Materials

When crafting high-quality nitinol materials, precision and expertise are key, and GEE SMA delivers on both fronts. They utilize state-of-the-art manufacturing techniques to ensure that their nitinol products meet the highest quality and performance standards. Whether wire, tubing, or complex components, GEE SMA's craftsmanship is second to none.

With a deep understanding of the unique properties of nitinol, GEE SMA can tailor their components to meet each customer's specific needs. Whether creating customized wire shapes or designing intricate tubing for medical devices, their expertise allows them to deliver solutions perfectly suited to the intended application. By working closely with clients to understand their requirements, GEE SMA ensures that their nitinol materials meet industry standards and exceed expectations.

Tailoring Nitinol Components for Unique Needs

One size does not fit all when it comes to nitinol components, which is why GEE SMA specializes in tailoring solutions for unique needs. They work closely with clients to understand their requirements and customize nitinol components accordingly. This personalized approach ensures that each product is optimized for its intended application, whether a medical implant or an industrial tool.

Furthermore, GEE SMA's expertise in nitinol allows them to create components with specific shape memory properties, superelasticity, and biocompatibility. This level of customization ensures that the nitinol components meet the exact requirements of the client's application, whether a complex medical device or a precision-engineered industrial tool. By tailoring nitinol components to unique needs, GEE SMA can provide solutions that are effective and cost-efficient for their clients.

What Is Nitinol Wire Used For?

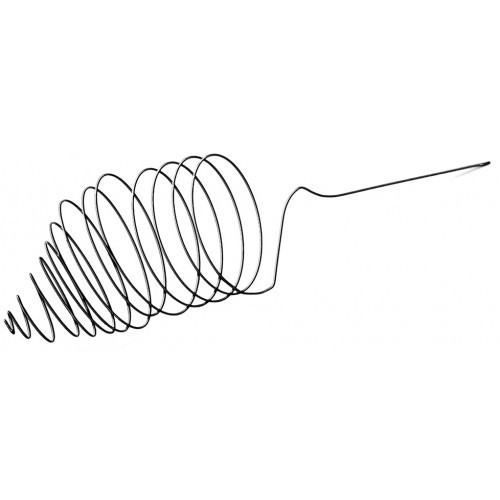

Nitinol wire is a versatile material with many applications, particularly in medicine and engineering. Thanks to its shape memory effect and superelasticity, its unique properties make it ideal for use in various industries.

Medical Applications of Nitinol

In medicine, nitinol wire is commonly used in minimally invasive surgical procedures, such as stents and guidewires. Its ability to return to its original shape after being deformed makes it an excellent choice for medical devices that must navigate through narrow blood vessels or other confined spaces within the body.

In addition to its use in surgical procedures, nitinol wire is used in orthodontic devices such as braces and archwires. The unique properties of nitinol allow these devices to apply a constant, gentle force to reposition teeth over time, resulting in more effective and comfortable treatment for patients. This versatility makes nitinol an essential material in orthodontics, providing reliable and long-lasting solutions for dental realignment.

Engineering and Industrial Uses

Nitinol wire is used in various applications in engineering and industrial settings, including actuators, sensors, and flexible connectors. Its unique properties make it an ideal material for these purposes, as it can withstand repeated bending and stretching without losing its shape or strength.

Advantages of Nitinol Wire

Nitinol wire, a nickel-titanium alloy, stands out for its exceptional properties, making it a highly sought-after material across various industries. Here's a closer look at the key advantages of nitinol wire:

- Biocompatible Champion: Nitinol excels in biocompatibility. Unlike many other metals, the human body readily accepts nitinol, minimizing the risk of rejection or adverse tissue reaction. This makes it a prime choice for medical devices like stents, implants, and surgical instruments.

- Corrosion Resistance: Nitinol wire boasts exceptional corrosion resistance. This ensures components can withstand harsh environments and maintain functionality over extended lifespans, minimizing replacements and maintenance costs.

- Fatigue Endurance Champion: Nitinol wire exhibits remarkable fatigue endurance. It can withstand repeated bending, deformation, and stress without succumbing to failure, making it ideal for applications requiring long-term performance under demanding conditions.

- Shape Memory Marvel: One of nitinol's defining characteristics is its shape memory. It can be deformed and then "remember" its original shape upon exposure to a specific temperature or trigger. This property allows for creating innovative components that adapt or deploy under specific conditions.

- Superelastic Superstar: Nitinol wire showcases exceptional superelasticity. It can undergo significant deformation and return to its original shape upon release of stress. This allows components to absorb high loads without permanent damage, making them ideal for flexible and resilient applications.

- Versatility in Design: Nitinol wire can be easily shaped and formed into intricate configurations. This design flexibility empowers engineers to create complex components with unique functionalities, pushing the boundaries of innovation.

- Cost-Effective for Specific Applications: While nitinol has a higher upfront cost than some materials, its exceptional durability, fatigue resistance, and reusability can make it a cost-effective option in the long run. Nitinol wire can minimize replacements and maintenance needs for projects requiring high-performance and long lifespans, leading to overall cost savings.

Nitinol wire's unique properties make it a valuable asset for various applications. From biocompatible medical devices to high-performance industrial components, nitinol wire continues revolutionizing various fields.

With its wide range of applications and unique properties, nitinol wire continues to be a valuable material across different industries. Whether in the operating room or on the factory floor, its versatility makes it essential for countless products and innovations.

Exploring the Nitinol Memory Effect

Nitinol metal is renowned for its fascinating memory effect, which allows it to return to a predetermined shape after being deformed. This unique property, known as the shape memory effect, enables Nitinol to be used in a wide range of innovative applications across various industries.

Understanding the Shape Memory Property

The shape memory property of Nitinol metal results from its ability to undergo reversible martensitic phase transformation under certain conditions. When heated, Nitinol can remember and revert to its original shape, making it an ideal material for applications requiring precise and controlled movements.

Nitinol's Superelasticity

In addition to its shape memory effect, Nitinol exhibits superelasticity, allowing it to undergo substantial deformation and recover without permanent damage. This unique characteristic makes Nitinol wire an excellent choice for medical devices, such as stents and orthodontic wires, where flexibility and resilience are crucial.

In addition to its shape memory effect, Nitinol's superelasticity has revolutionized the medical device industry. Its ability to undergo substantial deformation and recover without permanent damage has made it an indispensable material for stents and orthodontic wires. The flexibility and resilience of Nitinol wire have allowed for the development of more effective and longer-lasting medical devices, improving patient outcomes and quality of life.

Real-World Examples of Nitinol Memory Effect

Real-world examples of the remarkable memory effect of Nitinol metal can be found in minimally invasive medical procedures where Nitinol components are used in catheters, guidewires, and endoscopic instruments. Furthermore, in aerospace engineering, Nitinol actuators are employed for their ability to withstand extreme conditions while maintaining precise control.

By harnessing the extraordinary properties of Nitinol metal, engineers and designers continue to push the boundaries of what is possible across a wide range of industries. As market demand for this versatile material grows, GEE SMA remains committed to providing high-quality Nitinol products tailored to meet unique needs.

Nitinol Metal: Price and Availability

Pricing Factors of NitinolThe unique properties of nitinol, a nickel-titanium alloy, make it a valuable material in various industries. However, these same properties also contribute to its higher cost than other metals. Here's a breakdown of the key factors that influence the price of nitinol:

- Material Composition: Nitinol's specific properties are determined by the alloy's ratio of nickel and titanium. Higher nickel content typically translates to better shape memory and superelasticity, but also a higher cost.

- Production Methods: Manufacturing nitinol involves specialized processes like melting, shaping, and heat treatment. These intricate steps require specialized equipment and expertise, leading to higher production costs than simpler materials.

- Market Demand and Supply: Like any commodity, the price of nitinol fluctuates based on supply and demand. Increased demand or limited supply can drive prices up, while a surplus in the market can lead to lower costs.

- Complexity of Shaping and Processing: Nitinol sheet metal or wires often require precise shaping and processing to achieve the desired functional properties. These additional steps add to the overall manufacturing cost.

- Product Variations: Nitinol comes in various forms, such as sheet metal, wire, and tubing. Each form may have different processing complexities, leading to price variations. Similarly, the thickness or diameter of the nitinol can also affect the cost per unit.

By understanding these factors, you can make informed decisions when purchasing nitinol and ensure you get the best value for your project. Nitinol's unique properties often outweigh the higher upfront cost due to its exceptional performance and durability.

Availability of Nitinol Metal for Sale

Nitinol metal is readily available for sale through various suppliers and manufacturers. Whether you require nitinol wire, sheets, or components, there are numerous sources to acquire this versatile material. With its growing popularity across industries, finding a reliable supplier for nitinol is easier than ever.

Market Trends for Nitinol

The market trends for nitinol metal continue to show promising growth as its applications expand into new industries. With advancements in manufacturing techniques and increased demand from medical and engineering sectors, the future looks bright for nitinol. As more companies recognize the benefits of using this shape memory alloy, the market for nitinol is expected to flourish.

GEE SMA's Commitment to Quality

Nitinol metal is a remarkable material with various applications across various industries. From its unique shape memory properties to its superelasticity, nitinol has proven to be a versatile and valuable resource for engineers and medical professionals. Whether used in medical devices or industrial components, nitinol's impact is undeniable.

The Versatility of Nitinol Metal

The versatility of nitinol metal lies in its ability to return to a predetermined shape when heated, making it ideal for applications that require precise and controlled movements. Its superelasticity also allows for durable and flexible components, making it an attractive choice for various industries.

Nitinol's Impact Across Industries

From medical devices like stents and guidewires to engineering applications such as actuators and sensors, nitinol has significantly impacted various industries. Its unique properties have allowed for innovative solutions in fields ranging from healthcare to aerospace, showcasing the widespread influence of this exceptional material.

As a leading provider of high-quality nitinol materials, GEE SMA is committed to delivering top-notch products tailored to meet its clients' unique needs. With expertise in crafting custom nitinol components and ensuring the availability of this valuable resource, GEE SMA continues to play a crucial role in advancing the use of nitinol across industries.

Remember that understanding what is nitinol metal, what is nitinol wire used for, and the price and availability of nitinol are essential factors when considering this remarkable material for your next project or application. With its unique properties and widespread impact, it's clear that nitinol will continue to be an invaluable resource across various industries for years to come.