Introduction

Welcome to the fascinating world of Nitinol shape memory alloys. This revolutionary material has a rich history dating back to the 1960s when researchers at the Naval Ordnance Laboratory first discovered it. Nitinol's remarkable properties, including its ability to remember its original shape and return to it when heated, have made it a game-changer in modern engineering. Nitinol has found diverse applications across various industries, from biomedical devices to aerospace components.

The History of Nitinol Shape Memory Alloys

The discovery of Nitinol, a unique shape memory metal, marked a significant milestone in materials science. Its name is derived from its composition—a combination of nickel (Ni), titanium (Ti), and the Naval Ordnance Laboratory (NOL), where it was first developed. Initially created for missile components, this shape memory alloy gained attention for its extraordinary ability to return to a predetermined shape after being deformed at low temperatures.

The Remarkable Properties of Nitinol

Nitinol, a nickel-titanium alloy, is known for its remarkable shape memory effect. This unique property allows the material to "remember" its original form and return to it upon reaching a specific temperature. Here's what makes Nitinol so valuable:

- Shape Memory Effect: Nitinol retains its new shape when deformed at a low temperature. However, upon heating to a specific temperature (often around human body temperature, 37°C), it reverts to its original form with impressive accuracy.

- Precise and Controlled Movements: This temperature-induced transformation makes Nitinol ideal for applications requiring controlled movements. For instance, Nitinol stents used in minimally invasive surgeries can be compressed for insertion and then expand inside the body to their original shape, providing crucial support.

- Unparalleled Flexibility and Reliability: Nitinol exhibits exceptional elasticity and can withstand repeated cycles of deformation and recovery without losing its properties. This makes it highly reliable for demanding applications in various fields, including aerospace engineering,, where actuators must function flawlessly under extreme conditions.

Nitinol's unique combination of shape memory, precise movement, and lasting elasticity positions it as a revolutionary material with vast potential across various industries.

Applications of Nitinol in Modern Engineering

Nitinol shape memory alloys, known for their remarkable ability to "remember" their original shape, have revolutionized various engineering fields. Here's a closer look at their impact:

- Biomedical Engineering: Nitinol's biocompatibility and superelasticity make it ideal for medical devices. Stents and guidewires crafted from nitinol can easily and precisely navigate through delicate blood vessels.

- Aerospace Engineering: Nitinol's shape memory and superelastic properties are valuable in aerospace applications like actuators, enabling precise control and movement in demanding environments.

- Consumer Electronics: Even everyday devices benefit from nitinol. Its unique properties find applications in various consumer electronics.

Nitinol's potential extends far beyond these examples. By understanding the science behind its properties and through continuous innovation by companies like GEE SMA, nitinol alloys are poised to shape the future of engineering across various disciplines.

Understanding Nitinol Shape Memory Alloys

Nitinol shape memory alloys are a fascinating material class that exhibits the remarkable ability to remember their original shape and return to it when heated. This unique property is due to nitinol's crystal structure, which allows it to undergo a reversible phase transformation at specific temperatures. Nitinol's shape memory effect is particularly pronounced at 37 degrees Celsius, making it an ideal material for biomedical applications such as stents and orthodontic wires.

Nitinol's thermal properties are truly exceptional. Its shape-setting temperature can be precisely controlled during the manufacturing process, allowing engineers to program specific shapes into nitinol components, which will then return to these shapes when subjected to the appropriate thermal stimulus. Additionally, nitinol exhibits superelasticity, enabling it to recover large strains without permanent deformation. These unique characteristics make nitinol an invaluable material in various engineering fields.

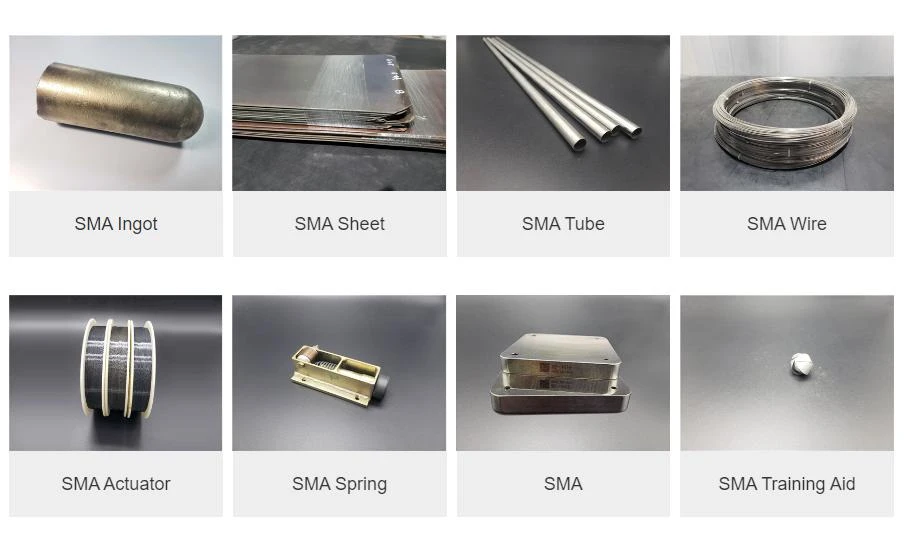

GEE SMA has established itself as a leader in crafting high-quality nitinol alloys for various applications. With extensive expertise in metallurgy and materials science, GEE SMA leverages cutting-edge techniques to develop customized nitinol solutions tailored to meet the specific needs of its clients. Whether it's medical devices, aerospace actuators, or consumer electronics, GEE SMA's precision-engineered nitinol alloys are setting new standards in the industry.

Nitinol's unique properties make it an ideal material for use in biomedical engineering. Its shape memory and superelasticity characteristics allow for the creation of innovative medical devices such as stents, guidewires, and orthodontic wires that can adapt to the body's natural movements. GEE SMA's expertise in developing customized nitinol solutions has been instrumental in advancing medical technology and providing healthcare professionals with reliable and effective tools for patient care. As the demand for minimally invasive procedures continues to grow, nitinol alloys are poised to play an increasingly important role in shaping the future of biomedical engineering.

Nitinol's Role in Biomedical Engineering

Nitinol shape memory alloys have revolutionized the field of biomedical engineering, offering unparalleled flexibility and biocompatibility for medical devices. These alloys exhibit properties such as nitinol shape memory at 37 degrees, making them ideal for applications in minimally invasive surgical tools and stents. The ability of nitinol to return to its original shape after deformation allows for the creation of self-expanding stents that can be inserted through small incisions and then expand to their predetermined shape once inside the body.

Nitinol's Contributions to Medical Devices

Nitinol shape memory alloys have significantly advanced the field of medical devices, enabling the development of innovative products that improve patient outcomes and quality of life. From orthodontic wires that exert gentle force on teeth to vascular filters that can be collapsed for insertion and then expanded upon deployment, nitinol has proven invaluable in various medical applications. Its unique combination of flexibility, durability, and biocompatibility has made it an indispensable material in the design of cutting-edge medical devices.

Nitinol's unique properties have also revolutionized minimally invasive surgery, allowing for the development of advanced tools and devices that can navigate through small incisions with precision and ease. For example, nitinol guidewires navigate blood vessels and other anatomical structures during procedures such as angioplasty and stent placement. The flexibility and shape memory of nitinol allows these guidewires to bend and navigate tortuous paths without kinking or breaking, providing physicians with the control they need to perform delicate procedures safely and effectively.

GEE SMA's Innovations in Biomedical Nitinol Materials

GEE SMA has been at the forefront of developing groundbreaking biomedical nitinol materials that push the boundaries of what is possible in medical device design. By leveraging their expertise in crafting nitinol alloys with precise thermal properties, GEE SMA has enabled the creation of next-generation implants and instruments that offer superior performance and reliability. Their commitment to advancing biomedical nitinol materials continues to drive innovation in the healthcare industry, paving the way for breakthroughs in patient care.

Furthermore, GEE SMA's innovations in biomedical nitinol materials have significantly impacted aerospace engineering. The unique properties of nitinol, such as its shape memory and superelasticity, make it an ideal material for aerospace applications. By developing nitinol alloys with enhanced strength and durability, GEE SMA has enabled the creation of lightweight components that contribute to improved fuel efficiency and overall performance of aircraft and spacecraft. As a result, the aerospace industry has benefited from the advancements made in biomedical nitinol materials, further demonstrating the versatility and potential of this innovative alloy.

Nitinol's Impact on Aerospace Engineering

Nitinol shape memory alloys have revolutionized the aerospace industry, offering lightweight, durable solutions for critical components. With its unique ability to return to a predetermined shape after deformation, nitinol is used in aerospace actuators and components, providing reliability and precision in extreme conditions.

Nitinol's Use in Aerospace Actuators and Components

Nitinol, a nickel-titanium alloy, stands out in the aerospace industry due to its remarkable properties. Here's how nitinol shape memory alloy benefits aerospace applications:

- Precise Movement: Nitinol's defining characteristic is its ability to "remember" its original shape when heated. This makes it ideal for applications requiring exact movements, such as those in aircraft wings and control surfaces.

- Lightweight Design: In aerospace, every pound counts. Nitinol boasts an impressive strength-to-weight ratio, enabling the creation of lightweight yet strong components. This translates to a lighter overall aircraft weight and improved fuel efficiency.

- Resilience in Extreme Environments: Nitinol can withstand harsh space conditions without compromising its shape or functionality. This exceptional tolerance for extreme temperatures makes it a reliable choice for various aerospace applications.

Nitinol's unique combination of shape memory, lightweight design, and extreme temperature resilience makes it a valuable material for the aerospace industry.

GEE SMA's Customized Nitinol Solutions for Aerospace Applications

GEE SMA specializes in crafting customized nitinol solutions for aerospace applications, ensuring that the unique requirements of the aerospace industry are met with precision and expertise. By leveraging their deep understanding of nitinol shape memory alloys, GEE SMA delivers tailored solutions that enhance the performance and reliability of aerospace systems.

GEE SMA's expertise in crafting customized nitinol solutions for aerospace applications also extends to the consumer electronics industry. With a keen understanding of this sector's unique requirements, GEE SMA leverages its knowledge of nitinol shape memory alloys to develop tailored solutions that enhance the performance and reliability of electronic devices. Whether it's creating innovative components for smartphones, wearables, or other consumer gadgets, GEE SMA ensures that its nitinol solutions meet the high standards demanded by the consumer electronics market.

Nitinol in Consumer Electronics

Nitinol shape memory alloys are revolutionizing the world of consumer electronics with their potential in smart materials and wearable devices. These remarkable materials can remember their original shape and return to it when heated, making them perfect for applications in flexible electronics and shape-changing wearables. As a leader in nitinol technology, GEE SMA is at the forefront of advancing these innovative materials for use in consumer electronics.

Nitinol's Potential in Smart Materials and Wearable Devices

The unique properties of nitinol shape memory alloys make them ideal for smart materials and wearable devices. These materials can be programmed to change shape, stiffness, or even color in response to temperature changes, making them perfect for applications such as self-fitting eyeglass frames, adaptive clothing, and even smart jewelry that adjusts to the wearer's body temperature. The potential for nitinol in this field is limitless, with new applications being discovered daily.

GEE SMA's Role in Advancing Nitinol Technology for Consumer Electronics

GEE SMA is playing a crucial role in advancing nitinol technology for consumer electronics by developing customized solutions tailored to the specific needs of this industry. From flexible circuitry to responsive sensors, GEE SMA is working on pushing the boundaries of what nitinol can do in consumer electronics. With a team of experts dedicated to research and development, GEE SMA is committed to unlocking the full potential of nitinol shape memory alloys for use in smart materials and wearable devices.

The Future of Nitinol in Engineering

With the rapid advancements in materials science, emerging nitinol research and development trends are paving the way for innovative engineering solutions. Researchers are exploring new ways to enhance the properties of nitinol shape memory alloys, such as improving its shape setting temperature and thermal stability. These developments aim to expand the applications of nitinol in various industries, from healthcare to aerospace.

Emerging Trends in Nitinol Research and Development

The future of nitinol shape memory alloys lies in harnessing its full potential through cutting-edge research and development. Scientists are delving into novel methods to fine-tune the material's shape memory temperature, enabling it to adapt to a wider range of environmental conditions. This opens doors for creating more versatile and responsive nitinol-based devices that can revolutionize engineering across diverse sectors.

GEE SMA's Commitment to Advancing Nitinol Functional Materials

As a leader in shaping the future of engineering with nitinol, GEE SMA is dedicated to pushing the boundaries of what is possible with this remarkable shape memory metal. Through relentless innovation and collaboration with industry partners, GEE SMA is at the forefront of developing next-generation nitinol functional materials that offer unparalleled performance and reliability. With a focus on customization and precision engineering, GEE SMA continues to drive the evolution of nitinol technology.

Explore the Boundless Opportunities of Shape Memory Alloys

Nitinol shape memory alloys are revolutionizing the field of engineering with their remarkable properties and diverse applications. From biomedical devices to aerospace components, nitinol's shape memory at 37 degrees Celsius and its unique thermal properties make it a game-changer in material science. Collaborating with GEE SMA for customized nitinol solutions ensures access to cutting-edge technology that maximizes the potential of this shape memory metal.

Harnessing the Potential of Nitinol in Engineering

Nitinol shape memory alloys are revolutionizing the field of engineering with their unique properties. Here's how:

- Unmatched Shape Memory: Nitinol can be deformed and then return to its original shape upon exposure to heat. Unlike traditional materials, this remarkable ability allows for creating components that can adapt and self-correct.

- Exceptional Durability: Nitinol exhibits superior resilience and can withstand repeated deformations without permanent damage. This makes it ideal for demanding applications where reliability is crucial.

- Diverse Applications: From medical implants that adjust to body temperature to aerospace components that deploy in extreme conditions, nitinol's adaptability opens doors to innovative solutions across various industries.

Unlocking nitinol's full potential requires collaboration with experts like GEE SMA. Their expertise in crafting custom nitinol solutions empowers engineers to push the boundaries of design and functionality. With nitinol, the future of engineering is built on shape-shifting possibilities.

Collaborating with GEE SMA for Nitinol Solutions

Collaborating with GEE SMA opens doors to advanced nitinol technology that can elevate engineering projects to new heights. Whether it's developing custom biomedical materials or precision aerospace components, GEE SMA's expertise in shaping nitinol alloys ensures high-quality, reliable solutions that meet the most demanding engineering requirements. By partnering with them, engineers can access knowledge and resources to optimize their use of nitinol shape memory alloys.

As we look towards the future, exploring the boundless opportunities offered by shape memory alloys like nitinol is essential for driving innovation in engineering. These materials' versatility and adaptability open up new possibilities for smart materials, wearable devices, and other cutting-edge technologies that can enhance our daily lives. Embracing these opportunities means staying at the forefront of material science advancements and leveraging the expertise of leaders like GEE SMA to unlock the full potential of shape memory metals.