Introduction

Nitinol memory alloy is a remarkable material that has captured the imagination of scientists and engineers alike since its discovery in the 1960s. This unique alloy, composed primarily of nickel and titanium, exhibits extraordinary properties such as shape memory and superelasticity, making it a game-changer in various industries. As we delve into the world of Nitinol, we'll explore its composition, applications, and the fascinating science behind this innovative material.

Discovering Nitinol Memory Alloy

The journey of nitinol memory alloy began with a serendipitous discovery at the Naval Ordnance Laboratory in Maryland. Researchers were investigating nickel-titanium alloys when they stumbled upon an unexpected behavior: the ability to return to a predetermined shape after deformation when heated. This groundbreaking revelation opened up new avenues for research and development, leading to an array of applications that utilize the unique properties of nitinol.

Applications of Nitinol in Modern Industry

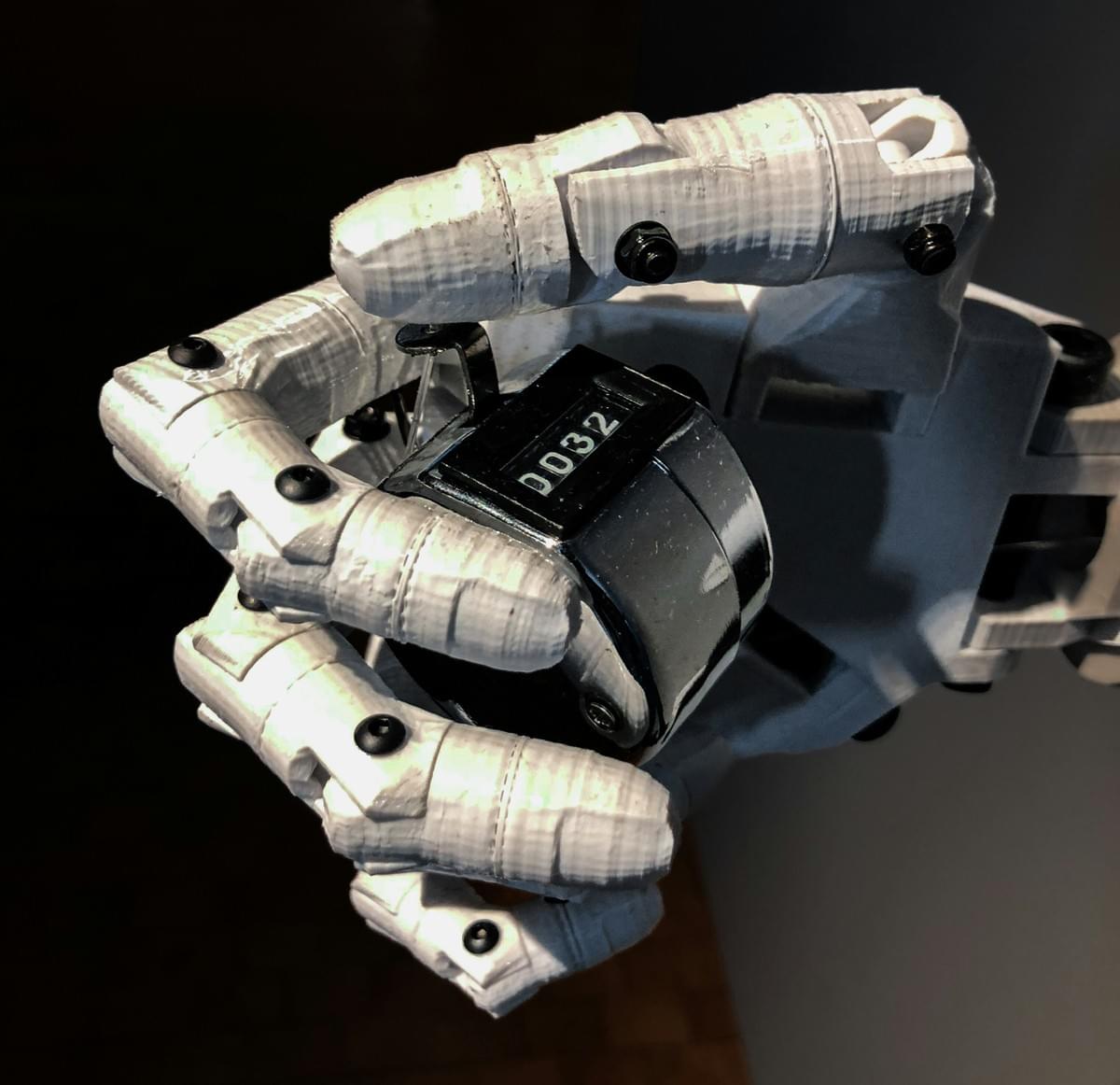

Today, nitinol memory alloy is employed across diverse fields such as medical devices, robotics, and aerospace engineering. In medicine, it is commonly used for stents and guidewires due to its biocompatibility and flexibility. Meanwhile, industries like robotics benefit from nitinol's ability to actuate movements without bulky motors or complex mechanisms—proving that this alloy isn't just a scientific curiosity but a practical solution for modern challenges.

The Science Behind Nitinol

At its core, understanding what nitinol alloy is made of involves exploring its unique crystalline structure that allows for shape memory effects. When heated above a specific temperature known as the transformation temperature, nitinol can revert to its original form after being deformed—a phenomenon that has intrigued researchers for decades. This scientific marvel not only highlights why nitinol is so expensive due to its intricate manufacturing process but also raises questions about whether it is stronger than titanium or presents certain limitations in application.

What is Nitinol Alloy Made Of?

Nitinol, a fascinating memory alloy, is primarily composed of nickel and titanium. This unique combination grants it remarkable properties that set it apart from traditional metals. But what exactly is Nitinol alloy made of? Let’s dive into the details.

Composition of Nitinol

The typical composition of Nitinol consists of approximately 55% nickel and 45% titanium, although variations can occur based on specific applications. This precise ratio is crucial because it determines the alloy's phase transformation temperatures, which are essential for its shape memory and superelastic properties. By adjusting the composition slightly, manufacturers can tailor the material to meet various engineering requirements, making Nitinol a versatile choice in many industries.

Unique Properties of Nitinol

Nitinol memory alloy boasts several unique properties that make it highly sought after in modern applications. Its most prominent features include shape memory effect and superelasticity, allowing it to return to its original shape after deformation when heated above a certain temperature. Additionally, Nitinol exhibits excellent corrosion resistance and biocompatibility, further enhancing its appeal in medical devices and other critical sectors.

Role of Nickel and Titanium

Nickel and titanium play pivotal roles in determining the characteristics of Nitinol memory alloy. Titanium contributes strength and lightweight properties while also enhancing corrosion resistance; nickel adds ductility and improves thermal stability during transformations between phases. Together, these elements create an alloy that not only performs well under stress but also stands up to harsh environments—making you wonder why is Nitinol so expensive? The answer lies in its complex manufacturing process as well as its unique attributes.

Why is Nitinol So Expensive?

Manufacturing Challenges

The production of nitinol memory alloy is no walk in the park; it involves intricate processes that require precision and expertise. To create this remarkable material, manufacturers must carefully control temperature and composition during the alloying process of nickel and titanium. These stringent requirements lead to higher production costs compared to more conventional alloys, which can be produced with less oversight.

Additionally, achieving the desired properties of nitinol—such as shape memory and superelasticity—demands specialized techniques like heat treatment and cold working. This level of sophistication ensures that only a limited number of facilities possess the capability to produce high-quality nitinol memory alloy consistently. Consequently, these manufacturing challenges not only raise costs but also limit supply.

Market Demand for Nitinol

The demand for nitinol memory alloy has surged across various industries due to its unique properties and applications ranging from medical devices to robotics. As industries seek innovative solutions that leverage these characteristics, manufacturers find themselves in a position where they can charge a premium price for their products. The increasing reliance on nitinol in critical applications amplifies its market value.

Moreover, as technology advances and new applications emerge—such as self-expanding stents or actuators—the appetite for this versatile material continues to grow. This heightened interest further drives up prices as companies scramble to secure their share of an increasingly competitive market landscape focused on high-performance materials like nitinol memory alloy.

Comparison with Other Alloys

When comparing nitinol with other alloys such as stainless steel or aluminum, it's clear why it commands a higher price point. While traditional alloys may offer certain benefits like lower cost or ease of fabrication, they often lack the extraordinary properties that make nitinol stand out—namely its shape-memory effect and superelasticity under stress conditions.

For instance, while titanium itself is known for strength (prompting questions like Is Nitnol stronger than titanium?), it doesn't exhibit the same unique behavior under temperature changes or deformation scenarios that make nitinol so desirable in specific applications. Thus, while you might pay less upfront for alternatives, you might end up sacrificing performance or longevity in critical uses—a trade-off many industries are unwilling to make.

Is Nitinol Stronger than Titanium?

When it comes to comparing materials, strength is often the first metric that springs to mind. In the world of alloys, titanium has long been celebrated for its impressive strength-to-weight ratio. However, when you delve into the properties of nitinol memory alloy, you'll discover that it offers unique advantages that can challenge traditional notions of strength.

Strength Comparison with Titanium

Nitinol memory alloy is not necessarily stronger than titanium in terms of tensile strength; however, its unique properties set it apart in various applications. While titanium boasts a higher ultimate tensile strength, nitinol excels in its ability to return to a predetermined shape after deformation due to its shape memory effect. This means that in situations where flexibility and resilience are required, nitinol can outperform titanium by absorbing stress and returning to its original form without permanent damage.

Advantages of Nitinol

One of the standout advantages of nitinol memory alloy is its remarkable ability to undergo significant deformation while still maintaining functionality. This property makes it ideal for applications such as medical devices and actuators where both flexibility and reliability are crucial. Additionally, nitinol's corrosion resistance outshines many metals including titanium, making it a preferred choice for long-term use in challenging environments.

Specific Uses for Nitinol

Nitinol's unique characteristics have led to innovative uses across various industries. In medicine, it's commonly found in stents and guidewires due to its ability to conform within the human body while retaining structural integrity once deployed. Beyond healthcare, nitinol memory alloy is also utilized in robotics and aerospace applications where lightweight yet durable materials are essential for performance and efficiency.

What are the Problems with Nitinol?

While the fascinating properties of Nitinol memory alloy have captured the attention of various industries, it is not without its challenges. Understanding these problems is crucial for potential applications and innovations involving this unique material. Let's delve into some of the key issues surrounding Nitinol.

Limitations in Application

One of the most significant limitations in applying Nitinol memory alloy lies in its operational temperature range. If temperatures exceed or fall below specific thresholds, the alloy may not exhibit its shape-memory effect, rendering it ineffective for certain applications. Additionally, while Nitinol is known for its flexibility and strength, it may not be suitable for high-load-bearing situations compared to traditional metals like titanium.

Another limitation is related to manufacturing processes; producing components from Nitinol can be complex and requires specialized techniques that not all manufacturers possess. This complexity can restrict its use in mass production scenarios where cost-efficiency and speed are paramount. Furthermore, some environments may cause degradation over time due to corrosion or wear, limiting long-term applications.

Cost vs. Benefit Analysis

When evaluating why Nitinol is so expensive, it's essential to consider both its advantages and drawbacks through a cost-benefit lens. The high costs associated with producing nitinol memory alloy often make it prohibitive for many industries when cheaper alternatives exist. While the benefits—such as flexibility and unique thermal properties—are appealing, businesses must weigh these against potential financial constraints.

Moreover, while some sectors like medical devices find immense value in using Nitinol due to its biocompatibility and functionality, other industries may struggle to justify the investment when cheaper materials could suffice for their needs. The decision to utilize this advanced material often hinges on whether the benefits truly outweigh the costs involved in sourcing and processing nitinol memory alloy components.

Potential Failure Modes

Despite its impressive attributes, nitinol memory alloy can experience failure modes that pose risks during operation or application. One primary concern involves fatigue failure; repeated cycles of deformation can lead to cracks or fractures over time if not properly managed or designed within specified limits. This issue necessitates careful engineering considerations when creating devices intended for repetitive stress environments.

Additionally, unexpected phase transformations can occur under certain conditions that might compromise performance—this unpredictability adds an element of risk that engineers must account for during design phases involving nitinol alloys. Lastly, manufacturing defects such as inclusions or improper heat treatment could lead to catastrophic failures in critical applications where reliability is paramount.

The Role of GEE SMA in Innovation

In the ever-evolving landscape of materials science, GEE SMA (Smart Materials and Applications) has emerged as a pivotal player in the development and application of nitinol memory alloy. This innovative company focuses on harnessing the unique properties of nitinol to create advanced solutions across various industries. By integrating cutting-edge technology with the remarkable capabilities of nitinol, GEE SMA is setting new standards for performance and efficiency.

Overview of GEE SMA

GEE SMA specializes in smart materials that adapt to environmental changes, with a strong emphasis on nitinol memory alloy. Their expertise lies in understanding what Nitinol alloy is made of—primarily nickel and titanium—and how these elements interact to produce shape memory effects and superelasticity. This knowledge allows them to innovate beyond traditional applications, exploring new frontiers for nitinol in fields like aerospace, medical devices, and robotics.

Contributions to Nitinol Technology

GEE SMA's contributions to nitinol technology are significant and multifaceted. They have developed proprietary manufacturing processes that address some common concerns about why nitinol is so expensive, such as production efficiency and material waste reduction. Furthermore, their research into enhancing the strength and durability of nitinol memory alloy has led to advancements that challenge traditional perceptions about whether nitinol is stronger than titanium in specific applications.

Future of Nitinol Memory Alloys

Looking ahead, the future of nitinol memory alloys appears promising thanks to innovative initiatives from companies like GEE SMA. The potential for new applications continues to expand as they tackle existing problems with nitinol—such as limitations in application due to cost or mechanical properties—through ongoing research and development efforts. As these innovations unfold, we can expect an increased adoption of nitinol across diverse sectors, driving both technological advancement and economic growth.

Conclusion

The journey through the fascinating world of nitinol memory alloy reveals its transformative potential in various industries. From medical devices to robotics, the unique properties of nitinol are reshaping how we approach design and functionality. As we conclude, it’s clear that understanding nitinol is not just about its composition and cost; it's about recognizing its role in innovation.

Applications Transforming Industries

Nitinol memory alloy has found a niche in numerous applications, particularly in the medical field where its superelasticity and biocompatibility are game-changers. Think of stents expanding within arteries or guidewires navigating complex paths; these innovations owe much to what is Nitinol alloy made of? The versatility of this material extends beyond healthcare into aerospace and automotive sectors, showcasing its ability to enhance performance while reducing weight.

Understanding Nitinol's Cost Factors

Why is nitinol so expensive? The answer lies in both its intricate manufacturing process and the high demand across various markets. With specialized production techniques required to maintain its unique properties, nitinol's price tag can be daunting compared to traditional alloys. However, when considering long-term benefits and efficiencies gained from using this remarkable material, many industries find it a worthy investment.

Insights into Nitinol's Strength and Limitations

When pondering whether nitinol is stronger than titanium, it's essential to look at context rather than just raw numbers. While titanium boasts impressive strength-to-weight ratios, nitinol excels through flexibility and adaptability under stress—qualities that are invaluable in specific applications. Nevertheless, what are the problems with nitinol? Limitations such as fatigue resistance and potential failure modes must be carefully considered when integrating this alloy into critical systems.