Introduction

In the world of robotics, Shape Memory Alloy Actuators are revolutionizing the way machines move and function. These advanced actuators, such as Nitinol Linear Actuators and Nitinol Finger Actuators, are built from Nitinol, a type of Shape Memory Alloy known for its exceptional power and flexibility. As an artificial actuator for exoskeletons and other robotic applications, Nitinol components offer unparalleled performance and precision. Whether it's product development design or consulting, the use of Nitinol for robots is paving the way for innovative advancements in the field of robotics.

Understanding Shape Memory Alloy Actuators in Robotics

Nitinol For Robots has become a game-changer in the industry, with its unique ability to retain a predetermined shape when heated above its transformation temperature. This makes it an ideal material for creating high-performance actuators that can seamlessly integrate into robotic systems. The versatility and reliability of Nitinol components make them a popular choice for engineers and designers looking to enhance the functionality of their robotic creations.

Advantages of Using Shape Memory Alloy Actuators

Actuators built from Nitinol have the highest power-to-weight ratio among all artificial actuator materials available today. This means that they can deliver exceptional force while remaining lightweight and compact, making them perfect for various robotic applications. Additionally, their ability to undergo millions of cycles without fatigue ensures long-term durability and consistent performance, setting them apart from traditional actuators.

Applications of Shape Memory Alloy Actuators in Robotics

From medical devices to industrial automation, the applications of Nitinol Linear Actuators and other Shape Memory Alloy actuators are vast and diverse. Their precise control and rapid response make them ideal for tasks requiring delicate movements or quick adjustments. Whether it's assisting with surgical procedures or enhancing the dexterity of robotic hands, these advanced actuators are at the forefront of innovation in robotics.

What are Shape Memory Alloys?

Definition and Composition of Shape Memory Alloys

Shape Memory Alloys (SMAs) are a unique class of materials that have the ability to remember their original shape and return to it when subjected to certain stimuli, such as temperature or stress. The most common SMA used in robotics is Nitinol, which is composed of nickel and titanium in roughly equal atomic percentages. SMAs exhibit superelasticity, meaning they can undergo large deformations and still return to their original shape. This property makes them ideal for applications in industries such as aerospace and medical devices, where precise and reliable performance is crucial.

Properties and Characteristics of Shape Memory Alloys

SMAs exhibit remarkable properties, including superelasticity and shape memory effect, making them ideal for actuators in robotics. Nitinol For Robots offers high strength, excellent fatigue resistance, and biocompatibility, making it suitable for various applications in the robotics industry.

In addition to their superelasticity and shape memory effect, SMAs also exhibit excellent corrosion resistance, making them highly durable in harsh environments. This makes Nitinol For Robots an ideal material for actuators and components used in robotics applications that require long-term reliability and performance. With its ability to withstand corrosion, SMAs can be utilized in marine robotics, aerospace applications, and other challenging environments where traditional materials may fail.

Types of Shape Memory Alloys Used in Robotics

In the field of robotics, Nitinol Actuators product development design and consulting has paved the way for innovative solutions. The Nitinol Linear Actuator (2 way) is a prime example of how SMAs are utilized as artificial actuators for exoskeletons, providing precise control and efficient movement. Actuators built from Nitinol have the highest power-to-weight ratio among all actuator types, making them highly sought after for robotic applications.

In addition to Nitinol, another type of shape memory alloy used in robotics is Copper-Aluminum-Nickel. This alloy offers high strain recovery and excellent fatigue resistance, making it ideal for applications requiring repeated actuation cycles. Its ability to maintain shape memory even after thousands of cycles makes it a reliable choice for long-term use in robotic systems. With its unique combination of properties, Copper-Aluminum-Nickel SMAs are increasingly being integrated into advanced robotics for enhanced performance and durability.

Working Principles of Shape Memory Alloy Actuators

Transformation Mechanism of Shape Memory Alloys

Shape memory alloys, such as Nitinol, exhibit a unique transformation mechanism called the shape memory effect. This allows them to return to their original shape after being deformed, making them ideal for actuators in robotics. Nitinol For Robots is a leading provider of Nitinol Actuators product development design and consulting, specializing in innovative solutions for various robotic applications.

Shape memory alloy actuators function in robotics by utilizing the unique properties of shape memory alloys, such as Nitinol, to provide precise and reliable movement. When an external force is applied to deform the alloy, it retains a memory of its original shape and returns to it when the force is removed. This ability makes Nitinol actuators ideal for applications requiring repetitive and accurate motion control, such as in robotic arms and grippers. Additionally, the high energy density of Nitinol allows for compact and lightweight actuator designs, making them well-suited for use in space-constrained robotic systems.

How Shape Memory Alloy Actuators Function in Robotics

Nitinol Linear Actuator (2 way) is a prime example of how shape memory alloy actuators function in robotics. These actuators built from Nitinol have the highest power-to-weight ratio among all artificial muscle technologies, making them perfect for use in robotic systems. Their unique properties allow for precise and efficient movement, enhancing the overall performance of robotic devices.

These shape memory alloy actuators are also known for their durability and reliability, making them ideal for use in demanding robotic applications. Whether it's in manufacturing, healthcare, or even space exploration, these actuators provide the necessary strength and precision to carry out intricate tasks with ease. Their ability to withstand repeated use without degradation ensures that robotic systems equipped with these actuators can operate consistently and effectively over time.

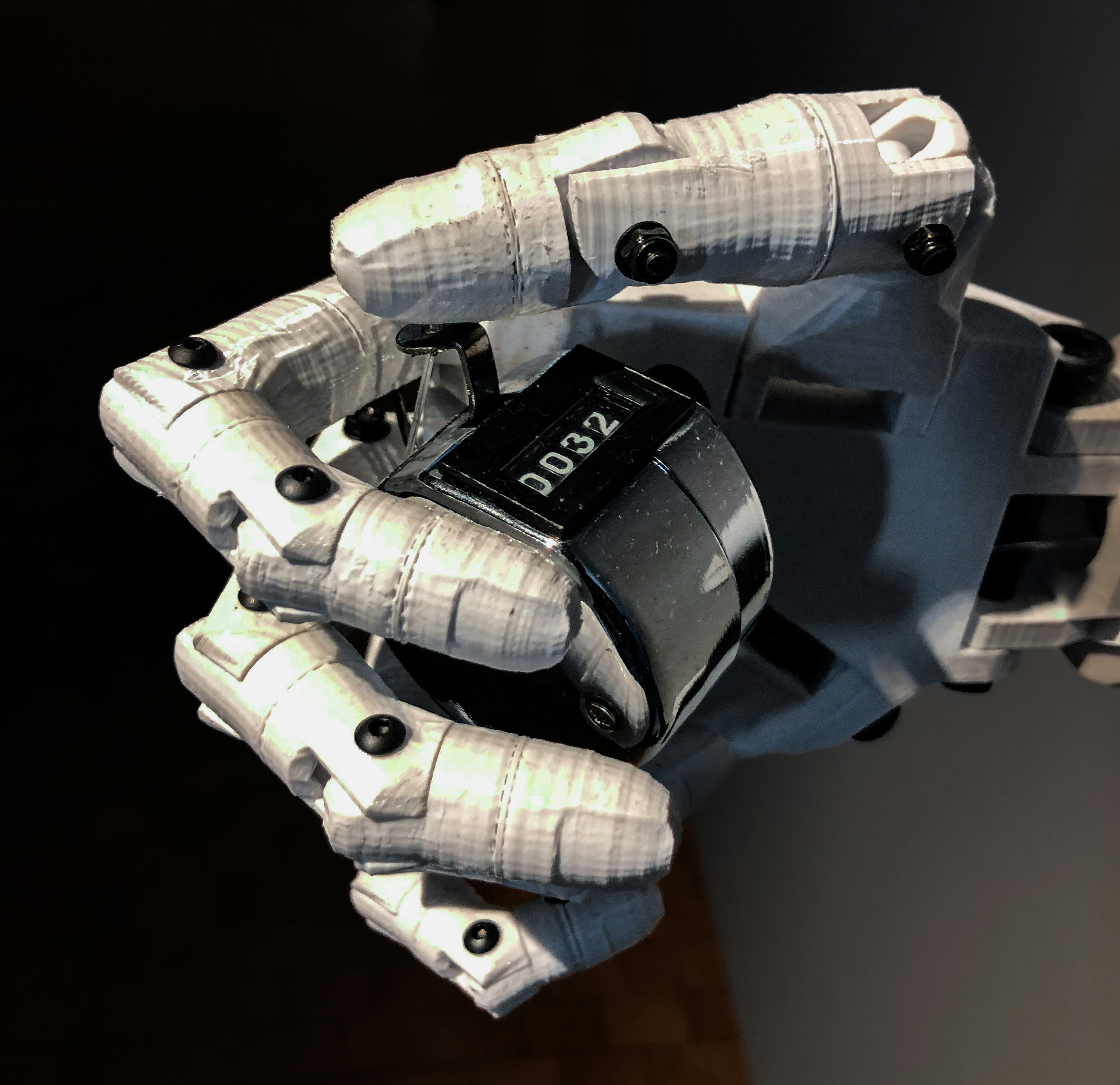

Examples of Shape Memory Alloy Actuators in Action

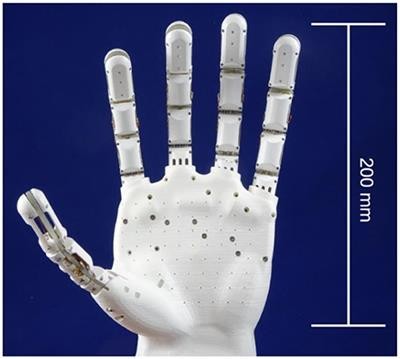

One notable application of shape memory alloy as an artificial actuator is in exoskeletons. The use of Nitinol Components in exoskeleton design has revolutionized the field by providing lightweight and powerful actuation for enhanced mobility and strength augmentation. A prime example is the Nitinol Finger Actuator, which offers dexterous and lifelike movement capabilities for robotic prosthetics and exoskeletons.

Another exciting application of shape memory alloy actuators is in the field of aerospace engineering. Nitinol components have been utilized in the development of adaptive wing designs, allowing for dynamic changes in wing shape to optimize aerodynamic performance during flight. This innovation has led to improved fuel efficiency and maneuverability, making it a game-changer in the aviation industry.

Design Considerations for Shape Memory Alloy Actuators

Factors to Consider When Designing with Shape Memory Alloys

When designing with shape memory alloys (SMAs) for actuators in robotics, it's crucial to consider the unique properties of Nitinol, a popular SMA used in robotics. Nitinol offers high power density, shape memory effect, and superelasticity, making it an ideal material for robotic actuators. Additionally, designers must take into account the specific requirements of the application and ensure that the Nitinol actuators are capable of meeting those needs.

In addition to the material properties of Nitinol, designers must also consider the temperature range at which the SMA will be operating. Nitinol's shape memory effect and superelasticity are highly dependent on temperature, so it's crucial to ensure that the actuator will function effectively within the specified temperature range of the robotic application. This may require additional thermal management systems or insulation to maintain consistent performance.

Challenges and Solutions in Designing Shape Memory Alloy Actuators

One of the challenges in designing Nitinol actuators for robots is achieving precise control over their movement. However, with advancements in product development and design consulting for Nitinol actuators, engineers have been able to overcome this challenge by implementing innovative control systems that ensure accurate and reliable performance. By leveraging cutting-edge technology and expertise in Nitinol linear actuator design, engineers can address these challenges effectively.

One key aspect of integrating shape memory alloy actuators in robotics is ensuring compatibility with existing robot designs and systems. This can be a challenge due to the unique properties of Nitinol and the need to tailor actuators to specific robot requirements. However, by working closely with robotics engineers and leveraging their expertise, designers can develop customized solutions that seamlessly integrate Nitinol actuators into robotic platforms. This collaborative approach allows for the creation of more efficient and effective robotic systems that benefit from the unique capabilities of shape memory alloy actuators.

Best Practices for Integrating Shape Memory Alloy Actuators in Robotics

Integrating Nitinol-based actuators into robotics requires careful consideration of mechanical design, material selection, and system integration. To ensure optimal performance, it's essential to work with experienced professionals who specialize in Nitinol components and finger actuators. By leveraging their expertise and knowledge of SMA technology, designers can implement best practices that maximize the potential of Nitinol as an artificial actuator for exoskeletons and other robotic applications.

After considering the mechanical design, material selection, and system integration, it's important to focus on the control and power supply aspects of integrating Nitinol-based actuators into robotics. The control system must be able to accurately and efficiently manage the actuator's shape memory effect, while the power supply should provide sufficient energy to activate the actuator without compromising its performance. By addressing these aspects, designers can ensure that Nitinol actuators operate reliably and consistently within robotic systems.

Advancements and Future Trends in Shape Memory Alloy Actuators

Innovations in Shape Memory Alloy Actuators Technology

In recent years, there has been a surge in the development of Nitinol For Robots, with a focus on enhancing the performance and efficiency of robotic systems. This has led to the creation of advanced Nitinol Linear Actuators that offer two-way motion capabilities, providing greater flexibility in robotics applications. Additionally, there has been significant progress in the design and consulting services for Nitinol Actuators product development, ensuring that cutting-edge technology is effectively integrated into various robotic platforms.

Potential Impact of Shape Memory Alloy Actuators on Robotics Industry

Actuators built from Nitinol have gained attention for their ability to deliver the highest power-to-weight ratio among all known actuator materials. This breakthrough has the potential to revolutionize the robotics industry by enabling the development of more compact and powerful robotic systems that can perform a wide range of tasks with increased precision and agility. As a result, Nitinol Components are being increasingly incorporated into robotics designs to leverage their superior performance characteristics.

Predictions for the Future of Shape Memory Alloy Actuators

Looking ahead, it is anticipated that Shape Memory Alloys such as Nitinol will continue to play a pivotal role as an Artificial Actuator for Exoskeletons, enabling advancements in wearable robotics for medical rehabilitation and industrial applications. The ongoing research and development efforts focused on enhancing Nitinol Finger Actuator technology are expected to yield even more sophisticated solutions that will further expand the capabilities of robots in diverse fields.

Conclusion

Nitinol For Robots has revolutionized the field of robotics with its innovative Nitinol Actuators product development design and consulting. The Nitinol Linear Actuator (2 way) has proven to be a game-changer, offering unmatched power and precision in robotics applications. This versatile Shape Memory Alloy as an Artificial Actuator for Exoskeletons has opened up new possibilities for enhancing human capabilities through advanced robotic technology.

Harnessing the Power of Shape Memory Alloy Actuators in Robotics

Actuators built from Nitinol have highest power, making them the go-to choice for designers and engineers looking to push the boundaries of what is possible in robotics. The use of Nitinol Components in various robotic systems has demonstrated unparalleled performance and reliability, showcasing the immense potential of this cutting-edge technology in shaping the future of robotics.

Embracing the Versatility of Shape Memory Alloy Actuators

Nitinol Finger Actuator is just one example of how shape memory alloy actuators can be integrated into a wide range of robotic applications, from delicate surgical procedures to heavy-duty industrial tasks. The adaptability and flexibility offered by these actuators make them an invaluable asset for any robotics project, allowing for precise control and seamless integration into complex systems.

Exploring the Limitless Potential of Shape Memory Alloy Actuators

As we look ahead, it's clear that the potential impact of Nitinol Actuators on the robotics industry is boundless. With ongoing innovations in Nitinol For Robots technology, we can expect to see even more advanced applications and groundbreaking developments that will continue to push the boundaries of what is achievable in robotics. The future holds endless possibilities for leveraging the power of shape memory alloy actuators to drive progress and innovation in robotics.