Introduction

In the world of automation and engineering, SMA linear actuators are carving out their niche with a unique blend of innovation and efficiency. These remarkable devices leverage the properties of Shape Memory Alloys (SMAs) to convert thermal energy into mechanical motion, opening up a realm of possibilities across various industries. Whether you're curious about what an SMA actuator is or how it stacks up against electric linear actuators, this introduction sets the stage for exploring the fascinating technology behind these actuators.

Understanding SMA Linear Actuators

SMA linear actuators represent a revolutionary approach to motion control, utilizing materials that remember their original shape when subjected to heat. This characteristic allows them to operate without complex motors or gears, making them both lightweight and compact. As we delve deeper into what an SMA actuator is, we’ll uncover how these devices can outperform traditional options like electric linear actuators in specific applications.

Unraveling Shape Memory Alloys

Shape Memory Alloys are materials that exhibit unique thermal properties; they can return to a predetermined shape when heated above a certain temperature threshold. Nitinol, a popular type of SMA, showcases impressive two-way functionality—meaning it can move in both directions depending on temperature changes. Understanding these alloys is crucial for grasping why SMA linear actuators are gaining traction in sectors ranging from robotics to medical devices.

Applications Across Industries

The versatility of SMA linear actuators extends far beyond simple applications; they’re making waves in diverse fields such as aerospace, automotive engineering, and healthcare technology. For instance, in robotics and automation, these shape memory actuators enable precise movements with minimal energy consumption—an invaluable trait for modern machinery. By examining practical applications and innovations driven by SMAs, we can better appreciate why they are becoming increasingly indispensable in today’s tech landscape.

What is an SMA Actuator?

SMA linear actuators are a fascinating intersection of materials science and engineering, leveraging the unique properties of shape memory alloys (SMAs) to create motion. But what exactly is an SMA actuator? It’s a device that converts thermal energy into mechanical work through the remarkable characteristics of SMAs, particularly Nitinol, which can change shape in response to temperature variations. This section delves into the science behind these innovative devices, how they operate, and why they stand out among various types of linear actuators.

The Science Behind SMA Technology

At the core of what is an SMA actuator lies the principle of shape memory effect. This phenomenon occurs when specific alloys—like Nitinol—can remember their original shapes after being deformed when heated above a certain temperature. When cooled, these materials revert to their pre-deformed state, creating movement that can be harnessed for various applications in robotics, medical devices, and beyond.

Nitinol linear actuators are particularly noteworthy due to their two-way functionality; they can expand and contract with changes in temperature. This ability allows them to perform tasks that traditional electric linear actuators might struggle with or require additional components to achieve. Thus, the science behind SMA technology not only demonstrates a clever use of materials but also opens doors for innovative designs in automation.

How Shape Memory Alloys Function

Understanding how shape memory alloys function is key to grasping what makes SMA linear actuators so special. When heat is applied to an SMA like Nitinol, it undergoes a phase transformation from its low-temperature martensite phase to its high-temperature austenite phase, resulting in significant movement or actuation. Conversely, cooling the material causes it to revert back and return to its original form.

This unique operational mechanism allows for precise control over motion without requiring complex electronic systems or bulky components often found in traditional options like electric or pneumatic linear actuators. Moreover, because SMAs can produce substantial force relative to their size and weight—making them ideal for applications where space is at a premium—they offer engineers exciting possibilities for design innovation.

Key Advantages Over Traditional Actuators

When comparing SMA linear actuators with traditional options like electric or hydraulic systems, several key advantages emerge that make them appealing across industries. One significant benefit is their compactness; these actuators take up less space while still delivering impressive performance levels—a crucial factor when designing intricate machinery or devices where every millimeter counts.

Another advantage lies in their simplicity and reliability; since they lack gears or motors typically required by electric linear actuators, there are fewer points of failure over time. Additionally, SMAs generally operate quietly and have minimal maintenance requirements compared to pneumatic systems that rely on compressed air sources—making them ideal candidates for sensitive environments such as medical facilities.

In summary, understanding what an SMA actuator entails reveals not just its functional capabilities but also highlights its potential impact across various sectors—from robotics innovations all the way through aerospace advancements!

Exploring Nitinol Linear Actuators

Characteristics of Nitinol Materials

Nitinol materials possess some fascinating characteristics that make them highly sought after in the world of actuators. One of the most intriguing features is their ability to exhibit two distinct phases: martensite and austenite. In the martensitic phase, Nitinol can be easily deformed at lower temperatures, while transitioning to the austenitic phase at higher temperatures allows it to regain its original shape—this property is what makes the SMA linear actuator so versatile.

Moreover, Nitinol's high strength-to-weight ratio adds another layer of appeal for applications where space and weight are critical factors. Unlike traditional actuators, which may require bulky components or extensive power supplies, Nitinol linear actuators can achieve significant force output in a compact form factor. This efficiency not only enhances design flexibility but also contributes to overall system performance.

Two-Way Functionality in Nitinol Actuators

What sets Nitinol linear actuators apart from other types is their impressive two-way functionality, which allows them to operate effectively in both directions without needing additional components or mechanisms. When heated above a certain threshold temperature, these Shape Memory Actuators contract; conversely, when cooled below that temperature, they expand back to their original state. This dual-action capability simplifies designs by eliminating the need for complex control systems often found in electric linear actuators.

This two-way functionality opens up exciting possibilities across various industries—from robotics where precise movements are crucial to medical devices requiring reliable actuation without bulky motors or batteries. The ability for these actuators to perform both pulling and pushing tasks efficiently makes them particularly appealing for automation solutions where space constraints are common.

Real-World Examples of Nitinol Usage

The versatility of Nitinol linear actuators has led to their adoption in numerous real-world applications that showcase their unique advantages over traditional options like electric or hydraulic systems. For instance, they have been utilized in minimally invasive surgical tools where precise movements are essential yet must be achieved with minimal invasiveness—eliminating the need for larger electric linear actuators that could complicate procedures.

In aerospace engineering, engineers have integrated SMA technology into control surfaces on aircraft wings—allowing adjustments based on aerodynamic conditions without adding significant weight or complexity compared to conventional methods. Furthermore, automotive manufacturers have begun exploring how these Shape Memory Actuators can improve seat adjustments and safety mechanisms while enhancing passenger comfort.

What are the 4 Types of Linear Actuators?

Linear actuators come in various forms, each tailored to specific applications and environments. Understanding the four primary types—electric, pneumatic, hydraulic, and SMA linear actuators—can help you determine which actuator best suits your needs. Among these options, Shape Memory Actuators have carved a niche for themselves due to their unique properties.

Overview of Linear Actuator Types

The four main types of linear actuators include electric, pneumatic, hydraulic, and SMA linear actuators. Electric linear actuators utilize electrical energy to produce motion and are known for their precision and control. Pneumatic actuators harness compressed air for movement, while hydraulic versions rely on liquid pressure; both offer high force output but can be less precise than electric options.

SMA linear actuators stand out due to their use of shape memory alloys like Nitinol. These materials can change shape in response to temperature variations, enabling compact designs with significant force output in a small footprint. The diverse functionalities across these actuator types cater to different industrial needs—from robotics to automotive applications.

Comparing Electric, Pneumatic, and Hydraulic Options

When comparing electric linear actuators with pneumatic and hydraulic alternatives, several factors come into play: efficiency, cost-effectiveness, and maintenance requirements. Electric linear actuators are typically more efficient and easier to control compared to their pneumatic counterparts that require a steady supply of compressed air. Hydraulic systems excel in heavy-duty applications but often demand more maintenance due to fluid leaks or pressure issues.

SMA linear actuators provide an appealing middle ground with their compactness and versatility while maintaining low power consumption. While electric options might be pricier upfront due to components like motors and controllers, SMA technology offers long-term savings thanks to its durability and minimal upkeep requirements. In contrast, pneumatic systems can incur ongoing costs related to air supply management.

Advantages of SMA Linear Actuators Over Others

SMA linear actuators boast several advantages that set them apart from traditional actuator types like electric or hydraulic models. One key benefit is their ability to operate without complex electronics or bulky components; this simplicity leads not only to weight savings but also reduced failure points over time—a crucial factor when considering why are linear actuators so expensive?

Additionally, Shape Memory Actuators can achieve two-way functionality using Nitinol materials effectively; they contract when heated and return when cooled without requiring external power sources during retraction phases—making them energy-efficient champions! Their compact design allows them to fit into tight spaces where larger electric or hydraulic systems might struggle.

In summary, while there’s no one-size-fits-all solution among the four types of linear actuators available today—be it an electric linear actuator or an SMA option—the unique characteristics of SMA technology may provide the edge needed for innovative applications across various industries.

Why are Linear Actuators So Expensive?

When diving into the world of linear actuators, one question often arises: why are linear actuators so expensive? The answer lies in a combination of advanced technology, material costs, and the intricate engineering that goes into creating devices like the SMA linear actuator. Understanding these factors can help clarify why investing in these components is often seen as a significant financial commitment.

Cost Breakdown of Linear Actuators

The cost of linear actuators varies widely based on type and application. For instance, electric linear actuators typically range from affordable to premium prices depending on their specifications and capabilities. When considering what is an SMA actuator?, it's essential to note that the integration of sophisticated control systems and precision manufacturing adds to their overall expense.

Moreover, the inclusion of specialized components such as sensors and feedback mechanisms further inflates costs. In contrast, traditional options may be less costly upfront but could lack the efficiency and longevity found in advanced models like Shape Memory Actuators. Thus, while you might pay more for an SMA linear actuator initially, it’s crucial to weigh that against potential savings in maintenance and operational efficiency over time.

The Role of Advanced Materials Like Nitinol

One significant factor contributing to the high price tag of certain linear actuators is the use of advanced materials such as Nitinol. This unique alloy not only provides remarkable flexibility but also has a two-way functionality that enhances its usability across various applications. As we explore what are the 4 types of linear actuators?, it becomes clear that those incorporating Nitinol offer superior performance characteristics compared to standard options.

Nitinol's ability to return to its original shape after deformation makes it ideal for applications requiring durability and reliability—qualities not easily achieved with conventional materials. However, this cutting-edge technology does come at a cost; producing Nitinol requires specialized processes and precise engineering techniques that drive up expenses significantly. Therefore, while you’re getting top-tier performance with a Nitinol linear actuator (2 way), be prepared for a corresponding investment.

Long-Term Value vs. Initial Investment

When pondering why are linear actuators so expensive?, it's essential to consider long-term value versus initial investment costs. While cheaper alternatives may seem appealing at first glance, they often lack longevity or require more frequent replacements—ultimately costing more over time than purchasing a high-quality SMA linear actuator upfront. In industries where reliability is paramount—such as robotics or aerospace—the initial expenditure can quickly justify itself through reduced downtime and enhanced productivity.

Furthermore, investing in an SMA actuator means you're acquiring cutting-edge technology designed for efficiency and effectiveness in demanding environments; this translates into savings on energy consumption as well as maintenance costs down the line. So when evaluating your options among what is an electric linear actuator? or other types available on the market today, remember that sometimes spending more initially can lead to greater returns later on.

Practical Applications of SMA Linear Actuators

SMA linear actuators are revolutionizing various industries by providing innovative solutions that traditional actuators simply can't match. With their unique properties, these Shape Memory Actuators offer flexibility and efficiency in applications ranging from robotics to healthcare. Let’s explore how SMA technology is making waves across different sectors.

Innovations in Robotics and Automation

In the realm of robotics and automation, the advantages of SMA linear actuators are becoming increasingly evident. These devices can mimic natural movements with precision, making them ideal for robotic joints and grippers. Their lightweight nature and compact design allow for more agile robots capable of performing complex tasks in confined spaces, which is a game-changer for industries reliant on automation.

Moreover, the two-way functionality of Nitinol linear actuators enhances robotic capabilities by enabling bidirectional movement without additional components. This feature simplifies designs while reducing weight—critical factors when developing efficient robotic systems. As we continue to push the boundaries in robotics, SMA technology stands out as a key player driving innovation forward.

Medical Devices Utilizing SMA Technology

The medical field is another area where SMA linear actuators shine brightly. From minimally invasive surgical tools to advanced prosthetics, these Shape Memory Actuators provide unparalleled performance and reliability. Their ability to contract and expand with temperature changes allows for precise control over medical devices, improving patient outcomes significantly.

For instance, Nitinol's unique properties make it an excellent choice for stents that adapt to body temperatures or surgical instruments that require quick adjustments during procedures. With their compact size and lightweight design, SMA linear actuators enable the development of portable medical devices that can be easily maneuvered in tight environments. As medical technology continues to advance, the role of SMA technology will undoubtedly expand further.

Aerospace and Automotive Advancements

In aerospace and automotive sectors, the use of SMA linear actuators is paving the way for smarter designs and improved functionality. These Shape Memory Actuators are employed in applications such as wing flaps or adjustable seating systems due to their high strength-to-weight ratio compared to traditional options like electric or hydraulic linear actuators. This not only enhances performance but also contributes to fuel efficiency—an essential factor in today's eco-conscious world.

Additionally, Nitinol's two-way actuation capability means that components can be both controlled and reset without complicated mechanisms or excess weight—a boon for engineers looking to optimize space within aircraft or vehicles. The versatility offered by these innovative materials makes them a preferred choice among manufacturers aiming for cutting-edge advancements while keeping costs manageable despite initial investments associated with advanced materials like Nitinol.

Conclusion

In summary, SMA linear actuators represent a significant advancement in actuator technology, offering unique benefits that traditional systems cannot match. As industries continue to evolve, the demand for innovative solutions like Shape Memory Actuators will only increase. By harnessing the remarkable properties of materials such as Nitinol, we can expect to see even more groundbreaking applications in various fields.

The Future of SMA Linear Actuators

The future of SMA linear actuators looks promising as research and development push the boundaries of what's possible with Shape Memory Alloys. Innovations in material science are likely to enhance the performance and reliability of these devices, making them even more attractive for applications across sectors. With their ability to be compact and efficient, SMA actuators could redefine standards in robotics, aerospace, and medical devices.

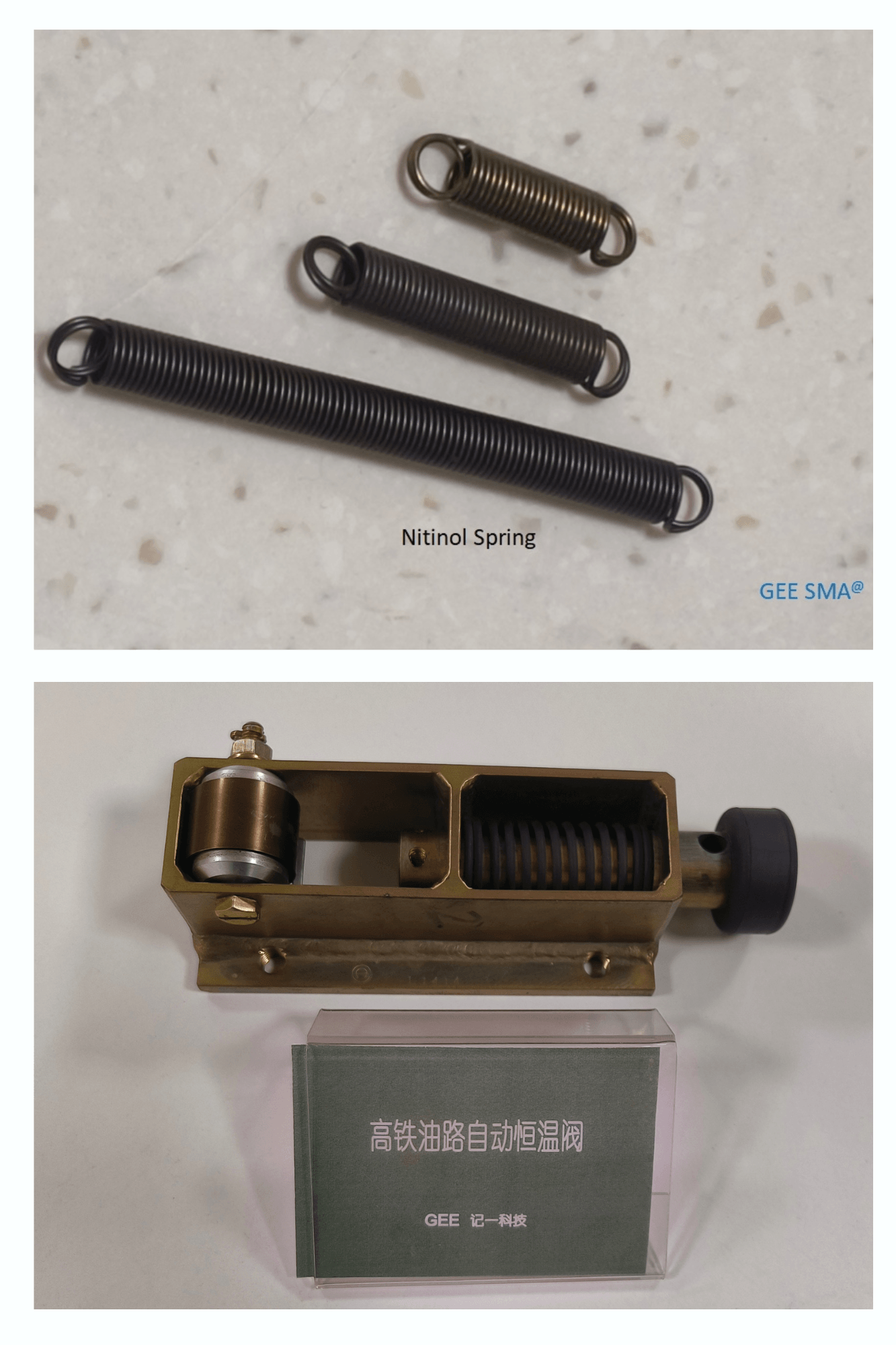

GEE SMA and Its Contributions

GEE SMA has been at the forefront of developing cutting-edge technologies around SMA linear actuators. Their commitment to advancing Shape Memory Actuator technology has led to numerous breakthroughs that benefit industries ranging from healthcare to automotive engineering. By focusing on quality and innovation, GEE SMA continues to pave the way for future advancements in this exciting field.

Choosing the Right Actuator for Your Needs

When it comes to choosing between different types of linear actuators—whether it's an electric linear actuator or a Nitinol linear actuator (2 way)—understanding your specific application is key. Factors such as cost, efficiency, and functionality should guide your decision-making process; after all, not every project requires a high-end solution like an SMA linear actuator! Ultimately, weighing these considerations will help you select the right actuator that meets both your technical requirements and budget constraints.