Introduction

When it comes to medical procedures, the nitinol guidewire has become a game-changer in the field of interventional cardiology. This flexible and durable wire is made from a unique nickel-titanium alloy, known for its shape memory and superelastic properties. As a result, it has revolutionized catheterization procedures and has opened up new possibilities in minimally invasive surgeries. Let's delve into the understanding of nitinol guidewire, its advantages, and its wide-ranging applications in medicine.

Understanding the Nitinol Guidewire

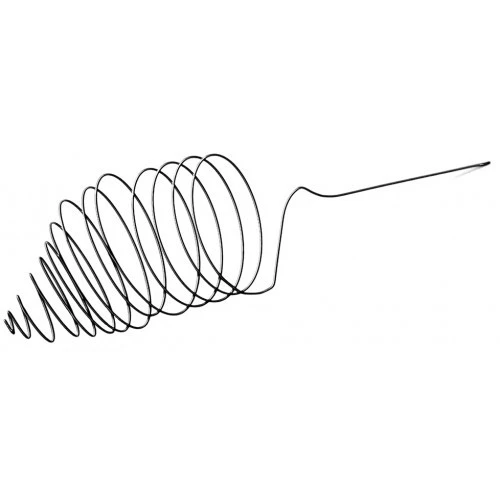

The nitinol guidewire is a medical tool made from a specialized alloy composed of nearly equal parts nickel and titanium. This unique composition gives it the ability to return to its original shape after being bent or deformed, making it ideal for navigating through complex blood vessels during medical procedures.

Advantages of Using Nitinol

One of the key advantages of using nitinol wire is its flexibility and kink resistance, allowing for smoother navigation through tortuous paths within the body. Additionally, its superelasticity ensures that it can withstand repeated bending without permanent deformation, making it a reliable tool for interventional procedures.

Applications of Nitinol in Medicine

Nitinol wire can be used for a range of medical applications including angioplasty, stent placement, embolization procedures, and various other catheter-based interventions. Its unique properties make it an essential component in minimally invasive surgeries, offering patients less discomfort and faster recovery times.

What is a Nitinol Guidewire?

Nitinol guidewire is a medical device made from a nickel-titanium alloy known for its unique shape memory and superelastic properties. This alloy, also called Nitinol, is composed of nearly equal parts of nickel and titanium, giving it the ability to return to its original shape when heated or subjected to stress. This makes it an ideal material for medical guidewires due to its flexibility and resilience.

Composition and Properties of Nitinol

The composition of Nitinol allows it to be easily manipulated into various shapes without losing its strength or integrity. Its unique properties make it suitable for use in minimally invasive procedures, as it can navigate through complex vascular structures with ease. The superelasticity of Nitinol allows the guidewire to bend without permanent deformation, reducing the risk of vessel damage during catheterization.

Benefits of Using Nitinol Guidewire

One of the key benefits of using Nitinol guidewires is their ability to provide excellent support and control during procedures while maintaining flexibility. This allows for precise navigation through tortuous vessels, ultimately improving patient outcomes. Additionally, the shape memory properties of Nitinol enable the guidewire to return to its original form after being manipulated, ensuring consistent performance throughout the procedure.

Furthermore, Nitinol guidewires are known for their kink resistance, which helps to maintain the structural integrity of the wire during complex procedures. This feature reduces the risk of vessel damage and ensures smooth advancement through the vasculature, contributing to a safer and more efficient intervention. The ability of Nitinol to withstand bending and torsion without permanent deformation makes it a reliable choice for navigating challenging anatomies, ultimately enhancing the overall success of catheterization procedures.

Versatility of Nitinol in Catheterization

Nitinol's versatility extends beyond traditional guidewires and includes hydrophilic coatings that enhance lubricity for smoother navigation through blood vessels. This makes it an ideal material for a wide range of catheterization procedures, from coronary angioplasty to peripheral vascular interventions. The adaptability and reliability of Nitinol make it a preferred choice for medical professionals seeking optimal outcomes in challenging anatomical conditions.

Nitinol's versatility extends beyond traditional guidewires and includes hydrophilic coatings that enhance lubricity for smoother navigation through blood vessels. This makes it an ideal material for a wide range of catheterization procedures, from coronary angioplasty to peripheral vascular interventions. The adaptability and reliability of Nitinol make it a preferred choice for medical professionals seeking optimal outcomes in challenging anatomical conditions.

Types of Guidewires

When it comes to types of guidewires, one popular comparison is between Glidewire and regular guidewire. Glidewire is known for its hydrophilic coating, which allows for smoother navigation through the vasculature. On the other hand, regular guidewires are made of nitinol, providing superior strength and kink resistance. Both have their own advantages and are used in different medical procedures depending on the specific requirements.

Comparison of Glidewire vs Guidewire

Glidewire is often favored for its hydrophilic coating, making it ideal for navigating tortuous vessels and tight lesions with ease. However, nitinol guidewires offer exceptional torque control and shape memory properties, allowing them to maintain their shape even after multiple uses. The choice between the two depends on the specific needs of the medical procedure and the patient's anatomy.

Hydrophilic Nitinol Guidewire Explained

The hydrophilic nitinol guidewire's innovative design also minimizes the risk of kinking or buckling during navigation, providing a reliable and consistent performance in challenging anatomies. This feature ensures that the guidewire maintains its shape and integrity, allowing for smoother advancement and reducing the need for repositioning. Additionally, the combination of hydrophilic coating and nitinol wire offers enhanced visibility under fluoroscopy, aiding in precise placement and reducing procedure time.

Advancements in Nitinol Guidewire Technology

Advancements in nitinol guidewire technology have led to improved flexibility, trackability, and pushability without compromising on strength or durability. These innovations have expanded the applications of nitinol guidewires in various medical procedures, making them a versatile tool for interventional radiologists and cardiologists.

The increased flexibility, trackability, and pushability of nitinol guidewires have also contributed to improved navigation through tortuous vessels and complex anatomies, allowing for more precise placement during procedures. This enhanced maneuverability has minimized the risk of vessel damage and reduced the need for additional interventions, ultimately improving patient outcomes. As a result, interventional radiologists and cardiologists can confidently perform a wider range of minimally invasive procedures with greater accuracy and efficiency.

Nitinol Safety and Strength

Nitinol guidewires are widely used in medical procedures due to their biocompatibility and safety in the human body. This unique alloy is composed of nickel and titanium, making it resistant to corrosion and safe for implantation. The flexibility and strength of nitinol wire make it an ideal choice for various medical applications, including catheterization and stent placement.

Is Nitinol Safe in the Human Body?

Nitinol is considered safe for use in the human body due to its non-toxic nature and excellent biocompatibility. It has been extensively tested and approved for medical use, with minimal risk of adverse reactions or tissue rejection. The unique properties of nitinol wire make it an ideal material for surgical implants, allowing for optimal healing and long-term performance within the body.

Nitinol wire is incredibly strong, with a high tensile strength that allows it to withstand the rigors of the human body. This makes it an ideal material for surgical implants, where durability and resilience are essential for long-term performance. Additionally, nitinol's superelasticity allows it to return to its original shape after deformation, providing stability and support within the body.

How Strong is Nitinol Wire?

Nitinol wire exhibits remarkable strength and resilience, allowing it to withstand the rigors of medical procedures without compromising its structural integrity. This exceptional strength-to-weight ratio makes nitinol an ideal material for manufacturing guidewires that can navigate through complex anatomical pathways with precision and ease.

Safety Measures for Nitinol Guidewire Usage

When using nitinol guidewires in medical procedures, it's essential to adhere to strict safety measures to ensure optimal patient outcomes. Proper training on handling and manipulating nitinol guidewires is crucial to minimize the risk of injury or complications during catheterization or stent placement. Additionally, regular inspection of nitinol guidewires for any signs of wear or damage is essential to maintain their safety and effectiveness in clinical settings.

Furthermore, it's important to ensure that nitinol guidewires are properly stored and handled to prevent any potential damage or contamination. Proper storage in a clean and dry environment, as well as careful handling to avoid kinking or bending, can help maintain the integrity of the guidewire. In addition, healthcare professionals should be aware of any contraindications or potential complications associated with the use of nitinol guidewires in specific patient populations, such as those with allergies or sensitivities to certain materials.

Nitinol Guidewire Applications

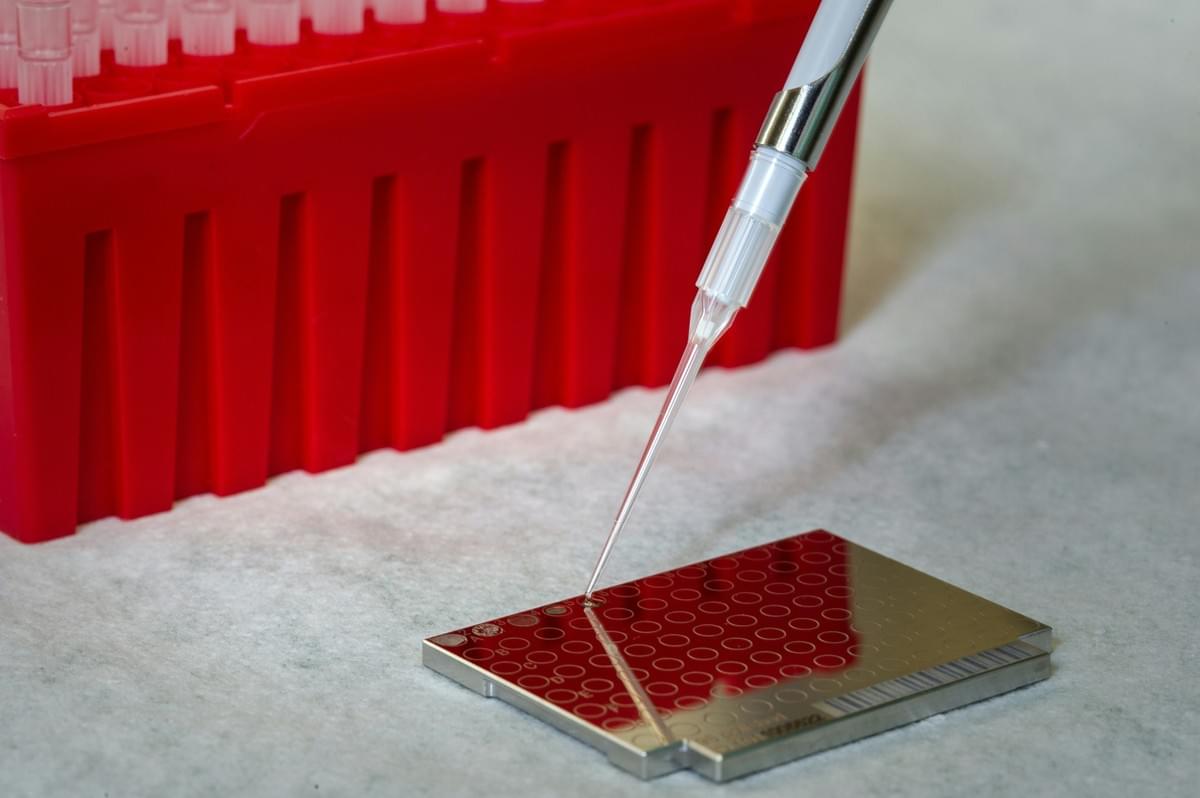

Effective Catheterization with Nitinol

Nitinol guidewires are widely used in catheterization procedures due to their flexibility and shape memory properties, allowing for smooth navigation through blood vessels and other pathways. The unique ability of nitinol wire to return to its original shape after bending or kinking ensures precise placement of medical devices, making it an indispensable tool in various interventional procedures.

Nitinol guidewires have also revolutionized the field of endovascular therapy by enabling the precise placement of stents and balloons within blood vessels. This has significantly improved the success rates of angioplasty and stenting procedures, reducing the risk of complications and enhancing patient outcomes. Furthermore, the flexibility and kink resistance of nitinol guidewires allow for more efficient navigation through tortuous anatomy, making complex interventions more manageable for physicians.

Innovative Uses for Nitinol Guidewire

Aside from catheterization, nitinol wire can be used for a variety of innovative medical applications such as stent delivery, embolic protection, and thrombus removal. Its flexibility and kink resistance make it suitable for navigating complex anatomical structures, while its biocompatibility ensures minimal tissue trauma during procedures. This makes nitinol an ideal material for developing cutting-edge medical devices.

Success Stories with Nitinol in Medical Procedures

Numerous success stories highlight the pivotal role of nitinol guidewires in improving patient outcomes and advancing medical technology. From enabling minimally invasive surgeries to facilitating precise device deployment, the versatility and reliability of nitinol have revolutionized the field of interventional medicine. Healthcare professionals continue to rely on nitinol guidewires for their exceptional performance and safety profile.

Healthcare professionals have found that nitinol guidewires offer unparalleled flexibility and kink resistance, allowing for smooth navigation through tortuous anatomy and tight spaces within the body. This has been particularly beneficial in complex procedures such as neurovascular interventions and cardiac catheterization, where precision and maneuverability are critical for successful outcomes. As a result, nitinol guidewires have become indispensable tools in the hands of medical practitioners, enabling them to address a wide range of clinical challenges with confidence and efficiency.

GEE SMA: Crafting Quality Nitinol Components

GEE SMA is a leading manufacturer specializing in the production of high-quality Nitinol Shape Memory Alloys. With expertise in shaping and manipulating Nitinol, GEE SMA ensures that their components meet the highest standards for medical applications.

Specialization in Nitinol Shape Memory Alloys

GEE SMA's specialization in Nitinol Shape Memory Alloys allows for the creation of intricate and precise components, such as nitinol guidewires, that are essential for medical procedures. Their in-depth understanding of Nitinol's unique properties enables them to craft materials that are both durable and flexible, making them ideal for use in various medical devices.

Tailoring Nitinol Materials to Customer Needs

GEE SMA works closely with their clients to tailor Nitinol materials to specific requirements, ensuring that the finished product meets the exact needs of the medical industry. Whether it's a specific size, shape, or functionality, GEE SMA can customize their Nitinol components to fit the individual needs of their customers.

Ensuring Product Quality and Customer Satisfaction

Quality control is paramount at GEE SMA, and they go above and beyond to ensure that every component meets rigorous standards before leaving their facility. Their dedication to product quality translates into customer satisfaction, as medical professionals can rely on GEE SMA's Nitinol components for safe and effective use in various procedures.

By providing top-notch materials tailored to customer needs with a focus on safety and quality, GEE SMA stands out as a trusted partner in the development of advanced medical devices using nitinol guidewire technology.

Conclusion

Nitinol guidewires have revolutionized medical procedures with their flexibility, strength, and biocompatibility. As the future of nitinol guidewire technology continues to evolve, we can expect even more innovative uses for this remarkable material in the medical field. Choosing the right nitinol guidewire for medical procedures is crucial for ensuring successful outcomes and patient safety.

Harnessing the Power of Nitinol in Medicine

The versatility and reliability of nitinol guidewires have made them indispensable in various medical applications, from cardiovascular interventions to neurosurgery. Their unique properties allow for precise navigation through complex anatomical structures, improving procedural success rates and patient outcomes.

Future of Nitinol Guidewire Technology

Advancements in nitinol manufacturing techniques and design are paving the way for even more sophisticated and specialized guidewires. With ongoing research and development, we can anticipate further improvements in flexibility, trackability, and durability, expanding the scope of procedures that can benefit from nitinol technology.

Choosing the Right Nitinol Guidewire for Medical Procedures

Selecting the appropriate nitinol guidewire tailored to specific procedural requirements is essential for achieving optimal results. Factors such as tip configuration, hydrophilicity, and torque response should be carefully considered to ensure seamless navigation through vasculature or other anatomical pathways.

By harnessing the power of nitinol in medicine and staying abreast of advancements in guidewire technology, healthcare providers can continue to offer cutting-edge solutions that enhance patient care across a wide range of specialties.