Introduction

Nitinol wire, a unique alloy of nickel and titanium, is known for its shape memory and superelasticity properties. It has a wide range of applications in various industries due to its remarkable characteristics. There are different types of nitinol wire available, each with specific properties and uses.

Understanding Nitinol Wire

Nitinol wire is a type of shape memory alloy that exhibits the ability to return to a predetermined shape when exposed to heat or stress. This makes it highly versatile and suitable for a variety of applications, from medical devices to robotics.

Applications of Nitinol Wire

Nitinol wire is used in various fields such as medicine, aerospace, automotive, and consumer goods. It is commonly found in orthodontic archwires, guide wires for minimally invasive surgery, actuators for robotics, and more.

Types of Nitinol Wire

There are different types of nitinol wire available on the market, including superelastic nitinol wire and high purity nitinol wire. Each type has specific characteristics that make it suitable for particular applications.

Exploring Nitinol Wire Options

When it comes to exploring nitinol wire options, one of the key factors to consider is the high purity nitinol price. High purity nitinol offers superior performance and reliability, making it a popular choice for various applications. Whether used in medical devices or industrial settings, investing in high purity nitinol can lead to long-term cost savings and improved product quality.

High Purity Nitinol Price

The price of high purity nitinol can vary depending on factors such as size, shape, and quantity needed. However, the benefits of using high purity nitinol often outweigh the initial investment. Its exceptional flexibility, shape memory, and biocompatibility make it a valuable material for a wide range of applications. When considering the cost of high purity nitinol, it's important to weigh the long-term value and performance it offers.

High purity nitinol may have a higher upfront cost, but its long-term value and performance make it a worthwhile investment. Its exceptional flexibility allows for intricate designs and precise movements, making it ideal for medical devices and robotics. Additionally, its shape memory properties ensure that it can return to its original shape even after being deformed, adding to its durability and reliability. When considering the price of high purity nitinol, it's important to focus on the advantages it provides in terms of functionality and longevity.

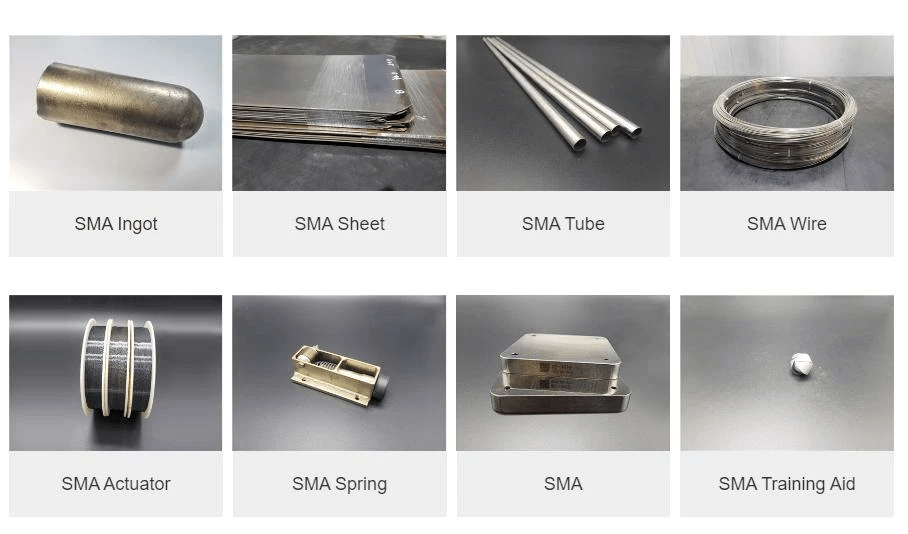

GEE SMA Nitinol Wire for Sale

For those in search of reliable nitinol wire for sale, GEE SMA offers an extensive selection of high-quality options. From standard sizes to custom solutions, GEE SMA provides a range of nitinol wire products designed to meet diverse application needs. With a focus on precision engineering and quality assurance, GEE SMA is a trusted source for acquiring top-notch nitinol wire at competitive prices.

In addition to offering a wide range of standard nitinol wire sizes, GEE SMA also specializes in providing custom solutions tailored to specific application requirements. Whether you need a unique diameter, shape, or surface finish, our team of experts is dedicated to delivering personalized nitinol wire products that meet your exact specifications. This commitment to customization sets GEE SMA apart as a go-to supplier for those seeking specialized nitinol wire options.

Nitinol Wire Archives

Exploring the nitinol wire archives can provide valuable insights into the history and evolution of this remarkable material. By delving into past research, developments, and case studies related to nitinol wire, engineers and designers can gain inspiration for innovative applications and product enhancements. The archives also serve as a valuable resource for understanding the different types of nitinol wire available and how they have been utilized across various industries.

Furthermore, the nitinol wire archives can provide valuable information on the properties and characteristics of different grades of nitinol, allowing engineers and designers to make informed decisions about which type best suits their specific application. By understanding the strengths and limitations of each type of nitinol wire, professionals can optimize their designs for maximum performance and reliability. This knowledge can also lead to cost savings by avoiding over-engineering or underperformance due to using the wrong grade of nitinol wire.

Advantages of Nitinol Wire

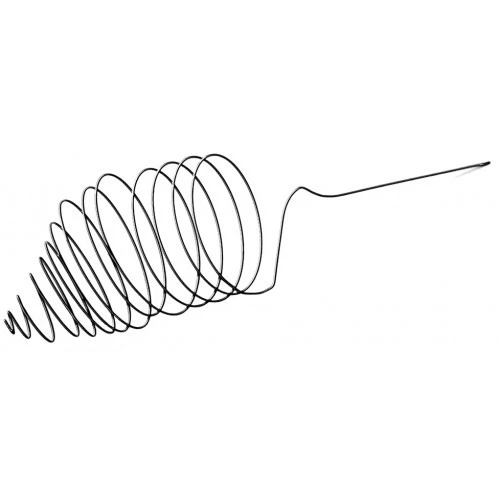

Nitinol wire offers several advantages that make it a sought-after material in various industries. One of its key benefits is its remarkable flexibility and shape memory, allowing it to return to its original shape after deformation. This unique property makes nitinol wire ideal for applications requiring precise and intricate movements, such as medical devices and robotics.

Flexibility and Shape Memory

The flexibility of nitinol wire, combined with its shape memory, makes it a versatile material for a wide range of applications. Whether used in orthodontic braces that need to maintain their shape or in minimally invasive medical devices that require precise movements, nitinol wire's ability to bend and recover its original form is unmatched.

In addition to its flexibility and shape memory, nitinol wire is also known for its biocompatibility, making it suitable for use in medical implants and devices. This means that it can be safely used within the human body without causing any adverse reactions. Its ability to seamlessly integrate with biological systems further expands its potential applications in the medical field, from stents and catheters to surgical tools and instruments.

Biocompatibility

Another advantage of nitinol wire is its biocompatibility, making it suitable for use in medical implants and devices without causing adverse reactions within the body. This property has led to the widespread use of nitinol wire in vascular stents, guide wires, and other critical medical applications where compatibility with the human body is essential.

Furthermore, nitinol wire's biocompatibility also extends to its durability and corrosion resistance within the body. This means that medical implants and devices made from nitinol wire can withstand the harsh conditions of the human body without degrading or causing harm. As a result, healthcare professionals can rely on nitinol wire to provide long-lasting and effective solutions for their patients, enhancing the overall quality of medical care.

Durability and Corrosion Resistance

Nitinol wire exhibits exceptional durability and corrosion resistance, making it an ideal choice for applications requiring long-term reliability. Whether used in aerospace engineering or biomedical devices, nitinol's ability to withstand harsh environments without degrading ensures the longevity of products utilizing this innovative material.

Nitinol wire's exceptional durability and corrosion resistance also make it an attractive option for applications that require minimal maintenance. With its ability to withstand harsh conditions without degrading, nitinol reduces the need for frequent repairs or replacements, saving time and resources for industries utilizing this versatile material. This low-maintenance aspect adds an additional layer of cost-effectiveness to the long list of benefits provided by nitinol wire.

Activation of Nitinol Wire

How do you activate nitinol wire?

To activate nitinol wire, it can be subjected to either heat or stress-induced activation. Heat activation involves exposing the wire to a specific temperature, causing it to return to its original shape. Stress-induced activation, on the other hand, occurs when the wire is mechanically deformed and then returns to its original shape when the stress is removed.

Heat and Stress-Induced Activation

Heat-induced activation of nitinol wire is achieved by heating it above its transition temperature, typically around 70°C for most applications. Once heated, the wire will revert to its predetermined shape due to its unique memory properties. Stress-induced activation occurs when the wire is deformed while below its transition temperature and then returns to its original shape when the stress is released.

Potential Applications in Medical Devices

The activation properties of nitinol wire make it ideal for a wide range of medical device applications, such as stents and guide wires used in minimally invasive procedures. Its ability to return to a predetermined shape allows for precise positioning within the body, making it invaluable in medical settings where accuracy is critical.

Common Uses of Nitinol Wire

Orthodontic and Dental Applications

Nitinol wire is widely used in orthodontics for its unique shape memory and flexibility, allowing it to move teeth more efficiently and with less discomfort for the patient. It is also used in dental braces to create a constant force for tooth movement, resulting in faster treatment times and improved outcomes.

Vascular Stents and Guide Wires

In the medical field, nitinol wire is commonly utilized in the production of vascular stents and guide wires due to its superelasticity and biocompatibility. These devices are crucial for treating cardiovascular conditions by providing support to blood vessels and ensuring proper blood flow, making nitinol an invaluable material in the healthcare industry.

Robotics and Actuators

Nitinol wire's ability to contract or expand with changes in temperature makes it ideal for use in robotics and actuators. This unique property allows for precise control of movements, making it an essential component in various robotic applications such as prosthetics, surgical tools, and industrial automation systems.

Is Nitinol Expensive?

Nitinol wire can be considered relatively expensive due to its unique properties and manufacturing process. However, the long-term value and performance of nitinol wire often outweigh the initial cost, making it a worthwhile investment for various applications.

Cost Considerations for Nitinol Wire

When considering the cost of nitinol wire for sale, it's important to factor in the material's high purity and specialized manufacturing methods. These contribute to the overall price of nitinol wire, but also ensure its exceptional quality and reliability for specific uses. Additionally, the long-term value of nitinol wire should be taken into account, as its durability and resistance to corrosion make it a cost-effective choice over time. Furthermore, the performance of nitinol wire in demanding applications, such as medical devices or aerospace components, justifies its initial investment due to its ability to maintain shape memory and superelasticity under extreme conditions.

Long-Term Value and Performance

Despite the initial expense, nitinol wire offers long-term value and performance that can justify its cost. Its shape memory properties, durability, and corrosion resistance make it a valuable material for applications where reliability is crucial.

Balancing Quality and Budget

While the initial cost of nitinol wire may be higher, it's important to consider the long-term benefits and cost savings that come with its superior performance and durability. By investing in high-quality nitinol wire, you can reduce the need for frequent replacements and repairs, ultimately saving money in the long run. This makes nitinol wire a smart choice for applications where reliability and longevity are crucial.

Conclusion

When it comes to high-quality nitinol options, there are various suppliers offering a range of products, from high purity nitinol wire to GEE SMA nitinol wire for sale. Custom nitinol solutions are also available to meet specific project needs. Exploring nitinol applications reveals its versatility across industries, making it a valuable material for various uses.

High-Quality Nitinol Options

For those seeking high purity nitinol at a reasonable cost, exploring nitinol wire archives can lead to finding the best deals on the market. With the demand for nitinol increasing, more suppliers are offering competitive prices and high-quality products to meet industry standards.

Custom Nitinol Solutions

Customized solutions for specific project requirements are available through various suppliers, ensuring that customers get precisely what they need for their applications. Whether it's a unique shape or size, there are options for customizing nitinol wire to fit any project specifications.

Exploring Nitinol Applications

From medical devices to robotics and actuators, the potential uses of nitinol wire are vast and varied. As technology advances and new applications emerge, the demand for this versatile material continues to grow.

Remember when considering whether is nitinol expensive? It's essential to weigh the long-term value and performance against the initial cost. With its durability and corrosion resistance, investing in high-quality nitinol can provide lasting benefits across different industries.