Introduction

In the world of advanced materials, Nitinol stands out as a unique alloy with remarkable properties, including shape memory and superelasticity. This versatility makes it a popular choice in various industries, particularly in medical manufacturing where precision and reliability are paramount. Understanding Nitinol and its uses lays the foundation for selecting the right nitinol supplier who can meet specific project requirements.

Understanding Nitinol and Its Uses

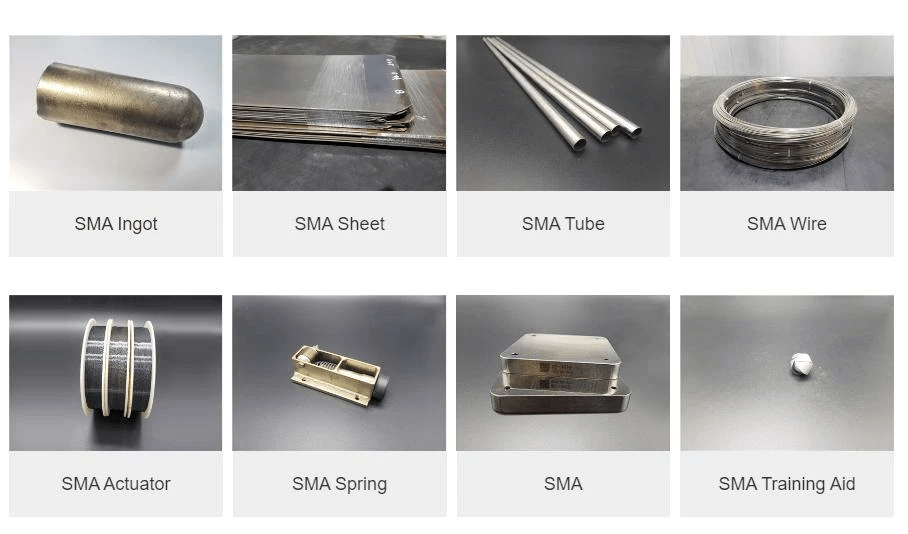

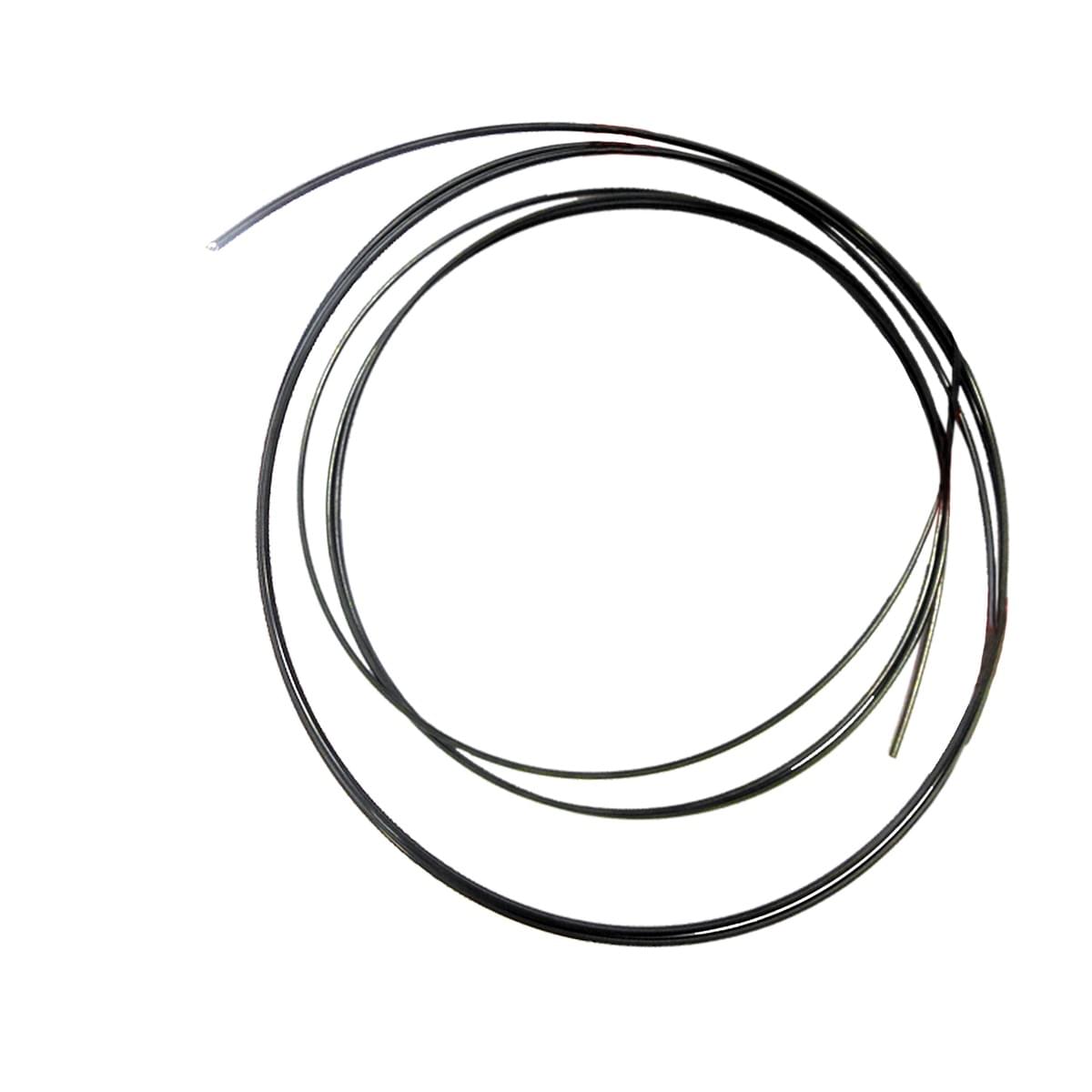

Nitinol is an alloy primarily composed of nickel and titanium, renowned for its ability to return to a predetermined shape when heated. Common applications include stents, guidewires, and other medical devices that benefit from its unique mechanical properties. As more industries explore the possibilities of this extraordinary material, the demand for reliable sources—such as those who manufacture nitinol—continues to grow.

The Importance of Quality Suppliers

When it comes to sourcing Nitinol, quality suppliers play a crucial role in ensuring that manufacturers receive materials that meet stringent standards. Partnering with a reputable nitinol supplier not only guarantees product quality but also enhances overall supply chain efficiency. Therefore, understanding how to evaluate potential suppliers is essential for making informed choices in procurement.

Key Considerations in Supplier Selection

Selecting the right supplier involves several key considerations beyond just cost; factors such as material quality, customization options, and production capabilities are equally important. Questions like Is nitinol expensive? or What is the cost of nitinol tube? often arise during this process but should be balanced with other critical aspects like reliability and service offerings. Additionally, exploring customized orders of nitinol wire for medical manufacturing can reveal how well suppliers align with specific project needs.

Verify Supplier Credentials

Research Manufacturer Background

The first step in verifying a Nitinol supplier's credentials is to research their background thoroughly. Start by asking questions like: Who manufactures Nitinol? Understanding the manufacturer’s history, expertise, and market presence can provide insights into their reliability and product quality. Look for manufacturers with a solid track record in producing high-quality Nitinol products, as this often correlates with better performance and consistency.

Check Certifications and Standards

Once you've done your homework on the manufacturer's background, it's time to check their certifications and adherence to industry standards. Quality certifications such as ISO 9001 or AS9100 indicate that the company follows rigorous quality management systems, which is essential when dealing with specialized materials like Nitinol tubes or wires. These certifications help ensure that you're sourcing from a reliable supplier who prioritizes quality control throughout their manufacturing processes.

Moreover, understanding where does nitinol come from can also shed light on its production methods and material integrity. Suppliers should be transparent about their sourcing practices; this not only builds trust but also assures you of the material's origin—critical for compliance in medical applications where standards are stringent.

Customer Feedback and Reviews

Customer feedback is an indispensable tool for verifying a supplier's credibility when searching for a reliable nitinol supplier. Scour online reviews or testimonials from previous clients to gauge overall satisfaction levels regarding product quality, delivery times, customer service, and post-sale support. If many customers report issues such as delays or subpar products related to cost of nitinol tube procurement, it might be wise to reconsider your options.

In addition to online reviews, consider reaching out directly to existing customers if possible; they can provide first-hand accounts of their experiences with specific suppliers. Remember that while no company will have a perfect record—especially if they handle large volumes—consistent positive feedback often indicates a dependable source for your nitinol needs.

Assess Material Quality

What is the Cost of Nitinol Tube?

The cost of a nitinol tube can vary significantly based on several factors including size, shape, and specific material properties required for your application. Generally speaking, nitinol is considered a premium material due to its unique properties such as superelasticity and shape memory; thus, many often wonder: Is nitinol expensive? While it may carry a higher price tag compared to traditional metals, the long-term benefits in terms of performance can outweigh initial costs. To get an accurate quote on what is the cost of nitinol tube for your specific needs, it's advisable to reach out directly to various nitinol suppliers who can provide tailored pricing based on your order specifications.

Who Manufactures Nitinol?

When searching for a reliable source for Nitinol components like tubes or wires, knowing who manufactures nitinol? becomes essential. Several reputable companies specialize in producing high-quality Nitinol products that cater to diverse industries including medical devices and aerospace applications. It's beneficial to research manufacturers not just by their product offerings but also their reputation within the industry; customer feedback can provide insights into their reliability and service quality as you navigate through various options available in the Nitinol Wire Archives.

Test Sample Materials for Performance

Before committing to bulk orders from any nitinol supplier, testing sample materials is crucial for ensuring that they meet your performance standards. This step allows you to evaluate how well potential suppliers' products align with your specific requirements—especially important if you're considering customized orders of nitinol wire for medical manufacturing where precision matters immensely. By conducting thorough tests on samples—such as assessing mechanical properties or fatigue life—you can gain confidence in your choice of supplier and ensure that you're investing in high-quality materials that will perform reliably in real-world applications.

Evaluate Customization Options

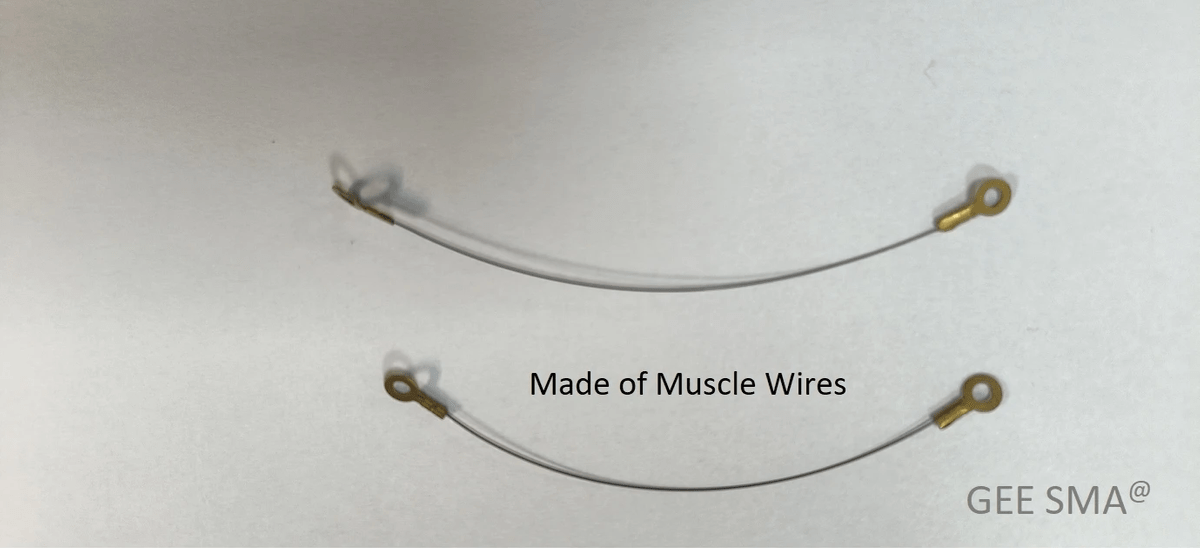

Customized Orders of Nitinol Wire for Medical Manufacturing

Customized orders of Nitinol wire for medical manufacturing are essential for companies that prioritize innovation and functionality. As medical devices become more sophisticated, the demand for specific wire characteristics increases, prompting many to ask, Who manufactures Nitinol? A reliable nitinol supplier should offer tailored solutions that meet stringent medical standards while accommodating unique design specifications.

In addition to quality and compliance, having the option for customized orders can significantly impact production timelines and cost-efficiency. Understanding the nuances of your project's needs allows you to collaborate effectively with your chosen nitinol supplier. This ensures that the final product aligns perfectly with your expectations and regulatory requirements.

Flexibility in Design and Production

Flexibility in design and production is another critical aspect when evaluating potential suppliers of Nitinol materials. A good nitinol supplier will not only provide high-quality materials but also adapt their processes to suit your evolving needs. Whether you require variations in thickness or special treatments, they should have the capability to accommodate these requests without compromising on quality.

Moreover, flexibility extends beyond just material specifications; it also includes responsiveness to changes in order size or delivery schedules. Is Nitinol expensive? While initial costs may vary based on customization, a flexible supplier can help optimize your budget through efficient production practices and minimized waste—ultimately leading to better long-term value.

Understanding Your Specific Needs

Understanding your specific needs is paramount when selecting a nitinol supplier capable of providing customized solutions. Engage in open dialogue about what you're looking for—whether that's performance metrics like shape memory or superelasticity—so that both parties are on the same page from the outset. The more clarity you provide regarding what constitutes success for your project, the easier it will be for suppliers to deliver tailored results.

Additionally, consider how factors like lead times and material availability can impact your overall timeline when discussing customization options with potential suppliers. If you've been wondering about What is the cost of nitinol tube? remember that investing time upfront into understanding your needs can lead to significant savings down the line by avoiding costly miscommunications or delays.

Analyze Production Capabilities

Capacity for Large Orders

A reliable nitinol supplier should have the capacity for large orders, especially if you're in industries that require high volumes like medical manufacturing. Who manufactures nitinol? The answer often lies with suppliers who have robust facilities capable of scaling production quickly and efficiently. If you anticipate needing a significant quantity of nitinol tubing or wire, it's essential to verify that your chosen supplier can handle your specific needs.

Lead Times and Delivery Reliability

Lead times are everything in today's fast-paced market, particularly when you're asking, Is nitinol expensive? The cost of nitinol tube may be less relevant if delays impact your operations negatively. A dependable supplier should provide clear timelines for production and delivery so you can plan accordingly and avoid any disruptions in your supply chain.

GEE SMA's Role in the Nitinol Market

GEE SMA has carved out a niche as a key player in the nitinol market due to its commitment to quality and reliability. They specialize in customized orders of nitinol wire for medical manufacturing, ensuring that their products meet stringent industry standards. By partnering with a reputable manufacturer like GEE SMA, you not only secure high-quality materials but also gain access to valuable insights about where does nitinol come from and how it’s processed.

Compare Pricing and Value

When it comes to sourcing materials like Nitinol, understanding the pricing and value is crucial for making informed decisions. Many potential buyers often wonder, Is Nitinol expensive? The answer isn't straightforward; it depends on several factors including the supplier, the specific type of Nitinol required, and the intended application.

Is Nitinol Expensive?

Nitinol's price point can be perceived as high compared to traditional metals due to its unique properties and manufacturing processes. However, when evaluating whether it's truly expensive, one must consider what makes this alloy special—its shape memory effect and superelasticity are game-changers in many applications. For businesses looking to invest in customized orders of Nitinol wire for medical manufacturing or other specialized uses, the initial cost may seem daunting but can yield significant benefits down the line.

Long-Term Cost vs. Initial Investment

While the upfront cost of sourcing Nitinol from a reputable nitinol supplier might raise eyebrows, it's essential to analyze long-term costs versus initial investments. In many cases, investing in high-quality materials leads to enhanced performance and durability that can save money on repairs or replacements over time. Additionally, industries that utilize Nitinol effectively often find that its unique properties can lead to lower operational costs due to increased efficiency and reduced maintenance requirements.

Understanding Pricing Structures

To navigate the complexities of pricing structures associated with Nitinol products, it's vital to know who manufactures Nitinol and how they determine their prices. Factors such as raw material sourcing (where does nitinol come from?), production methods, and market demand all play significant roles in setting prices for items like nitinol tubes or wires. By comparing quotes from multiple suppliers while considering these elements, you can better assess whether you're getting a fair deal or if there's room for negotiation.

Conclusion

In the dynamic world of Nitinol procurement, establishing robust supplier relationships is vital for success. A reliable nitinol supplier can mean the difference between project delays and seamless production flows. By fostering long-lasting partnerships, businesses can ensure they have access to high-quality materials and responsive service when needed.

Building Long-Lasting Supplier Relationships

Creating strong ties with your nitinol supplier should be a priority for anyone in the industry. The right manufacturer not only provides quality products but also understands your specific requirements—whether that's customized orders of Nitinol wire for medical manufacturing or standard materials. Over time, these relationships can lead to better pricing, improved communication, and a deeper understanding of each other's capabilities.

Ensuring Supply Chain Reliability

When considering where does nitinol come from, it's essential to choose suppliers who maintain consistent quality and reliability in their supply chains. A dependable nitinol supplier will have established processes that mitigate risks associated with delivery times and material shortages. This reliability not only impacts production schedules but also helps businesses avoid costly interruptions that could arise from sourcing issues.

Making Informed Procurement Decisions

Understanding whether nitinol is expensive requires a comprehensive analysis of both short-term costs and long-term value. What is the cost of nitinol tube? This question often leads to discussions about pricing structures that reflect material quality, customization options, and order volume. By comparing different suppliers' offerings—especially those found in Nitinol Wire Archives—companies can make informed decisions that align with their budgetary constraints while ensuring they receive top-notch materials suited for their applications.