Introduction

Nitinol, a versatile alloy of nickel and titanium, has gained widespread recognition for its unique shape memory and superelastic properties. With a wide range of applications in various industries, the material has proven indispensable in modern technology and medicine.

The Versatile Nitinol Alloy

Nitinol, known as NiTi, is a shape memory alloy with remarkable flexibility and durability. Its ability to return to a predetermined shape after deformation makes it an ideal material for many innovative applications.

Nitinol's unique properties have led to its use in various applications, from medical devices to robotics. Its shape memory and superelasticity make it an ideal material for minimally invasive medical procedures, such as stents that can be inserted into blood vessels and then expand to their original shape. In addition, Nitinol's flexibility and durability make it a popular choice for orthodontic wires that can apply gentle, continuous force to move teeth into the desired position. Beyond the medical field, Nitinol is also used in actuators for robotics, where its ability to return to its original shape allows for precise and reliable movement.

Exploring Nitinol Applications

From orthodontic instruments to medical devices, nitinol has revolutionized the way we approach technological advancements. Its exceptional properties have opened doors for groundbreaking solutions in diverse fields such as aerospace engineering and biomedical research.

Understanding Nitinol Properties

The unique composition of nitinol allows it to remember its original shape when subjected to external stimuli, making it an invaluable resource for intricate designs and complex mechanisms. This remarkable material has become synonymous with reliability and precision across various industries.

Nitinol's unique properties make it an ideal material for use in stents and medical devices designed to support and open blocked arteries. The shape memory and superelasticity of nitinol allow stents to be compressed for insertion and then expand to their original shape once in place, providing a secure and effective treatment for patients with cardiovascular issues. This remarkable capability has revolutionized the field of cardiology, offering a reliable and precise solution for improving blood flow and saving lives.

Nitinol in Stents

Nitinol, a shape memory alloy composed of nickel and titanium, has revolutionized the medical field with diverse applications. One of the most significant uses for nitinol is in stents, where its unique properties enhance medical devices and improve patient outcomes.

Enhancing Medical Devices

Nitinol is a remarkable material with unique properties that make it ideal for stent production.

Nitinol offers several advantages for medical device applications:

- Flexibility and superelasticity: These properties allow for easy insertion of stents into the body without damaging delicate tissues, ensuring optimal device performance.

- Shape memory: Nitinol can return to its original shape after deformation, enhancing stent functionality and durability.

- Biocompatibility: This characteristic minimizes the risk of adverse reactions or rejection, improving patient outcomes and reducing the need for interventions.

These combined properties make Nitinol a superior choice for stents, contributing to overall patient care and treatment efficacy.

Improving Patient Outcomes

Nitinol stents improve treatment outcomes due to their biocompatibility and resistance to corrosion. This reduces the risk of complications or adverse reactions within the body, leading to better overall patient recovery and satisfaction.

Additionally, nitinol stents are known for their flexibility and shape memory, allowing them to adapt to the body's natural movements without causing discomfort or obstruction. Patients can experience a more natural and seamless recovery as the stents work harmoniously with their bodily functions. Furthermore, the durability of nitinol stents ensures long-lasting support for the affected area, reducing the need for frequent replacements and minimizing disruptions to the patient's daily life.

Advantages of Nitinol in Stents

Nitinol has proven to be an invaluable material in the development of stents. This unique alloy offers several advantages that contribute to improved patient outcomes.

The benefits of using nitinol in stents include:

- Precise placement: Nitinol's combination of strength and malleability allows for accurate positioning within blood vessels or other anatomical structures.

- Enhanced patient comfort: The material's flexibility minimizes discomfort during stent placement.

- Long-term durability: Nitinol's resilience ensures the stent's effectiveness over an extended period, reducing the need for replacements.

These properties collectively make nitinol a superior choice for stent manufacturing, leading to better patient treatment results.

Nitinol in Orthodontic Instruments

Nitinol, a unique and versatile alloy, finds numerous uses for nitinol in orthodontics. With its remarkable shape memory technology, nitinol instruments can retain their original form even after being bent or twisted, making them ideal for orthodontic applications. This exceptional feature allows orthodontists to create custom patient fittings, ensuring a precise and comfortable fit.

Shape Memory Technology

The nitinol alloy's shape memory properties enable orthodontic instruments to return to their predetermined shape when exposed to heat, providing flexibility and durability in various dental procedures. This remarkable characteristic allows the instruments to withstand repeated use without losing their original form, making them highly reliable for orthodontic treatments.

The flexibility and durability of nitinol alloy also contribute to orthodontic patients' overall comfort. Instruments made from this material can be easily adjusted to fit each patient's individual needs, providing a more customized and comfortable experience. Additionally, the durability of nitinol ensures that the instruments maintain their shape and effectiveness throughout the treatment process, reducing the need for frequent adjustments and replacements.

Flexibility and Durability

Nitinol's composition of nickel and titanium gives it the unique ability to bend and flex without losing its strength or resilience. This flexibility allows orthodontic instruments made from nitinol to easily navigate the intricate contours of the mouth, ensuring precise adjustments during dental procedures.

Nitinol's unique composition also provides exceptional durability, allowing orthodontic instruments made from this material to withstand the rigors of dental procedures without losing their shape or effectiveness. This durability ensures that the instruments maintain their precision and functionality over time, reducing the need for frequent replacements and contributing to cost savings for dental practices. Additionally, the ability of nitinol to resist corrosion makes it an ideal choice for orthodontic instruments, ensuring a longer lifespan and reliable performance for dental professionals.

Benefits

of Orthodontic Treatment

Nitinol has revolutionized the orthodontics field by offering many benefits for both patients and practitioners. This advanced material's unique properties have made it a preferred choice for creating orthodontic appliances.

Nitinol's applications in orthodontics provide several advantages:

- Enhanced Patient Comfort: Its flexibility and shape memory allow for gentler tooth movement, reducing discomfort.

- Improved Treatment Outcomes: Customized fittings and consistent force application contribute to more effective tooth alignment.

- Increased Efficiency: Nitinol's shape memory minimizes the need for frequent adjustments, saving time for both patients and orthodontists.

By incorporating nitinol into orthodontic treatments, practitioners can deliver more comfortable, efficient, and successful outcomes, ultimately enhancing the patient experience.

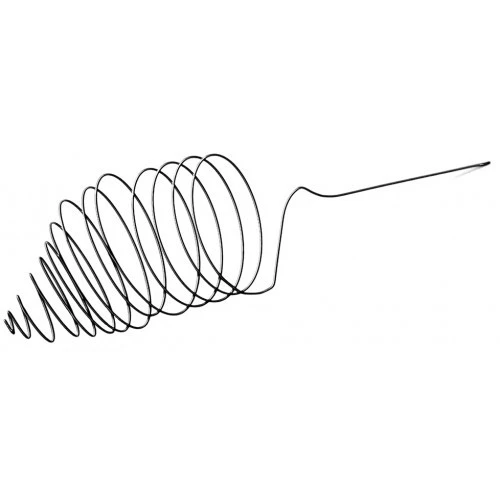

Nitinol in Guidewires

Nitinol's unique material composition makes it ideal for medical guidewires. The alloy's shape memory and superelasticity allow for precision and reliability, ensuring accurate navigation through complex vascular systems. Nitinol's exceptional flexibility and durability make it a superior option for guiding catheters during minimally invasive surgeries, allowing healthcare professionals to perform delicate procedures easily.

Precision and Reliability

Nitinol's shape memory properties enable guidewires to return to their original shape after bending or twisting, ensuring consistent performance during medical procedures. This remarkable feature allows for precise maneuvering through intricate anatomical structures, enhancing the accuracy of diagnostic and interventional treatments. With nitinol guidewires, healthcare providers can trust in the reliability of their tools, leading to improved patient outcomes and overall procedural success.

Navigating Vascular Systems

The superelasticity of nitinol enables guidewires to navigate through tortuous blood vessels with unparalleled ease, reducing the risk of vessel injury or trauma during insertion. This capability is particularly valuable in endovascular procedures where accessing specific areas within the body's vascular system requires exceptional dexterity and control. Nitinol guidewires empower medical professionals to confidently perform intricate interventions, ultimately benefiting patients by minimizing procedural complications.

Nitinol's Unique Material Composition

Nitinol is composed of nearly equal parts nickel and titanium, giving it its distinct shape memory and superelastic properties, which are essential for its use in guidewires. This alloy undergoes a phase transition when exposed to temperature changes, allowing it to revert to its predetermined shape once heated—a crucial attribute for maintaining the integrity of guidewires during medical procedures. The exceptional mechanical properties of nitinol make it an indispensable material for fabricating high-performance guidewires that meet the rigorous demands of modern healthcare practices.

Nitinol in Surgical Tools

Nitinol, a unique alloy of nickel and titanium, is renowned for its shape memory characteristics, making it ideal for surgical tools. This extraordinary material can be bent or deformed and then return to its original shape when exposed to heat, allowing for precision and flexibility in various medical procedures.

Shape Memory Characteristics

Surgical tools made from nitinol are designed to adapt to the body's natural contours, ensuring a minimally invasive approach to surgery. Nitinol's shape memory properties enable these instruments to navigate through delicate tissues with ease, reducing trauma and promoting faster healing for patients.

Minimally Invasive Procedures

Medical professionals can use nitinol surgical tools to perform minimally invasive procedures that result in smaller incisions, less scarring, and reduced recovery times for patients. This innovative application of nitinol improves patient outcomes and overall satisfaction with surgical interventions.

Enhanced Surgical Performance

The exceptional properties of nitinol contribute to enhanced surgical performance by providing surgeons with reliable instruments that offer superior maneuverability and durability. These tools enable precise manipulation within the body, ensuring optimal outcomes for complex surgical procedures.

Nitinol in Endovascular Treatment

Nitinol alloy has revolutionized endovascular treatment by offering customized therapy options for patients with vascular diseases. Its unique shape memory properties allow for the creation of stents and other medical devices that can adapt to the specific needs of each individual, providing more effective and personalized treatment options.

Customized Therapy Options

Nitinol's uses in endovascular treatment are vast. The alloy is being utilized in the development of self-expanding stents, embolic protection devices, and catheter-delivered valves. These innovative applications allow for tailored solutions that conform to the patient's anatomy, ensuring optimal performance and long-term success in treating vascular conditions.

Nitinol's versatility in endovascular treatment extends beyond stents and valves. It is also used in the development of specialized retrieval devices for removing blood clots or other blockages in the arteries. These devices offer a minimally invasive solution for patients with vascular conditions, reducing the need for open surgery and allowing for quicker recovery times. By incorporating nitinol into these innovative tools, medical professionals can provide more customized and effective therapy options for their patients.

GEE SMA's High-Quality Nitinol

GEE SMA is a leading provider of high-quality nitinol alloy that meets stringent medical standards. Their nitinol products are known for their exceptional flexibility, durability, and shape memory characteristics, making them ideal for endovascular devices requiring precision engineering and reliable performance.

GEE SMA's high-quality nitinol alloy is also designed to minimize the risk of material fatigue and corrosion, ensuring the longevity and reliability of medical devices. This level of performance is crucial for applications such as stents, guidewires, and retrieval devices used in minimally invasive procedures. Furthermore, GEE SMA's nitinol components are meticulously crafted to provide consistent and predictable behavior within the body, giving healthcare professionals the confidence they need during delicate interventions.

Tailoring Nitinol Components for Medical Use

Nitinol is primarily composed of nickel and titanium, which gives it its unique shape, memory properties, and superelasticity. This allows nitinol components to return to their original shape after deforming, making them ideal for endovascular treatments where flexibility and resilience are crucial. GEE SMA specializes in tailoring nitinol components to meet the specific requirements of medical applications, ensuring that healthcare professionals have access to cutting-edge materials for their patients' needs.

Embracing the versatility of nitinol alloy has led to significant advancements in endovascular treatment options, providing patients with tailored solutions that improve outcomes and enhance quality of life. With GEE SMA's high-quality nitinol products at the forefront of these innovations, medical professionals can rely on superior materials designed specifically for the demands of modern healthcare practices.

GEE SMA: Your Nitinol Solution Provider

Nitinol is revolutionizing modern medicine with its remarkable shape memory and unique material composition. The alloy's versatility has led to various applications, from stents and orthodontic instruments to surgical tools and endovascular treatment. As the demand for nitinol continues to grow, it's essential to embrace these innovations and recognize nitinol's crucial role in advancing medical technology.

Embracing Nitinol Innovations

As the medical industry continues to evolve, embracing nitinol innovations is vital for staying ahead. With its shape memory capabilities and exceptional flexibility, nitinol offers endless possibilities for improving medical devices and treatment options. Embracing these innovations means embracing a future where patient outcomes are enhanced, and medical procedures are more efficient.

Nitinol's Role in Modern Medicine

Nitinol's role in modern medicine cannot be understated. Its unique properties make it an invaluable resource in developing cutting-edge medical devices that improve patient care and outcomes. From stents that enhance vascular health to advanced orthodontic instruments that revolutionize dental treatment, nitinol is at the forefront of shaping the future of healthcare.

When finding a reliable source for high-quality nitinol solutions, GEE SMA stands out as a top provider in the industry. With expertise in customizing nitinol components for medical use and a commitment to delivering precision-engineered products, GEE SMA is dedicated to meeting the evolving needs of the healthcare sector. Trust GEE SMA as your go-to partner for all your nitinol requirements.