Introduction

When it comes to designing a robot arm actuator, the choice of materials is crucial. One of the most innovative options available is the Nitinol Shape Memory Alloy (SMA), which offers unique properties that make it ideal for actuator springs. This introduction will explore the significance of selecting the right robot arm actuator spring and outline key factors to consider when choosing a Nitinol spring for your application.

Understanding Nitinol Shape Memory Alloys (GEE SMA)

Nitinol, a combination of nickel and titanium, exhibits remarkable shape memory and superelasticity properties, making it an excellent choice for robot arm actuators. Its ability to return to its original shape after deformation allows for precise and reliable motion control in robotic applications.

Importance of Choosing the Right Robot Arm Actuator Spring

Selecting the appropriate nitinol spring actuator is essential for ensuring optimal performance and longevity of your robotic arm. The right spring will provide the necessary force, flexibility, and durability required for smooth operation in various environments and conditions.

Key Factors to Consider When Selecting a Nitinol Spring

When choosing a nitinol spring for your robot arm actuator, several factors must be taken into account, including quality standards, customization options, supplier reliability, and long-term maintenance requirements. These considerations will play a significant role in determining the success of your robotic application.

The Basics of Robot Arm Actuator Springs

Nitinol springs are a type of shape memory alloy actuator that are widely used in robot arm actuators due to their unique properties. These springs are made from a nickel-titanium alloy that can remember its original shape and return to it when heated, making them ideal for robotic applications.

What is a Nitinol Spring?

A Nitinol spring is a type of actuator spring made from a shape memory alloy composed of nearly equal parts nickel and titanium. This unique material allows the spring to change shape in response to temperature changes, making it an excellent choice for robot arm actuators where precise movements are required.

Nitinol springs are also known for their durability and long lifespan, making them a cost-effective choice for applications requiring reliable and consistent performance. Additionally, the ability of Nitinol springs to exert high forces at relatively low temperatures makes them ideal for use in compact spaces where traditional actuators may not fit. This versatility and adaptability make Nitinol springs a popular choice in the robotics industry, where engineers are constantly seeking innovative solutions to improve efficiency and precision in robotic systems. With their unique properties and wide range of applications, Nitinol springs are revolutionizing the field of actuator technology.

Advantages of Using Nitinol Spring Actuators

The use of nitinol spring actuators offers several advantages in comparison to traditional metal springs. These include higher energy density, greater durability, and the ability to provide more consistent force over time. Additionally, nitinol springs can be designed to operate at specific temperatures, allowing for customized performance in various robotic applications.

Furthermore, nitinol springs have the unique ability to remember their original shape, allowing them to return to their initial form after being deformed. This property, known as shape memory, makes nitinol springs ideal for applications where repeated bending or deformation is required. This feature sets them apart from traditional metal springs and opens up new possibilities for use in robotics and other precision engineering fields.

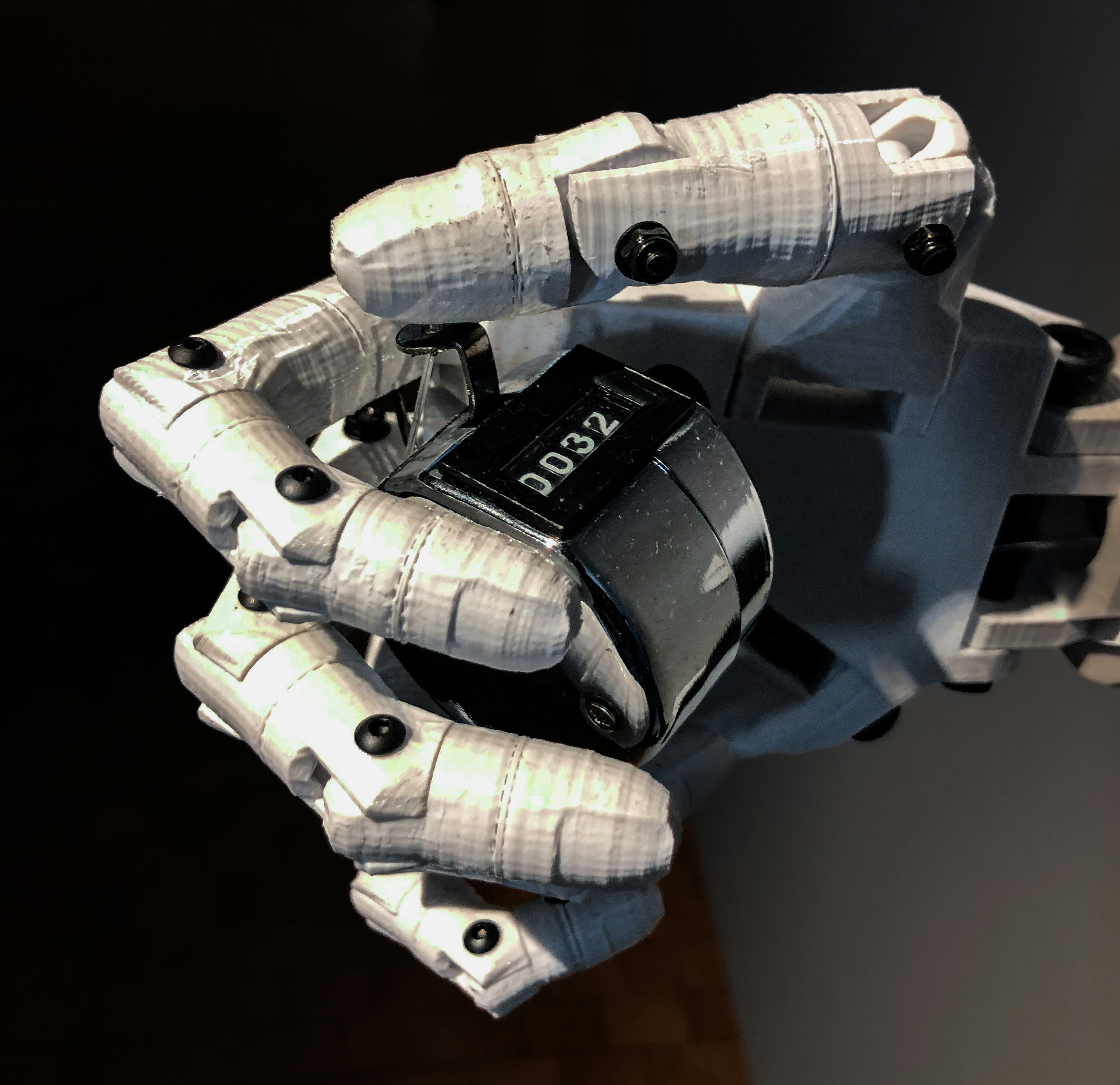

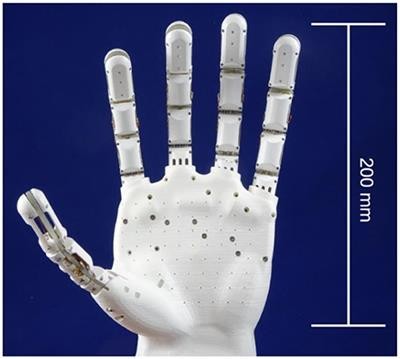

Applications of Nitinol Micro Springs

Nitinol micro springs have found widespread use in the robotics industry due to their small size and exceptional performance characteristics. They are commonly utilized in miniature robotic components such as medical devices, microsurgical tools, and small-scale automation systems where precision and reliability are critical.

Nitinol micro springs are also used in the aerospace industry, where their lightweight and durable properties make them ideal for small-scale mechanisms in satellites, spacecraft, and unmanned aerial vehicles. Their ability to withstand extreme temperatures and harsh conditions makes them a valuable component in these high-stakes applications. Additionally, their small size allows for intricate designs that can be easily integrated into the limited space available in aerospace technology.

Factors to Consider When Choosing a Robot Arm Actuator Spring

When selecting a robot arm actuator spring, it's crucial to consider the quality standards for nitinol springs. Look for suppliers that adhere to industry certifications such as ISO 9001 and AS9100, ensuring that their products meet stringent quality requirements. High-quality nitinol springs are essential for the reliable and efficient performance of robot arm actuators.

Quality Standards for Nitinol Springs

Choosing a reputable supplier that adheres to strict quality standards is paramount when selecting a nitinol spring for your robot arm actuator. Look for manufacturers that have a proven track record of producing high-quality nitinol springs with consistent mechanical properties and dimensional accuracy. This will ensure the longevity and reliability of your robot arm actuator spring in demanding applications.

When evaluating potential nitinol spring suppliers, it's important to consider their quality control processes. A reputable supplier will have stringent quality control measures in place to ensure that each nitinol spring meets the required specifications. This includes thorough testing and inspection of the material properties, as well as dimensional accuracy. By choosing a supplier with robust quality control processes, you can have confidence in the performance and reliability of your robot arm actuator spring.

Key Considerations for Selecting Nitinol Spring Suppliers

When evaluating nitinol spring suppliers, consider factors such as their experience in the industry, technological capabilities, and commitment to continuous improvement. A reliable supplier should have expertise in producing nitinol micro springs specifically designed for robot arm actuators, along with the ability to customize springs to meet unique application requirements.

In addition to expertise and technological capabilities, it is essential to assess a nitinol spring supplier's quality control processes and certifications. A reliable supplier should adhere to strict quality standards and have ISO certification, ensuring that their products meet industry requirements for performance and reliability. By partnering with a supplier that prioritizes quality control, you can minimize the risk of defects or inconsistencies in nitinol springs used for critical applications.

Comparing China Nitinol Spring Manufacturers

With the rise of manufacturing capabilities in China, it's important to compare different nitinol spring manufacturers in the region. Look for suppliers with advanced production facilities, stringent quality control processes, and a focus on innovation in nitinol spring engineering. By carefully evaluating China nitinol spring manufacturers, you can find a partner that delivers high-quality products at competitive prices.

When comparing China nitinol spring manufacturers, it's crucial to consider their track record in delivering customized solutions. Look for suppliers that have a proven ability to tailor nitinol springs to meet unique specifications and performance requirements. A manufacturer with a strong focus on customization can provide you with springs that are perfectly suited to your specific application, giving you a competitive edge in your industry.

Tailoring Nitinol Springs to Your Unique Needs

Customization Options for Nitinol Spring Engine

When it comes to robot arm actuator springs, customization is key to meeting specific project requirements. Nitinol spring engines can be tailored in terms of size, shape, and performance characteristics to ensure a perfect fit for your application. Whether you need a specific force profile or a unique shape, nitinol springs can be engineered to meet your exact specifications.

Nitinol Spring Suppliers' Ability to Address Customer Requirements

China nitinol spring manufacturers are known for their ability to address customer requirements with precision and expertise. With a deep understanding of nitinol spring technology and vast experience in the field, these suppliers can work closely with clients to ensure that their unique needs are met. From custom designs to specialized performance parameters, these manufacturers have the capability to deliver tailored solutions.

Enhancing Product Quality with Customized Nitinol Springs

By opting for customized nitinol springs from reputable suppliers, you can enhance the quality and performance of your robot arm actuator. Tailored springs are designed to fit seamlessly into your application, providing optimal functionality and longevity. With the right customization options, you can ensure that your nitinol spring engine meets the highest standards of quality and reliability.

Remember that choosing the right supplier is crucial in obtaining top-quality nitinol springs that meet your specific needs. By working with experienced China nitinol spring suppliers who offer customization options, you can ensure that your robot arm actuator performs at its best while meeting all project requirements.

Ensuring Longevity and Performance

Proper Maintenance of Nitinol Springs

To ensure the longevity of your robot arm actuator, proper maintenance of nitinol springs is crucial. Regular inspection for signs of wear and tear, such as corrosion or fatigue, is essential to prevent unexpected failures. Applying a protective coating can also help to extend the lifespan of nitinol springs and maintain their performance over time.

Regular maintenance of nitinol springs should also include proper lubrication to reduce friction and wear. This can be achieved by using a high-quality lubricant specifically designed for nitinol materials. Additionally, ensuring that the springs are properly installed and aligned within the robot arm actuator is crucial for maximizing their efficiency and preventing premature failure. Proper installation can help distribute the load evenly, reducing stress on individual springs and promoting overall longevity.

Maximizing Efficiency of Robot Arm Actuator Springs

Maximizing the efficiency of robot arm actuator springs involves optimizing their design and material properties. By working closely with reputable nitinol spring suppliers, you can tailor the specifications of the springs to meet your specific application requirements. This customization can lead to improved energy efficiency and overall performance of the robot arm actuators.

When customizing nitinol springs for robot arm actuators, it's important to consider the specific requirements of the application, such as load capacity and operating temperature. By working with suppliers who have expertise in nitinol spring design, you can ensure that the springs are tailored to withstand the unique demands of the robot arm actuators. This level of customization can result in increased durability and longevity of the springs, ultimately improving the overall efficiency of the robot arm.

Addressing Common Challenges in Nitinol Spring Applications

In addressing common challenges in nitinol spring applications, it's important to consider factors such as temperature sensitivity and material fatigue. China nitinol spring manufacturers have developed innovative solutions to mitigate these challenges, including advanced heat treatment processes and alloy compositions that enhance the durability and reliability of nitinol micro springs.

In addition to heat treatment processes and alloy compositions, China nitinol spring manufacturers have also focused on refining the design and manufacturing techniques for nitinol micro springs. By incorporating advanced CAD/CAM technology and precision machining methods, they are able to produce springs with consistent performance and dimensional accuracy, further enhancing their reliability in various applications. These advancements in design and manufacturing have allowed for greater customization and optimization of nitinol springs to meet specific performance requirements in different industries.

Conclusion

In conclusion, selecting the best nitinol spring supplier for your project is crucial to ensure high-quality and reliable performance. With a wide range of options available, it's important to carefully consider the capabilities and track record of China nitinol spring manufacturers before making a decision. Optimizing performance with the right nitinol spring engine involves tailoring the springs to your unique needs and ensuring proper maintenance for longevity. Lastly, choosing the perfect robot arm actuator spring for your application requires thorough consideration of key factors such as quality standards, customization options, and addressing common challenges in nitinol spring applications.

Selecting the Best Nitinol Spring Supplier for Your Project

When selecting a nitinol spring supplier for your project, it's essential to thoroughly evaluate China nitinol spring suppliers' capabilities and track record. Look for suppliers with extensive experience in producing high-quality nitinol springs specifically designed for robot arm actuators. Consider factors such as production capacity, quality control measures, and their ability to meet custom requirements.

Optimizing Performance with the Right Nitinol Spring Engine

Optimizing performance with the right nitinol spring engine involves tailoring the springs to your unique needs. This may include customizing the shape, size, and properties of the springs to ensure they meet specific application requirements. Additionally, proper maintenance of nitinol springs is crucial for maximizing efficiency and longevity, ultimately optimizing overall performance.

Choosing the Perfect Robot Arm Actuator Spring for Your Application

Choosing the perfect robot arm actuator spring for your application requires careful consideration of various factors such as quality standards, customization options, and addressing common challenges in nitinol spring applications. By working closely with reputable nitinol spring suppliers who can address your specific requirements, you can ensure that you choose a spring that meets your application's unique needs.