Introduction

Are you curious about the incredible properties of Nitinol alloy, nickel-titanium or NiTi? This remarkable material has gained attention for its unique shape memory and superelasticity, making it a popular choice in various industries. Let's dive into the world of Nitinol and explore its uses and properties and how to choose the right supplier.

Understanding Nitinol Alloy

Nitinol is a nickel-titanium alloy known for its exceptional flexibility and shape memory properties. It can remember its original shape and return to it when heated, making it ideal for various applications. This remarkable ability has led to the development of innovative medical, aerospace, automotive, consumer, and industrial products.

Exploring Nitinol Properties

Nitinol, a nickel-titanium alloy, stands out for its remarkable properties, making it a valuable material across various fields. Here's a closer look at its key characteristics:

- Superelasticity: Nitinol can undergo significant deformation, up to 10-30 times more than typical metals, without sustaining permanent damage. Upon releasing the pressure, it springs back to its original shape.

- Biocompatibility and Corrosion Resistance: These properties make Nitinol ideal for medical implants and devices. It integrates well with the human body and resists corrosion, minimizing the risk of rejection or complications.

- Shape Memory Effect: Nitinol can be deformed at low temperatures and "remember" its original form. When heated above a specific temperature, it returns to its initial shape. This unique property allows for innovative applications in various industries.

Nitinol's exceptional combination of properties paves the way for groundbreaking advancements in medicine, aerospace, and beyond.

Choosing the Right Nitinol Supplier

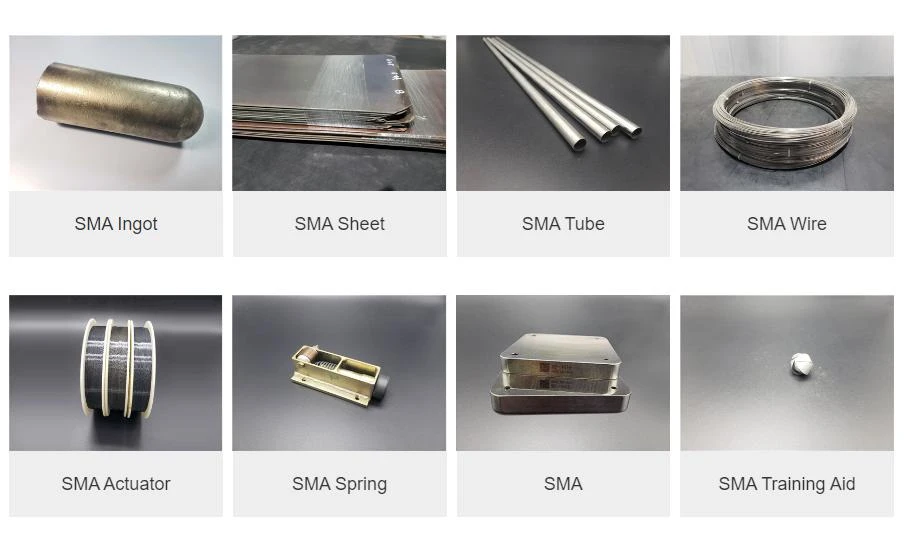

Selecting the right supplier is crucial when working with Nitinol alloys. From quality and certification to customization capabilities and customer support, finding a reliable supplier is essential for ensuring the success of your project. Whether in the medical field or aerospace industry, partnering with a trusted supplier like GEE SMA can provide you with high-quality Nickel Titanium wire tailored to your needs.

What is Nitinol Made of?

Nitinol alloy, nickel-titanium or NiTi, is a unique material comprising almost equal parts of nickel and titanium. This combination allows it to exhibit remarkable properties such as shape memory and superelasticity, making it highly sought after in various industries.

Composition of Nitinol Alloy

Manufacturing Process of Nitinol

Nitinol, a remarkable material known for its shape-memory and superelastic properties, undergoes a meticulous manufacturing process to achieve its unique characteristics. Here's a breakdown of the key steps involved:

- Vacuum Melting: To minimize contamination, nickel and titanium are melted together at extremely high temperatures in a vacuum environment.

- Hot Working: The molten nitinol is then cooled and shaped into desired forms like wires, tubes, or sheets through hot forging or rolling processes.

- Heat Treatment: The final step involves a precise heat treatment where the nitinol is heated and cooled controlled. This crucial step programs the shape memory and superelastic properties into the material.

Through this intricate process, nitinol gains its ability to "remember" its original shape and return to it upon application of heat. This unique property makes nitinol invaluable in various applications, from stents and orthodontic wires to eyeglass frames and aerospace components.

Unique Properties of Nickel Titanium (NiTi)

Nickel titanium, or NiTi, possesses unique properties that set it apart from other materials. It can remember its original shape after being deformed, a phenomenon known as the shape memory effect, making it ideal for applications requiring precise movement or force.

Nickel titanium's shape memory effect is also highly suitable for medical applications, such as orthodontic wires and stents. The ability to return to its original shape allows for comfortable and effective treatment, reducing the need for frequent adjustments. Additionally, NiTi's superelasticity makes it a preferred material for minimally invasive medical devices, where flexibility and durability are crucial.

Nitinol Applications

Medical Industry Implementations

Nitinol shape memory alloys are widely used in medicine due to their unique properties. From stents and guidewires to orthodontic wires and surgical tools, nitinol's superelasticity and biocompatibility make it an ideal material for various medical applications. Its ability to withstand repeated bending and twisting without permanent deformation makes it a popular choice for minimally invasive procedures, improving patient outcomes.

Nitinol shape memory alloys are revolutionizing the medical industry and finding extensive aerospace and automotive engineering applications. The unique properties of nitinol, such as its superelasticity and shape memory, make it an ideal material for various components in aircraft and automobiles. From actuators and sensors to engine components and structural reinforcements, nitinol's ability to withstand extreme conditions while maintaining its shape adds value to the aerospace and automotive industries.

Aerospace and Automotive Uses

In the aerospace and automotive industries, nickel-titanium wire is utilized in various components such as actuators, valves, and sensors. Its shape memory effect allows for the creation of self-actuating mechanisms that respond to changes in temperature or stress. This makes nitinol a valuable material for applications where precise control and reliable performance are essential, such as in aircraft landing gear and automotive engine components.

In addition to aerospace and automotive uses, nickel-titanium wire is employed in consumer and industrial applications. For example, nitinol is used in eyeglass frames, where its flexibility and shape memory properties allow for a comfortable fit that can withstand bending and twisting. In the medical field, nitinol is utilized in stents and other implantable devices due to its biocompatibility and ability to adapt to the body's temperature. Furthermore, in industrial settings, nitinol wire is used in various types of machinery where its self-actuating capabilities can improve efficiency and reliability.

Consumer and Industrial Applications

Nitinol, a nickel-titanium alloy, is a remarkable material prized for its unique flexibility, durability, and shape-memory properties. These characteristics have led to its use in many applications, extending far beyond its initial applications in medicine and aerospace.

- Consumer Products: Nitinol's shape memory allows for self-adjusting eyeglass frames, while its durability makes it ideal for cell phone antennas and bra underwires.

- Industrial Settings: Nitinol is a valuable material for robotics, actuators, and smart manufacturing automation. It offers precise control over mechanical properties.

- Sports and Recreation: Nitinol's flexibility and ability to withstand stress make it perfect for fishing lures, golf club shafts, and bicycle components.

Nitinol's versatility continues to expand across various fields, making it a crucial material for innovation and performance today.

Nitinol Properties

Nitinol, nickel-titanium, is a unique alloy with remarkable properties, making it highly versatile and valuable in various industries. These include the shape memory effect, superelasticity, and biocompatibility with corrosion resistance.

Shape Memory Effect

Nitinol's shape memory effect allows it to return to its original shape after being deformed at specific temperatures. This property makes it ideal for applications such as medical stents and orthodontic wires, where the material can be easily manipulated into a desired shape and revert to its original form once inside the body.

Nitinol's shape memory effect is beneficial not only for medical applications but also for other industries, such as aerospace and automotive. In aerospace, It can be used in actuators and deployable structures that need to withstand extreme conditions. It can be utilized in components like valves and sensors that require precise shape memory properties in the automotive industry. The versatility of Nitinol makes it a valuable material across various sectors, showcasing its potential beyond just medical devices.

Superelasticity

One of the most intriguing properties of nitinol is its superelasticity, which enables it to undergo substantial deformation and return to its undeformed shape when the load is removed. This makes it perfect for applications in industries such as aerospace and automotive, where components need to withstand significant stress without permanent deformation.

Nitinol's superelasticity also makes it an ideal material for medical devices and implants. Its ability to withstand deformation without permanent damage means it can be used in applications such as stents, orthodontic wires, and surgical tools. This is particularly important in the medical field, where maintaining shape and function under stress is crucial for patient safety and successful treatment outcomes.

Biocompatibility and Corrosion Resistance

Nitinol's biocompatibility makes it suitable for medical implants and devices that come into contact with bodily fluids or tissues. Additionally, its corrosion resistance ensures longevity and reliability in harsh environments, making it an excellent choice for industrial applications where durability is essential.

With these exceptional properties, nitinol has become an indispensable material in various fields due to its unique combination of strength, flexibility, and resilience. As technology advances, the potential uses for nickel titanium continue to expand, making it an exciting material for innovation and development across multiple industries.

How to Choose the Right Supplier

When selecting a nickel-titanium (NiTi) product supplier, it's crucial to consider their quality and certification. Look for suppliers that adhere to strict industry standards and have certifications such as ISO 13485 for medical devices or AS9100 for aerospace applications. These certifications ensure that the supplier meets the necessary quality requirements for your specific nitinol needs.

Quality and Certification

Choosing a supplier with reliable quality and certification guarantees that you'll receive high-quality nitinol alloy products that meet industry standards. Whether you require nitinol shape memory alloys for medical devices or aerospace components, a certified supplier ensures that their materials are manufactured with precision, consistency, and reliability.

In addition to ensuring high-quality nitinol alloy products, a certified supplier with reliable quality and certification also offers customization capabilities. You can work with the supplier to create tailored nitinol shape memory alloys that meet your specific requirements for medical devices or aerospace components. Customizing the alloys allows for greater flexibility in design and functionality, ensuring that the final products are ideally suited to their intended applications.

Customization Capabilities

Another important factor when choosing a nitinol supplier is their customization capabilities. Look for a supplier to tailor nickel-titanium wire or other nitinol products to your specifications. Whether you need specific shapes, sizes, or performance characteristics, a supplier with comprehensive customization capabilities can provide tailored solutions for your unique applications.

In addition to customization capabilities, it's important to consider the customer support offered by a nitinol supplier. A supplier that provides excellent customer support can help you navigate the customization process, answer any questions, and meet your unique requirements. Look for a supplier that is responsive, attentive, and dedicated to meeting your needs promptly and efficiently.

Customer Support and Lead Times

Lastly, consider the level of customer support and lead times potential suppliers offer. A reliable supplier should provide exceptional customer service, technical assistance, responsive communication, and efficient order processing. Additionally, prompt lead times are essential to ensure the timely delivery of your nitinol materials for uninterrupted production or development processes.

Furthermore, it's important to inquire about the supplier's return policy and warranty options for nitinol materials. A reputable supplier should offer a fair and transparent return policy for defective or unsatisfactory products. Additionally, a solid warranty can provide peace of mind and assurance that the supplier stands behind the quality of their materials. This level of support can make a significant difference in your overall satisfaction with the supplier and the products you receive.

Benefits of Using Nitinol Shape Memory Alloys

Nitinol shape memory alloys offer many benefits, from their unique properties to their versatile applications. Nitinol is a game-changer in the medical, aerospace, automotive, and consumer and industrial industries. With GEE SMA's unwavering commitment to quality and customization capabilities, finding the perfect Nitinol solution has never been easier.

The incredible properties of Nitinol shape memory alloys make them ideal for various applications. Their ability to remember and return to a predetermined shape after deformation is remarkable. This makes them perfect for minimally invasive medical procedures, where precision and reliability are crucial. Additionally, their superelasticity allows for durable and long-lasting performance in aerospace and automotive components.

GEE SMA's Commitment to Quality

GEE SMA is dedicated to providing high-quality Nickel Titanium products that meet stringent industry standards. With certifications and rigorous testing processes, customers can trust that they are always getting top-notch Nitinol alloy products. The company's focus on quality control ensures that each batch of Nickel Titanium wire meets the highest standards for performance and reliability.

Finding the Perfect Nitinol Solution

When finding the perfect Nitinol solution for your specific needs, GEE SMA stands out with its customization capabilities. Whether you require a specific Nitinol alloy size, shape, or composition, GEE SMA can tailor their products to meet your exact specifications. Their dedication to customer support and quick lead times ensures you get the perfect solution without hassle.

GEE SMA's expertise in Nitinol customization extends beyond size, shape, and composition. Their team of experienced engineers and metallurgists can also work with you to develop unique Nitinol solutions for complex applications. Whether you need a specific level of superelasticity, shape memory properties, or corrosion resistance, GEE SMA has the knowledge and resources to create the perfect Nitinol alloy for your project.