Introduction

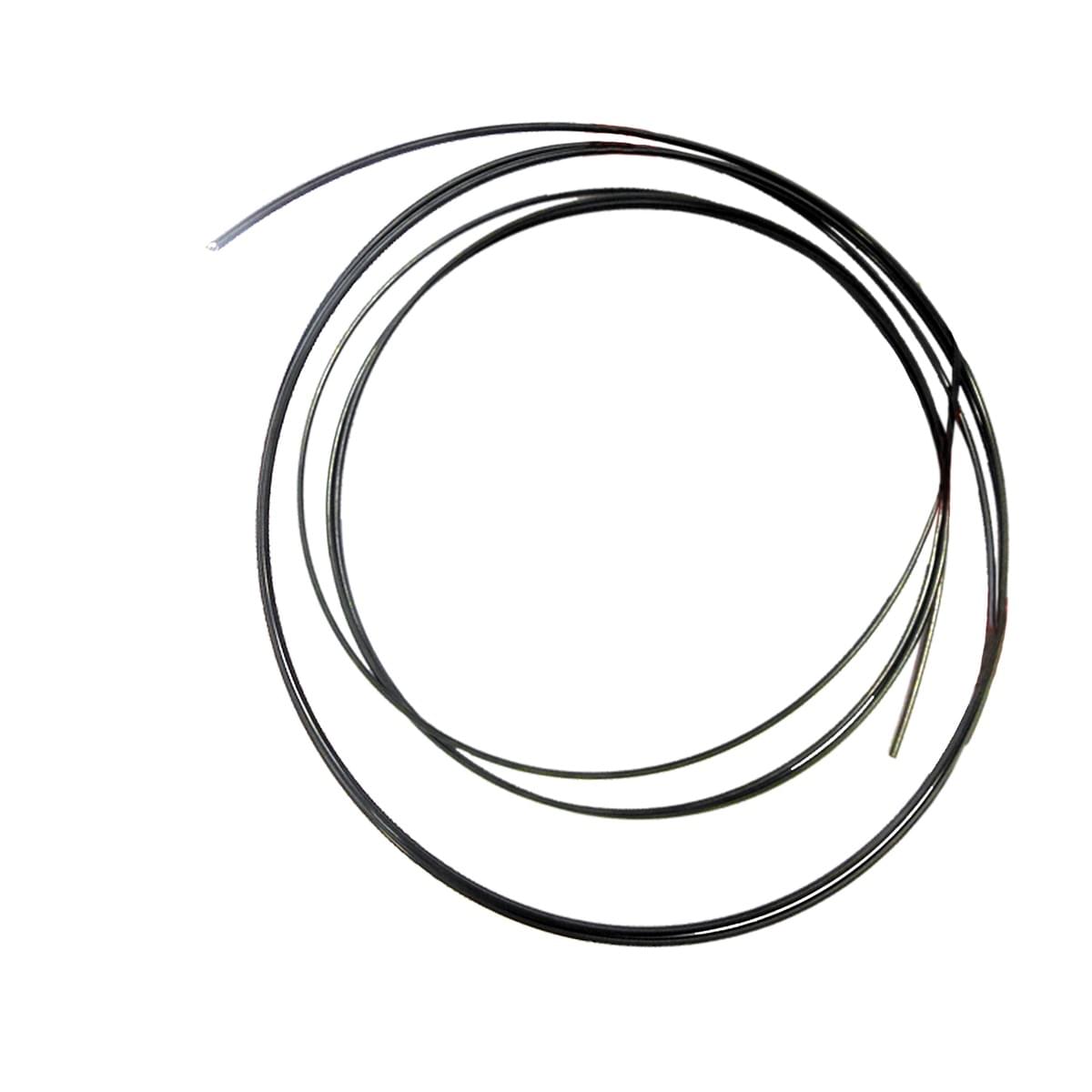

Welcome to the fascinating world of Nitinol alloys and their application in medical devices, particularly in the form of nitinol guide wires. These wires are essential tools used by medical professionals for a variety of procedures, from cardiovascular interventions to minimally invasive surgeries. Understanding the different types of nitinol guide wires and their advantages is crucial for making informed decisions in patient care.

Understanding Nitinol Alloys

Nitinol is a nickel-titanium alloy known for its unique shape memory and superelastic properties. In the medical field, nitinol wires are used to navigate through blood vessels and other pathways within the body with precision and flexibility. This makes them invaluable tools for various medical procedures.

Nitinol guide wires are also known for their durability and resistance to corrosion, making them reliable tools for repeated use in medical procedures. Additionally, the superelastic properties of nitinol allow the wires to bend and flex without permanent deformation, providing a level of maneuverability that is unmatched by traditional guide wires. This flexibility reduces the risk of vessel damage during insertion and ensures a smoother navigation process for medical professionals.

Advantages of Nitinol Guide Wires

The medical use of nitinol wire offers several advantages, including excellent kink resistance, torque control, and pushability. These properties make nitinol guide wires highly effective in guiding catheters through complex anatomical structures during interventional procedures.

In addition to its exceptional performance during interventional procedures, nitinol guide wires also offer superior flexibility and shape memory. This allows the wire to maintain its original shape after being bent or deformed, ensuring precise navigation through tortuous blood vessels and other challenging anatomical structures. The ability of nitinol guide wires to adapt to various shapes and curves makes them an invaluable tool for physicians performing minimally invasive procedures, ultimately leading to better patient outcomes.

Superelastic vs Shape Memory: Which is Better?

When it comes to choosing a nitinol guide wire, understanding the differences between superelastic and shape memory varieties is crucial. Both offer unique benefits, but determining which type is best suited for a specific medical application requires careful consideration. Superelastic nitinol guide wires are known for their ability to return to their original shape after being bent or deformed, making them ideal for navigating tortuous vessels with ease. On the other hand, shape memory nitinol guide wires can be pre-shaped to a specific configuration and will return to that shape when exposed to body heat, providing precise control during procedures. Understanding the specific needs of the medical application will help determine which type of nitinol guide wire is better suited for the task at hand.

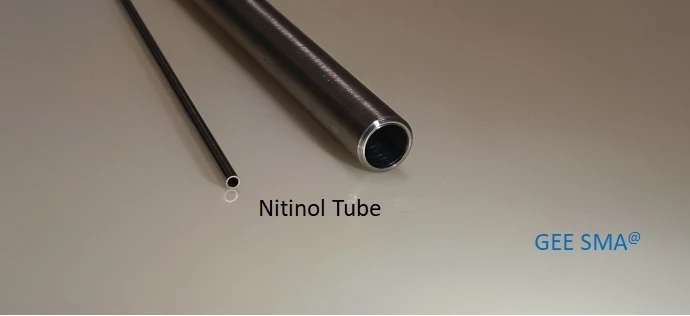

What is Nitinol?

Nitinol is a nickel-titanium alloy known for its unique properties, including shape memory and superelasticity. This versatile material is widely used in medical devices due to its ability to return to a predetermined shape when subjected to heat or stress, making it ideal for applications such as stents, orthodontic wires, and guide wires.

Composition of Nitinol Alloys

Nitinol alloys are typically composed of approximately 50% nickel and 50% titanium, although slight variations in composition can result in different properties. The addition of small amounts of other elements can further enhance specific characteristics, such as corrosion resistance or biocompatibility, making nitinol alloys highly customizable for medical applications.

Nitinol alloys are known for their shape memory and superelasticity, which are highly desirable properties in medical devices such as stents and orthodontic wires. By carefully adjusting the composition of the alloy, manufacturers can fine-tune these characteristics to meet specific application requirements. For example, adding small amounts of iron or chromium can improve the corrosion resistance of nitinol alloys, making them suitable for long-term implantation in the human body. This level of customization makes nitinol alloys a top choice for medical device designers looking for reliable and versatile materials.

Properties of Nitinol Alloys

The most notable properties of nitinol alloys are their shape memory and superelasticity. Shape memory allows the material to return to a predetermined shape when heated above its transformation temperature, while superelasticity enables it to undergo significant deformation and recover its original shape when the applied stress is removed.

Nitinol alloys are widely used in medical devices due to their unique properties. The shape memory feature allows for the creation of self-expanding stents that can be inserted in a collapsed state and then expand to the desired shape once inside the body. This makes procedures less invasive and reduces the risk of complications for patients.

Applications in Medical Devices

Nitinol alloys are extensively used in various medical devices, including stents for cardiac and vascular interventions, orthodontic wires for dental treatments, and guide wires for minimally invasive procedures such as angioplasty and endovascular surgery. The unique properties of nitinol make it an invaluable material in the field of medicine.

Nitinol's superelasticity and shape memory properties make it an ideal material for medical devices that require flexibility and durability. For example, in orthodontic treatments, nitinol wires can exert a constant force on teeth to move them into the desired position without breaking or deforming. This unique ability to maintain its shape under stress is crucial for the success of orthodontic interventions, making nitinol an indispensable material in dental care.

Superelastic Nitinol Guide Wires

Superelastic nitinol guide wires are a crucial component in minimally invasive medical procedures. These wires are designed to provide exceptional flexibility and durability, allowing for smooth navigation through the body's intricate pathways. This makes them ideal for use in delicate medical procedures where precision is key.

Flexibility and Durability

The superelastic properties of nitinol guide wires allow them to maintain their shape even after being bent or twisted, making them highly flexible and durable. This enables healthcare professionals to navigate through tortuous vessels with ease, reducing the risk of damage to surrounding tissues.

The flexibility and durability of nitinol guide wires also contribute to their advantages in minimally invasive procedures. Because of their ability to maintain shape, these guide wires can be used repeatedly without compromising their performance, reducing the need for frequent replacements and saving time and resources. Additionally, their resilience allows for smoother and more precise navigation within the body, enhancing the overall efficiency and success of minimally invasive interventions.

Advantages in Minimally Invasive Procedures

One of the main advantages of superelastic nitinol guide wires is their ability to facilitate minimally invasive procedures such as angioplasty and stent placement. Their flexibility allows for easier access to target areas within the body, minimizing trauma and recovery time for patients.

Additionally, superelastic nitinol guide wires are designed to navigate through complex anatomical structures with precision and ease. This allows for more accurate placement of angioplasty balloons and stents, reducing the risk of complications and the need for additional procedures. The advanced technology of these guide wires also enables physicians to perform minimally invasive interventions in challenging cases, expanding the range of patients who can benefit from these procedures.

Case Studies Demonstrating Effectiveness

Numerous case studies have demonstrated the effectiveness of superelastic nitinol guide wires in various medical procedures. These studies showcase how these wires have improved patient outcomes by enabling precise navigation through complex anatomical structures, ultimately leading to successful treatment interventions.

Remember that when it comes to choosing the right type of nitinol guide wire for a specific medical procedure, it's essential to consider factors such as patient anatomy and the nature of the intervention required. The versatility and reliability of superelastic nitinol guide wires make them an invaluable tool in modern healthcare, contributing to better patient care outcomes.

Shape Memory Nitinol Guide Wires

Thermomechanical Properties

Shape memory nitinol guide wires are designed to exhibit unique thermomechanical properties, allowing them to return to their original shape after being deformed. This makes them ideal for navigating through complex anatomical structures during medical procedures, providing precision and reliability.

Shape memory nitinol guide wires are also known for their high flexibility and kink resistance, allowing them to easily navigate through tortuous pathways without compromising their structural integrity. This flexibility is crucial in ensuring that the guide wires can reach the intended target area within the body with precision, reducing the risk of damage to surrounding tissues. Additionally, their ability to maintain their shape and structural integrity under varying temperatures makes them reliable tools for medical professionals performing intricate procedures.

Precision in Navigation and Positioning

The shape memory properties of nitinol guide wires enable them to be precisely positioned within the body, ensuring accurate placement for various medical interventions. Their flexibility and responsiveness make them indispensable tools for healthcare professionals seeking optimal outcomes for their patients.

The precision and accuracy of nitinol guide wires also contribute to reducing the risk of complications during medical procedures. By allowing for controlled and targeted navigation within the body, these wires minimize the potential for damage to surrounding tissues and organs. This not only enhances patient safety but also promotes faster recovery times and improved overall outcomes.

Comparison with Superelastic Wires

When compared to superelastic nitinol guide wires, shape memory wires offer enhanced precision and control due to their ability to retain a specific shape at body temperature. While both types have their advantages, shape memory wires are particularly valuable in applications requiring exact positioning and navigation.

GEE SMA’s Contribution to Nitinol Guide Wires

GEE SMA has revolutionized the manufacturing processes for medical nitinol guide wires, ensuring high-quality products that meet the stringent standards of the healthcare industry. With cutting-edge technology and precision engineering, they have perfected the customization of nitinol components for various medical applications, including hydrophilic nitinol guide wires used in minimally invasive procedures.

High-Quality Manufacturing Processes

GEE SMA's state-of-the-art facilities and stringent quality control measures ensure that every medical nitinol guide wire produced meets the highest standards. Their team of experts meticulously oversees every step of the manufacturing process to guarantee superior performance and reliability in medical settings.

GEE SMA's commitment to high-quality manufacturing processes extends to their dedication to customization for medical applications. Their team works closely with medical professionals to understand specific needs and requirements, allowing them to tailor their nitinol guide wires to meet the unique demands of different procedures and patient conditions. This level of customization ensures that healthcare providers can rely on GEE SMA's products for optimal performance and patient safety, giving them peace of mind in critical medical settings.

Customization for Medical Applications

The versatility of nitinol allows GEE SMA to customize guide wires according to specific medical needs, ensuring optimal performance and patient safety. Whether it's shaping, coating, or other modifications, their ability to tailor nitinol components for different medical applications sets them apart in the industry.

Customer Success Stories

Countless healthcare professionals have experienced remarkable success with GEE SMA's customized nitinol guide wires. Their commitment to excellence has resulted in numerous positive outcomes, improving patient care and advancing medical procedures worldwide.

Many healthcare professionals have reported that GEE SMA's nitinol guide wires have significantly improved their ability to navigate complex vascular systems, leading to more accurate and successful procedures. The flexibility and durability of these guide wires have allowed for smoother insertion and reduced risk of damage to delicate tissues, resulting in better patient outcomes. As a result, medical professionals around the world are turning to GEE SMA's products as their go-to choice for guide wires in challenging cases.

Conclusion

Nitinol guide wires are essential tools in minimally invasive medical procedures, offering flexibility, durability, and precision. When choosing the right nitinol guide wire, it's crucial to consider the specific needs of the procedure and patient. The future of nitinol in medical devices looks promising, with ongoing advancements in manufacturing processes and customization for various medical applications. Making informed decisions for patient care involves staying updated on the latest developments in nitinol technology.

Choosing the Right Nitinol Guide Wire

When selecting a medical nitinol guide wire, it's important to consider factors such as flexibility, durability, and precision. Different types of nitinol wires, including superelastic and shape memory wires, offer unique benefits that cater to specific medical needs. Understanding the specific application and patient requirements is crucial for choosing the most suitable nitinol guide wire.

The Future of Nitinol in Medical Devices

The future of nitinol in medical devices holds promise for continued innovation and improvement. Ongoing advancements in manufacturing processes are enhancing the quality and performance of nitinol components used in medical devices. Customization options are also expanding, allowing for tailored solutions that meet the diverse needs of various medical applications.

Making Informed Decisions for Patient Care

Staying informed about the latest developments in nitinol technology is essential for making informed decisions that prioritize patient care. With continuous advancements in materials science and engineering, healthcare professionals can expect to see new and improved applications of nitinol in medical devices. By staying updated on these developments, healthcare providers can ensure optimal outcomes for their patients.