Introduction

In recent years, nitinol medical devices have been gaining significant traction in the healthcare industry. From implants to surgical tools, the versatility and unique properties of nitinol have revolutionized patient care. This has led to an increasing demand for nitinol components in various medical applications, showcasing its potential to transform the way we approach healthcare.

The Rising Popularity of Nitinol Medical Devices

The rising popularity of nitinol medical devices and implants can be attributed to their exceptional durability and biocompatibility. Nitinol's ability to return to its original shape after deformation makes it an ideal material for a wide range of medical devices, ensuring long-term reliability and performance.

Nitinol's unique properties also make it an excellent choice for minimally invasive medical procedures. Its flexibility and shape memory allow for the creation of devices such as stents, guidewires, and catheters that can be inserted into the body with minimal discomfort to the patient. This has revolutionized many medical treatments, allowing for quicker recovery times and reduced risk of complications.

Advantages of Nitinol in Patient Care

One of the key advantages of nitinol in patient care is its superelasticity, allowing for safer and more effective medical procedures. Additionally, nitinol's flexibility and resistance to corrosion make it a preferred choice for implants, minimizing the risk of complications and enhancing patient outcomes.

Furthermore, nitinol's unique shape memory properties allow for the creation of innovative medical devices that can adapt to the body's natural movements and changes. This means that patients experience less discomfort and a quicker recovery time post-surgery, leading to a higher overall satisfaction with their treatment. The versatility of nitinol components also enables the development of minimally invasive procedures, reducing scarring and the risk of infection for patients.

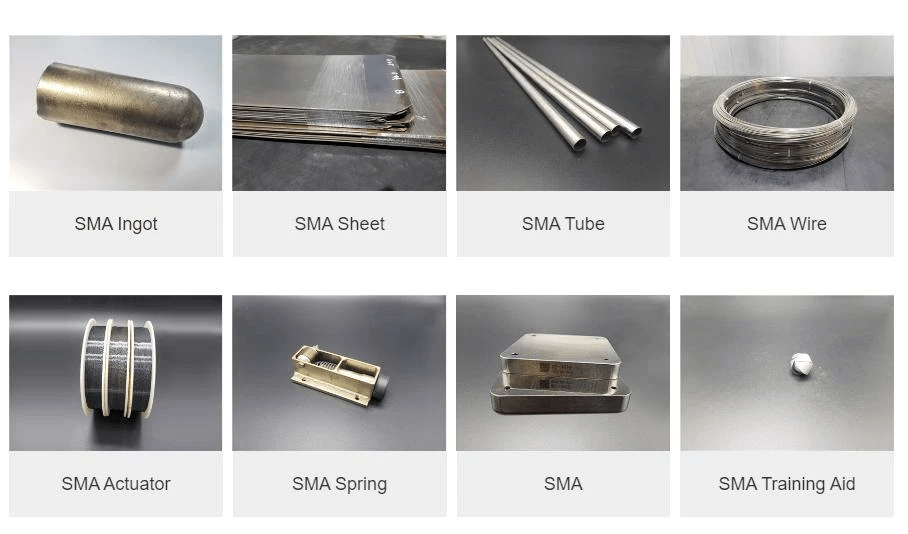

The Versatility of Nitinol Components

Nitinol's versatility extends beyond its physical properties, as it can be tailored to meet specific design requirements for medical applications. Whether used in stents, guidewires, or orthopedic implants, nitinol components offer unparalleled adaptability and precision in addressing diverse patient needs. Moreover, the unique shape memory and superelasticity of nitinol allow for minimally invasive procedures, reducing patient discomfort and recovery time. This makes it an ideal material for devices such as cardiovascular implants or neurovascular retrieval systems, where precision and flexibility are paramount.

Nitinol Medical Devices: A Brief Overview

Nitinol, a nickel-titanium alloy, has revolutionized the medical industry with its unique properties and versatility. Its shape memory and superelasticity make it ideal for a wide range of medical applications, from stents to orthodontic wires. Nitinol's ability to recover its original shape after deformation is particularly valuable in medical devices and implants.

Understanding Nitinol Properties

Nitinol's remarkable properties stem from its ability to undergo phase transitions, allowing it to return to a predetermined shape when subjected to heat or stress. This makes it an excellent material for self-expanding stents that can be inserted into blood vessels or other tubular structures and then expand to their original shape once deployed.

Nitinol's unique properties also make it an ideal material for orthodontic wires. When placed in the mouth, these wires can return to their original shape, exerting a gentle force on the teeth to move them into the desired position. This flexibility and resilience make Nitinol a popular choice among orthodontists and patients alike, as it allows for more comfortable and efficient tooth movement compared to traditional metal wires.

Nitinol Components in Medical Applications

From cardiovascular devices like stents and guidewires to orthopedic implants such as bone anchors and spinal fixation systems, nitinol components have become indispensable in modern medicine. Their biocompatibility and corrosion resistance make them suitable for long-term implantation within the human body.

Superelastic Nitinol for Medical Devices

Superelastic nitinol is particularly valuable in medical devices due to its ability to undergo large deformations without permanent damage. This property allows for the creation of novel devices such as retrievable filters that can be compressed for delivery through catheters before expanding back to their original shape once deployed.

The Impact of Nitinol in Patient Care

Enhanced Performance of Nitinol Implants

Nitinol medical devices and implants have revolutionized patient care with their enhanced performance and durability. The unique properties of Nitinol, such as its shape memory and superelasticity, allow for implants to adapt to the body's natural movements, providing greater comfort and reducing the risk of complications. Whether it's a stent in a blood vessel or a bone fixation device, Nitinol implants offer superior functionality and long-term reliability, making them a preferred choice for medical professionals.

Nitinol devices have also played a crucial role in advancing minimally invasive procedures. The flexibility and adaptability of Nitinol implants allow for smaller incisions, reducing trauma to the body and leading to faster recovery times for patients. Additionally, the biocompatibility of Nitinol ensures that the risk of adverse reactions or rejections is minimized, making it an ideal choice for use in minimally invasive surgeries. This has led to a significant shift in medical practices towards less invasive techniques, benefiting both patients and healthcare professionals.

Nitinol Devices in Minimally Invasive Procedures

Nitinol for medical applications has significantly contributed to the advancement of minimally invasive procedures. The flexibility and resilience of Nitinol components enable the development of intricate medical devices that can be inserted through small incisions, minimizing trauma to the patient's body. From endovascular devices to neurovascular interventions, Nitinol plays a pivotal role in enabling less invasive treatment options that result in faster recovery times and reduced risks for patients.

Nitinol's unique properties also contribute to improved patient comfort during minimally invasive procedures. The flexibility of Nitinol components allows for smoother navigation through the body, reducing discomfort for the patient. Additionally, the resilience of Nitinol devices ensures that they can withstand the forces exerted on them during procedures, providing a sense of security for both patients and medical professionals. This enhanced comfort can lead to better patient outcomes and overall satisfaction with their medical experience.

Improving Patient Comfort with Nitinol Components

Nitinol components not only enhance performance but also prioritize patient comfort during medical treatments. Whether it's orthodontic wires that exert gentle forces on teeth or guide wires used in catheter-based procedures, Nitinol's unique properties contribute to smoother operations and improved patient experiences. By minimizing discomfort and reducing the need for frequent adjustments or replacements, Nitinol components have become indispensable in providing optimal care while prioritizing patient comfort.

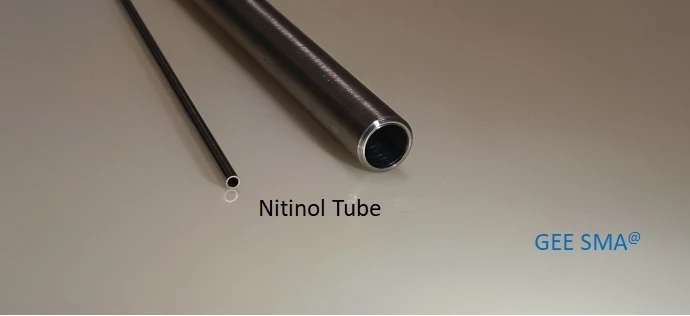

Manufacturing Nitinol Medical Devices

Nitinol medical devices and implants have revolutionized patient care, and at the heart of this innovation is the manufacturing process. GEE SMA stands as a leader in producing Nitinol shape memory alloys, ensuring top-notch quality for medical applications. The meticulous crafting of high-quality Nitinol materials is crucial in creating reliable and durable components that meet the stringent demands of healthcare settings.

GEE SMA: A Leader in Nitinol Shape Memory Alloys

GEE SMA has established itself as a frontrunner in providing Nitinol for medical applications, with a focus on shape memory alloys that exhibit remarkable flexibility and resilience. Their expertise in shaping Nitinol components has led to breakthroughs in developing advanced medical devices that cater to diverse patient needs, from cardiovascular stents to orthopedic implants.

GEE SMA's commitment to crafting high-quality Nitinol materials is evident in their dedication to research and development. By staying at the forefront of technological advancements, they are able to continuously improve the properties of Nitinol, making it an ideal material for medical applications. Their rigorous testing and quality control processes ensure that the Nitinol components they produce meet the highest standards, providing healthcare professionals and patients with reliable and durable solutions.

Crafting High-Quality Nitinol Materials

The manufacturing process of Nitinol medical devices involves precision engineering to ensure the highest quality materials are produced. GEE SMA's commitment to excellence guarantees that every component meets rigorous standards for biocompatibility, corrosion resistance, and mechanical properties, assuring both healthcare providers and patients of reliable performance and long-term durability.

In addition to meeting industry standards, GEE SMA goes above and beyond to tailor Nitinol components to the specific needs of our customers. Our team of experienced engineers works closely with clients to understand their unique requirements and design custom solutions that optimize performance and functionality. This personalized approach ensures that every Nitinol medical device not only meets quality standards but also exceeds expectations in terms of efficacy and patient satisfaction.

Tailoring Nitinol Components to Customer Needs

One key advantage of manufacturing Nitinol medical devices lies in the ability to customize components based on specific customer requirements. GEE SMA's dedication to tailoring Nitinol components ensures that each device aligns with the unique needs of healthcare professionals and their patients, fostering greater confidence in using these cutting-edge solutions for improved patient care.

Advancing Patient Care with Nitinol

Nitinol's Role in Innovative Medical Solutions

Nitinol medical devices have revolutionized the medical industry, offering innovative solutions for various healthcare needs. From advanced stents to intricate surgical tools, Nitinol's unique properties and flexibility have paved the way for groundbreaking medical advancements.

Nitinol's ability to withstand deformation and return to its original shape has made it an ideal material for the development of advanced stents. These stents can be inserted into narrowed or blocked arteries to help improve blood flow and prevent complications such as heart attacks and strokes. The flexibility of Nitinol allows these stents to be easily navigated through the body, providing a minimally invasive treatment option for patients with cardiovascular issues.

Nitinol Devices Enhancing Treatment Outcomes

Nitinol medical devices and implants are known for their exceptional performance in enhancing treatment outcomes for patients. The use of Nitinol components in minimally invasive procedures has led to reduced recovery times and improved patient comfort, making it a game-changer in modern healthcare.

The flexibility and shape memory of Nitinol allow for the creation of innovative medical devices that can adapt to the body's natural movements, providing a more comfortable experience for patients. This unique characteristic also enables Nitinol implants to maintain their original shape and function even after being bent or deformed during implantation, ensuring long-term treatment success. As medical technology continues to advance, Nitinol is expected to play an increasingly significant role in improving patient outcomes and revolutionizing healthcare practices.

The Future of Nitinol in Medical Advancements

As technology continues to evolve, the future of Nitinol in medical advancements looks promising. With ongoing research and development, we can expect to see even more sophisticated Nitinol devices that further improve patient care and treatment outcomes, solidifying its position as a cornerstone of modern medicine. One exciting area of development is the potential for Nitinol to be used in minimally invasive surgical procedures, allowing for smaller incisions and faster recovery times for patients. Additionally, the biocompatibility of Nitinol makes it an ideal material for implants and prosthetics, offering long-term solutions for patients with a wide range of medical needs. As the medical community continues to explore the possibilities of Nitinol, we can anticipate groundbreaking innovations that will revolutionize patient care across various specialties.

Conclusion

Nitinol has undeniably revolutionized patient care with its remarkable properties and versatile applications. From enhancing treatment outcomes to improving patient comfort, Nitinol medical devices and implants have proven to be a game-changer in the medical field. Embracing Nitinol for enhanced medical solutions is crucial for advancing patient care and unlocking the potential of Nitinol devices in shaping the future of healthcare.

Nitinol: A Game-Changer in Patient Care

The widespread use of Nitinol medical devices has significantly improved patient care by offering superior performance, durability, and biocompatibility. As a result, healthcare professionals can rely on these innovative solutions to provide better treatment options for their patients, ultimately leading to improved quality of life.

Embracing Nitinol for Enhanced Medical Solutions

With its unique properties and adaptability, Nitinol has opened doors to a wide range of enhanced medical solutions that were previously unattainable. From minimally invasive procedures to complex implantable devices, embracing Nitinol in medical applications is essential for driving innovation and improving overall healthcare outcomes.

Unlocking the Potential of Nitinol Devices

As we continue to explore the capabilities of Nitinol, it's clear that there is still untapped potential waiting to be unlocked. By pushing the boundaries of material science and engineering, we can further harness the power of Nitinol devices to develop groundbreaking medical advancements that will shape the future of healthcare.

Remember that innovation never stops - and neither should our exploration of the possibilities offered by Nitinol in advancing patient care and improving overall health outcomes!