Introduction

Nitinol components have revolutionized various industries with their remarkable properties and diverse applications. From medical devices to renewable energy solutions, nitinol composition offers unparalleled flexibility, durability, and precision. As a leader in nitinol devices and Components Inc., understanding the unique properties of nitinol is essential for crafting high-quality nitinol coils, wires, tubes, and heat engines that meet the most demanding requirements.

Exploring the Versatility of Nitinol Components

Nitinol components are known for their shape memory and superelasticity, making them ideal for various applications. Whether creating custom nitinol springs for medical implants or crafting high-performance nitinol tubes for aerospace engineering, their versatility knows no bounds. These unique properties allow for intricate designs that withstand extreme conditions while maintaining their shape and functionality.

The Unique Properties of Nitinol

Nitinol, a nickel and titanium metal alloy, possesses some remarkable properties. Here are some of the key characteristics that set nitinol apart:

- Shape Memory Effect: Nitinol can be deformed at a certain temperature and then "remember" its original shape when heated back up. This allows medical devices to be compressed for easier insertion and then expand to their proper form inside the body.

- Superelasticity: Nitinol exhibits incredible elasticity, returning to its original shape after undergoing significant bending or deformation. This makes it ideal for applications requiring flexibility and resilience, such as orthodontic wires and eyeglass frames.

- Biocompatibility: Nitinol is highly biocompatible, meaning it doesn't cause adverse reactions within the human body. This makes it a valuable material for medical implants and devices that must stay in place for extended periods.

These unique properties make nitinol a versatile and valuable material across various industries. From its life-saving applications in medicine to its use in everyday items, nitinol continues to revolutionize design and functionality.

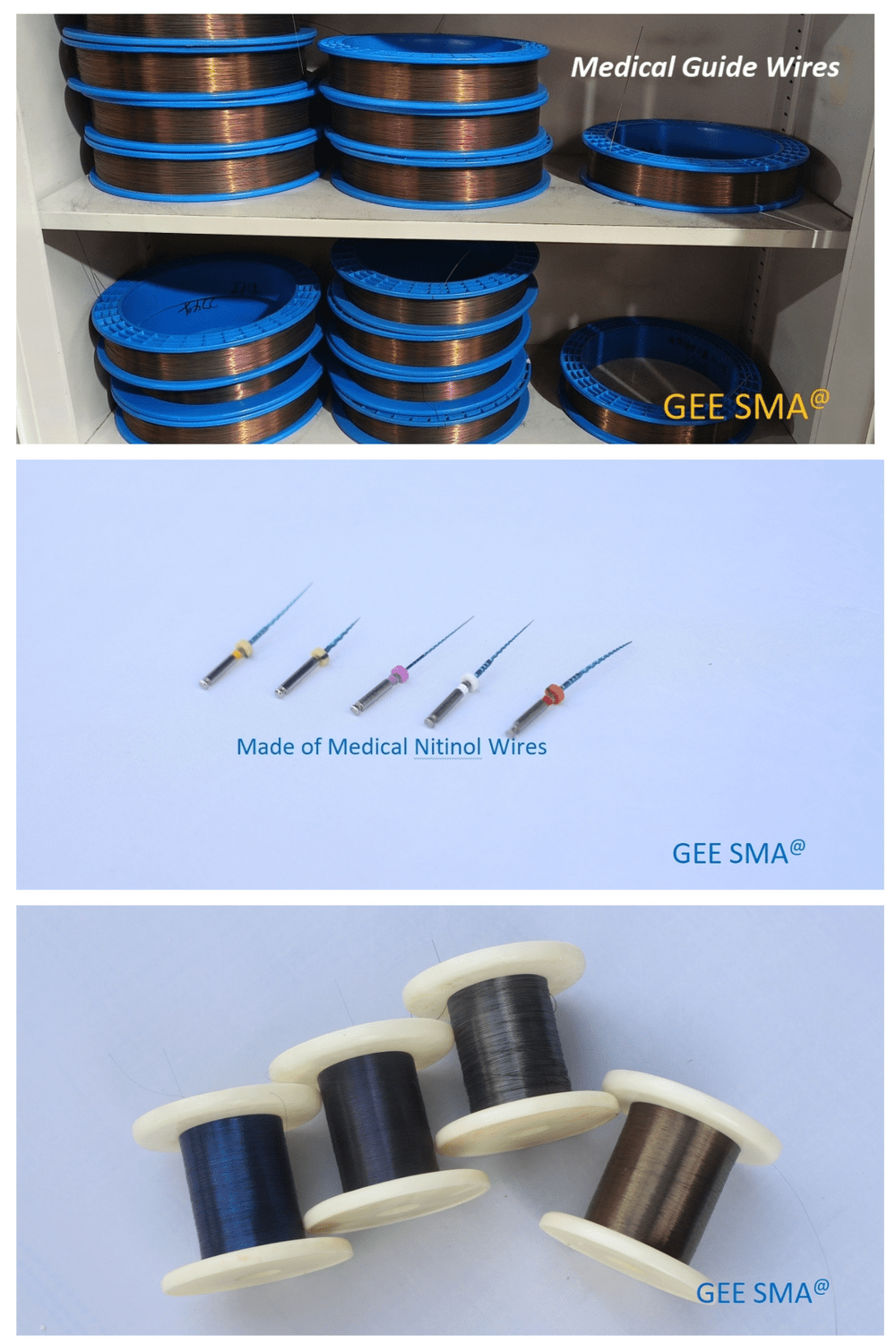

GEE SMA: Crafting High-Quality Nitinol Components

GEE SMA is a leading manufacturer of nitinol components, renowned for the superiority of its nitinol alloys. With a precise understanding of nitinol composition, GEE SMA crafts high-quality nitinol components that offer unmatched flexibility and durability for various applications. From nitinol coils to custom-designed devices, GEE SMA's expertise in nitinol devices and components ensures top-notch quality and reliability.

The Superiority of GEE SMA's Nitinol Alloys

GEE SMA's nitinol alloys are meticulously engineered to deliver exceptional performance in diverse applications. The unique composition of nitinol metal allows for superior shape memory and superelasticity, making it an ideal choice for critical applications where precision and reliability are paramount. With a comprehensive nitinol datasheet, GEE SMA ensures that its alloys meet the highest industry standards, providing customers with peace of mind and confidence in their products.

Custom Nitinol Components for Diverse Applications

GEE SMA specializes in crafting custom nitinol components tailored to specific application requirements, from intricate medical devices to innovative industrial solutions. Whether it's designing complex nitinol springs or precision-engineered wire solutions, GEE SMA's expertise in nitinol components enables the development of cutting-edge products that push the boundaries of what is possible with shape memory alloys.

Meeting Unique Customer Requirements with GEE SMA

At GEE SMA, customer satisfaction is at the core of everything. Our team works closely with clients to understand their unique needs and challenges, leveraging our extensive experience crafting bespoke nitinol components that exceed expectations. Collaborating closely with our customers ensures that every custom-designed component meets their exact specifications, delivering unparalleled value and performance.

Our commitment to meeting unique customer requirements extends beyond the initial design phase. We also provide comprehensive testing and validation services to ensure that each nitinol component performs flawlessly in its intended application. Our dedication to quality and precision means our clients can trust in our components' reliability and durability, providing them with peace of mind and confidence in their final product.

Nitinol Springs: Unmatched Flexibility and Durability

Nitinol springs are widely recognized for their unmatched flexibility and durability, making them ideal for various dynamic applications. Whether in the medical field, aerospace industry, or even consumer electronics, nitinol springs offer a reliable and resilient solution for diverse needs. The unique composition of nitinol metal allows these springs to exhibit exceptional shape memory and superelasticity, ensuring consistent performance in demanding environments.

The Dynamic Applications of Nitinol Springs

From minimally invasive surgical tools to intricate robotics, nitinol springs play a pivotal role in various applications. Their ability to return to their original shape after deformation makes them invaluable for devices that require precise and repetitive movements. Whether in stents, actuators, or even eyeglass frames, their dynamic nature enables innovative solutions across various industries.

Nitinol springs are also highly durable and able to withstand millions of cycles without experiencing significant performance degradation. This makes them ideal for long-term use in medical devices such as catheters or guidewires, where reliability is paramount. Additionally, their biocompatibility and corrosion resistance make nitinol springs a top choice for applications within the human body, ensuring patient safety and comfort.

Advantages of Nitinol Springs for Custom Needs

Nitinol wire springs offer unique advantages that make them perfect for applications requiring custom designs and high performance. Here's why:

- Superior Durability: Nitinol springs can withstand high-stress levels without permanent deformation. This exceptional strength makes them ideal for demanding applications where reliability is critical.

- Tailored Performance: Nitinol's unique properties allow springs to be custom-designed to meet specific performance criteria. This enables engineers to achieve the desired functionality within compact dimensions.

- Exceptional Fatigue Resistance: Nitinol springs exhibit excellent fatigue resistance, making them perfect for applications requiring repeated use and long-term durability. Custom designs can maintain performance over extended periods, reducing maintenance and replacement needs.

Thanks to these advantages, industries such as medical devices, aerospace, and automotive engineering can use the precision and reliability of nitinol springs in their custom designs.

Nitinol Wire: Precision and Reliability in Custom Designs

Nitinol wire is a unique nickel and titanium alloy known for its shape memory properties and superelasticity. This composition allows for precision engineering, making it ideal for custom designs in various industries. Due to its flexibility and durability, nitinol wire is widely used in medical devices and components and nitinol coil applications.

Precision Engineering with Nitinol Wire

Nitinol wire offers unparalleled precision engineering capabilities, allowing for creating intricate designs with exceptional reliability. Its shape memory properties enable it to return to its original shape after deformation, making it perfect for applications that require precise movements or adjustments. The nitinol datasheet provides detailed information on its composition and properties so engineers can confidently create custom nitinol wire solutions tailored to specific industry requirements.

Furthermore, nitinol wire's biocompatibility makes it an ideal choice for medical devices and implants, allowing for precise and reliable performance within the human body. Its corrosion resistance and durability make it suitable for various industrial applications, from aerospace to automotive engineering. With its unique properties and customizability, nitinol wire offers endless possibilities for precision engineering solutions across various industries.

Custom Nitinol Wire Solutions for Various Industries

From aerospace to automotive and robotics to electronics, nitinol wire has extensive use across various industries. Its unique flexibility, durability, and shape memory make it an ideal material for custom solutions in diverse applications. Whether crafting intricate components or developing innovative devices, nitinol wire offers the reliability and performance needed to meet the demands of various industries.

From medical devices to consumer products, nitinol wire revolutionizes how industries approach design and manufacturing. Its ability to return to a predetermined shape after deformation allows for creating innovative products with unique functionalities. This makes it an ideal material for custom solutions that require precision, reliability, and long-term performance in various applications.

By leveraging nitinol wire's versatility and unique properties, industries can achieve unparalleled precision and reliability in their custom designs while meeting specific requirements with ease.

Nitinol Tubes: Tailoring High-Performance Designs

Nitinol tubes are crucial in various industries, offering unparalleled flexibility and durability. The unique nitinol composition allows for creating custom tubes that meet the specific requirements of medical devices and other high-performance applications. Nitinol tubes from Nitinol Devices and Components Inc. are crafted with precision engineering to ensure optimal performance and reliability.

Custom Nitinol Tubes for Medical Devices

Nitinol tubes play a vital role in the design and manufacturing of medical devices, offering exceptional biocompatibility and shape memory properties. These custom nitinol tubes are tailored to meet the stringent requirements of medical applications, providing superior performance and reliability in critical procedures. Whether used in stents, catheters, or other medical instruments, nitinol tubes from Nitinol Devices and Components Inc. ensure unmatched quality and precision.

Enhancing Product Performance with Nitinol Tubes

The versatility of nitinol tubes extends beyond the medical field, with applications across various industries such as aerospace, automotive, and consumer electronics. These high-performance nitinol tubes enhance product performance by offering superior strength, flexibility, and corrosion resistance. Whether used in actuators, sensors, or heat exchangers, nitinol tubes provide unmatched durability and reliability for demanding applications.

Nitinol tubes are also being increasingly used to develop energy-efficient heat engines. These engines harness nitinol's unique shape memory and superelastic properties to convert thermal energy into mechanical work, offering a sustainable and cost-effective solution for power generation. By leveraging nitinol tubes' exceptional thermal conductivity and shape memory effect, heat engines can achieve higher efficiency and lower environmental impact than traditional combustion-based systems.

Nitinol Heat Engines: Efficient Energy Solutions

Nitinol heat engines are revolutionizing how we harness thermal energy, offering unparalleled efficiency and sustainability. With their unique nitinol composition, these engines convert heat into mechanical work with remarkable precision and reliability. Nitinol devices and components has been at the forefront of developing cutting-edge nitinol heat engines tailored for various renewable energy applications, showcasing the immense potential of this remarkable material.

Harnessing Thermal Energy with Nitinol Heat Engines

Nitinol heat engines operate on the principle of shape memory effect, where the nitinol coil undergoes reversible phase transformation when exposed to temperature changes, resulting in mechanical work output. This innovative mechanism allows for efficient thermal energy conversion into useful power, making nitinol heat engines a game-changer in sustainable energy solutions. The versatility and adaptability of nitinol components make them ideal for crafting high-performance heat engines that can be customized to meet specific renewable energy requirements.

Nitinol heat engines are revolutionizing the renewable energy industry by offering a sustainable and efficient solution for harnessing thermal energy. The shape memory effect of nitinol coils allows for a reversible phase transformation, converting temperature changes into mechanical work output. This unique mechanism maximizes the utilization of thermal energy and reduces the environmental impact, making nitinol heat engines an attractive option for sustainable power generation.

Custom Nitinol Heat Engine Designs for Renewable Energy

At Nitinol devices and components, our experts specialize in designing bespoke nitinol heat engine solutions tailored to diverse renewable energy needs. Our custom nitinol engine designs offer unmatched efficiency and durability, whether for solar power generation, waste-heat recovery systems, or geothermal applications. By leveraging the exceptional properties of nitinol composition, we can engineer heat engines that maximize energy output while minimizing environmental impact, paving the way for a greener and more sustainable future.

Elevate Product Performance with Nitinol Components

Nitinol components offer unparalleled versatility and reliability, making them essential for various industries. From nitinol springs to heat engines, the unique composition of nitinol metal ensures exceptional performance in custom devices and components. With Nitinol Devices and Components Inc., businesses can access high-quality nitinol solutions tailored to their specific requirements, whether a nitinol coil, wire, or tube. Elevate your product performance with the unmatched flexibility and durability of nitinol components.

Nitinol components are revolutionizing industries with their unique composition and exceptional properties. Whether it's crafting custom nitinol springs or precision engineering with nitinol wire, these components offer unmatched reliability and flexibility for diverse applications. With GEE SMA's superior nitinol alloys and custom solutions, businesses can elevate their product performance.

Unleashing Innovation with Nitinol Solutions

Nitinol devices and components' dynamic applications are driving innovation across various industries. Custom nitinol tubes for medical devices and efficient energy solutions with nitinol heat engines are just a few examples of how businesses can unleash innovation with these cutting-edge materials. Embrace the future of functional materials by exploring the endless possibilities of nitinol solutions.

Tailoring Functional Materials to Unique Requirements

Nitinol datasheets showcase the precision and reliability of using these functional materials in custom designs. By tailoring nitinol components to unique requirements, businesses can enhance product performance while effectively meeting specific industry needs. Embrace the unparalleled versatility of nitinol composition to create tailored solutions that set you apart from the competition.