Introduction

Resonetics Memry is a leading expert in nitinol alloy and its applications, specializing in manufacturing high-quality nitinol products. With a focus on precision and innovation, Resonetics Nashua plays a vital role in shaping the future of nitinol manufacturing. Resonetics Memory sets the industry's standard for excellence, from machining to tailored nitinol products.

Understanding Resonetics Memory and Nitinol

Resonetics Memry is a leader in nitinol alloy technology. With a deep understanding of its unique properties, the company provides innovative solutions for various industries.

Here are some of the key areas where Resonetics Memry excels:

- Shape Memory Technology: Resonetics Memry has mastered the art of utilizing nitinol's shape memory properties to create functional and durable components.

- Advanced Manufacturing Techniques: The company has developed cutting-edge processes for shaping and manipulating nitinol into complex designs, meeting the precise requirements of medical devices and engineering applications.

- Industry-Leading Expertise: Resonetics Memry's extensive knowledge and experience in nitinol alloy make them a trusted partner for businesses seeking innovative solutions.

By continuously pushing the boundaries of nitinol technology, Resonetics Memry is committed to delivering exceptional products and services that drive progress in various fields.

Exploring Nitinol Alloy and Its Applications

Nitinol alloy offers a wide range of applications across different sectors due to its remarkable properties, such as superelasticity and shape memory effect. From medical stents to orthodontic wires, nitinol's versatility makes it an essential material for innovative solutions in healthcare and engineering.

Nitinol's unique properties have also found applications in other industries, such as aerospace, automotive, and consumer electronics. Its ability to return to its original shape after being deformed under certain conditions makes it an ideal material for actuators, sensors, and valves in various mechanical systems. Additionally, its superelasticity allows for the creation of lightweight components that can withstand high levels of stress and strain, making it a preferred choice for applications where durability is essential.

The Role of Resonetics Nashua in Nitinol Manufacturing

Resonetics Nashua serves as a key player in the production of nitinol components, ensuring high-quality craftsmanship and swift response to customer requirements. As one of the leading nitinol manufacturers, Resonetics Nashua is crucial in driving advancements in functional materials and tailored solutions for nitinol components.

Resonetics Nashua's expertise in nitinol manufacturing extends beyond production. The company also strongly emphasizes research and development, constantly seeking innovative ways to improve the performance and functionality of nitinol components. This commitment to advancement ensures that Resonetics Nashua remains at the forefront of the industry, offering cutting-edge solutions to meet the evolving needs of its customers.

What is Nitinol?

Nitinol, a unique alloy of nickel and titanium, exhibits remarkable shape memory and superelasticity properties. When subjected to heat or stress, it can return to its original shape, making it ideal for various industrial applications. Resonetics Memry has been at the forefront of utilizing nitinol alloy to create innovative solutions for medical devices and advanced engineering projects.

The Science Behind Nitinol Shape Memory

Nitinol's shape memory results from its phase transformation ability, allowing it to change from one crystalline structure to another under specific conditions. This unique property enables the material to remember its original shape and recover it when temperature or stress changes are triggered. Resonetics Memry leverages this science to develop cutting-edge nitinol products that offer tailored solutions for complex medical procedures and intricate engineering designs.

Nitinol's shape memory and phase transformation ability have revolutionized the medical industry, particularly in minimally invasive procedures. The material's unique properties allow for the creation of intricate medical devices that can be easily inserted into the body in a compact form and then expand to their original shape once inside. This has led to advancements in treatments for conditions such as cardiovascular disease, urology, and neurology, providing patients with less invasive options and faster recovery times.

Key Nitinol Applications in Various Industries

From minimally invasive medical devices like stents and guidewires to orthodontic wires and actuators in robotics, nitinol's versatility makes it indispensable across multiple industries. Resonetics Memry's expertise in nitinol machining ensures the precise fabrication of components for these applications, meeting stringent quality standards while delivering superior performance in demanding environments.

Nitinol's unique shape memory and superelastic properties make it a top choice for applications in the aerospace and automotive industries. From lightweight components in aircraft to durable engine parts in cars, nitinol offers high strength and resistance to corrosion, making it ideal for demanding environments. With Resonetics Memry's precision machining capabilities, manufacturers can rely on nitinol components' consistent quality and performance for these critical applications.

Advantages of Nitinol Machining

Nitinol machining requires specialized techniques to create components with intricate shapes and precise tolerances. Here are some of the common methods used:

- Laser Cutting: This process uses a focused laser beam to cut through nitinol with high accuracy and minimal heat-affected zone.

- Electrical Discharge Machining (EDM): EDM utilizes electrical sparks to erode material away, creating complex geometries and fine features.

- Wire EDM: Similar to EDM, wire EDM uses a thin wire electrode to cut intricate shapes in nitinol with exceptional precision.

Resonetics Memory's expertise in nitinol machining enables it to produce a wide range of custom components that meet the demanding requirements of various industries, particularly the healthcare sector. Their products, including stents, guidewires, and orthodontic devices, benefit from nitinol's unique strength, flexibility, and shape memory properties. The ability to create intricate shapes and patterns with nitinol sets Resonetics Memory apart as a leader in nitinol machining.

Resonetics Memry Overview

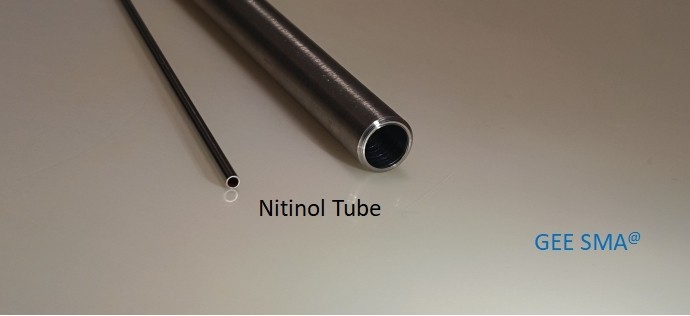

Resonetics Memry is a pioneering force in nitinol alloy and its applications, focusing on delivering high-quality products and solutions. The collaboration between Resonetics and GEE SMA has resulted in cutting-edge advancements in nitinol technology, positioning them as leaders in the industry.

Collaboration between Resonetics and GEE SMA

The partnership between Resonetics and GEE SMA brings together expertise in nitinol manufacturing, allowing for the development of innovative solutions that push the boundaries of what is possible with nitinol alloys. This collaboration has led to breakthroughs in shaping nitinol products for various industries, from medical devices to advanced engineering projects.

This collaboration has also allowed for the exploration of new applications for nitinol in industries such as aerospace and automotive, where the unique properties of nitinol can be leveraged to create cutting-edge components and systems. By combining Resonetics' expertise in precision laser processing with GEE SMA's advanced nitinol fabrication capabilities, the partnership has opened up new possibilities for using nitinol in previously thought impossible ways.

Resonetics Memry Products and Solutions

Resonetics Memry offers a wide range of products and solutions tailored to meet the diverse needs of its clients. From custom-designed components to ready-to-use nitinol products, it provides cutting-edge solutions that harness the full potential of nitinol alloy.

In addition to its nitinol products, Resonetics Memry offers comprehensive engineering and design services to assist clients in developing customized solutions for their specific applications. Its team of experts works closely with customers to understand their unique requirements and challenges, providing innovative designs and prototypes tailored to their needs. This collaborative approach ensures clients receive high-quality, reliable products optimized for performance and efficiency.

Nitinol Products for Medical Devices

One key area where Resonetics Memry excels is providing nitinol products for medical devices. Their expertise in crafting precision components has led to significant advancements in medical technology, enabling the development of innovative devices that improve patient care and outcomes.

Resonetics Memry's expertise in crafting nitinol products for medical devices has revolutionized the way medical technology is advancing. Providing precision components has paved the way for innovative devices that have significantly improved patient care and outcomes. Their dedication to excellence in nitinol manufacturing has positioned them as a leader in the industry.

Nitinol Manufacturing Process

Nitinol manufacturing involves the high-quality crafting of nitinol alloys, ensuring precision and reliability in every component. Resonetics Memry utilizes state-of-the-art techniques to produce top-notch nitinol products that meet the highest industry standards.

High-Quality Crafting of Nitinol Alloys

The process begins with carefully selecting raw materials, followed by a meticulous manufacturing process that ensures the integrity and functionality of the nitinol alloy. Resonetics Memry's expertise in working with nitinol alloys guarantees exceptional quality and performance in every product.

Tailoring Nitinol Components to Customer Needs

Resonetics Memry understands that each customer has unique requirements for their nitinol components. With advanced machining capabilities, they can customize nitinol products to meet specific design specifications, ensuring a perfect fit for any application.

Swift Addressing of Customer Requirements by Nitinol Manufacturers

Resonetics Memry prides itself on swiftly addressing customer requirements and providing efficient solutions for even the most complex nitinol components. Their responsive approach ensures that customers receive personalized attention and quick project turnaround times.

Nitinol in Action

Nitinol alloy, known for its remarkable shape memory and superelasticity, has found real-world applications in various industries. From orthodontic wires to eyeglass frames, nitinol's versatility has made it a popular choice for products that require flexibility and durability. Resonetics Memry has been at the forefront of developing innovative nitinol solutions for these applications, ensuring high-quality and reliable performance.

Real-World Examples of Nitinol Applications

In the medical field, nitinol products such as stents and guidewires have revolutionized minimally invasive procedures, providing patients with less invasive treatment options. Additionally, nitinol's ability to return to its original shape after deformation makes it ideal for applications like actuators in robotics and aerospace components. Resonetics Memry's expertise in crafting precision nitinol components has significantly brought these innovations to life.

In addition to medical applications, nitinol has also found its way into consumer electronics, particularly in developing high-performance headphones and earbuds. Its unique properties allow for the creation of lightweight, durable components that can withstand repetitive bending and stretching, making it an ideal material for everyday consumer products. As a result, consumers can enjoy longer-lasting and more reliable electronic devices capable of withstanding the rigors of daily use.

Impact of Nitinol Products on the Healthcare Industry

Nitinol, a shape-memory alloy, has revolutionized the healthcare industry with its unique properties and applications. Here are some key areas where nitinol products have made a significant impact:

- Minimally Invasive Surgery: Nitinol-based stents, filters, and other devices enable less invasive surgical procedures, resulting in smaller incisions, reduced pain, and faster patient recovery times.

- Orthopedic Implants: Nitinol is used in joint replacement components, such as hip and knee implants, offering improved durability, flexibility, and biocompatibility.

- Endovascular Therapies: Nitinol coils and stents treat aneurysms and vascular occlusions, reducing the risk of stroke and other complications.

- Dental Applications: Nitinol wires and braces are used in orthodontics, providing gentle and effective tooth alignment.

- Drug Delivery Systems: Nitinol-based implants can deliver drugs in a controlled and targeted manner, improving treatment outcomes for various diseases.

Resonetics Nashua's expertise in nitinol manufacturing ensures that healthcare professionals can rely on high-quality and reliable components for various applications. The continued development and innovation of nitinol products hold immense promise for advancing patient care and improving overall health outcomes.

Nitinol's Role in Advanced Engineering Projects

In advanced engineering projects, such as space exploration and automotive design, nitinol's unique properties have created new possibilities for creating lightweight yet resilient components. Whether deploying solar panels in space or designing adaptive engine parts for cars, using nitinol allows engineers to push the boundaries of what's possible. With expert guidance from experienced nitinol manufacturers like Resonetics Memry, these projects can continue to push the limits of innovation.

With nitinol's remarkable ability to return to its original shape after being deformed, engineers can now create components that can adapt to changing conditions, such as temperature fluctuations or mechanical stress. In space exploration, for example, nitinol can be used to design deployable structures that can withstand the harsh conditions of space and unfold seamlessly when needed. Similarly, in automotive design, nitinol's adaptive properties allow for the creation of engine parts that can adjust their shape and performance based on driving conditions, leading to enhanced efficiency and durability.

Advancements in Nitinol Functional Materials

Resonetics Memry and Nitinol are set to revolutionize the medical and engineering industries with innovative products and solutions. The future of Nitinol and Resonetics memory looks bright as advancements in Nitinol functional materials continue to drive progress. Tailored solutions for Nitinol components are a game-changer, offering customized options for various applications.

The Future of Nitinol and Resonetics Memry

The future of Nitinol and Resonetics Memry is promising, with ongoing research and development paving the way for groundbreaking innovations in shape memory technology. As we move forward, the collaboration between Resonetics and GEE SMA will continue to push the boundaries of what's possible with Nitinol alloy, opening up new possibilities for medical devices and advanced engineering projects.

Advancements in Nitinol functional materials are driving significant progress in various industries. From healthcare to aerospace, the unique properties of Nitinol alloy are being harnessed to create cutting-edge solutions that were once thought impossible. As manufacturers refine their processes, we expect even more exciting developments shortly.

Tailored Solutions for Nitinol Components

Tailored solutions for Nitinol components empower businesses to meet specific requirements with precision and efficiency. By offering customized options for machining and manufacturing, nitinol manufacturers are enabling companies to bring their visions to life without compromise. This level of flexibility is a game-changer in industries where precision is paramount.

Tailored solutions for Nitinol components are revolutionizing the precision and efficiency of manufacturing and driving innovation in product design. With the ability to customize machining and manufacturing processes, businesses can now create unique and intricate nitinol components that were once thought impossible. This level of creative freedom sparks new ideas and pushes the boundaries of what is achievable with nitinol, leading to breakthroughs in various industries.