Introduction

When it comes to cutting-edge medical devices, one material stands out for its remarkable properties and versatility: nitinol wires. Nitinol, an acronym for Nickel Titanium Naval Ordnance Laboratory, is a Shape Memory Alloy (SMA) wire that has gained popularity in the medical industry for its unique capabilities. From its exceptional flexibility to its biocompatibility, nitinol SMA wire has revolutionized the design and functionality of various medical devices.

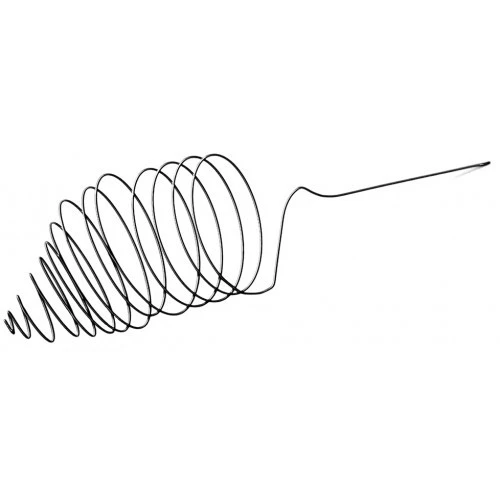

Understanding Nitinol Wires

Nitinol wires are composed of a nickel-titanium alloy known for its shape memory and superelasticity. This means that the wire can return to its original shape after being deformed, making it an ideal material for intricate medical applications. The unique properties of nitinol SMA wire have made it a game-changer in the field of medical device manufacturing.

Nitinol SMA wire has revolutionized the medical industry by allowing for the creation of devices with intricate shapes and designs that were previously impossible to achieve. This has opened up new possibilities for minimally invasive procedures and improved patient outcomes. Additionally, the superelasticity of nitinol wire allows for greater flexibility and durability in medical devices, reducing the risk of breakage or failure during use.

Benefits of Nitinol SMA Wire

The benefits of using nitinol SMA wire in medical devices are abundant. Its superelasticity allows for greater durability and resistance to deformation, ensuring longevity and reliability in critical applications. Additionally, nitinol wires exhibit excellent biocompatibility and corrosion resistance, making them safe for use within the human body.

Furthermore, the unique shape memory properties of nitinol SMA wire allow it to return to its original shape after being deformed, making it ideal for use in medical devices that require precise and controlled movements. This makes nitinol particularly well-suited for applications such as stents, guidewires, and orthodontic wires, where maintaining the intended shape is crucial for successful treatment outcomes. The ability of nitinol to withstand repeated bending and flexing without experiencing fatigue or failure makes it an invaluable material in the field of medical device manufacturing.

Applications of Nitinol in Medical Devices

Nitinol's remarkable properties have led to its widespread use in various medical devices. From stents and guidewires to orthodontic instruments and surgical tools, nitinol wires have proven indispensable in enhancing the performance and effectiveness of these devices.

Nitinol's unique shape memory and superelasticity make it an ideal material for stents used in minimally invasive procedures. These properties allow the stent to be compressed and inserted into the body through a small incision, then expand to its original shape once in position. This capability reduces patient discomfort and recovery time, making nitinol stents a preferred choice for treating narrowed or weakened arteries.

Now let's delve deeper into the world of nitinol wires and explore their fascinating properties that make them an integral part of modern healthcare solutions.

What is Nitinol?

Nitinol, short for Nickel Titanium Naval Ordnance Laboratory, is a unique alloy known for its shape memory and superelastic properties. This Shape Memory Alloy Nitinol Wire exhibits the ability to return to a predetermined shape when heated, making it ideal for various medical device applications. Its remarkable flexibility and durability make it a sought-after material in the healthcare industry.

Properties of Nitinol SMA Wire

Nitinol SMA wire 1.5mm boasts exceptional properties such as superelasticity, biocompatibility, and corrosion resistance. This makes it an excellent choice for medical devices that require intricate movements within the body without compromising patient safety. Its unique shape memory capability allows it to withstand repeated deformations while retaining its original shape.

Manufacturing Process of Nitinol Wires

The manufacturing process of Nitinol wires involves a series of precise steps including alloying, hot and cold working, heat treatment, and shaping to achieve the desired mechanical properties. This meticulous process ensures that the Nitinol SMA Shape Memory Alloy Muscle Wire Sample meets stringent quality standards for use in medical devices.

The precise steps involved in the manufacturing process of Nitinol wires result in a material with exceptional flexibility and durability, making it ideal for use in medical devices. The alloying process ensures that the Nitinol wire possesses the necessary properties to withstand various conditions within the human body. Additionally, the hot and cold working stages further enhance the wire's strength and resilience, allowing it to maintain its shape memory properties even after repeated use.

Advantages of Nitinol in Medical Devices

One of the key advantages of using nitinol wires in medical devices is their ability to provide consistent performance under varying conditions due to their unique material properties. Their high tensile strength makes them suitable for a wide range of applications in surgical tools and orthodontic instruments, offering healthcare professionals reliable solutions for patient care.

In addition to their high tensile strength, nitinol wires also exhibit superelasticity, allowing them to return to their original shape after being deformed. This property is particularly valuable in medical devices such as stents and guidewires, where the ability to navigate through complex anatomical structures and then expand or contract as needed is essential for successful patient outcomes. The use of nitinol in these devices has revolutionized minimally invasive procedures, providing patients with less discomfort and faster recovery times.

Now let's move on to explore how these remarkable nitinol wires are utilized in various medical devices and their impact on healthcare industry!

Nitinol Wires in Medical Devices

Nitinol SMA Wire 1.5mm

Nitinol SMA wire 1.5mm is a versatile and reliable material used in various medical devices due to its unique properties. Its superelasticity and shape memory capabilities make it ideal for applications such as stents, guidewires, and orthodontic instruments.

Nitinol SMA Shape Memory Alloy Muscle Wire Sample

The Nitinol SMA shape memory alloy muscle wire sample showcases the remarkable ability of nitinol to return to its original shape after being deformed, making it perfect for minimally invasive surgical tools and devices that require precise movements.

Tensile Nitinol SMA Wire for Multiple Products

Tensile nitinol SMA wire is a crucial component in the production of multiple medical products such as retrieval devices and vascular closure implants. Its high tensile strength ensures durability and reliability in demanding medical procedures.

Now that we've explored the different types of nitinol wires used in medical devices, let's delve into the advantages of utilizing this innovative material in healthcare applications.

Advantages of Using Nitinol Wires

Nitinol wires offer exceptional advantages in medical device applications. The flexibility and durability of Shape Memory Alloy Nitinol Wire make it ideal for intricate designs and repeated use, ensuring reliable performance in critical procedures.

Flexibility and Durability

The unique properties of Nitinol SMA wire 1.5mm allow it to bend and twist without losing its shape, making it perfect for devices that require precise navigation through the body's intricate pathways. Its remarkable durability ensures longevity, making it a cost-effective choice for medical device manufacturers.

Biocompatibility and Corrosion Resistance

Nitinol SMA Shape Memory Alloy Muscle Wire Sample exhibits excellent biocompatibility, meaning it is well-tolerated by the human body without causing adverse reactions. Additionally, its corrosion resistance ensures that the wire remains intact even in harsh bodily environments, enhancing patient safety.

Unique Shape Memory Capability

Tensile nitinol sma wire for multiple products possesses a remarkable shape memory capability, allowing it to return to its original shape after being deformed - a crucial feature for devices that need to undergo various shapes during use. This unique property sets Nitinol SMA Wire apart from traditional materials, offering innovative solutions in medical device design.

With these outstanding advantages, Nitinol wires continue to revolutionize the field of medical devices, providing unmatched performance and reliability in critical healthcare procedures.

Applications of Nitinol in Medical Devices

Nitinol wires are widely used in medical devices for their unique properties and versatility. One of the key applications of nitinol is in stents and stent delivery systems. Nitinol SMA wire 1.5mm is often used to create self-expanding stents that can be inserted into blood vessels or other tubular structures within the body. These stents provide support and help maintain proper flow, making them essential in treating conditions such as coronary artery disease.

Stents and Stent Delivery Systems

Nitinol SMA Shape Memory Alloy Muscle Wire Sample is also utilized in guidewires and retrieval devices, which are essential tools for navigating through the body during minimally invasive procedures. The flexibility and durability of nitinol wires make them ideal for these applications, allowing physicians to access hard-to-reach areas with precision and ease.

Guidewires and Retrieval Devices

In addition, nitinol wires are commonly found in orthodontic instruments and surgical tools due to their biocompatibility, corrosion resistance, and unique shape memory capability. Orthodontic braces often incorporate nitinol wires for their ability to exert constant force while being highly flexible, making them more comfortable for patients.

Orthodontic Instruments and Surgical Tools

As we can see, nitinol wires play a crucial role in various medical devices, offering unmatched performance and reliability across different applications within the healthcare industry.

Future of Nitinol in Medical Devices

Ongoing Research and Development

As the demand for advanced medical devices continues to grow, ongoing research and development in the field of nitinol wires is crucial. Scientists and engineers are constantly exploring new ways to enhance the properties of Shape Memory Alloy Nitinol Wire, such as improving its biocompatibility and corrosion resistance. This relentless pursuit of innovation ensures that nitinol wires will remain at the forefront of medical device technology.

The potential for innovation and expansion in the field of nitinol wires is immense, with countless opportunities for new applications and advancements. As the medical industry continues to evolve, there is a growing need for nitinol wires that can be used in minimally invasive procedures and implantable devices. This opens up possibilities for developing new shapes and sizes of nitinol wires to meet these specific needs, as well as exploring alternative methods of manufacturing to increase efficiency and reduce costs.

Potential for Innovation and Expansion

The potential for innovation and expansion in the use of nitinol wires within medical devices is vast. With advancements in manufacturing processes, there is a growing opportunity to create even smaller and more intricate Nitinol SMA wire 1.5mm components for minimally invasive procedures. Additionally, ongoing collaboration between material scientists and medical professionals opens up new possibilities for integrating nitinol SMA shape memory alloy muscle wire samples into a wider range of medical devices.

Impact on Healthcare Industry

The impact of nitinol wires on the healthcare industry is undeniable. The unique properties of tensile nitinol SMA wire for multiple products have revolutionized the design and functionality of various medical devices, leading to improved patient outcomes and reduced recovery times. As research continues to uncover new applications for Nitinol SMA Wire, we can expect to see an even greater impact on healthcare, with more innovative solutions that address complex medical challenges.

The use of nitinol wires in medical devices has also led to advancements in minimally invasive procedures. The flexibility and shape memory of nitinol allow for the creation of smaller, more maneuverable instruments, reducing the need for large incisions and resulting in faster recovery times for patients. With ongoing research and development, we can anticipate even more innovative tools and techniques that will further improve the efficiency and effectiveness of minimally invasive procedures, ultimately benefiting patients and healthcare providers alike.

Remember that GEE SMA is your partner in Nitinol solutions! Harnessing the potential of nitinol wires is essential for better healthcare outcomes.

Conclusion

When it comes to choosing the right nitinol wire for your medical device, make sure to consider the unique properties of Shape Memory Alloy Nitinol Wire. Its flexibility, durability, and shape memory capability make it an ideal choice for various applications in the healthcare industry. Whether you need Nitinol SMA Wire 1.5mm, Nitinol SMA Shape Memory Alloy Muscle Wire Sample, or Tensile nitinol sma wire for multiple products, GEE SMA has got you covered with high-quality solutions tailored to your specific needs.

Choosing the Right Nitinol Wire for Your Medical Device

Selecting the right nitinol wire is crucial for the success of your medical device. Whether you require Nitinol SMA Wire for stents, guidewires, or orthodontic instruments, understanding the unique properties and applications of nitinol wires is essential in making informed decisions that will ultimately benefit patient outcomes.

GEE SMA: Your Partner in Nitinol Solutions

As a leading provider of nitinol solutions, GEE SMA offers a wide range of high-quality nitinol wires designed to meet the diverse needs of medical device manufacturers. With a focus on innovation and quality, GEE SMA is committed to delivering reliable and customized nitinol solutions that drive advancements in healthcare technology.

Harnessing the Potential of Nitinol for Better Healthcare

The potential of nitinol in revolutionizing healthcare is undeniable. As ongoing research and development continue to explore new possibilities for nitinol applications in medical devices, harnessing this potential is key to driving better patient care and improved treatment outcomes.

By choosing the right nitinol wire, partnering with industry leaders like GEE SMA, and leveraging the potential of this remarkable material, we can collectively contribute to better healthcare outcomes and advancements in medical technology through the use of nitinol wires.