Introduction

Welcome to the exciting world of Shape Memory Alloy (SMA) Actuators! These innovative materials have revolutionized the field of engineering and robotics with their unique properties. From medical devices to aerospace technology, SMA actuators have found a wide range of applications due to their shape memory effect and remarkable advantages.

Understanding Shape Memory Alloys

Shape Memory Alloys are a special class of materials that have the ability to remember their original shape and return to it when subjected to certain stimuli. This unique feature makes them ideal for use in actuators, allowing for precise control and movement in various applications.

Applications of Shape Memory Alloy Actuators

SMA actuators are used in a wide range of industries, including biomedical devices, automotive components, and consumer electronics. Their ability to provide precise and reliable motion control has made them invaluable in fields where accuracy is crucial.

Advantages of Using Shape Memory Alloy Actuators

The use of SMA actuators offers several advantages over traditional actuator technologies, including lightweight design, low power consumption, and high force output. These benefits make them an attractive option for engineers and designers looking to optimize performance while minimizing size and weight.

What are Shape Memory Alloy Actuators?

Shape Memory Alloy (SMA) Actuators are innovative devices that utilize the unique properties of shape memory alloys to produce mechanical motion. These actuators are capable of undergoing significant deformation and then reverting to their original shape when heated, making them highly versatile in various applications.

Definition of SMA Actuators

SMA actuators are devices that convert thermal energy into mechanical work by utilizing the shape memory effect of certain alloys, such as Nitinol. When exposed to a specific temperature range, these alloys can change their shape and return to their original form when the temperature changes again, allowing for precise control over movement.

SMA actuators are incredibly versatile and can be used in a wide range of applications, from robotics to medical devices. The ability to convert thermal energy into mechanical work with such precision makes them ideal for tasks that require fine motor control. Additionally, the shape memory effect allows for a high degree of repeatability, making SMA actuators reliable and consistent in their movements. This makes them an attractive option for industries where accuracy and reliability are paramount.

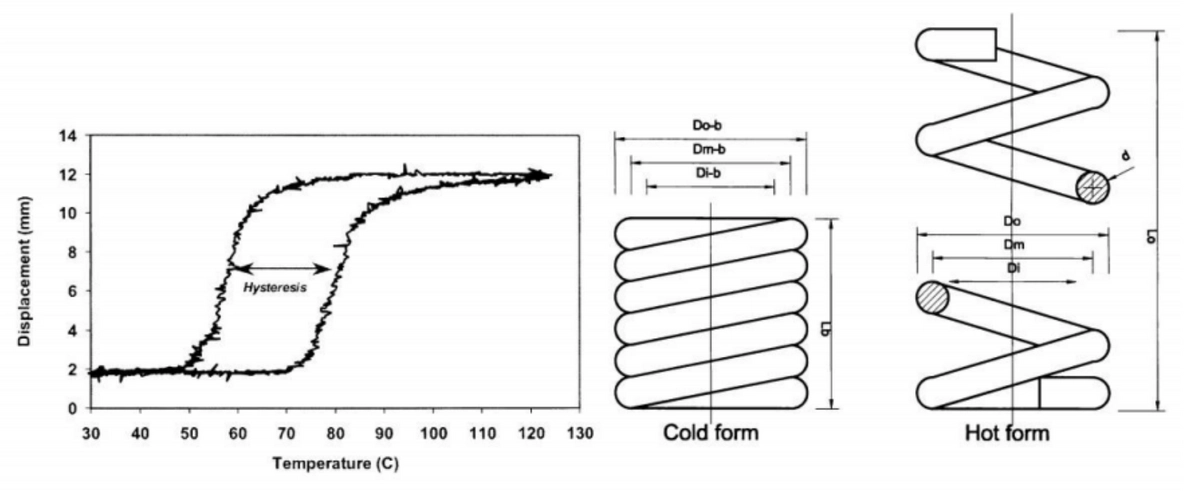

Mechanism of Shape Memory Effect

The mechanism behind the shape memory effect involves a reversible phase transformation in the atomic structure of the alloy. This transformation allows the material to remember its original shape and return to it when heated, providing a reliable and repeatable actuation process for various engineering applications.

In addition to its ability to remember and return to its original shape, shape memory alloy (SMA) actuators offer several other benefits for engineering applications. These materials have a high power-to-weight ratio, making them ideal for use in small-scale devices where space and weight are limited. Furthermore, SMAs can produce large forces and displacements, allowing for efficient actuation in a variety of mechanical systems. This combination of properties makes SMAs a versatile and valuable option for engineers seeking reliable and effective actuation solutions.

Benefits of Using SMA Actuators

The use of SMA actuators offers several advantages, including lightweight construction, high energy density, precise control over movement, and minimal maintenance requirements. These actuators also exhibit excellent fatigue resistance and can be designed with complex shapes for specific tasks.

In addition, SMA actuators are highly reliable and can withstand harsh environmental conditions, making them suitable for a wide range of applications. Their ability to operate effectively in extreme temperatures and corrosive environments makes them an ideal choice for industries such as aerospace, automotive, and medical devices. This reliability ensures that the actuators can perform consistently over time, reducing the need for frequent replacements or repairs.

Is Shape Memory Alloy Expensive?

Cost Considerations for SMA Actuators

When considering the cost of shape memory alloy actuators, it's essential to factor in the initial investment for the high-quality materials and intricate manufacturing process. However, the long-term benefits of SMA actuators can outweigh the upfront expense, as they offer durability and reliability, reducing maintenance and replacement costs over time.

It's also important to consider the energy efficiency of SMA actuators when comparing costs with traditional actuators. While the initial investment may be higher, the energy-saving capabilities of SMA actuators can result in long-term cost savings on electricity or other power sources. This can make them a more cost-effective option in the long run, especially for applications that require frequent use or continuous operation.

Comparing Cost with Traditional Actuators

In comparison to traditional actuators, shape memory alloy actuators may appear more expensive at first glance. However, when evaluating the overall lifecycle cost and performance, SMAs prove to be a cost-effective choice due to their extended lifespan and minimal maintenance requirements.

In addition to their extended lifespan and minimal maintenance requirements, shape memory alloy actuators also offer energy efficiency benefits, reducing long-term operational costs. Their ability to respond quickly and precisely to changes in temperature or electrical current means that they consume less energy compared to traditional actuators, resulting in lower utility bills and reduced environmental impact. This makes SMAs a sustainable and cost-effective choice for various applications, from aerospace and automotive industries to medical devices and consumer electronics.

Long-term Cost Benefits of SMA Actuators

The long-term cost benefits of using shape memory alloy actuators are substantial. Their ability to withstand repeated use without degradation ensures a longer service life compared to traditional actuators, resulting in reduced downtime and replacement expenses. Investing in SMA technology ultimately leads to significant cost savings in the long run.

In addition to the cost savings associated with longer service life, shape memory alloy actuators also offer energy efficiency benefits. Their ability to convert thermal energy into mechanical work means they require less power to operate, resulting in lower energy consumption and reduced operating costs. This makes SMA actuators a sustainable and cost-effective choice for a wide range of applications, from aerospace to medical devices.

Exploring the Shape Memory Effect of Alloys

Shape memory alloy actuators are fascinating due to their unique ability to remember and return to their original shape after being deformed. This transformation process is made possible by the crystal structure of the alloy, which allows it to undergo reversible phase transitions. When heated, the alloy reverts to its original shape, making it ideal for various applications.

Understanding the Transformation Process

The transformation process in shape memory alloys involves two main phases: martensite and austenite. When the alloy is deformed at low temperatures, it enters the martensite phase, retaining its new shape. However, upon heating, it transitions back to the austenite phase, returning to its original form. This unique behavior makes SMAs highly sought after in industries such as aerospace, automotive, and medical devices.

The unique properties of shape memory alloys have led to a wide range of real-world applications. In the aerospace industry, SMAs are used in components that require precise and reliable movement, such as actuators and deployable structures. Their ability to return to their original shape after deformation makes them ideal for use in space missions and satellite deployments. In the automotive sector, SMAs are utilized in various applications including safety systems, such as seatbelt pre-tensioners and airbag deployment mechanisms, where their shape memory effect ensures rapid and reliable response in the event of a collision.

Real-world Applications of Shape Memory Effect

The shape memory effect of alloys has revolutionized several industries. In aerospace, SMA actuators are used for adaptive wing structures that change shape during flight for improved aerodynamics. In medicine, SMA stents can expand and contract within blood vessels without causing damage. As technology advances, we can expect even more innovative applications of SMA technology in robotics and consumer electronics.

Potential Future Developments in SMA Technology

The future of SMA technology holds exciting possibilities for advancements in material science and engineering. Researchers are exploring ways to enhance the properties of SMAs for improved performance and durability in extreme conditions. Additionally, efforts are underway to make SMAs more cost-effective and accessible for a wider range of applications.

Now that we've delved into the fascinating world of SMAs and their transformative capabilities, let's explore GEE SMA's expertise in crafting high-quality nitinol alloys for diverse industrial needs!

GEE SMA's Expertise in SMA Actuators

GEE SMA is a leading manufacturer of high-quality Nitinol alloys, the primary material used in shape memory alloy actuators. Our expertise lies in crafting these alloys to precise specifications, ensuring top-notch performance and reliability in SMA actuators.

Crafting High-Quality Nitinol Alloys

Our team is dedicated to meeting the specific needs of our customers by customizing Nitinol alloys to their exact specifications. Whether it's a certain level of flexibility, durability, or another property, we work closely with clients to understand their requirements and tailor the materials accordingly. This personalized approach ensures that our Nitinol alloys not only meet but exceed the expectations of our customers, providing them with high-quality materials that perfectly suit their applications.

Tailoring Materials to Customer Needs

At GEE SMA, we understand that different applications require specific material characteristics. That's why we offer custom-tailored Nitinol alloys to meet our customers' unique requirements. Whether it's a certain level of elasticity or thermal responsiveness, we can modify the alloy to ensure it perfectly suits the intended use in shape memory alloy actuators.

Swift Customer Response and Product Enhancement

We take pride in our customer-centric approach, providing swift responses to inquiries and requests for product enhancements. Our team works closely with clients to address any concerns or modifications needed for their shape memory alloy actuators, ensuring that they receive top-notch support throughout the entire process.

Conclusion

Shape memory alloy actuators represent the future of advanced engineering solutions, offering unprecedented potential for innovation and efficiency. As industries continue to discover the remarkable capabilities of SMA technology, the demand for these actuators is set to soar, revolutionizing the way we approach automation and robotics.

The Future of Shape Memory Actuators

The future of shape memory alloy actuators is incredibly promising, with ongoing research and development paving the way for even more sophisticated applications across various industries. As technology continues to evolve, SMA actuators are expected to become increasingly versatile and cost-effective, driving a new era of precision engineering.

The ongoing research and development in the field of shape memory alloy actuators is driving innovation and pushing the boundaries of what is possible. As technology continues to evolve, these actuators are expected to become increasingly versatile, enabling them to be used in a wider range of applications. This versatility will not only expand their potential uses across various industries but also make them more cost-effective, paving the way for a new era of precision engineering.

Discovering the Potential of SMA Technology

Exploring the potential of SMA technology also presents an opportunity to revolutionize the medical field. With the ability to create small, precise movements, shape memory alloy actuators can be used in minimally invasive surgical procedures, allowing for greater precision and reduced recovery times for patients. Additionally, SMA technology has the potential to improve the functionality of prosthetic limbs, providing amputees with more natural and responsive movement.

Investing in Shape Memory Alloy Actuators

Investing in shape memory alloy actuators is a strategic move for businesses seeking a competitive edge in today's dynamic market. With their exceptional durability and adaptability, SMA actuators offer long-term value that far outweighs their initial cost. Embracing this innovative technology is an investment in future success. Additionally, SMA actuators provide precise control and high force output, making them ideal for a wide range of applications across industries such as aerospace, automotive, and robotics. This versatility ensures that businesses can leverage SMA actuators for various purposes, maximizing their return on investment.