Introduction

In the ever-evolving world of technology, SMA actuators stand out as a remarkable innovation that combines elegance with functionality. These powerful miniature actuators harness the unique properties of shape memory alloys (SMAs) to create movement and force in ways traditional materials cannot. With applications ranging from aerospace to robotics, understanding what an SMA actuator is can unlock new possibilities in design and engineering.

Exploring the Magic of SMA Actuators

SMA actuators are truly magical devices that respond to temperature changes by altering their shape, which allows them to perform precise movements. This capability makes them ideal for applications where space is limited, yet performance requirements are high. The enchanting nature of these smart material actuators lies in their ability to provide reliable actuation without bulky components or complicated mechanisms.

Understanding Shape Memory Alloys

So, what are shape memory alloy actuators? At their core, SMAs are materials that remember their original shape and return to it when heated after being deformed. This fascinating property is due to a phase transformation within the material's structure, enabling it to exert significant force while maintaining a compact form factor—perfect for powerful miniature actuators.

The Role of Miniature Actuators in Technology

Miniature actuators play an increasingly vital role in modern technology by enabling automation and precision control across various industries. From medical devices that require exact movements to aerospace innovations demanding lightweight efficiency, these small yet mighty components have become indispensable tools. As we delve deeper into the world of SMA actuators and explore their types and applications, we begin to appreciate how they revolutionize our approach to engineering challenges.

What are Shape Memory Alloy Actuators?

Shape Memory Alloy (SMA) actuators are remarkable devices that leverage the unique properties of shape memory alloys to produce motion in a controlled manner. These powerful miniature actuators can change shape in response to temperature variations, making them incredibly versatile for various applications. But what is an SMA actuator exactly? Simply put, it’s a type of actuator that utilizes the inherent characteristics of certain alloys to achieve movement.

Definition and Mechanism

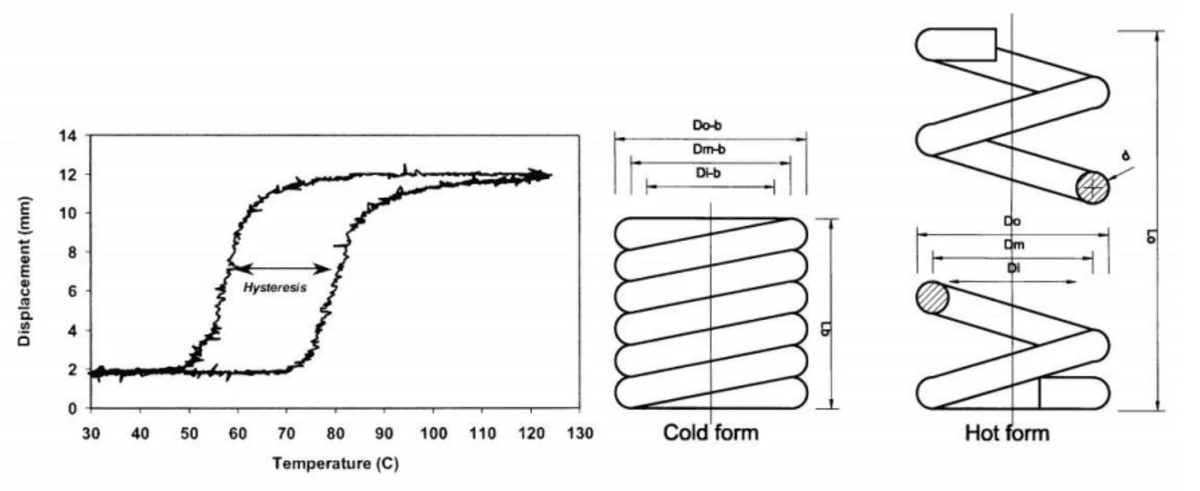

At its core, an SMA actuator operates on the principle of phase transformation within the material. When heated above a specific temperature, the alloy transitions from a martensitic phase (flexible and deformable) to an austenitic phase (rigid and strong). This transition allows SMA actuators to exert force and move components with precision, making them ideal for applications requiring reliable actuation in compact spaces.

The mechanism behind these smart material actuators is both fascinating and efficient. The ability to return to a predetermined shape after deformation means that SMA actuators can perform repetitive tasks without mechanical wear typical of traditional motors or gears. This unique functionality not only enhances durability but also opens up new frontiers in design possibilities across various industries.

History and Development

The journey of shape memory alloys began in the 1930s when researchers first discovered their unique properties. However, it wasn't until the 1960s that significant advancements were made with nickel-titanium alloys, which showcased exceptional shape memory effects. Over decades, innovations have led to increased understanding and manipulation of these materials, paving the way for modern SMA actuators as we know them today.

As technology progressed into the 21st century, so did applications for SMAs expand exponentially beyond initial uses in aerospace and automotive sectors. The development of more refined manufacturing techniques allowed for smaller forms of SMA actuators—powerful miniature actuators that fit seamlessly into medical devices and consumer electronics alike. Today’s landscape sees these smart material actuators at the forefront of robotics, providing unprecedented levels of control in compact designs.

Applications in Real World

When exploring what are shape memory alloy actuators used for today, one quickly realizes their versatility spans numerous industries. In aerospace innovations, they enable precise control surfaces on aircraft wings while minimizing weight—a critical factor in flight efficiency. In medical device advancements, these powerful miniature actuators contribute significantly by powering stents or prosthetics that respond dynamically to body temperature changes.

Moreover, robotics and automation sectors benefit immensely from SMAs due to their ability to function without bulky motors or complex gearing systems—allowing robots to be more agile and responsive than ever before. As demand grows for smarter technologies across various fields, it becomes clear that SMA actuators will continue playing an essential role in shaping our future.

The Four Types of Linear Actuators

Overview of Linear Actuator Types

There are primarily four types of linear actuators that dominate the market: electric, pneumatic, hydraulic, and shape memory alloy (SMA) actuators. Electric actuators utilize electrical energy to produce motion, while pneumatic ones rely on compressed air to create movement. Hydraulic actuators are powered by pressurized fluid, and lastly, SMA actuators leverage the unique properties of shape memory alloys to achieve precise movement.

What are shape memory alloy actuators? They are a type of smart material actuator that transforms from one shape to another when subjected to heat or electrical current. This remarkable ability allows them to perform tasks with minimal energy input while maintaining high reliability—perfect for applications where space and efficiency are paramount.

Advantages of Each Type

Each type of linear actuator has its own unique advantages that cater to different needs. Electric actuators offer precise control and easy integration with electronic systems; they’re often quieter than their pneumatic or hydraulic counterparts. Pneumatic actuators are known for their rapid response times and lightweight design but may lack precision in some applications.

Hydraulic actuators excel in delivering high force output in compact designs; they’re ideal for heavy-duty tasks but can be more complex due to fluid management systems. Shape Memory Alloy (SMA) Actuators stand out because they require no external power source during operation; once heated or electrically activated, they return to their original shape automatically—making them both efficient and reliable.

When to Use Each Type

Choosing the right actuator depends on your specific application needs and constraints. If you require precision control in a quiet environment, electric linear actuators might be your best bet; they're perfect for robotics or automation tasks where accuracy is key. On the other hand, if speed is crucial—think quick-acting valves or clamping mechanisms—pneumatic options could be your go-to choice.

For heavy lifting scenarios such as construction equipment or industrial machinery, hydraulic linear actuators provide unmatched power capabilities despite their complexity. Finally, when looking at powerful miniature actuators with shape memory capabilities that save space without compromising efficiency, SMA actuators shine brightly—they're ideal for medical devices or aerospace innovations where every millimeter counts.

The Science Behind Shape Memory Alloys

Understanding the science behind Shape Memory Alloys (SMAs) is crucial for grasping how SMA actuators work their magic. These materials exhibit unique properties that allow them to return to a predefined shape when heated, making them powerful miniature actuators with remarkable capabilities. In this section, we will delve into the composition and properties of SMAs, the fascinating phase transformation process they undergo, and the practical implications of these smart material actuators in various industries.

Composition and Properties

Shape Memory Alloys are typically composed of metals such as nickel and titanium, which form a solid solution that allows for their unique behavior. The most common SMA used in actuators is Nitinol, an alloy made from nickel and titanium, known for its exceptional flexibility and strength. What are shape memory alloy actuators? They leverage the distinct properties of SMAs to convert thermal energy into mechanical motion efficiently.

The key property that defines SMA actuators is their ability to undergo phase transformations between two distinct crystalline structures: austenite and martensite. In the austenitic state, SMAs exhibit high strength and rigidity; conversely, in the martensitic state, they become soft and pliable. This transition enables SMA actuators to perform complex movements with precision while maintaining compactness—ideal for applications where space is at a premium.

Phase Transformation Explained

Phase transformation is at the heart of what makes shape memory alloy actuators so special. When an SMA actuator is cooled below its transformation temperature, it enters the martensitic phase, allowing it to be easily deformed into various shapes without permanent changes. Upon heating above this critical temperature, it reverts to its original austenitic configuration—hence shape memory.

This clever mechanism not only allows for efficient actuation but also enables precise control over movement without requiring bulky components or complex systems often associated with traditional linear actuators. So when pondering what are the 4 types of linear actuators? It's essential to note that while conventional types rely on electric motors or hydraulic systems for movement, SMA actuators stand out by utilizing thermal energy instead.

The ability of SMAs to remember their original shape has significant implications for design engineers looking for innovative solutions across multiple fields—from robotics to aerospace innovations—where space-saving designs are paramount.

Practical Implications of Smart Materials

Smart material actuators like SMA offer numerous practical advantages that revolutionize how we approach engineering challenges today. Their lightweight nature combined with high power-to-weight ratios makes them ideal candidates for applications ranging from medical devices to aerospace technologies where every gram counts toward efficiency.

Moreover, because these powerful miniature actuators can operate without external power sources once activated by heat, they open new avenues in energy-efficient designs—a crucial factor as industries strive toward sustainability goals. The versatility of shape memory alloy (SMA) actuators means they can be integrated into existing systems seamlessly or used in entirely new applications that were previously thought impossible due to size constraints.

In conclusion, understanding the science behind Shape Memory Alloys not only explains how these materials function but also highlights their transformative potential across industries seeking innovative solutions through smart materials technology.

Applications of SMA Actuators Across Industries

Shape Memory Alloy (SMA) actuators are transforming various industries with their unique properties and capabilities. These powerful miniature actuators utilize the remarkable characteristics of shape memory alloys to perform tasks that were once thought impossible. From aerospace to medical devices and robotics, the applications of SMA actuators are as diverse as they are innovative.

Aerospace Innovations

In the aerospace industry, SMA actuators are revolutionizing aircraft design and functionality. What is an SMA actuator? Simply put, it’s a device that uses the properties of shape memory alloys to create movement in response to temperature changes. This technology enables lightweight, efficient actuation systems that can adapt to varying flight conditions, reducing weight and improving fuel efficiency.

The ability of SMA actuators to provide precise control makes them ideal for applications like morphing wings and adjustable control surfaces on aircraft. Additionally, their compact size allows for integration into tight spaces where traditional actuators might not fit. With ongoing advancements in materials science, we can expect even more innovative uses for SMA actuators in aerospace technology.

Medical Device Advancements

Medical devices have also greatly benefited from the incorporation of smart material actuators like SMA actuators. These devices offer unique solutions for minimally invasive surgeries and patient care technologies by providing reliable actuation without bulky components or complex mechanisms. What are shape memory alloy actuators doing in healthcare? They enable precise movements in surgical tools and prosthetics that mimic natural motion.

For instance, SMA actuators can be found in stents that expand within blood vessels or in robotic-assisted surgical instruments that require delicate manipulation during procedures. Their biocompatibility combined with powerful performance makes them indispensable in modern medicine. As research continues into new applications, we may soon see even more groundbreaking medical innovations driven by these powerful miniature actuators.

Robotics and Automation

SMA actuators play a crucial role in advancing robotics and automation technologies as well. With their ability to deliver significant force while remaining compact, these smart material actuators allow robots to perform tasks with greater dexterity than ever before. What are the 4 types of linear actuators? Among them, SMA-based linear actuators stand out due to their unique ability to change shape based on thermal input.

In industrial automation settings, these powerful miniature actuators can enhance robotic arms' flexibility and responsiveness, allowing for more intricate assembly processes or adaptive manufacturing techniques. Furthermore, their energy-efficient operation makes them suitable for battery-powered robots used in remote environments or sensitive applications like search-and-rescue missions. As industries continue embracing automation trends, the demand for efficient solutions like SMA actuators will undoubtedly grow.

GEE SMA: Leading the SMA Actuator Market

When it comes to SMA actuators, GEE SMA stands out as a beacon of innovation and excellence. This company has carved a niche for itself in the realm of Shape Memory Alloy (SMA) Actuators, focusing on delivering powerful miniature actuators that meet the evolving demands of various industries. With a mission centered around harnessing smart material technology, GEE SMA is committed to pushing the boundaries of what is possible with these remarkable devices.

Company Overview and Mission

GEE SMA was founded with a clear vision: to revolutionize the actuator landscape using advanced Shape Memory Alloys. The team at GEE SMA is driven by a passion for innovation, aiming to create solutions that not only meet but exceed customer expectations in performance and efficiency. Their mission emphasizes sustainability and cutting-edge technology, ensuring that their products contribute positively to both industry and environment.

Product Offerings and Innovations

The product lineup at GEE SMA includes an impressive range of smart material actuators designed for versatility across multiple applications. From aerospace components to medical devices, their Shape Memory Alloy (SMA) Actuators are engineered for precision and reliability. Continuous innovation is key; GEE SMA invests in research and development to enhance actuator performance while exploring new materials that can further elevate their capabilities.

Customer-Centric Approach

GEE SMA takes pride in its customer-centric philosophy, which places client needs at the forefront of every decision made within the company. They foster strong relationships with customers by offering tailored solutions that address specific challenges faced in various sectors—be it robotics or automation technologies. By actively engaging with clients throughout the design process, GEE SMA ensures that their powerful miniature actuators align perfectly with end-user requirements.

Conclusion

As we wrap up our exploration of SMA actuators, it's clear that these powerful miniature actuators are not just a passing trend but a significant leap in technology. The future of miniature actuators in technology is bright, with the potential for SMA actuators to revolutionize various sectors. As industries continue to embrace innovation, the versatility and efficiency of shape memory alloy (SMA) actuators will undoubtedly play a pivotal role in shaping tomorrow's solutions.

Future of Miniature Actuators in Technology

The future looks promising for miniature actuators, especially those utilizing shape memory alloys. What is an SMA actuator? It's a device that leverages the unique properties of smart materials to deliver precise movements in compact packages. As research progresses and manufacturing techniques improve, we can expect even more advanced applications for SMA actuators, enhancing everything from robotics to aerospace technology.

The Growing Importance of Smart Materials

In recent years, the importance of smart material actuators has surged as industries seek more adaptable and efficient solutions. What are shape memory alloy actuators? They are materials that remember their original shape and can return to it when subjected to specific conditions like temperature changes. This ability makes them invaluable for applications requiring reliable performance under varying conditions, highlighting their growing significance across sectors.

How SMA Actuators Are Changing Industries

SMA actuators are already making waves across multiple industries by introducing innovative solutions that were previously unimaginable. What are the 4 types of linear actuators? Each type brings its own advantages and ideal use cases; however, SMA actuators stand out due to their compact size and energy efficiency. By integrating these powerful miniature actuators into existing systems, companies can enhance functionality while reducing costs—truly changing the game in fields like aerospace innovations and medical device advancements.