Introduction

In the world of robotics, the use of Nitinol Shape Memory Alloys (SMAs) has revolutionized the design and functionality of soft robotic actuators. These innovative materials have found a wide range of applications in robotics, from Driven Springs for Robots to SMA Actuators. The importance of soft robotic actuators cannot be overstated, as they enable robots to perform delicate and precise tasks with dexterity and flexibility.

Understanding Nitinol Shape Memory Alloys

Nitinol Shape Memory Alloys (SMAs) are a unique class of materials that have the ability to remember their original shape and return to it when heated. This property makes them ideal for use in soft robotic actuators, where flexibility and adaptability are crucial. The memory metal nature of nitinol allows for intricate movements and shape changes, making it an indispensable component in modern robotics.

Nitinol SMAs are also used in the development of exoskeletons and prosthetics, where the ability to conform to the body's natural movements is essential. This unique property of nitinol allows for comfortable and natural motion, improving the quality of life for individuals with mobility impairments. Additionally, the lightweight and durable nature of nitinol make it a preferred material for these applications, ensuring long-lasting and reliable performance in assisting individuals with physical challenges.

Applications of Nitinol in Robotics

The versatility of nitinol extends to various applications in robotics, including the development of Driven Springs for Robots and SMA Actuators. These components play a pivotal role in enhancing the performance and functionality of robots by providing them with the ability to mimic natural movements and perform complex tasks with precision. Nitinol's unique properties make it an invaluable resource for advancing robotic technology.

Another important application of nitinol in robotics is in the development of soft robotic actuators. These actuators are designed to provide robots with a more flexible and adaptable range of motion, allowing them to navigate through tight spaces and interact with delicate objects. By incorporating nitinol into the design of these actuators, engineers can create robots that are better equipped to handle real-world tasks in various environments. This makes nitinol an essential material for advancing the field of soft robotics and creating robots that can seamlessly integrate into human-centric settings.

Importance of Soft Robotic Actuators

Soft robotic actuators are essential for enabling robots to interact with their environment in a gentle yet effective manner. They allow robots to navigate through confined spaces, handle delicate objects, and perform tasks that require finesse and accuracy. The use of nitinol memory metal in these actuators enhances their capabilities, opening up new possibilities for innovation in the field of robotics.

Additionally, the use of nitinol memory metal in soft robotic actuators allows for more efficient energy transfer, resulting in improved overall performance and longevity. This means that robots can operate for longer periods without needing recharging or maintenance, making them more reliable and cost-effective. The enhanced capabilities of nitinol-based actuators also enable robots to perform a wider range of tasks with greater precision and control, further expanding their potential applications in various industries.

What is Nitinol and How Does it Work in Soft Robotic Actuators?

Nitinol, a unique alloy of nickel and titanium, exhibits shape memory properties, allowing it to return to its original shape when heated. This makes it an ideal material for soft robotic actuators, providing flexibility and adaptability in movement. When integrated into soft robotics, Nitinol enables precise control and manipulation, offering a wide range of motion for various applications.

Shape Memory Properties of Nitinol

The shape memory properties of Nitinol make it a game-changer in the field of soft robotic actuators. When deformed at low temperatures, it retains this new shape until heated above its transformation temperature, at which point it returns to its original form. This unique ability allows for complex movements in robotic systems, making Nitinol a key component in creating lifelike motions and interactions.

Integration of Nitinol in Soft Robotics

Incorporating Nitinol into soft robotics involves careful design and engineering to harness its shape memory capabilities effectively. By strategically placing SMA actuators within the robot's structure, engineers can create lifelike movements that mimic natural organisms' flexibility and dexterity. This integration opens up new possibilities for robots to navigate challenging environments with ease.

Advantages of Nitinol in Actuators

The use of Nitinol in soft robotic actuators offers several advantages over traditional materials such as metals or plastics. Its lightweight nature contributes to the overall agility and mobility of the robot, while its durability ensures long-lasting performance under various conditions. Additionally, the energy-efficient nature of nitinol memory metal allows for precise control over movements without excessive power consumption.

Furthermore, Nitinol's unique shape memory properties allow for precise and repeatable movements, making it an ideal material for soft robotic actuators. This means that robots can perform complex tasks with accuracy and consistency, enhancing their overall functionality and performance. In addition, the ability of nitinol to return to its original shape after being deformed ensures that the robot's movements remain reliable and predictable, even after prolonged use.

Now that we have explored how nitinol works within soft robotic actuators let's delve deeper into how this innovative material drives spring functionality for robots.

Driven Spring for Robot: Exploring the Functionality of Nitinol Memory Metal

Nitinol memory metal plays a crucial role in the development of driven springs for robots. The unique shape memory properties of Nitinol allow it to be deformed at low temperatures and then return to its original shape when heated, making it ideal for creating resilient and adaptable springs in soft robotic actuators.

Role of Nitinol in Driven Springs

In the realm of soft robotic actuators, Nitinol serves as the backbone of driven springs, providing the necessary flexibility and durability required for seamless robotic movements. Its ability to withstand repeated cycles of deformation makes it an essential component in creating reliable and long-lasting SMA actuators.

Benefits of Using Nitinol in Robotics

The use of Nitinol in robotics offers numerous benefits, including lightweight construction, high energy density, and exceptional shape memory characteristics. These properties make it an ideal material for building efficient and responsive soft robotic actuators that can perform complex tasks with precision and agility.

Comparison with Traditional Materials

When compared to traditional materials used in robotics, such as steel or aluminum, Nitinol stands out due to its superior elasticity and resilience. Its unique ability to revert to its original shape after being deformed sets it apart from conventional materials, making it a game-changer in the field of soft robotic actuators.

Additionally, Nitinol's lightweight nature makes it a preferred choice for soft robotic actuators, as it allows for more agile and flexible movements. This is in stark contrast to the heavy and rigid nature of steel and aluminum, which can limit the range of motion in robotic applications. Furthermore, Nitinol's biocompatibility also makes it suitable for use in medical robotics, opening up new possibilities for minimally invasive surgical procedures and other healthcare applications.

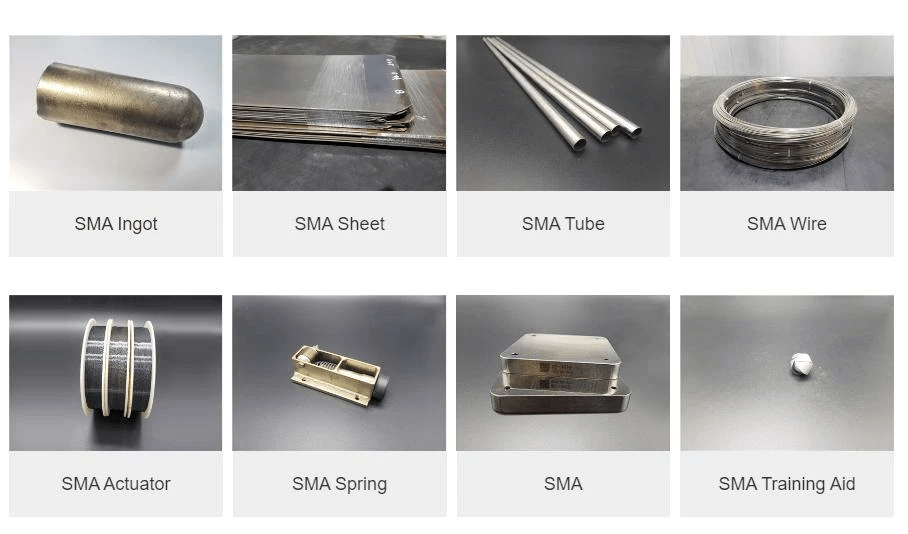

GEE SMA: Crafting High-Quality Materials for Soft Robotic Actuators

GEE SMA is at the forefront of specializing in Nitinol Shape Memory Alloys, offering top-notch materials for soft robotic actuators. Our expertise lies in tailoring Nitinol components specifically for robotics, ensuring optimal performance and durability. By addressing customer requirements with precision and attention to detail, we deliver exceptional solutions for the most demanding applications.

Specialization in Nitinol Shape Memory Alloys

At GEE SMA, our specialization in Nitinol Shape Memory Alloys (SMAs) allows us to provide cutting-edge materials tailored for soft robotic actuators. Our deep understanding of the unique properties of SMAs enables us to craft high-quality components that are crucial for achieving superior performance in robotic systems.

Our expertise in Nitinol SMAs also allows us to customize components for a wide range of robotic applications, from surgical instruments to exoskeletons. By tailoring the shape memory properties of Nitinol, we can create actuators and sensors that respond precisely to the needs of each specific robotic system. This level of customization ensures optimal functionality and efficiency, setting our materials apart in the rapidly evolving field of robotics.

Tailoring Nitinol Components for Robotics

We take pride in our ability to customize Nitinol components specifically for robotics, ensuring seamless integration and optimal functionality within soft robotic actuators. By leveraging our expertise, we can tailor the shape memory properties of Nitinol to meet the precise requirements of various robotic applications.

Our team of experts understands the unique challenges and demands of robotics, which is why we go above and beyond to ensure that our tailored Nitinol components are not only seamlessly integrated but also optimized for maximum performance. With a deep understanding of shape memory properties, we can fine-tune Nitinol to respond exactly as needed within soft robotic actuators, providing unparalleled precision and reliability in various robotic applications. This level of customization allows us to address specific customer requirements with precision and efficiency, delivering solutions that are truly tailored to the needs of each individual project.

Addressing Customer Requirements

At GEE SMA, we prioritize customer satisfaction by meticulously addressing their specific needs and preferences when it comes to Nitinol components for soft robotic actuators. Our commitment to delivering tailored solutions sets us apart as a trusted partner in the robotics industry, providing unparalleled support and expertise every step of the way.

Our team at GEE SMA understands that the field of soft robotics is constantly evolving, and we are dedicated to staying at the forefront of innovation. By leveraging Nitinol’s unique properties, we are able to develop cutting-edge components that meet the demands of next-generation soft robotic actuators. This forward-thinking approach allows us to anticipate and exceed customer expectations, providing solutions that are not only tailored to current needs but also future-proof.

Innovative Uses for Nitinol in Soft Robotic Actuators

Nitinol Actuators in Medical Robotics

Nitinol shape memory alloys (SMAs) are revolutionizing medical robotics with their unique ability to mimic human muscle movements. SMA actuators made from nitinol memory metal are being used in minimally invasive surgical procedures, allowing for precise and delicate movements within the body. These soft robotic actuators provide a high level of dexterity and flexibility, making them invaluable tools in the field of medical robotics.

Nitinol-based grippers and manipulators are also being utilized in medical robotics to enhance the precision and effectiveness of surgical procedures. These advanced tools allow for delicate tissue manipulation and grasping, enabling surgeons to perform intricate tasks with greater accuracy. The use of nitinol-based grippers and manipulators is paving the way for more sophisticated and minimally invasive surgical techniques, ultimately leading to improved patient outcomes.

Nitinol-based Grippers and Manipulators

The versatility of nitinol in soft robotic actuators extends to the development of grippers and manipulators that can handle delicate objects with precision and control. These nitinol-based devices are ideal for applications requiring gentle handling, such as in assembly lines or medical settings. The use of nitinol allows for a lightweight yet strong construction, making it an ideal material for creating grippers and manipulators that can perform intricate tasks with ease.

Future Trends in Nitinol Applications

As technology continues to advance, the future holds exciting possibilities for the use of nitinol in soft robotic actuators. Researchers and engineers are exploring new ways to leverage the unique properties of nitinol shape memory alloys, leading to innovations in fields such as prosthetics, exoskeletons, and wearable robotics. The future trends indicate a growing reliance on nitinol for creating advanced soft robotic actuators that can adapt to various environments and perform complex tasks with precision.

Conclusion

Nitinol's future in robotics is bright, with its unique properties making it an ideal material for soft robotic actuators. As the demand for more advanced and flexible robots grows, the opportunities for nitinol in soft robotic actuators will continue to expand. It's essential to harness the potential of nitinol in robotics to drive innovation and meet the evolving needs of various industries.

The Future of Nitinol in Robotics

The future of nitinol in robotics looks promising, with ongoing research and development focused on enhancing its capabilities for use in soft robotic actuators. As technology advances, we can expect to see more sophisticated applications of nitinol memory metal, further revolutionizing the field of robotics.

Opportunities for Nitinol in Soft Robotic Actuators

The opportunities for nitinol in soft robotic actuators are abundant, as its shape memory properties make it a valuable material for creating versatile and adaptable robot components. With continued investment and exploration, we can expect to see a wide range of innovative uses for nitinol in this field.

The unique properties of nitinol, such as its ability to remember and return to a specific shape, make it an ideal material for soft robotic actuators. This shape memory allows for intricate movements and precise control, making nitinol a valuable asset in the development of advanced robotic systems. As researchers continue to push the boundaries of soft robotics, we can anticipate the integration of nitinol in a wide range of applications, from medical devices to industrial automation.

Harnessing the Potential of Nitinol in Robotics

It's crucial to harness the potential of nitinol in robotics by continuing to explore its uses and capabilities within soft robotic actuators. By leveraging this unique material, we can push the boundaries of what is possible with robotics, paving the way for groundbreaking advancements that will benefit various industries.