Introduction

Nitinol memory wire suppliers are crucial in providing high-quality nitinol wire for various industries. Understanding nitinol memory wire's unique properties and applications is essential for businesses looking to source reliable suppliers. From its shape memory capabilities to its superelasticity, nitinol wire offers a wide range of key features that make it an attractive material for engineering and medical applications. Exploring the market for nitinol wire reveals a growing demand for this versatile alloy, prompting businesses to consider their options carefully when choosing a supplier.

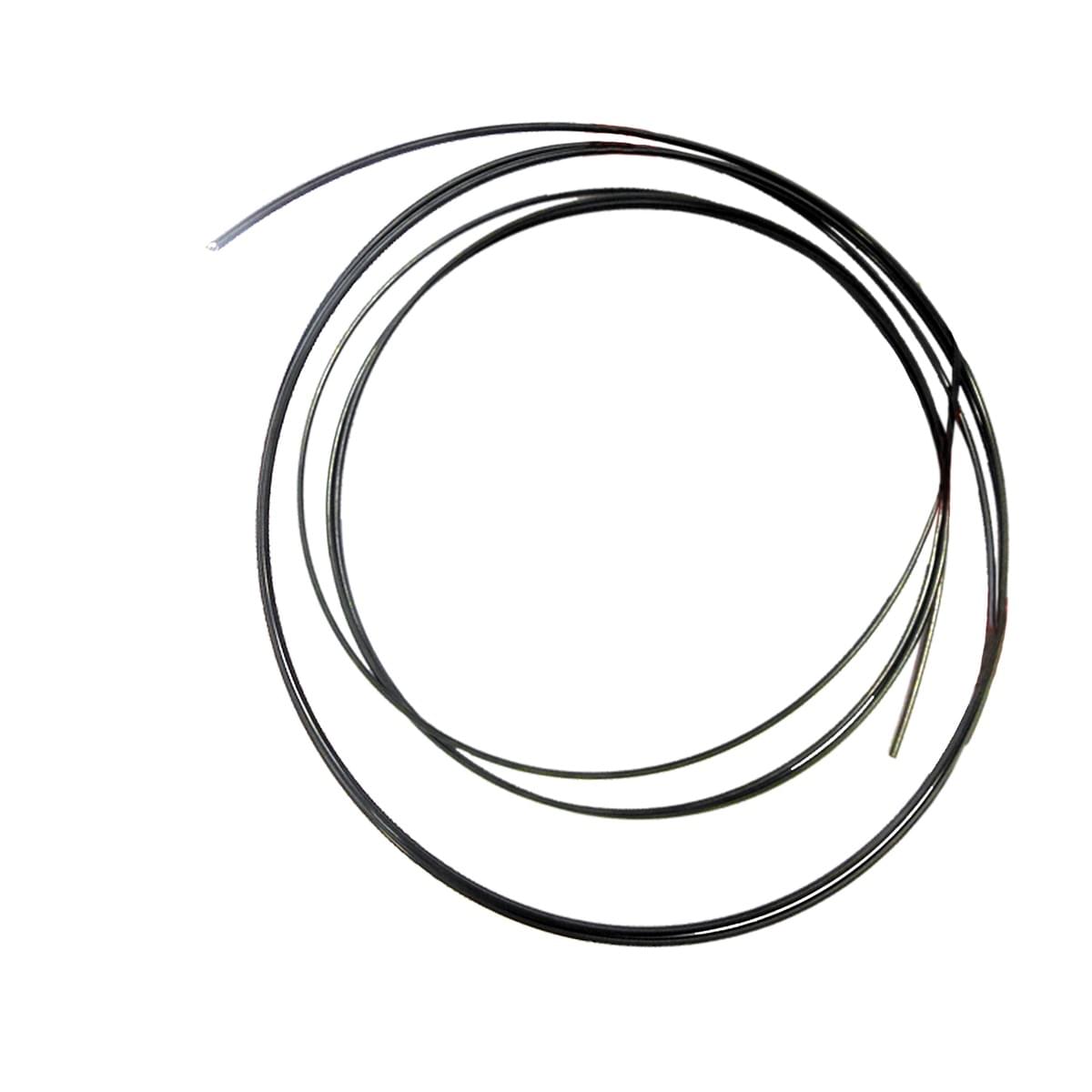

Understanding Nitinol Memory Wire

Nitinol memory wire, also known as shape memory alloy (SMA), is a type of metal that can remember its original shape and return to it when heated. This unique property makes it ideal for various applications such as actuators, sensors, and medical devices.

Key Features of Nitinol Wire

Nitinol wire, a unique alloy of nickel and titanium, offers a remarkable combination of properties that make it valuable in various industries. Here's a breakdown of its key features:

- Superelasticity: Nitinol wire can undergo significant deformation without permanent damage, springing to its original shape once the stress is released.

- Biocompatibility: This non-toxic property makes nitinol wire ideal for medical implants, minimizing rejection risks in the human body.

- Corrosion Resistance: Nitinol wire is highly resistant to rust and degradation, ensuring long-lasting performance in various environments.

- Fatigue Endurance: Nitinol wire can withstand repeated bending and flexing without failure, making it reliable for applications requiring constant movement.

- Shape Memory: Perhaps its most fascinating feature, nitinol wire can be deformed at a specific temperature and then "remember" its original shape when heated again. This property allows for innovative applications in medical devices and actuators.

Nitinol wire's unique strength, flexibility, and shape memory makes it a versatile material with vast potential across various industries.

Exploring the Market for Nitinol Wire

The market for nitinol wire is diverse, with suppliers catering to industries such as aerospace, automotive, healthcare, and consumer electronics. As the demand for nitinol wire grows, businesses have many options when sourcing this specialized material.

With the increasing demand for nitinol wire in various industries, suppliers have been innovating to offer businesses a wide range of options. Companies can now choose from different types of nitinol, from shape memory alloys to superelastic nitinol wire, based on their specific needs and applications. This diversity in product offerings allows businesses to find the most suitable nitinol wire for their projects, whether creating medical devices or developing advanced aerospace technologies.

Types of Nitinol Memory Wire Suppliers

When sourcing nitinol memory wire, finding the right supplier for your specific needs is crucial. Whether you're looking for a reliable industry leader or a more specialized manufacturer, understanding the different types of nitinol wire suppliers is essential for making an informed decision.

GEE SMA: The Leader in Nitinol Shape Memory Alloys

GEE SMA is a top choice for nitinol memory wire due to its extensive experience and expertise in shape memory alloys. With a strong focus on research and development, GEE SMA offers cutting-edge solutions and high-quality products that meet the most demanding requirements of various industries.

Nitinol Wire Manufacturers: Finding the Right Fit

For businesses with specific customization needs or unique project requirements, working directly with nitinol wire manufacturers can provide tailored solutions and personalized services. This approach allows for greater flexibility and control over the manufacturing process, ensuring your specifications are met.

Nitinol Wire for Sale: Evaluating Quality and Price

When exploring nitinol wire for sale, it's essential to carefully evaluate both quality and price to ensure you're getting the best value for your investment. While cost is an important factor, prioritizing quality and reliability can ultimately lead to long-term savings by reducing potential issues or failures.

Memory Wire Material Options: Comparing Suppliers

Different suppliers may offer varying material options for nitinol memory wire, including different compositions, sizes, and shapes. Comparing these options across multiple suppliers can help you identify the best match for your application or project requirements.

How Much Does Nitinol Cost: Balancing Quality and Budget

Understanding how much nitinol costs is crucial for balancing quality with budget constraints. While higher-priced options may offer superior quality and performance, it's important to weigh these benefits against your available budget and overall project needs.

By carefully considering these different types of nitinol memory wire suppliers and their respective offerings, businesses can make informed decisions that align with their specific needs while securing high-quality components at competitive prices.

Factors to Consider When Choosing a Supplier

Quality Standards and Certifications

When selecting nitinol memory wire suppliers, it's crucial to prioritize those with recognized quality standards and certifications. Look for suppliers that adhere to industry-specific standards such as ISO 9001 and AS9100, ensuring their products meet stringent quality requirements.

In addition to quality standards and certifications, it's important to consider the customization and tailoring services offered by nitinol memory wire suppliers. Look for suppliers that can customize their products to meet your specific needs and requirements. This could include custom sizes, shapes, or unique alloy compositions tailored to your application.

Customization and Tailoring Services

When buying nitinol wire, customization and tailoring services are essential factors to consider when choosing a supplier. Seek suppliers who can accommodate specific design requirements and offer tailored solutions to meet your unique needs, providing flexibility in material specifications and product dimensions.

Customer Support and Responsiveness

When evaluating nitinol wire manufacturers, it's important to assess their customer support and responsiveness levels. Opt for suppliers that prioritize clear communication, quick response times, and proactive problem-solving, ensuring a seamless experience from initial inquiries to post-purchase support.

Now, you comprehensively understand the factors to consider when choosing nitinol memory wire suppliers. From quality standards and customization services to customer support and responsiveness, these elements are crucial in securing high-quality nitinol wire components for your business needs.

Researching Nitinol Wire Suppliers

Online Marketplaces and Directories

When researching nitinol memory wire suppliers, online marketplaces and directories can be valuable resources. Websites like Alibaba and ThomasNet offer various nitinol wire options from various suppliers, allowing you to compare prices, specifications, and customer reviews in one place. Using these platforms, you can easily find reputable nitinol wire manufacturers that meet your needs.

In addition to providing a wide range of suppliers, online marketplaces and directories also offer the convenience of filtering options based on specific criteria such as minimum order quantity, shipping location, and certification. This makes finding nitinol wire manufacturers that can accommodate your production needs and logistical requirements is easier. With just a few clicks, you can narrow your options and focus on suppliers best suited for your business.

Industry Trade Shows and Conferences

Attending industry trade shows and conferences is another effective way to research nitinol wire suppliers. These events provide an opportunity to meet with different suppliers face-to-face, ask questions, and see samples of their products firsthand. Additionally, you can gain insights into the latest advancements in nitinol memory wire technology and build relationships with potential suppliers for future collaborations.

Furthermore, industry trade shows and conferences often feature seminars and workshops where experts in nitinol wire technology share their knowledge and insights. By attending these sessions, you can stay updated on the latest trends and developments in the industry, which can help you make informed decisions when choosing a nitinol wire supplier. Additionally, these events provide a platform for networking with other professionals in the field, allowing you to exchange ideas and best practices for working with nitinol wire.

Referrals and Recommendations

Seeking referrals and recommendations from industry peers or professional networks can also lead you to reliable nitinol memory wire suppliers. Word-of-mouth recommendations often provide valuable insights about a supplier's reliability, product quality, and customer service. By tapping into your network, you may uncover hidden gems in the form of trustworthy nitinol wire manufacturers that could perfectly fit your business needs.

Remember that when researching nitinol wire suppliers, utilizing online marketplaces, attending trade shows, and seeking referrals are all effective strategies for finding the right fit for your business needs.

Evaluating Supplier Capabilities

Material Testing and Quality Assurance

When evaluating nitinol memory wire suppliers, it's crucial to consider their material testing and quality assurance processes. Look for suppliers who conduct thorough testing to ensure the highest quality nitinol wire components. This includes testing for shape memory properties, superelasticity, and fatigue resistance to guarantee reliable application performance.

In addition to material testing and quality assurance, it's also essential to consider the production capacity and lead times of nitinol memory wire suppliers. Look for suppliers who can meet your demand for nitinol wire components within your required timeframe. A supplier with a robust production capacity and efficient lead times can help ensure you have a consistent supply of high-quality nitinol wire for your applications. This can be critical in maintaining the seamless operation of your products or projects.

Production Capacity and Lead Times

Another important factor to consider when choosing a nitinol wire supplier is their production capacity and lead times. You'll want a supplier capable of meeting your demand for nitinol wire components while adhering to your project timelines. Assess their manufacturing capabilities and inquire about their lead times for custom orders.

Case Studies and Customer Testimonials

Reviewing case studies and customer testimonials can provide valuable insight into a supplier's track record of delivering high-quality nitinol memory wire components. Seek out case studies that highlight successful applications of nitinol wire in various industries and customer testimonials that speak to the reliability and performance of the supplier's products.

When evaluating potential nitinol memory wire suppliers, consider their material testing and quality assurance procedures, production capacity, lead times, case studies, and customer testimonials to make an informed decision for your business needs.

Find Reliable Nitinol Memory Wire Suppliers

When finding reliable nitinol memory wire suppliers, it's essential to consider factors such as quality standards, customization options, and customer support. By making informed decisions for your business and securing high-quality nitinol wire components, you can ensure the success of your projects and operations.

Researching and evaluating nitinol wire manufacturers is crucial in finding a reliable supplier. Look for companies with a strong track record in producing high-quality nitinol wire for sale, backed by certifications and positive customer testimonials.

When researching and evaluating nitinol wire manufacturers, consider their production capacity and ability to meet your specific needs. Look for suppliers who can offer custom solutions and have the flexibility to accommodate your unique requirements. This will ensure you can rely on them for consistent supply and tailored products that align with your business goals.

Making Informed Decisions for Your Business

Understanding how much nitinol costs and comparing different memory wire material options will empower you to make informed decisions for your business. Consider quality and budget when choosing a supplier that meets your needs. It's essential to thoroughly research different suppliers and their track record of delivering high-quality nitinol wire components. Additionally, don't forget to factor in the supplier's customer service and lead times, as these can greatly impact your business operations. By considering all these aspects, you can ensure that you make the best choice for your business.

Securing High-Quality Nitinol Wire Components

By conducting thorough research and requesting samples from potential suppliers, you can gain valuable insight into the quality and consistency of their nitinol wire components. This hands-on approach will allow you to make informed decisions based on tangible evidence rather than relying solely on supplier claims. Additionally, engaging in open communication with suppliers regarding your specific project requirements will help to establish a clear understanding of expectations and ensure that the components delivered meet your exact specifications.

Remember to prioritize reliability and quality when selecting a nitinol memory wire supplier to achieve the best results for your business endeavors.