Introduction

Nitinol foil is a type of nickel-titanium alloy that exhibits shape memory and superelasticity, making it a versatile material for various applications. Its unique properties allow it to return to its original shape after deformation, offering significant benefits in engineering and design. Commonly used in medical devices, aerospace components, and consumer electronics, nitinol foil has proven to be an invaluable material in multiple industries.

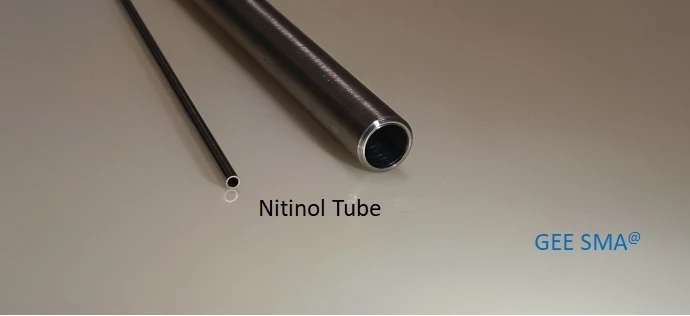

What is Nitinol Foil?

Nitinol foil is a type of shape memory alloy (SMA) that consists of nearly equal parts nickel and titanium. This composition gives nitinol the ability to revert to its original shape after being deformed, making it ideal for applications where flexibility and resilience are crucial.

Benefits of Nitinol Shape Memory Alloy Foil

The unique properties of nitinol shape memory alloy foil make it highly desirable for a range of applications. Its ability to remember its original shape allows for the creation of self-expanding stents in medical devices, while its superelasticity makes it suitable for use in flexible aerospace components.

Common Applications of Nitinol Foil

Nitinol foil finds widespread use in various industries due to its exceptional properties. It is commonly employed in medical devices such as stents and guidewires, as well as in aerospace components like actuators and sensors. Additionally, nitinol foil is utilized in consumer electronics for innovations such as eyeglass frames and headphone wires.

By understanding the unique characteristics and practical uses of nitinol foil, we can fully appreciate the potential advantages it offers across different industries while also being mindful of potential challenges that may arise.

Understanding Nitinol

Nitinol, short for Nickel Titanium Naval Ordnance Laboratory, is a unique shape memory alloy renowned for its exceptional properties and characteristics. This remarkable material exhibits superelasticity and shape memory effect, allowing it to return to its original shape after deformation. Moreover, Nitinol possesses excellent biocompatibility, making it suitable for various medical applications.

Properties and Characteristics of Nitinol

Nitinol boasts an impressive combination of properties, including high strength, corrosion resistance, and biocompatibility. Its unique superelasticity enables it to undergo significant deformation without permanent damage, making it ideal for applications that require flexibility and resilience. Additionally, Nitinol's shape memory effect allows it to revert to its predetermined shape when subjected to heat.

Furthermore, Nitinol's biocompatibility makes it an excellent choice for medical devices and implants, as it can safely interact with the human body without causing adverse reactions. Its high corrosion resistance also ensures that it can withstand harsh environmental conditions, making it suitable for a wide range of applications in various industries. The combination of these properties makes Nitinol a versatile and reliable material for engineering and medical purposes.

Manufacturing Process of Nitinol Foil

The manufacturing process of Nitinol foil involves a series of intricate steps that require precision and expertise. It begins with the melting and mixing of nickel and titanium in specific proportions, followed by the casting of ingots. The ingots are then hot-rolled into thin sheets before undergoing a series of heat treatments to attain the desired mechanical properties.

After the heat treatments, the Nitinol foil is then subjected to a process known as superelasticity training, which involves stretching the material to align its crystalline structure. This imparts the unique superelastic properties that allow Nitinol foil to return to its original shape after being deformed. The final step in the manufacturing process involves precision cutting and shaping of the foil into specific dimensions, ready for use in various applications such as medical devices, aerospace components, and consumer electronics.

Unique Features of NT0402 Nitinol Foil

NT0402 is a specialized grade of Nitinol foil known for its exceptional performance in various applications. This particular type of Nitinol exhibits superior fatigue resistance, enabling it to withstand repeated deformations without compromising its structural integrity. Furthermore, NT0402 Nitinol foil offers precise temperature control for shape memory activation, making it an ideal choice for advanced engineering solutions.

In addition to its exceptional fatigue resistance and precise temperature control, NT0402 Nitinol foil also boasts excellent biocompatibility, making it suitable for medical and biomedical applications. This unique feature allows the material to be used in various medical devices and implants without causing adverse reactions within the body. Whether it's for cardiovascular stents or orthodontic wires, NT0402 Nitinol foil provides a reliable and safe solution for healthcare professionals and patients alik

Practical Uses

Nitinol foil, also known as Nitinol Shape Memory Alloy Foil, is a versatile material with a wide range of practical applications. From medical devices to aerospace and automotive components, as well as consumer electronics, the unique properties of nitinol foil make it an invaluable material in various industries.

Medical Applications of Nitinol Foil

In the medical field, nitinol foil is used in a variety of applications such as stents, orthodontic wires, and surgical tools. Its shape memory properties allow for minimally invasive procedures and customized solutions for patients. The biocompatibility of nitinol makes it safe for use in the human body, offering reliability and durability in critical medical devices.

Additionally, nitinol foil is also used in the aerospace and automotive industries for various applications. Its unique combination of flexibility, strength, and resistance to corrosion makes it an ideal material for components such as actuators, sensors, and engine parts. The shape memory properties of nitinol allow for precise control and movement in these high-performance systems, contributing to improved efficiency and reliability.

Nitinol in Aerospace and Automotive Industries

Nitinol foil plays a crucial role in the aerospace and automotive industries due to its lightweight yet durable nature. It is used in actuators, sensors, and other critical components where precise control and resilience are necessary. Its ability to withstand extreme conditions makes it an ideal material for these demanding environments.

Consumer Electronics and Nitinol Foil Innovations

In consumer electronics, nitinol foil has been utilized in innovative ways such as smart eyewear frames that adjust to fit the user's face or self-repairing phone cases that can revert back to their original shape after impact. These applications showcase the adaptability and potential for creative solutions using nitinol foil.

In addition to smart eyewear frames and self-repairing phone cases, nitinol foil has also been integrated into wearable technology such as fitness trackers and smartwatches. The unique properties of nitinol allow for comfortable, flexible bands that can withstand daily wear and tear while maintaining their shape and functionality. This application demonstrates the versatility of nitinol foil in consumer electronics, offering durable and reliable solutions for everyday use.

GEE SMA specializes in crafting high-quality NT0402 Nitinol Foil with precision engineering tailored to meet specific industry requirements. Our commitment to excellence ensures that our customers receive top-notch materials designed to enhance performance and innovation across various sectors.

Advantages and Challenges

Nitinol foil, also known as Nitinol Shape Memory Alloy Foil, offers a myriad of advantages that make it a sought-after material in various industries. Its unique shape memory properties allow it to return to its original shape after deformation, making it ideal for applications requiring precise and reliable performance. Additionally, its superelasticity and biocompatibility make it suitable for medical devices and implants, showcasing its versatility and adaptability.

Advantages of Using Nitinol Foil

The flexibility and durability of NT0402 Nitinol Foil make it an excellent choice for intricate components in medical devices, such as stents and guidewires. Its ability to withstand repeated deformations without permanent damage ensures longevity and reliability in critical applications. Furthermore, the biocompatibility of Nitinol makes it compatible with the human body, reducing the risk of rejection or adverse reactions.

In addition to its flexibility and biocompatibility, Nitinol foil also offers excellent shape memory properties, allowing it to return to its original shape after being deformed. This unique characteristic makes it ideal for use in devices that require precise positioning or deployment, such as self-expanding stents. The ability of Nitinol to maintain its shape under varying conditions adds an extra layer of reliability to medical devices, ensuring consistent performance over time.

Potential Problems with Nitinol

While Nitinol offers numerous advantages, there are potential challenges associated with its use. One common problem with nitinol is its susceptibility to stress-induced martensitic transformation, which can lead to fatigue failure under certain conditions. Additionally, achieving precise control over the transformation temperatures can be challenging during manufacturing processes, impacting the material's performance in specific applications.

Another potential challenge with nitinol is its biocompatibility in the human body. While the material is widely used in medical devices such as stents and orthodontic wires, there have been concerns about the release of nickel ions from nitinol implants, which can cause allergic reactions in some individuals. This issue requires careful consideration and testing to ensure the safety of nitinol-based medical devices for all patients.

Safety of Nitinol in Human Body

When considering the use of nitinol in medical devices intended for implantation within the human body, safety is a paramount concern. While nitinol is generally considered safe due to its biocompatibility and corrosion resistance properties, proper testing and validation are crucial to ensure its suitability for long-term use inside the body.

Cost and Value

Nitinol Foil is a high-quality material known for its exceptional properties, but is it expensive? The cost of Nitinol may vary depending on the specific application and requirements. While the initial investment in Nitinol may be higher than other materials, its long-term value often outweighs the upfront costs.

Is Nitinol Expensive?

The cost of Nitinol Foil can be perceived as higher compared to traditional materials due to its unique properties and manufacturing process. However, when considering its durability, shape memory capabilities, and long-term performance, the investment in Nitinol proves to be cost-effective for various industries.

While the initial investment in Nitinol may seem high, its long-term performance and durability actually make it a cost-effective choice for industries such as medical devices, aerospace, and automotive. The shape memory capabilities of Nitinol also contribute to its cost-effectiveness, as it allows for the creation of complex components that would otherwise require multiple parts and assembly processes. This not only reduces material and labor costs but also increases reliability and efficiency in the final product.

Cost-effectiveness of Nitinol Foil

Despite the initial expense, the cost-effectiveness of Nitinol Shape Memory Alloy Foil becomes evident over time. Its ability to withstand numerous cycles of deformation and recovery makes it a durable and reliable material for applications in medical devices, aerospace components, and consumer electronics.

In addition to its durability, Nitinol Shape Memory Alloy Foil offers a high level of precision and flexibility, making it an ideal choice for intricate medical devices and aerospace components. This versatility reduces the need for frequent replacements or repairs, further contributing to its cost-effectiveness over time. The long-term value of Nitinol components lies in their ability to maintain their shape memory properties even after prolonged use, ensuring consistent performance and reliability in various applications.

Long-term Value of Nitinol Components

The long-term value of using NT0402 Nitinol Foil lies in its longevity and performance consistency. With minimal maintenance requirements and extended lifespan, Nitinol components offer significant advantages over conventional materials. This makes them a valuable investment for industries seeking reliable and efficient solutions.

Furthermore, Nitinol components are highly durable and resistant to corrosion, making them ideal for applications in harsh environments. This reliability ensures that businesses can minimize downtime and reduce the need for frequent replacements, ultimately saving on maintenance costs. Additionally, the consistent performance of Nitinol components contributes to improved operational efficiency and overall productivity for industries.

Conclusion

Nitinol foil is a remarkable material with endless potential for innovation and advancement. Whether it's in the medical field, aerospace, automotive, or consumer electronics, the versatility of Nitinol Shape Memory Alloy Foil is truly awe-inspiring. GEE SMA's NT0402 Nitinol Foil showcases the unique features and characteristics that make it a standout material in various industries.

Exploring the Potential of Nitinol Foil

The potential of nitinol foil is vast and exciting, with its shape memory properties and superelasticity opening up new possibilities in product design and engineering. Its ability to return to a predetermined shape after deformation makes it an invaluable material for creating innovative products with unique functionalities.

Harnessing the Versatility of Nitinol in Various Industries

From life-saving medical devices to cutting-edge aerospace technologies, nitinol foil has proven to be an indispensable material in various industries. Its exceptional durability, biocompatibility, and resistance to corrosion make it an ideal choice for creating components that can withstand harsh environments and demanding applications.

Embracing the Future with Nitinol Functional Materials and Components

As we move into the future, nitinol functional materials and components will continue to play a crucial role in shaping technological advancements across industries. With ongoing research and development, there's no limit to what can be achieved with this remarkable material, paving the way for groundbreaking innovations that will revolutionize how we live and work.

By embracing the potential of nitinol foil and harnessing its versatility across different sectors, GEE SMA is at the forefront of driving innovation through high-quality materials and components that are tailored to meet specific customer needs. With a commitment to excellence and customer satisfaction, GEE SMA continues to lead the way in advancing the capabilities of nitinol functional materials.