Introduction

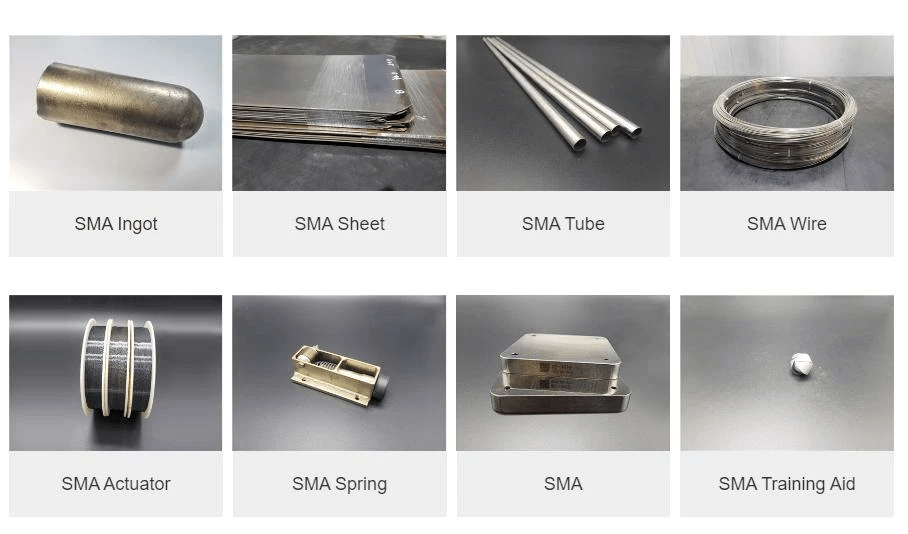

In the world of robotics, the use of Nitinol for robots has revolutionized the field of robotic actuators. Nitinol, a shape memory alloy, offers unique advantages that make it an ideal choice for creating efficient and durable robotic actuators. As we delve into the advantages of using Nitinol in robotic actuators and explore other options available, it becomes clear that Nitinol is at the forefront of innovation in this industry.

Understanding Nitinol and Robotic Actuators

Nitinol is a nickel-titanium alloy with unique shape memory and superelastic properties, making it an ideal material for creating efficient and powerful robotic actuators. Its ability to return to its original shape after being deformed sets it apart from other materials used in actuator construction. This makes Nitinol an innovative choice for developing advanced robotics.

Advantages of Using Nitinol in Robotic Actuators

The use of Nitinol in robotic actuators offers numerous advantages, including exceptional power and efficiency, durability, longevity, and cost-effectiveness. These characteristics make Nitinol an attractive option for creating high-performance robotic systems that can withstand rigorous use while maintaining their functionality over time.

Exploring Other Robotic Actuators

While there are various options available for creating robotic actuators, such as hydraulic and pneumatic systems, the unique properties of Nitinol set it apart from traditional materials used in actuator construction. By exploring other types of robotic actuators alongside those built from Nitinol, we can gain a deeper understanding of how this shape memory alloy is transforming the field of robotics.

Nitinol vs Other Robotic Actuators

When comparing Nitinol with other robotic actuators, it's clear that Nitinol for robots offers superior power and efficiency. The unique properties of Nitinol allow for quick response times and precise control, making it an ideal choice for high-performance robotic applications. Unlike traditional actuators, Nitinol linear actuators (2 way) provide exceptional power output while maintaining energy efficiency, giving robots the strength and agility they need to perform complex tasks.

Power and Efficiency

Nitinol's shape memory alloy properties give it a significant advantage over other robotic actuators in terms of power and efficiency. Its ability to return to a predetermined shape when heated allows for quick and seamless movement, resulting in higher performance and reduced energy consumption. Whether it's powering a robotic arm or controlling intricate movements in a surgical robot, Nitinol components deliver unmatched power and efficiency, setting new standards for robotic actuation.

Durability and Longevity

In the realm of durability and longevity, Nitinol actuators stand out as a reliable choice for robotics applications. The exceptional resilience of Nitinol ensures that robotic systems equipped with Nitinol linear actuators (2 way) can withstand rigorous use without compromising performance. This longevity not only reduces maintenance costs but also extends the operational lifespan of robots, making them more dependable in various industries such as manufacturing, healthcare, and aerospace.

Cost-effectiveness and Affordability

Despite its advanced capabilities, Nitinol remains cost-effective and affordable compared to other high-performance materials used in robotic actuators. The long-term benefits of using Nitinol for robots far outweigh its initial investment, offering a compelling value proposition for businesses seeking to enhance their automation processes with reliable actuation technology. With customized solutions available through expert consultation on Nitinol applications, businesses can optimize their robotics systems while staying within budget constraints.

Nitinol For Robots

Nitinol for robots offers a wide range of applications, including the innovative Nitinol Linear Actuator (2 way) that provides precise and efficient movement for robotic systems. This cutting-edge technology allows for seamless integration into various robotic designs, enhancing their overall performance and functionality.

Nitinol Linear Actuator (2 way)

The Nitinol Linear Actuator (2 way) is a game-changer in the world of robotic actuators, offering bi-directional movement with exceptional speed and accuracy. This unique feature allows for more dynamic and versatile robotic applications, providing engineers with greater flexibility in designing advanced robotics systems that can perform complex tasks with ease.

Nitinol Components

Nitinol components play a crucial role in the development of high-performance robotic actuators. These components are known for their durability, resilience, and shape memory properties, making them ideal for use in demanding robotic environments where precision and reliability are paramount.

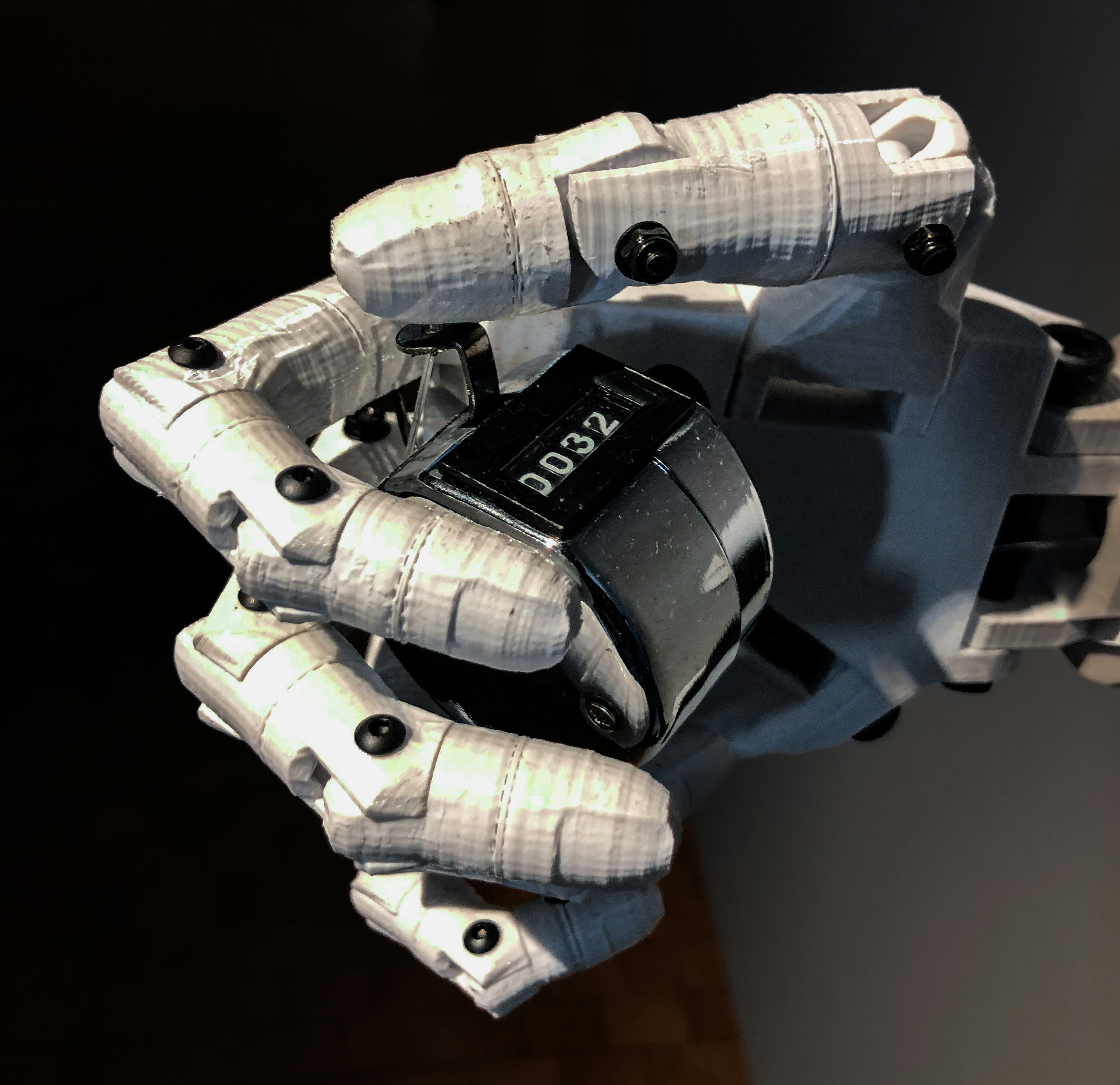

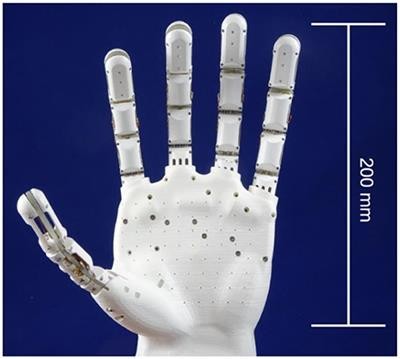

Nitinol Finger Actuator

The Nitinol Finger Actuator is another groundbreaking innovation that has revolutionized the field of robotics. This compact yet powerful actuator design enables robots to perform delicate tasks with precision and dexterity, opening up new possibilities for applications in industries such as healthcare, manufacturing, and logistics.

By leveraging the power of Nitinol for robots, engineers can unlock unprecedented potential in the development of next-generation robotic systems that are capable of performing tasks with unparalleled efficiency and accuracy.

Nitinol Actuators Product Development Design and Consulting

Innovative Solutions for Robotics

Our team at GEE SMA specializes in providing innovative solutions for robotics through the development and design of Nitinol actuators. With our expertise in shape memory alloy technology, we are able to create cutting-edge robotic actuators that offer unparalleled performance and precision, making them ideal for a wide range of robotic applications.

Customized Nitinol Actuators

When it comes to robotic actuators, one size does not fit all. That's why we offer customized Nitinol actuators that are tailored to meet the specific needs of each robotics project. Whether it's a Nitinol linear actuator (2 way) or a Nitinol finger actuator, we have the capabilities to design and manufacture actuators that perfectly align with the unique requirements of our clients.

Expert Consultation on Nitinol Applications

At GEE SMA, we don't just stop at providing products – we also offer expert consultation on Nitinol applications for robotic actuators. Our team of experienced engineers and designers can provide valuable insights and guidance on how to best integrate Nitinol components into robotics projects, ensuring optimal performance and efficiency.

By offering innovative solutions, customized products, and expert consultation on Nitinol applications for robotic actuators, GEE SMA is at the forefront of shaping the future of robotics with advanced shape memory alloy technology.

Shape Memory Alloy as an Artificial Actuator for Exoskeletons

Advancements in Exoskeleton Technology

As exoskeleton technology continues to evolve, the demand for advanced robotic actuators has increased. Nitinol for robots has emerged as a game-changer in this field, offering superior performance and durability. With the ability to mimic natural muscle movements, Nitinol actuators are revolutionizing the way exoskeletons operate, providing users with enhanced mobility and strength.

Furthermore, Nitinol actuators are lightweight and compact, making them ideal for integration into exoskeleton designs without adding unnecessary bulk or weight. This allows for greater freedom of movement and flexibility for users, ensuring a more natural and comfortable experience while wearing the exoskeleton. Additionally, the durability of Nitinol ensures that the actuators can withstand prolonged use and heavy loads, making them reliable for a wide range of applications in various industries.

Benefits of Nitinol in Exoskeleton Actuators

The use of Nitinol components in exoskeleton actuators brings a multitude of benefits to the table. From improved flexibility and precision to increased energy efficiency and reduced weight, Nitinol finger actuators and linear actuators are setting new standards for exoskeleton performance. These advancements are paving the way for more functional and user-friendly exoskeleton designs that can seamlessly integrate with human movement.

The use of Nitinol components in exoskeleton actuators not only enhances performance but also contributes to the overall comfort and usability of the exoskeleton. With Nitinol's ability to remember and return to its original shape, users can experience a more natural range of motion without feeling restricted by the exoskeleton. This means that individuals wearing these advanced exoskeletons can move more freely and comfortably, making them suitable for a wider range of activities and applications.

Future of Shape Memory Alloy Actuators

As we look ahead, the future of shape memory alloy actuators, particularly those built from Nitinol, holds great promise for the robotics industry. With ongoing research and development efforts focused on enhancing Nitinol's capabilities, we can expect to see even more innovative applications in exoskeleton technology. The potential for shape memory alloy actuators to further augment human capabilities is truly exciting, signaling a new era of possibilities in robotic advancements.

Actuators Built from Nitinol Have Highest Power

Nitinol actuators are renowned for their exceptional power, outperforming other robotic actuators in the market. With its unique shape memory and superelastic properties, Nitinol offers unmatched strength and force, making it the top choice for high-power robotics.

Nitinol's Exceptional Performance

Nitinol's exceptional performance as a robotic actuator stems from its ability to withstand high stress and strain, while maintaining its shape and functionality. This allows for precise and powerful movements in robotic applications, ensuring optimal performance and reliability in various environments. In high-power robotics, Nitinol's unique properties make it an ideal material for applications requiring strong and durable actuators, such as industrial automation, aerospace technology, and medical robotics. Its ability to deliver consistent and efficient performance under demanding conditions sets it apart from other materials commonly used in robotic actuators.

Applications in High-power Robotics

Nitinol's unique ability to generate high power output also makes it an ideal choice for robots operating in extreme environments, such as deep-sea exploration or outer space missions. The durability and resilience of Nitinol actuators allow them to withstand harsh conditions and continue performing at optimal levels, ensuring the success of critical operations in challenging settings. This competitive edge positions Nitinol as a top choice for high-power robotics applications that demand reliability and performance under demanding circumstances.

Competitive Edge of Nitinol Actuators

The competitive edge of Nitinol actuators lies in their ability to deliver unparalleled power without compromising on size or weight. This gives them a significant advantage over other actuator technologies, making them the go-to choice for demanding robotic applications that require maximum power output.

Nitinol actuators also offer superior precision and control, allowing robots to perform delicate tasks with accuracy and finesse. This level of control is essential in industries such as healthcare, where surgical robots need to operate with utmost precision. The ability of Nitinol actuators to deliver both power and precision makes them the top choice for a wide range of robotic applications, from heavy-duty industrial tasks to intricate medical procedures.

Conclusion

Nitinol's Role in Robotic Advancements

Nitinol has revolutionized the field of robotic actuators, providing unparalleled power and efficiency. Its unique properties make it the ideal choice for advanced robotics, ensuring smooth and precise movements in Nitinol for robots.

Nitinol's remarkable flexibility and shape memory properties have opened up new possibilities in the field of robotics. This unique material allows for intricate and complex movements that were previously unattainable with traditional actuators. As a result, robots powered by Nitinol can perform tasks with a level of precision and dexterity that was once thought to be only achievable by human hands. The potential for Nitinol in future robotics is limitless, as researchers continue to explore its applications and push the boundaries of what is possible in robotic technology.

Embracing Nitinol for Future Robotics

As we look to the future of robotics, it's clear that Nitinol will continue to play a pivotal role. With its durability and longevity, Nitinol actuators are poised to drive innovation in the industry, offering unmatched performance and reliability.

Looking ahead, the potential applications of Nitinol in robotics are virtually limitless. From medical robotics to industrial automation, Nitinol actuators are proving to be a game-changer in terms of precision and control. As the technology continues to evolve, we can expect to see even more sophisticated designs and capabilities, further solidifying Nitinol's position as a cornerstone of the robotics industry.

GEE SMA: Tailored Nitinol Solutions

At GEE SMA, we specialize in customized Nitinol actuators product development design and consulting. Our expertise in Nitinol linear actuators (2 way) and Nitinol finger actuators ensures that our clients receive innovative solutions tailored to their specific needs.

Our team at GEE SMA is committed to staying at the forefront of Nitinol actuator technology, constantly researching and developing new solutions to meet the evolving needs of our clients. By collaborating with us, you can be assured that you will have access to the latest advancements in Nitinol linear actuators and finger actuators, giving you a competitive edge in your industry. We take pride in our ability to deliver cutting-edge products that not only meet but exceed our clients' expectations, setting a new standard for excellence in the field of Nitinol actuator development.