Introduction

In the world of advanced materials, nitinol muscle wire stands out as a remarkable innovation that combines the principles of engineering and biology. This unique alloy, known for its shape memory properties, mimics the functionality of natural muscles, making it a game-changer in various industries. As we delve into the science behind nitinol and its real-world applications, we’ll uncover how this extraordinary material is reshaping our approach to technology and design.

Understanding Nitinol Muscle Wire

Nitinol muscle wire is an alloy primarily composed of nickel and titanium, celebrated for its ability to return to a predetermined shape when heated. This characteristic allows it to function similarly to biological muscles, contracting and expanding in response to temperature changes. As we explore what nitinol wire is used for, it becomes clear that its applications are vast and varied, from robotics to medical devices.

The Science Behind Shape Memory Alloys

The magic of nitinol lies in its classification as a shape memory alloy (SMA), which means it can remember its original form after being deformed. When subjected to specific thermal conditions, nitinol muscle wire undergoes a phase transformation that enables it to revert back to its memorized shape—an effect driven by the unique atomic structure of the alloy. Understanding this science not only clarifies what are nitinol muscles but also highlights their potential across multiple fields.

Real-World Applications of Muscle Wire

The versatility of muscle wire has led to innovative applications across various sectors including robotics and automation, where it provides lightweight actuation solutions without compromising power or efficiency. In medical devices and prosthetics, nitinol’s biocompatibility makes it an ideal choice for creating responsive components that enhance patient care. Moreover, advancements in aerospace engineering are leveraging nitinol spring technology for improved performance in flight systems—showcasing just how integral this material has become in modern engineering.

What is Nitinol Muscle Wire?

Nitinol muscle wire is a remarkable material that has captured the imagination of engineers and innovators alike. This unique alloy, primarily composed of nickel and titanium, exhibits extraordinary properties that make it ideal for various applications. Understanding what nitinol muscle wire is and how it functions can unlock new possibilities in technology and design.

Definition and Characteristics

Nitinol muscle wire is a type of shape memory alloy (SMA) known for its ability to return to a predetermined shape when heated above a certain temperature. This characteristic allows it to mimic the function of biological muscles, providing movement without the need for traditional motors or actuators. The defining feature of nitinol wire lies in its two-phase structure: at lower temperatures, it exists as a martensitic phase, while at higher temperatures, it transforms into an austenitic phase, enabling its unique functionality.

Unique Properties of Nitinol

What sets nitinol apart from other materials are its unique properties: shape memory effect and superelasticity. The shape memory effect allows nitinol muscle wire to remember its original form after being deformed, while superelasticity enables it to withstand significant stress without permanent deformation. These properties make nitinol an invaluable resource in various fields—such as robotics, medicine, and aerospace engineering—where lightweight and reliable components are essential.

How it Resembles Muscle Function

When we talk about what are nitinol muscles or how they resemble actual muscle function, we're essentially referring to their ability to contract and expand in response to temperature changes. Just like biological muscles respond to neural signals by contracting or relaxing, nitinol muscle wire can be activated by heat from electrical currents or external sources. This innovative application leads us toward more efficient designs in robotics where traditional power sources may fall short.

What is Muscle Wire Used For?

Nitinol muscle wire, a fascinating innovation in the realm of materials science, finds its applications across various industries due to its unique properties. Often referred to as memory or muscle wire, this shape memory alloy can return to a predetermined shape when heated, mimicking the functionalities of biological muscles. So, what is nitinol wire used for? Let’s explore some significant applications that highlight its versatility and effectiveness.

Applications in Robotics and Automation

In robotics and automation, nitinol muscle wire has carved out a niche for itself by acting as an efficient actuator. Its ability to contract and expand with temperature changes allows robotic systems to perform delicate tasks with precision—much like human muscles do. The lightweight nature of nitinol spring technology further enhances robotic mobility, making it ideal for applications where weight is a critical factor.

Moreover, these wires enable robots to achieve complex movements that require high flexibility and strength without bulky motors or gears. This efficiency not only streamlines design but also reduces energy consumption—an essential aspect in today’s eco-conscious world. As industries continue to integrate automation into their processes, the demand for innovative solutions like nitinol muscle wire will only grow.

Use in Medical Devices and Prosthetics

Prosthetic limbs equipped with this remarkable material can mimic natural movement more closely than ever before. By harnessing the unique properties of memory/muscle wire technology, developers create prosthetics that adapt seamlessly to user needs—improving quality of life significantly for individuals with limb loss. As advancements continue in this sector, we can expect even more innovative uses of nitinol in medical applications.

Advancements in Aerospace Engineering

The aerospace industry has also discovered the benefits of using nitinol muscle wire in various applications ranging from actuation systems to adaptive structures on aircraft wings. What is muscle wire doing here? Its lightweight yet strong characteristics make it an attractive option for enhancing fuel efficiency while maintaining structural integrity during flight.

Nitinol spring technology allows engineers to design systems that can change shape based on flight conditions—this adaptability could revolutionize how aircraft operate under different environments! However, challenges remain; what are the problems with nitinol? Factors such as temperature sensitivity need careful consideration during design phases to ensure reliability under extreme conditions often encountered at high altitudes.

As aerospace engineering continues evolving towards smarter designs utilizing advanced materials like nitinol muscle wire, we anticipate groundbreaking innovations that push boundaries further than ever before.

The Benefits of Nitinol Spring Technology

Nitinol muscle wire, a standout in the realm of shape memory alloys, brings numerous benefits to various industries. Its unique properties allow for lightweight and compact designs that can revolutionize how we approach engineering challenges. By leveraging nitinol spring technology, developers can create innovative solutions that are both efficient and effective.

Lightweight and Compact Solutions

One of the most appealing aspects of nitinol muscle wire is its lightweight nature, which makes it an ideal choice for applications where weight is a critical factor. In robotics and aerospace engineering, every gram counts; thus, using nitinol springs can lead to significant improvements in performance without compromising structural integrity. Additionally, the compact design of nitinol muscle wire allows engineers to integrate these components into smaller spaces, paving the way for more versatile product designs.

Energy Efficiency and Performance

When considering what is nitinol wire used for?, energy efficiency is a key benefit that cannot be overlooked. Nitinol muscle wire operates on a principle known as the shape memory effect, allowing it to return to its original shape when heated after being deformed. This unique property means less energy consumption during operation compared to traditional actuators or motors, making it an attractive option for applications requiring high performance without draining resources.

Long Lifespan and Durability

What are the problems with nitinol? While there are challenges associated with this material, one undeniable advantage is its long lifespan and durability under various conditions. Nitinol muscle wires can withstand repeated cycles of deformation without significant wear or loss of functionality, making them ideal for use in demanding environments such as medical devices or prosthetics. Their resilience ensures that they maintain performance over time while minimizing maintenance costs—an important consideration when evaluating the overall value of nitinol spring technology.

What Are the Problems with Nitinol?

While Nitinol muscle wire has gained popularity for its remarkable properties, it is not without its challenges. Understanding these issues is crucial for developers and engineers looking to harness the full potential of this innovative material. From limitations in application to cost considerations, let’s dive deeper into what are the problems with nitinol.

Limitations and Challenges

One of the primary limitations of nitinol muscle wire is its restricted operating temperature range. This restricts where and how it can be effectively utilized, particularly in environments that experience extreme temperatures. Additionally, while nitinol offers impressive force generation capabilities, it may not always match the performance requirements needed for high-load applications or rapid actuation scenarios.

Another challenge lies in the complexity of controlling the shape memory effect precisely. While nitinol muscles can return to their original shape when heated, achieving consistent results often requires intricate control systems that can complicate designs. These design challenges may deter some engineers from choosing what is muscle wire over more traditional actuators.

Temperature Sensitivity Issues

Temperature sensitivity is a significant concern when working with nitinol muscle wire. The material's ability to change shape depends heavily on temperature fluctuations; thus, maintaining optimal conditions is crucial for reliable operation. In applications where ambient temperatures vary significantly, this sensitivity can lead to unpredictable performance or even failure.

Moreover, if a device using nitinol springs operates outside of its designated temperature range, there may be irreversible changes in its properties over time. This unpredictability can pose risks in critical applications such as medical devices or aerospace engineering—where precision and reliability are paramount. Consequently, users must carefully consider environmental factors when integrating what are known as nitinol muscles into their designs.

Cost Considerations in Manufacturing

When exploring what is nitinol wire used for?, one cannot overlook cost considerations associated with manufacturing this advanced material. The production process for Nitinol spring technology involves specialized techniques that drive up costs compared to conventional materials like steel or aluminum. As a result, manufacturers must balance performance benefits against budget constraints when deciding whether to incorporate muscle wire into their products.

Additionally, sourcing quality raw materials can further inflate expenses associated with Nitinol muscle wire price trends over time. For smaller companies or startups looking to innovate using this technology, these costs might limit their ability to compete effectively within their respective markets. Therefore, understanding these financial implications becomes essential for anyone considering utilizing what are the problems with nitinol?

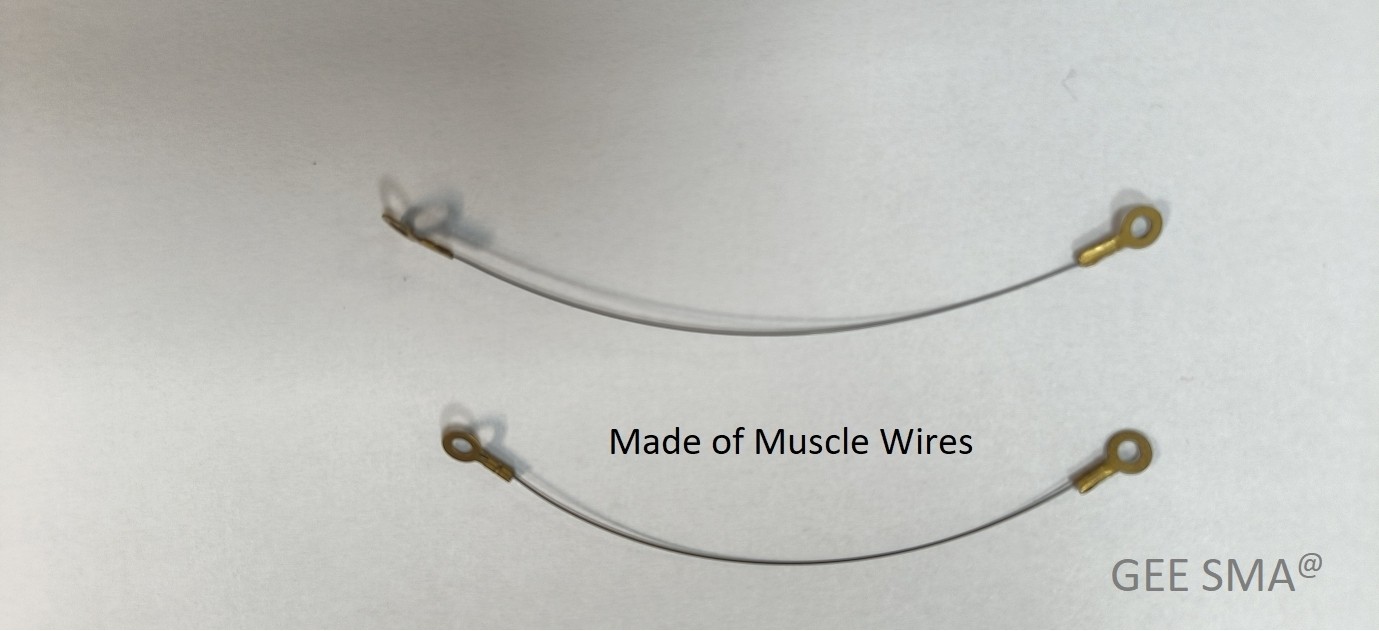

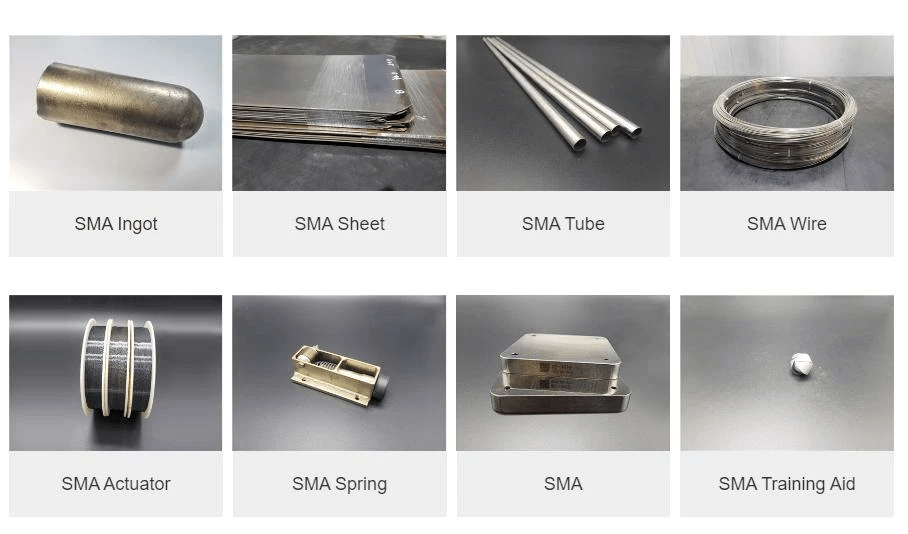

GEE SMA: A Leader in Nitinol Production

Quality and Innovation in Nitinol Manufacturing

GEE SMA prides itself on utilizing cutting-edge techniques in nitinol manufacturing, which sets them apart from competitors. Their rigorous quality control processes ensure that every batch of nitinol muscle wire exhibits the unique properties that make this material so sought after. By constantly innovating and refining their methods, GEE SMA delivers products that excel in durability and functionality—key factors when considering what is nitinol wire used for?

Custom Solutions for Diverse Applications

One size does not fit all when it comes to nitinol muscle wire; different applications require tailored solutions. GEE SMA understands this need and offers custom solutions designed specifically for various industries—from robotics to medical devices. Whether clients are looking for specific dimensions or unique performance characteristics, GEE SMA can provide exactly what they need, making them a go-to source for those asking what are nitinol muscles?

Commitment to Customer Satisfaction

At GEE SMA, customer satisfaction is more than just a slogan; it's embedded in their company culture. They work closely with clients throughout the entire process—from initial inquiry to final delivery—to ensure that every expectation is met or exceeded. This dedication not only fosters long-lasting relationships but also reassures customers about their investment in Nitinol spring technology, especially given concerns regarding what are the problems with nitinol?

Conclusion

In conclusion, the future of nitinol muscle wire is bright, with ongoing advancements promising to enhance its applications across various fields. As industries continue to explore the potential of this remarkable material, we can expect innovations that leverage the unique properties of nitinol to create smarter and more efficient solutions. With a growing understanding of what nitinol wire is used for, we are likely to see even more creative uses emerge.

The Future of Nitinol Muscle Wire

The future of nitinol muscle wire lies in its ability to mimic natural muscle function while providing advantages such as lightweight design and energy efficiency. Researchers are continuously exploring new avenues for this innovative material, pushing the boundaries of what are nitinol muscles can achieve in robotics and automation. As technology evolves, we may witness breakthroughs that further integrate memory/muscle wire into everyday applications, revolutionizing how we think about movement and mechanics.

Exploring Innovative Applications

Nitinol muscle wire has already made significant strides in sectors like medical devices and aerospace engineering; however, the possibilities are virtually limitless. From soft robotics that can adapt their shape to complex prosthetics that closely resemble natural limb movement, there’s no shortage of innovative applications waiting to be explored. By understanding what is muscle wire capable of and addressing what are the problems with nitinol?, industry leaders can develop tailored solutions that meet specific needs across various domains.

Understanding Nitinol Muscle Wire Price Trends

When it comes to discussing nitinol muscle wire price trends, several factors come into play—ranging from manufacturing costs to market demand for advanced technologies. As production techniques improve and economies of scale kick in, prices may stabilize or even decrease over time making it more accessible for diverse applications. However, it's essential for buyers to keep an eye on fluctuations due to raw material sourcing or technological advancements that could influence what is nitinol wire used for in different industries.