Introduction

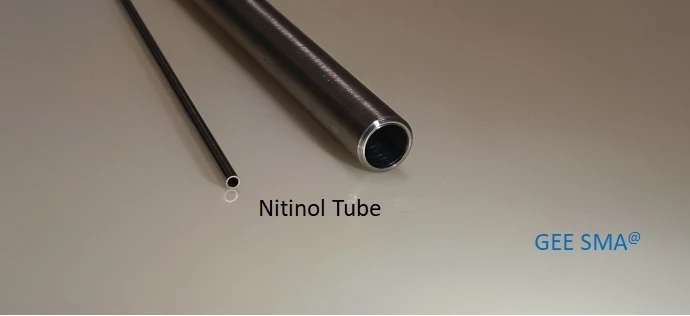

Are you looking for unbeatable prices on nitinol sheets? Look no further! Nitinol is a unique shape memory alloy with remarkable properties, making it an ideal material for various applications. But the big question remains: is nitinol expensive? And where can you find the best source for nitinol sheet metal? Let's dive in and explore the benefits of using nitinol sheet and why GEE SMA is the ultimate destination for all your needs.

Unbeatable Prices on Nitinol Sheets

When it comes to the price of nitinol sheet, affordability is key. At GEE SMA, we understand the importance of competitive pricing without compromising quality. Our commitment to offering unbeatable prices on top-notch nitinol sheets sets us apart as a leading supplier in the industry.

In addition to our unbeatable prices, GEE SMA offers a wide range of nitinol sheet sizes and thicknesses to meet our customers' diverse needs. Whether you require small, precise pieces or large, durable sheets, we have you covered. Our extensive inventory ensures you can find the perfect nitinol sheet for your application without compromising on quality or price.

Benefits of Using Nitinol Sheet

Nitinol sheet metal offers compelling advantages that make it a valuable material across various industries. Here's a closer look at the key benefits of using nitinol sheet:

Unique Functional Properties

- Shape Memory: Nitinol sheets can be deformed and then "remember" their original shape upon exposure to a specific temperature or trigger. This property allows for the creation of innovative components that can adapt or deploy to specific conditions.

- Superelasticity: Nitinol sheet exhibits exceptional elasticity, returning to its original shape after undergoing significant deformation. This allows components to withstand high loads and maintain functionality under challenging conditions.

Biocompatibility Advantage

- Biocompatible Champion: Nitinol possesses excellent biocompatibility, making it suitable for use in medical devices like stents, implants, and surgical instruments. The human body readily accepts nitinol, minimizing the risk of rejection or adverse tissue reaction.

Additional Advantages

- Durability and Corrosion Resistance: Nitinol sheet offers exceptional durability and resistance to corrosion. This ensures components can withstand harsh environments and maintain their functionality over extended lifespans.

- Versatility in Design: Nitinol sheet can be formed and machined into complex shapes, creating intricate components with unique functionalities. This design flexibility empowers engineers to push the boundaries of innovation.

- Low Maintenance: Nitinol's inherent properties minimize the need for frequent maintenance or replacements, reducing long-term operational costs.

Nitinol sheet metal offers a unique combination of functional properties, biocompatibility, and design versatility. These advantages position it as a valuable material for various industries, from medical devices to aerospace and beyond. By understanding its capabilities, engineers and designers can unlock the potential of nitinol sheet to create innovative and high-performance products.

Why GEE SMA is the Best Source for Nitinol Sheet

Finding a reliable source for high-quality nitinol sheets can be challenging, but GEE SMA makes it easy. With our dedication to superior customer service, extensive industry expertise, and unwavering commitment to competitive pricing, we are your go-to destination for nitinol.

At GEE SMA, we understand the importance of delivering high-quality nitinol sheets that meet the specific needs of our customers. Our extensive industry expertise allows us to provide tailored solutions for various applications, ensuring that you get the right product for your project. Whether you require a standard size or custom dimensions, our team is dedicated to delivering top-notch nitinol sheets that exceed your expectations.

Understanding the Price of Nitinol Sheet

When it comes to understanding the price of nitinol sheet, several factors can affect the cost. The composition and purity of the nitinol alloy, the production process, and market demand all play a significant role in determining the price of nitinol sheets. Additionally, the size and thickness of the sheet metal can impact its cost, so it's essential to evaluate these factors carefully when considering a purchase.

Factors Affecting the Cost of Nitinol

Several key factors influence the cost of nitinol sheet metal. Here's a breakdown of these factors to help buyers make informed decisions:

Material and Manufacturing

- Raw Material Costs: Nickel and titanium, the primary elements in nitinol, experience price fluctuations based on global market demands and supply chains. An increase in their cost directly impacts the overall price of nitinol sheet.

- Manufacturing Complexity: Producing nitinol sheet involves specialized processes like melting, hot rolling, cold rolling, and heat treatment. These intricate steps require specialized equipment and expertise, contributing to higher production costs than simpler materials.

Unique Properties

- Shape Memory and Superelasticity: These are the defining characteristics of nitinol. Achieving these properties necessitates complex processing techniques, adding to the overall manufacturing cost. Standard materials like steel or aluminum don't require such specialized processes, making them less expensive.

Market Dynamics

- Supply and Demand: Similar to raw materials, the overall supply and demand for nitinol sheet can influence its price. Limited supply with high demand can drive prices up, while a surplus in the market can lead to lower costs.

- Industry Trends: The increasing use of nitinol in various industries like medical devices and aerospace can influence its overall market value. Growing demand can put upward pressure on prices.

Product Variations

- Sheet Thickness: The thickness of the nitinol sheet can affect the cost per unit. Thicker sheets might require additional processing steps or specialized equipment, leading to a higher price.

- Surface Finish: Nitinol sheet can be supplied with various surface finishes depending on the application. Certain finishes requiring additional polishing or treatment steps may command a premium.

Supplier Factors

- Quality and Reputation: Reputable manufacturers with a proven track record of producing high-quality nitinol sheet might command a premium compared to lesser-known suppliers. However, the consistency and reliability of their product can justify the higher cost.

- Location and Overhead: A supplier's geographic location and operational overhead can influence the final price of nitinol sheet. Suppliers in certain regions might have higher production costs due to factors like labor or regulations, which can be reflected in the pricing.

Comparing Nitinol Price to Other Materials

In comparison to other materials like titanium or aluminum sheet metal, nitinol does tend to have a higher price point due to its specialized properties and manufacturing requirements. However, the value outweighs its initial cost when considering the long-term benefits and performance capabilities of nitinol sheets in specific applications such as medical devices or aerospace components. It's important for buyers to weigh these factors when making comparisons between different materials for their intended use.

While nitinol may have a higher price point initially, the unique shape memory and superelastic properties of this material make it a cost-effective choice in the long run. Its ability to return to its original shape after deformation and withstand repetitive loading without permanent damage can reduce maintenance and replacement costs. This makes nitinol an attractive option for industries where durability and reliability are paramount.

How GEE SMA Offers Competitive Pricing

GEE SMA stands out as a reliable source for competitive pricing on high-quality nitinol sheets. GEE SMA can offer cost-effective solutions without compromising quality or performance by leveraging strategic partnerships with top manufacturers and optimizing their supply chain management. Their commitment to competitive pricing ensures customers can access premium nitinol sheet metal at unbeatable prices without sacrificing reliability or durability.

Furthermore, GEE SMA's commitment to quality is evident in its rigorous testing and inspection processes for nitinol sheets. By ensuring that every sheet meets strict industry standards, customers can have confidence in the reliability and durability of the products they purchase. This dedication to quality sets GEE SMA apart from competitors and provides peace of mind for customers seeking long-lasting and high-performing nitinol sheet metal.

Quality of Nitinol Sheets

The Superior Properties of Nitinol

Nitinol sheets are renowned for their exceptional properties, including superelasticity and shape memory. These unique characteristics make nitinol ideal for various applications, from medical devices to aerospace components. With its ability to return to a predetermined shape when heated, nitinol offers unmatched flexibility and durability.

Nitinol's superelasticity and shape memory make it ideal for intricate and complex designs. It can easily be manipulated into various shapes without losing its original form, allowing for the creation of innovative and efficient products that would be difficult to achieve with traditional materials. Whether it's a medical implant requiring precise shaping or a lightweight aerospace component needing resilience, nitinol's properties provide endless possibilities for engineering breakthroughs.

Ensuring High Quality in Nitinol Sheet Production

At GEE SMA, we prioritize quality at every step of the nitinol sheet production process. Our state-of-the-art manufacturing facilities and stringent quality control measures ensure that every sheet meets the highest standards. From raw material selection to final inspection, we are committed to delivering nitinol sheets that exceed expectations in terms of performance and reliability.

Why Quality Matters in Nitinol Applications

When it comes to critical applications such as medical implants or precision engineering, the quality of the material is non-negotiable. Inferior nitinol sheets can lead to product failures, safety risks, and costly setbacks. By choosing high-quality nitinol from a trusted supplier like GEE SMA, you can have peace of mind knowing that your applications will benefit from the superior properties and consistent performance of top-grade nitinol.

Nowadays, manufacturers use advanced technology with automated machinery to produce high-quality products such as Nitinol Sheets. This image shows a modern production facility where strict quality control measures are implemented at every process stage.

Is Nitinol Expensive?

Dispelling Myths About Nitinol Cost

Many people believe that nitinol is an expensive material, but the truth is that the price of nitinol sheet is quite competitive. While it may be pricier than some other materials, nitinol's unique properties and benefits make it a worthwhile investment for many applications. When considering its long-term value and cost-effectiveness, nitinol is often a smart choice for various industries.

While the initial cost of nitinol may seem higher than other materials, its durability and resistance to corrosion can lead to significant long-term cost savings. This makes it an attractive option for industries that require reliable and low-maintenance materials. Additionally, nitinol's unique shape memory and superelasticity properties make it a versatile material for various applications, further adding to its overall value. When weighing the upfront investment against the long-term benefits, nitinol often emerges as a cost-effective choice that can deliver substantial returns over time.

The Long-Term Value of Investing in Nitinol

When evaluating the price of nitinol sheet, it's important to consider this material's long-term value. Nitinol's exceptional shape memory and superelasticity make it a durable and reliable option for numerous applications. Its ability to withstand repeated deformations without permanent damage means that investing in nitinol can lead to significant cost savings over time, making it a wise choice for those looking for high-quality materials.

Cost-Effectiveness of Nitinol Sheet

While the initial price of sheet aluminum may seem more appealing at first glance, it's crucial to recognize the cost-effectiveness of the nitinol sheet. Nitinol's unique properties allow for innovative solutions in industries such as medical devices, aerospace, and consumer electronics, ultimately leading to improved performance and reduced maintenance costs. When weighing these factors against its initial price, it becomes clear that nitinol is a highly cost-effective option.

Applications and Uses of Nitinol Sheet

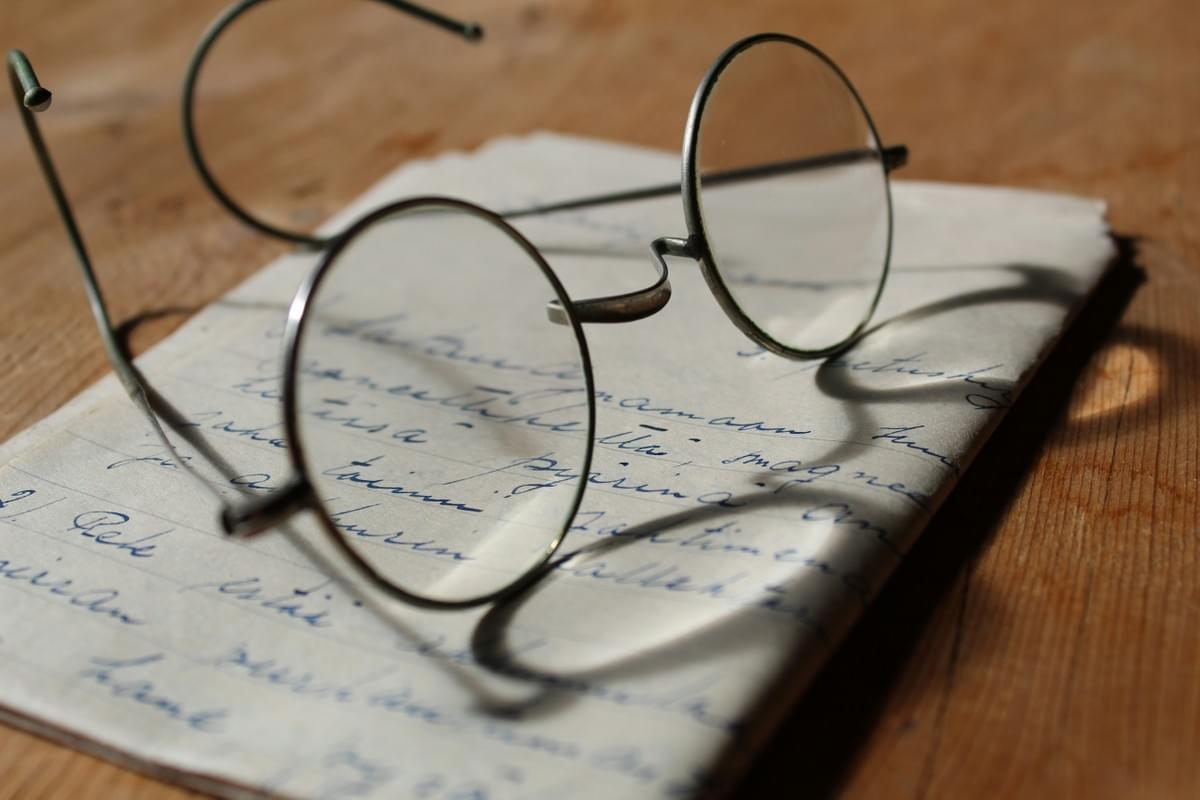

Nitinol sheets have many applications across industries, from medical devices to aerospace engineering. Due to their unique shape memory and superelastic properties, these versatile sheets are used in stents, braces, and even eyeglass frames. For intricate medical instruments or durable mechanical components, nitinol sheets offer unparalleled performance.

Diverse Applications for Nitinol Sheets

Due to their biocompatibility and flexibility, nitinol sheets are commonly used in the medical field for minimally invasive procedures such as stent implants and orthodontic wires. In the aerospace industry, nitinol is used in actuators, valves, and other critical components requiring lightweight yet durable materials. Additionally, due to their shape memory properties, nitinol sheets are also found in consumer products like eyeglass frames and mobile phone antennas.

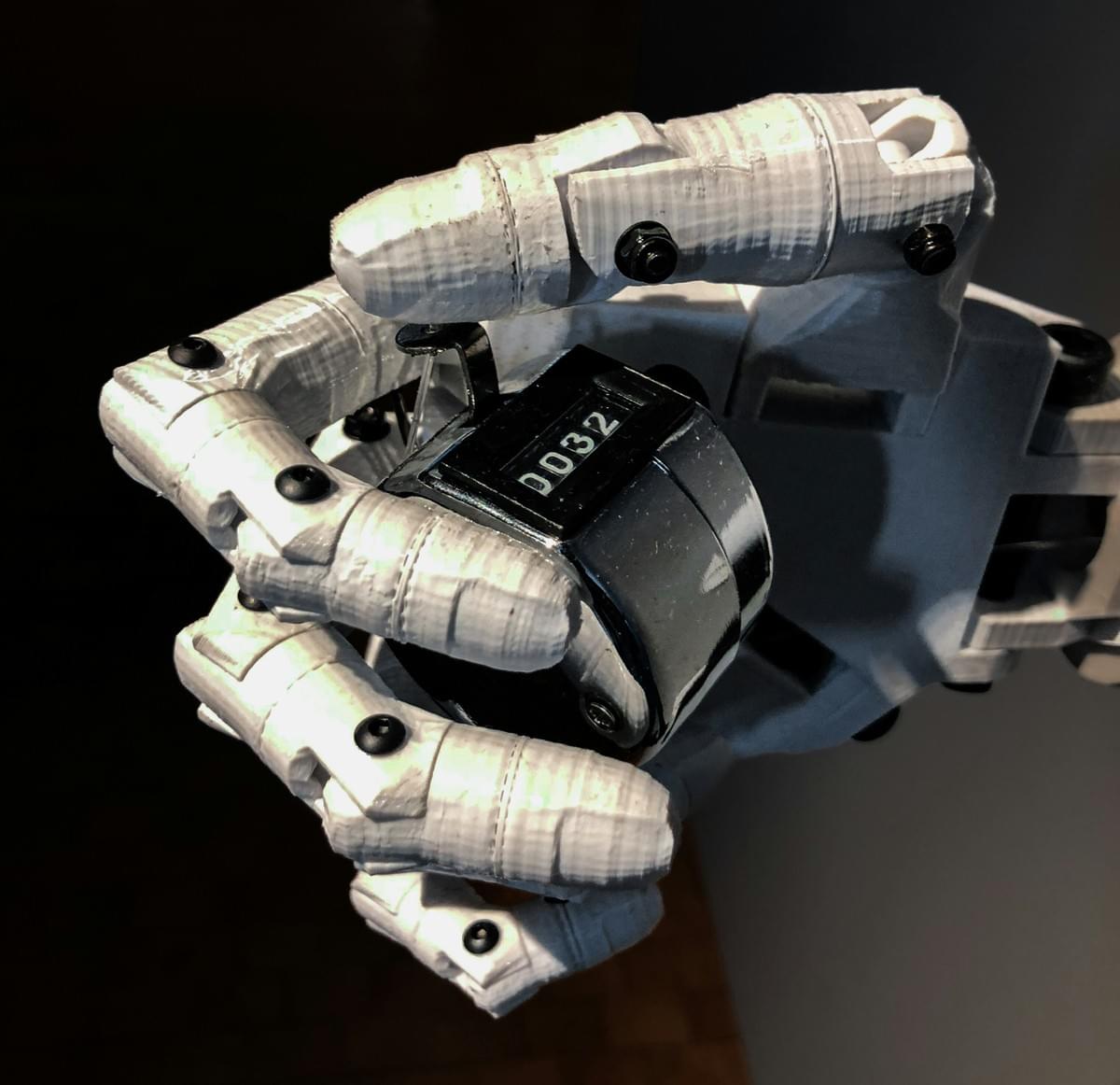

Nitinol sheets have also revolutionized the field of robotics, with their unique combination of flexibility and shape memory properties. These sheets are used to develop robotic grippers and actuators that can adapt to different shapes and sizes, making them ideal for handling delicate objects in manufacturing and assembly processes. Additionally, nitinol sheets are being incorporated into soft robotics, creating more lifelike and adaptable robotic systems for various applications.

Innovations Enabled by Nitinol

The unique properties of nitinol have enabled groundbreaking innovations in various fields. For instance, nitinol actuators have revolutionized robotics by allowing for precise control and movement in small spaces. In the medical field, nitinol-based devices have transformed treatment options for cardiovascular diseases by providing reliable support within blood vessels.

In addition to robotics and medical applications, nitinol has played a crucial role in the aerospace industry. Its unique ability to return to its original shape after being deformed has made it an ideal material for components such as actuators, valves, and sensors in aircraft and spacecraft. This capability enhances aerospace systems' performance and contributes to their overall reliability and safety, making nitinol a sought-after material in this field.

How GEE SMA Supports Nitinol Sheet Users

GEE SMA offers unbeatable prices on high-quality nitinol sheets and provides comprehensive technical support to help customers maximize the potential of this remarkable material. From custom fabrication to expert guidance on material selection, GEE SMA is committed to empowering users with the knowledge and resources they need to succeed.

Finding the Best Price for Nitinol Sheet

When evaluating nitinol suppliers, it's crucial to consider not just the initial price of nitinol sheet, but also the quality and reliability of the supplier. Look for a supplier with a proven track record of delivering high-quality nitinol at competitive prices. GEE SMA stands out, offering top-notch nitinol sheets at unbeatable prices.

Factors to Consider When Evaluating Nitinol Suppliers

While price is naturally a significant factor, it shouldn't be the sole consideration when evaluating nitinol sheet suppliers. Here's a breakdown of key factors to ensure you choose a reliable partner for your nitinol needs:

Supplier Expertise and Reputation

- Experience with Nitinol: Look for a supplier with a proven track record of working with nitinol sheet metal. Their experience ensures they understand the material's intricacies and can provide technical guidance.

- Industry Reputation: Research the supplier's reputation within the nitinol industry. Look for positive customer reviews and testimonials highlighting their quality, reliability, and customer service.

Quality Control and Certifications

- Commitment to Quality: Prioritize suppliers with a robust quality control system. This ensures consistent material properties and adherence to industry standards like ASTM International or ISO standards. Certifications demonstrate their commitment to quality.

- Traceability: Reliable nitinol suppliers can provide proper material traceability documentation. This ensures you know the origin and processing history of the nitinol sheet, which can be crucial for specific applications, particularly in medical devices.

Customer Service and Support

- Responsiveness: A supplier with responsive customer service is essential. They should be able to answer your questions promptly and address any concerns you may have throughout the buying process.

- Technical Support: Look for a supplier with technical support regarding nitinol properties, selection guidance, and potential application considerations. This ensures you make informed decisions and get the most out of the material.

Additional Considerations

- Delivery and Lead Times: Evaluate the supplier's delivery timelines and reliability. Can they meet your project deadlines?

- Minimum Order Quantities: Be aware of any minimum order quantity requirements, especially if your project needs are smaller.

- Value-Added Services: Some suppliers offer additional services like custom cutting, machining, or surface finishing for the nitinol sheet. These services can streamline your manufacturing process.

GEE SMA's Commitment to Competitive Pricing

GEE SMA is dedicated to providing customers with the best value for their investment in nitinol sheets. By streamlining production processes and leveraging economies of scale, they are able to offer competitive pricing without compromising on quality. This ensures that customers get high-quality nitinol sheets at affordable prices.

Tips for Getting the Best Value for Nitinol Sheet

To maximize the value of your purchase, consider buying in bulk or partnering with a reliable supplier like GEE SMA for long-term supply agreements. Establishing a strong relationship with your supplier can often help you negotiate better pricing and ensure consistent access to high-quality nitinol sheets for your applications.

Partner with GEE SMA for Nitinol Solutions

When it comes to the price of nitinol sheet, it's important to consider the long-term value and cost-effectiveness. Nitinol sheets may have a higher upfront cost, but their durability and unique properties make them a worthwhile investment for various applications. At GEE SMA, we understand the importance of unlocking the potential of nitinol sheet and offer competitive pricing to support our customers in maximizing cost-effectiveness.

Unlocking the Potential of Nitinol Sheet

Nitinol sheets offer unparalleled flexibility, shape memory, and superelasticity, making them an ideal choice for medical devices, aerospace, and automotive industries. Their ability to return to a predetermined shape after deformation sets them apart from other materials. Investing in nitinol sheets opens up possibilities for innovative designs and solutions.

At GEE SMA, we are committed to providing high-quality nitinol sheets at unbeatable prices. Our team works closely with customers to understand their requirements and offer tailored solutions that meet their needs. With our expertise in nitinol production and extensive industry knowledge, we are the perfect partner for businesses looking to leverage the benefits of nitinol.

Maximizing Cost-Effectiveness with Nitinol Sheets

Despite initial assumptions about the price of nitinol sheet metal, its long-term value far outweighs its upfront cost. Nitinol's durability and reliability make it a cost-effective choice for applications where performance is crucial. By choosing GEE SMA as your supplier, you can maximize cost-effectiveness without compromising on quality or innovation.