Introduction

Nitinol, a unique shape memory alloy, possesses remarkable mechanical properties that set it apart from traditional materials. Its ability to return to a predetermined shape after deformation, exceptional superelasticity, and biocompatibility make it an attractive choice for various applications. However, there are also disadvantages to consider when utilizing nitinol in engineering and biomedical devices.

Understanding Nitinol Mechanical Properties

Nitinol exhibits extraordinary properties such as shape memory, superelasticity, and biocompatibility. These characteristics allow the alloy to be deformed at low temperatures and then revert to its original shape when heated, making it ideal for medical implants and devices.

Exploring the Unique Properties of Nitinol

In addition to its shape memory and superelasticity, nitinol is highly resistant to corrosion and fatigue. This makes it a durable material for long-term use in challenging environments such as aerospace engineering and industrial applications.

Uncovering the Disadvantages of Nitinol

Despite its many advantages, nitinol does have limitations including high cost and difficulty in processing due to its unique properties. These factors can impact its widespread use in certain industries.

What Makes Nitinol Superior

Nitinol mechanical properties and applications are truly exceptional, with three unique properties that set it apart from other materials. First, its exceptional flexibility and shape memory allow it to return to its original shape after being deformed, making it ideal for various applications in industries such as biomedical devices and aerospace engineering. Second, nitinol exhibits superelasticity and biocompatibility, making it a preferred material for medical implants and devices. Lastly, nitinol boasts high fatigue resistance and corrosion resistance, ensuring its durability in harsh environments.

Exceptional Flexibility and Shape Memory

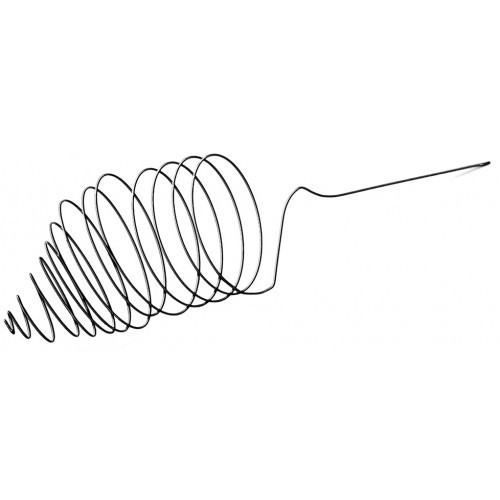

Nitinol's exceptional flexibility and shape memory make it a standout material in the field of engineering and medical technology. This unique property allows nitinol to be easily bent or deformed without permanent damage, making it an ideal choice for applications that require intricate shapes or precise movements. Whether used in orthodontic wires or minimally invasive surgical tools, nitinol's flexibility and shape memory make it a superior material for various innovative designs.

Superelasticity and Biocompatibility

In addition to its flexibility, nitinol's superelasticity and biocompatibility make it a sought-after material in the medical industry. Its ability to undergo large deformations while still returning to its original shape makes it perfect for stents, vascular grafts, and other implantable medical devices. Moreover, its biocompatibility ensures that it is well-tolerated by the human body, reducing the risk of adverse reactions when used in medical applications.

High Fatigue Resistance and Corrosion Resistance

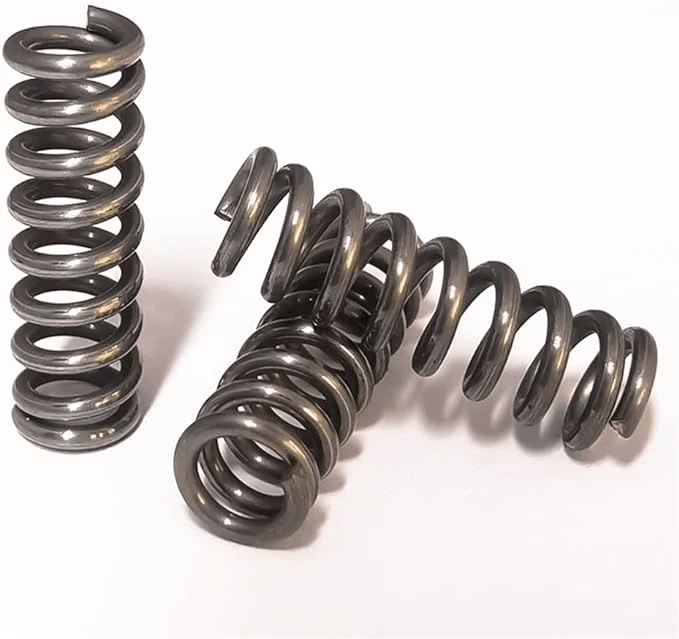

Furthermore, nitinol's high fatigue resistance and corrosion resistance contribute to its superiority as a material of choice in various industries. Its ability to withstand repeated stress without undergoing permanent deformation makes it highly durable for long-term use in critical applications such as aerospace components or industrial machinery. Additionally, its corrosion resistance ensures that it can maintain its structural integrity even when exposed to harsh environmental conditions.

Nitinol vs Stainless Steel

When comparing nitinol and stainless steel, it's essential to consider their strength and durability. Nitinol boasts superior strength and durability compared to stainless steel, making it a preferred choice for applications requiring resilience and longevity. With its exceptional mechanical properties, including shape memory and superelasticity, nitinol outperforms stainless steel in various demanding environments.

Strength and Durability Comparison

Nitinol's unique properties, such as its exceptional flexibility, shape memory, and superelasticity, give it a significant advantage over stainless steel in terms of strength and durability. These properties allow nitinol to withstand high levels of stress and deformation without compromising its structural integrity, making it an ideal material for critical applications in industries such as aerospace engineering and biomedical devices.

Flexibility and Versatility in Applications

Nitinol's remarkable flexibility and versatility make it a standout choice for a wide range of applications. Unlike stainless steel, which is rigid and less adaptable, nitinol can be engineered to exhibit specific responses to temperature changes or mechanical stress. This adaptability opens up new possibilities for innovative designs in mechanical engineering and biomedical devices that require precision performance under varying conditions.

Impact on Mechanical Engineering and Biomedical Devices

The unique mechanical properties of nitinol have revolutionized the fields of mechanical engineering and biomedical devices. Its exceptional fatigue resistance, biocompatibility, and corrosion resistance make it an invaluable material for creating advanced components in these industries. From intricate surgical instruments to intricately designed aerospace components, the impact of nitinol on these fields cannot be overstated.

By leveraging the unmatched strengths of nitinol over stainless steel in terms of mechanical properties, engineers can create cutting-edge solutions that push the boundaries of what is possible in various industries. The versatility offered by nitinol paves the way for groundbreaking innovations that will continue to shape our future.

Exploring Nitinol Applications

Nitinol, with its remarkable mechanical properties and shape memory characteristics, has found extensive applications in various industries. From medical devices to industrial engineering, the unique properties of nitinol have revolutionized the way we approach design and innovation.

Medical Devices and Implants

Nitinol's exceptional flexibility, superelasticity, and biocompatibility make it an ideal material for medical devices and implants. Its ability to adapt to the body's movements while maintaining strength and durability has made it a preferred choice for stents, orthodontic wires, and even minimally invasive surgical tools.

Nitinol's unique properties have also found applications in industrial and aerospace engineering. Its ability to return to its original shape after being deformed, along with its resistance to corrosion and high fatigue strength, has made it a valuable material for components in aircraft, spacecraft, and industrial machinery. The flexibility and durability of Nitinol allow for the creation of complex shapes and designs that can withstand the harsh conditions of these environments.

Industrial and Aerospace Engineering

In industrial and aerospace engineering, nitinol's high fatigue resistance and corrosion resistance have made it indispensable in critical applications. From actuators in aircraft wings to components in advanced robotics, nitinol's reliability under extreme conditions has elevated the standards of performance in these industries.

In addition to its use in critical aerospace and industrial applications, nitinol has also found its way into the consumer goods and electronics industry. Its unique properties make it an ideal material for items such as eyeglass frames, cell phone antennas, and headphone wires. With nitinol's high fatigue resistance and corrosion resistance, consumers can rely on their products to withstand everyday wear and tear, while maintaining their functionality for longer periods of time.

Consumer Goods and Electronics

The versatility of nitinol extends to consumer goods and electronics, where its unique properties are harnessed for innovative products. From eyeglass frames that can return to their original shape after bending to smartphone antennas that can withstand repeated bending without damage, nitinol has opened up new possibilities for design in consumer goods.

Nitinol's ability to withstand repeated bending without damage has also revolutionized the design of wearable technology. Smartwatches and fitness trackers are now able to incorporate flexible, durable bands that can withstand the rigors of daily use. This has not only improved the longevity and reliability of these devices but has also enhanced user comfort and convenience, showcasing nitinol's impact on the evolution of consumer electronics.

By understanding the diverse applications of nitinol across different industries, we can appreciate how this extraordinary material continues to shape the future of engineering and innovation.

Understanding Nitinol Alloys

Nitinol alloys are composed of a combination of nickel and titanium, with the unique ability to undergo significant deformation and still return to their original shape. This remarkable property is known as superelasticity, making nitinol an exceptional material for various applications such as medical devices and aerospace engineering.

The Role of Titanium and Nickel

The role of titanium in nitinol alloys is crucial as it provides strength, corrosion resistance, and biocompatibility. Nickel, on the other hand, contributes to the shape memory effect and superelasticity, allowing the material to withstand repeated bending without permanent deformation.

Properties of TI 6al 4v Alloy

TI 6al 4v is a specific nitinol alloy that consists of titanium (Ti), aluminum (Al), vanadium (V), and iron (Fe). This alloy exhibits high strength-to-weight ratio, excellent corrosion resistance, and good mechanical properties at elevated temperatures, making it suitable for demanding applications in aerospace engineering and medical implants.

Advantages and Limitations of Nitinol Alloys

The advantages of nitinol alloys include exceptional flexibility, shape memory effect, superelasticity, biocompatibility, high fatigue resistance, and corrosion resistance. However, limitations such as cost and processing difficulties may pose challenges in certain industries where cost-effectiveness is a critical factor.

By understanding the role of titanium and nickel in nitinol alloys along with the properties of TI 6al 4v alloy, we can appreciate the exceptional mechanical properties that make nitinol a superior material for various applications. Its unique combination of flexibility, shape memory effect, superelasticity, biocompatibility makes it an indispensable material in industries ranging from biomedical devices to aerospace engineering.

GEE SMA's Impact on Nitinol Innovation

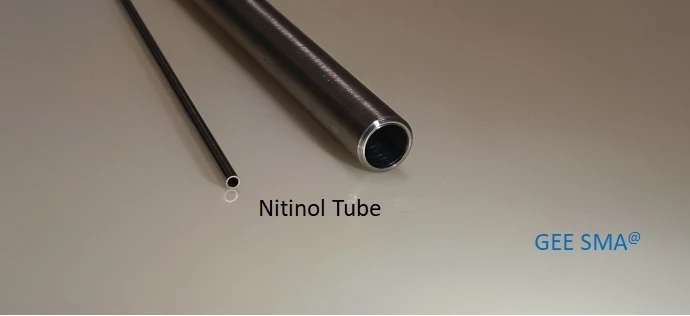

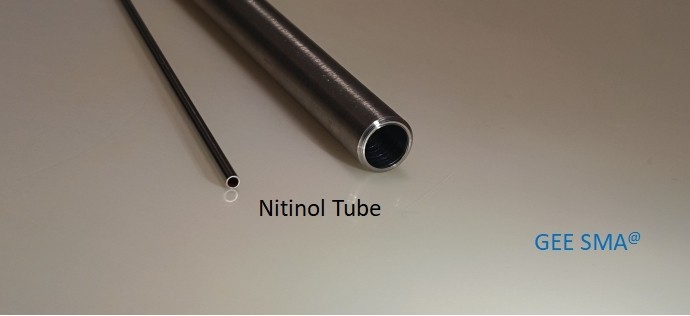

Nitinol mechanical properties and applications have been revolutionized by GEE SMA, a leading manufacturer in the industry. Their expertise lies in crafting high-quality materials and components that harness the exceptional flexibility, shape memory, and superelasticity of nitinol. By enhancing product quality and performance, they have propelled nitinol to the forefront of various industries.

Crafting High-Quality Materials and Components

GEE SMA's meticulous approach to crafting nitinol materials and components ensures that they meet the highest standards of quality and reliability. Their expertise in understanding nitinol mechanical properties allows them to create products with exceptional durability, biocompatibility, and corrosion resistance. This commitment to excellence has solidified their reputation as a trusted partner for innovative solutions.

GEE SMA's dedication to quality extends beyond the manufacturing process, as they also prioritize rigorous testing and inspection protocols to ensure that each nitinol product meets or exceeds industry standards. By investing in state-of-the-art equipment and highly trained personnel, they are able to guarantee consistent performance and reliability across their entire product line. This attention to detail not only sets them apart from competitors but also provides customers with peace of mind knowing that they are receiving top-notch materials and components.

Enhancing Product Quality and Performance

Through rigorous testing and continuous improvement, GEE SMA consistently enhances the quality and performance of their nitinol products. Their dedication to pushing the boundaries of what is possible with nitinol has resulted in cutting-edge advancements that have expanded its applications across diverse industries. From medical devices to aerospace engineering, their contributions have made a lasting impact.

Furthermore, GEE SMA's commitment to tailoring nitinol solutions to customer needs sets them apart in the industry. By actively engaging with clients to understand their specific requirements, they are able to develop customized nitinol products that deliver exceptional performance and reliability. This customer-centric approach has earned them a reputation for being a trusted partner in providing innovative solutions across various sectors.

Tailoring Nitinol Solutions to Customer Needs

One of GEE SMA's key strengths lies in their ability to tailor nitinol solutions to meet specific customer needs. By collaborating closely with clients, they develop customized products that leverage the unique properties of nitinol for optimal results. This customer-centric approach has led to breakthrough innovations that address complex challenges in various fields.

Furthermore, GEE SMA's commitment to continuous improvement and innovation ensures that their nitinol solutions remain at the forefront of technological advancement. By staying abreast of the latest industry trends and developments, they are able to offer cutting-edge products that address emerging challenges and opportunities. This proactive approach not only benefits their clients but also contributes to the overall evolution of nitinol applications in diverse sectors.

Conclusion

Nitinol is a revolutionary material with the potential to transform various industries due to its exceptional mechanical properties and unique characteristics. From medical devices to aerospace engineering, the flexibility, shape memory, and superelasticity of nitinol make it a game-changer in material science.

Unlocking the Potential of Nitinol in Various Industries

The remarkable properties of nitinol make it an ideal choice for a wide range of applications across different industries. Its biocompatibility and high fatigue resistance have opened doors for innovative medical devices and implants, while its corrosion resistance has made it invaluable in industrial and aerospace engineering.

Nitinol's unique shape memory and superelasticity properties have also contributed to its widespread use in consumer products, such as eyeglass frames, dental braces, and even undergarment wires. The ability of nitinol to return to its original shape after deformation makes it an attractive material for products requiring flexibility and resilience. This has led to the development of innovative consumer goods that offer enhanced comfort and durability, further expanding the reach of nitinol across various industries.

Harnessing the Benefits of Nitinol for Future Innovations

As we continue to explore the possibilities of nitinol, there is immense potential for future innovations that can leverage its unique properties. From developing advanced consumer goods to enhancing electronic components, nitinol holds the key to unlocking new opportunities for technological advancements.

Nitinol's unique properties extend beyond just consumer goods and electronic components. Its shape memory and superelasticity make it an ideal material for medical devices, such as stents and orthodontic wires. The biocompatibility of nitinol also makes it suitable for use in implants and surgical tools, opening up a whole new realm of possibilities for the healthcare industry. With ongoing research and development, we can expect to see even more innovative applications of nitinol in the medical field.

Maximizing the Potential of Nitinol Mechanical Properties

By understanding and harnessing the mechanical properties of nitinol alloys like TI 6al 4v, we can maximize their potential in various applications. The strength and durability comparison with stainless steel further emphasizes the superiority of nitinol, paving the way for groundbreaking advancements in mechanical engineering and biomedical devices.

With ongoing research and development, GEE SMA is at the forefront of crafting high-quality materials and components using nitinol alloys. By tailoring nitinol solutions to meet customer needs, GEE SMA is driving innovation and setting new standards for product quality and performance in various industries.