Introduction

Welcome to the fascinating world of shape memory alloys, where innovation and technology combine to create groundbreaking solutions. In this article, we will explore the intricacies of 2-way shape memory alloy technology, exploring its potential and common applications in various industries.

Understanding 2-Way Shape Memory Alloy Technology

As we embark on this journey, we must grasp the 2-way shape memory alloy technology concept. This cutting-edge material can remember its original shape and return to it when subjected to certain stimuli, making it a game-changer in engineering and manufacturing.

This incredible technology is revolutionizing the way we approach design and manufacturing processes. Because it can revert to its original shape, 2-way shape memory alloy opens up a world of possibilities for creating products with enhanced functionality and durability. As engineers and manufacturers continue to explore this material's potential, we can expect to see even more innovative applications in various industries.

Exploring the Potential of Shape Memory Alloys

The potential of shape memory alloys knows no bounds, with their unique properties opening up a world of possibilities across different sectors. From healthcare to aerospace, these alloys offer innovative solutions that revolutionize how we approach design and functionality.

Shape memory alloys are used in the automotive industry, where they are used in various components such as actuators, sensors, and valves. Their ability to return to their original shape after deformation makes them ideal for safety devices such as airbags and seatbelt pre-tensioners. This unique property also enables shape memory alloys to be used in adaptive materials for vehicle design, allowing for greater flexibility and efficiency in automotive engineering.

Common Applications of Shape Memory Alloys

Intriguingly versatile, shape memory alloys are used in an array of applications, including medical devices, automotive components, and even consumer electronics. Their adaptability and resilience make them a sought-after material for engineers and designers alike.

Shape memory alloys are particularly well-suited for medical devices due to their ability to return to a predetermined shape after deforming. This makes them ideal for applications such as stents, orthodontic wires, and surgical instruments. These materials' biocompatibility also makes them safe for use within the human body, further expanding their potential in the medical field.

What are Shape Memory Alloys?

Shape memory alloys (SMAs) are materials that can remember their original shape and return to it when subjected to certain stimuli, such as temperature or stress. These unique alloys are revolutionizing industries with their remarkable properties and applications.

Properties of Shape Memory Alloys

Shape memory alloys (SMAs) are renowned for their ability to "remember" their original shape. This unique property makes them valuable in various fields, including aerospace, automotive, and biomedicine.

Here's a closer look at their key characteristics:

- Shape Memory Effect: SMAs can significantly deform at a specific temperature. However, they remarkably return to their original shape upon exposure to a different temperature.

- High Strength and Durability: SMAs boast exceptional strength and resilience, allowing them to function effectively in challenging environments like outer space or underwater. Their ability to withstand extreme conditions without compromising their form or structural integrity makes them ideal for demanding applications.

- Lightweight: Compared to traditional materials, SMAs offer lightweight advantages. This property is particularly valuable in industries like the automotive sector, where weight reduction is crucial for improved performance and fuel efficiency.

The unique combination of shape memory effect, high strength, and lightweight properties makes SMAs a versatile material with the potential to revolutionize various fields.

Shape Memory Alloy Wire for Various Industries

One of the most popular forms of SMAs is shape memory alloy wire, which can be easily manipulated into different shapes and sizes. This flexibility makes it an invaluable resource in robotics, actuators, and medical devices, requiring intricate movements and high strength.

Shape memory alloy wire is also highly resistant to corrosion and wear, making it ideal for use in harsh environments such as aerospace and automotive industries. Its ability to maintain its shape and strength even under extreme conditions ensures the reliability and longevity of the components it is used in. This makes shape memory alloy wire a cost-effective solution for industries that require durable and high-performance materials.

Advantages of Using Shape Memory Alloys

Shape memory alloys (SMAs) have unique properties that transform various fields. Here are some of their key advantages:

- High Strength-to-Weight Ratio: SMAs boast exceptional strength while maintaining a lightweight profile. This makes them ideal for applications where weight is crucial, such as aerospace components and robotics.

- Corrosion Resistance: Unlike many traditional materials, SMAs exhibit remarkable corrosion resistance, allowing them to function effectively in harsh environments without degrading.

- Exceptional Temperature Tolerance: SMAs can withstand extreme temperatures without compromising their functionality, making them suitable for applications in environments with drastic temperature fluctuations.

- Shape Memory Effect: The most distinctive property of SMAs is their ability to return to their original shape after deforming. This unique characteristic allows for the creation of intricate and adaptable components, which is particularly beneficial in medical devices and micromanipulation tools.

Combining these remarkable properties positions SMAs at the forefront of material science advancements. Their potential for innovative designs and problem-solving applications continues to drive advancements in various sectors.

The Science Behind 2-Way Shape Memory Alloy

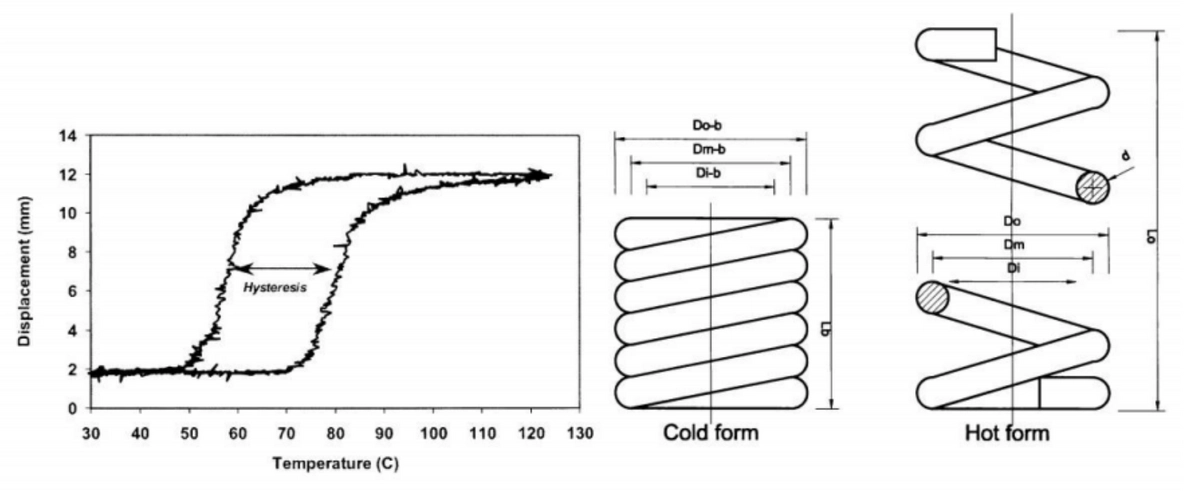

How Two-Way Shape Memory Alloys Work

Two-way shape memory alloys are unique materials that can remember their original shape and return to it when heated, even after being deformed. This is due to a reversible phase transformation between the austenite and martensite phases, which allows the material to exhibit two distinct shapes.

Shape Memory Alloy for Sale: Where to Find Quality Materials

If you're in the market for shape memory alloys, some reputable suppliers offer high-quality materials suitable for various applications. Look for suppliers with a proven track record in providing reliable shape memory alloy wire and other related products to ensure you get the best materials.

When searching for a supplier of shape memory alloys, it's important to consider the specific applications you have in mind. Some suppliers may specialize in certain industries or materials, so find one that aligns with your needs. Additionally, look for suppliers offering customization options to ensure the materials you receive are tailored to your specifications. This level of flexibility can significantly affect the performance and effectiveness of the shape memory alloys for your intended use.

Innovative Uses of Two-Way Shape Memory Polymer

Two-way shape memory polymer (SMP) is a groundbreaking material that can remember and return to multiple temporary shapes upon specific stimuli. This remarkable property presents exciting possibilities in various fields:

- Self-healing materials: SMPs can be incorporated into structures to automatically repair minor cracks or damages when exposed to a specific temperature, enhancing the material's longevity and reducing maintenance needs.

- Smart textiles: Clothing embedded with SMPs could adjust to the wearer's body temperature, providing a comfortable fit and enhanced functionality in varying environments.

- Biomedical devices: SMPs hold immense potential for developing stents, implants, and targeted drug delivery systems that can adapt to their surroundings within the body, improving medical procedures and patient outcomes.

The unique capabilities of two-way SMPs are pushing the boundaries of material science and hold immense promise for creating smarter and more adaptable technologies across diverse industries. With ongoing research and development, this revolutionary material has the potential to impact our daily lives significantly.

Benefits and Limitations of Shape Memory Alloys

Practical Applications of Shape-Memory Alloy

One practical application of shape-memory alloy is in the medical field, where it is used for minimally invasive surgical procedures due to its flexibility and ability to return to its original shape. Additionally, it is utilized in aerospace engineering for its lightweight and durable properties, making it ideal for components such as actuators and landing gear. Furthermore, shape-memory alloy wire is commonly used in robotics for its ability to perform complex movements with precision and reliability.

In addition to its medical and aerospace applications, shape-memory alloy is also used in the automotive industry for various components such as sensors, actuators, and safety devices. Its ability to withstand high temperatures and maintain its shape under stress makes it an ideal material for improving the performance and efficiency of automotive systems. Furthermore, shape-memory alloy is finding its way into consumer electronics, where it is being used in products such as smartphones and wearable devices to create more durable and flexible components that can withstand everyday wear and tear.

Understanding the Drawbacks of Shape Memory Alloys

Shape-memory alloys (SMAs) have captured attention for their unique ability to "remember" and return to a specific shape. However, alongside their benefits, several limitations come into play:

- High Cost: SMAs are significantly more expensive than traditional materials like steel or plastic, which can hinder their widespread adoption in various industries.

- Susceptibility to Corrosion: Over time, SMAs are prone to corrosion, requiring careful maintenance and protective measures like coatings to ensure long-term durability.

- Complex Training Process: Programming the desired shape memory behavior in SMAs can be intricate and time-consuming, adding to the overall implementation complexity.

While SMAs boast remarkable properties, addressing these drawbacks through continued research and development is crucial for their broader utilization across various applications.

Potential Future Developments in Shape Memory Alloy Technology

The future of shape memory alloy technology holds exciting possibilities, with ongoing research focusing on enhancing their performance and versatility. Scientists are exploring ways to improve shape memory alloys' fatigue resistance, making them more durable for long-term use in various applications. Furthermore, advancements in manufacturing techniques aim to reduce production costs and make shape memory alloys more accessible for a wider range of industries.

Researchers are also investigating the potential use of shape memory alloys in biomedical applications, such as medical implants and devices. By exploring the biocompatibility of these materials and their ability to withstand the harsh conditions within the human body, scientists hope to expand the use of shape memory alloys in the healthcare industry. This could lead to more efficient and longer-lasting medical devices that improve patient outcomes and quality of life.

Latest Innovations in 2-Way Shape Memory Alloy Technology

Cutting-Edge Research and Development in Shape Memory Alloys

In recent years, there has been a surge in cutting-edge research and development focused on advancing shape memory alloys. Scientists and engineers are tirelessly working to unlock the full potential of 2-way shape memory alloy technology, pushing the boundaries of what is possible in various industries.

Furthermore, the development of shape memory alloys has opened up new possibilities in the medical field, with potential applications in minimally invasive surgical procedures and implantable medical devices. The biocompatibility and unique properties of shape memory alloys make them attractive for medical tools and implants, offering improved patient outcomes and recovery times. As research advances in this area, we can expect to see even more innovative uses for shape memory alloys in the healthcare industry.

GEE SMA: Pioneering Advancements in Nitinol Shape Memory Alloys

One company at the forefront of these pioneering advancements is GEE SMA, which has been making significant strides in developing Nitinol shape memory alloys. Their innovative approach has led to the creation of high-quality shape memory alloy wire and other materials that revolutionize how these alloys are used across different sectors.

GEE SMA's expertise in Nitinol shape memory alloys has opened up new possibilities with the development of 2-way shape memory alloys. This innovative material can return to its original shape not only when heated but also when cooled, offering a wider range of applications across various industries. By pushing the boundaries of traditional shape memory alloys, GEE SMA is paving the way for advanced technologies and products that can adapt to different temperature variations, making them ideal for cutting-edge engineering solutions.

Exploring New Possibilities with 2-Way Shape Memory Alloys

The ongoing exploration of new possibilities with 2-way shape memory alloys has opened up a world of potential applications. From biomedical devices to aerospace components, researchers are constantly finding novel ways to harness the unique properties of shape-memory alloys, paving the way for exciting advancements in technology and engineering.

The versatility of 2-way shape memory alloys has also led to innovative applications in robotics. These alloys can remember and return to their original shape after deforming, making them ideal for creating self-repairing and adaptable robotic components. As a result, researchers are exploring how these alloys can be integrated into next-generation robots, leading to more resilient and efficient machines capable of performing a wide range of tasks in various environments.

Conclusion

As we look to the future of shape memory alloy technology, the potential for innovation is limitless. With the unique properties of 2-way shape memory alloys, there are exciting opportunities for breakthroughs in various industries. From healthcare to aerospace, shape memory alloys' versatility is unmatched, making them a valuable resource for engineers and designers alike.

Embracing the Future of Shape Memory Alloy Technology

The future of shape memory alloy technology is bright, with ongoing research and development pushing the boundaries of what is possible. As we continue exploring the potential applications of 2-way shape memory alloys, we expect to see even more groundbreaking advancements in materials science and engineering. The ability to manipulate materials precisely opens up a world of possibilities for creating innovative solutions to complex challenges.

The Versatility of Shape Memory Alloys in Various Industries

From automotive to robotics, shape memory alloy wire has proven valuable in many industries. Its ability to return to a predetermined shape after deforming makes it an invaluable resource for creating responsive and adaptive technologies. Whether used in actuators, sensors, or medical devices, shape memory alloys continue revolutionizing our approach to design and engineering.

Harnessing the Potential of 2-Way Shape Memory Alloy Technology

With two-way shape memory polymer on the horizon, there's no telling what new frontiers we will explore next. The potential for this innovative material is vast, offering new opportunities for creating smart materials that respond dynamically to their environment. By harnessing the full potential of 2-way shape memory alloy technology, we can expect to see even more remarkable developments that will reshape industries and improve quality of life.