Introduction

Welcome to the fascinating world of superelastic shape memory alloy, a remarkable material revolutionizing various industries. From medical devices to aerospace components, shape memory alloys' versatility is astounding. In this article, we will delve into superelastic alloys' intricacies and explore their endless possibilities.

Understanding Super Elastic Shape Memory Alloy

Shape memory alloys (SMAs) are a fascinating class of materials known for their ability to "remember" their original shape. Here's a closer look at their properties and applications:

- Shape Memory Effect: When deformed at a low temperature, SMAs can return to their original shape upon heating. This "memory" is triggered by a change in internal crystal structure.

- Superelasticity: SMAs exhibit remarkable elasticity at higher temperatures, undergoing significant deformation without permanent change. Once the stress is released, they return to their original shape.

- Diverse Applications: These unique properties make SMAs valuable in various fields. From orthodontic wires and self-deploying stents in medicine to eyeglass frames and grippers in consumer products, SMAs offer innovative solutions.

In conclusion, shape memory alloys bridge the gap between flexibility and resilience, offering exciting possibilities for various applications.

Exploring the Versatility of Shape Memory Alloys

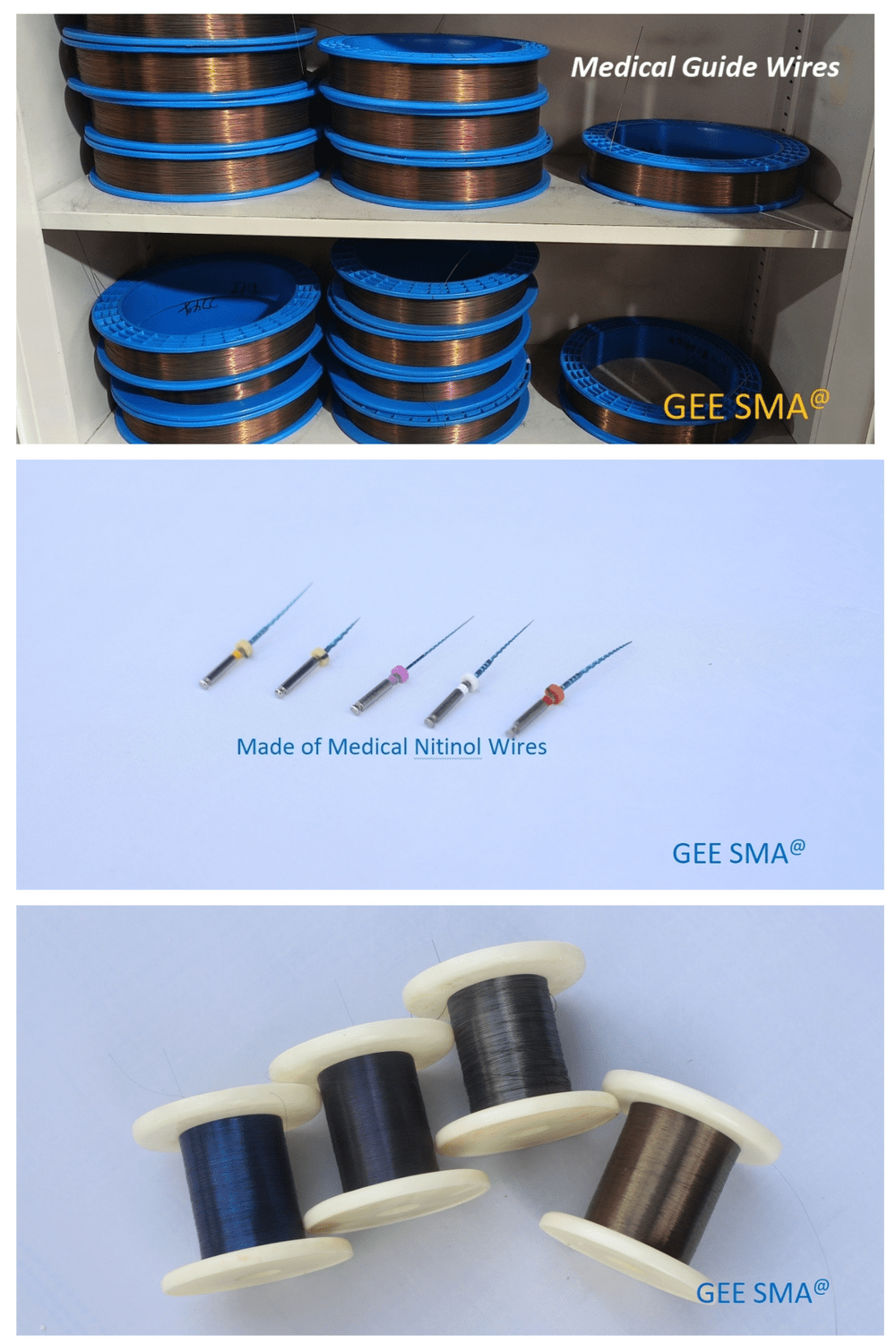

Shape memory alloy products come in various forms, from wires and tubes to sheets and foils. This versatility allows them to be used in diverse industries, such as healthcare, aerospace, automotive, and more.

The Fascinating World of Superelastic Alloys

Superelastic alloys are at the forefront of material science innovation, offering unparalleled strength and flexibility. Their ability to withstand extreme conditions makes them indispensable in cutting-edge technologies and groundbreaking advancements.

What is Super Elastic Shape Memory Alloy?

Super elastic shape memory alloys are remarkable materials that can undergo large deformations and return to their original shape. GEE SMA's Nitinol shape memory alloys exhibit this extraordinary property, making them highly sought after in various industries. These alloys can recover their initial shape even after being subjected to substantial strain, making them ideal for various applications.

Characteristics of GEE SMA's Nitinol Shape Memory Alloys

Nitinol, a nickel-titanium alloy developed by GEE SMA, boasts remarkable properties that make it ideal for demanding applications. Here's what sets it apart:

- Exceptional Elasticity and Flexibility: Nitinol can withstand repeated bending and twisting without permanent deformation, making it highly resilient.

- Shape Memory Effect: This unique property allows Nitinol to "remember" its original shape and return to it upon a specific trigger like heat or stress, perfect for applications requiring a return to a particular form.

- High Corrosion Resistance: Nitinol excels in harsh environments like marine or aerospace settings due to its exceptional corrosion resistance, maintaining its shape and functionality.

- Unmatched Fatigue Resistance: Nitinol can withstand prolonged use and repetitive stress without degradation, ideal for applications requiring long-term performance under demanding conditions.

GEE SMA's Nitinol shape memory alloys offer a unique combination of elasticity, shape memory, corrosion resistance, and fatigue resistance, making them a valuable material for various demanding applications.

Applications of Super Elastic Shape Memory Alloy Products

The versatility of superelastic shape memory alloy products is truly astounding, with applications ranging from medical devices and implants to aerospace and automotive components. These alloys are used in stents, orthodontic wires, actuators, and various other critical components, where their superelasticity and shape memory properties are leveraged for optimal performance.

Super elastic shape memory alloy products are also finding their way into robotics, where their unique properties are being harnessed to create more agile and responsive robotic components. These alloys are used to construct robotic limbs, grippers, and other moving parts, allowing for greater flexibility and precision in movement. The ability of super elastic materials to withstand repeated deformation without permanent damage makes them an ideal choice for the demanding requirements of robotics.

Advantages of Utilizing Super Elastic Materials

Superelastic materials like shape memory alloys offer a game-changing combination of properties, making them ideal for various demanding applications. Here's why:

- Durability in Extreme Environments: These materials can withstand extreme temperatures, pressures, and stresses without losing their integrity, perfect for applications like medical devices or aerospace components.

- Extended Lifespan and Reduced Maintenance: Their unique properties contribute to a longer product lifespan and less frequent maintenance needs.

- Precise and Repeatable Shape Memory: They can return to their original shape after deformation, ensuring consistent performance over time – crucial for applications requiring high precision and reliability.

Superelastic materials offer a unique blend of strength, flexibility, and shape memory, making them valuable assets in various industries. Their potential applications and the underlying science behind their remarkable properties will be explored further in the next section.

How Does Shape Memory Alloy Work?

The Science Behind Super Elasticity

Super elastic shape memory alloy, also known as shape-memory alloy, is a fascinating material that can return to its original shape after deformation. This remarkable property is due to the alloy's unique crystalline structure, which allows it to undergo reversible martensitic phase transformations. When subjected to stress or temperature changes, the material can recover its original shape, making it ideal for various applications.

Shape Memory Alloy Transformation Mechanism

The transformation mechanism of superelastic shape memory alloy involves two distinct phases: austenite and martensite. At lower temperatures or under mechanical stress, the material transforms into a more flexible martensitic phase, allowing for deformation without permanent damage. When the stress is removed or temperature increases, the alloy reverts to its original austenitic phase, regaining its original shape and properties.

In addition to its unique transformation mechanism, super elastic shape memory alloy exhibits excellent fatigue resistance, making it ideal for applications in industries such as aerospace and medical devices. The alloy's ability to withstand repeated deformations without permanent damage makes it a reliable choice for critical components that experience constant stress or strain. This exceptional fatigue resistance sets shape memory alloy apart from traditional materials and opens new possibilities for innovative engineering solutions.

Practical Examples of Shape Memory Alloy Applications

The versatility of superelastic shape memory alloy products is evident in various practical applications across different industries. From medical devices such as stents and orthodontic wires that adapt to body temperature and movements to aerospace components like actuators and deployable structures that respond to changing environmental conditions, these alloys demonstrate their remarkable capabilities in real-world scenarios.

Furthermore, shape memory alloys are also used in the automotive industry for actuators and sensors that respond to temperature changes and mechanical stress. These alloys improve vehicle safety and performance by providing reliable and efficient solutions for various automotive components. Additionally, shape memory alloys in consumer electronics, such as mobile phone antennas and smartwatch straps, showcase their adaptability to miniaturized and high-tech devices, further expanding their practical applications.

Super Elastic Shape Memory Alloy Applications

Medical Devices and Implants

Superelastic shape memory alloys have revolutionized the medical industry. Their unique ability to return to their original shape after deformation makes them ideal for applications such as stents, orthodontic wires, and surgical instruments. The flexibility and biocompatibility of superelastic alloys make them a popular choice for medical devices and implants.

Superelastic shape memory alloy has also found its way into the aerospace and aircraft industry, where its unique properties are highly valued. These alloys' ability to withstand extreme temperatures and return to their original shape makes them ideal for use in components such as actuators, landing gear, and fuel system components. The lightweight nature of superelastic alloys also contributes to fuel efficiency and overall performance in aerospace applications.

Aerospace and Aircraft Components

In the aerospace industry, super elastic shape memory alloy is used in various components such as actuators, valves, and landing gear. Its ability to withstand extreme temperatures and return to its original form makes it a valuable material for aircraft systems. The lightweight nature of shape memory alloy products also contributes to fuel efficiency in aerospace applications.

In addition to its use in aircraft components, super elastic shape memory alloy is also employed in aerospace applications for its corrosion resistance and high fatigue strength. This makes it an ideal material for parts subject to constant stress and exposure to harsh environmental conditions. Furthermore, the unique ability of shape memory alloy to return to its original shape after deformation ensures the reliability and longevity of crucial aircraft systems.

Automotive Industry Innovations

Super elastic-shaped memory alloy has made significant contributions to the automotive industry, particularly in safety mechanisms such as airbag deployment systems and seatbelt buckles. Using shape-memory alloy in these components ensures quick response times and reliable performance during critical moments. Additionally, the durability of superelastic alloys adds an extra layer of protection for vehicle occupants.

By utilizing the remarkable properties of superelastic material, diverse industries have achieved innovative solutions that enhance performance and safety across various applications.

GEE SMA: Crafting High-Quality Super Elastic Shape Memory Alloy

When it comes to producing top-notch superelastic shape memory alloy, GEE SMA goes above and beyond to meet superior customer requirements. Our team takes the time to understand our client's specific needs, ensuring that every product we create is tailored to their exact specifications.

Superior Customer Requirements

By prioritizing open communication and collaboration with our customers, we can deliver shape memory alloy products that exceed expectations. Whether it's a unique size or a specific performance requirement, we work closely with our clients to ensure their needs are met with precision and excellence. Our team of experts is dedicated to tailoring Nitinol functional materials to fit the exact specifications of each project. This tailored approach allows us to create custom solutions that meet and exceed our customers' superior requirements.

Tailoring Nitinol Functional Materials

At GEE SMA, we specialize in tailoring Nitinol functional materials to create custom solutions for various applications. Our expertise in manipulating the properties of superelastic shape memory alloy allows us to craft products that are ideally suited for diverse industries, from medical devices to aerospace components.

Consistently Enhancing Product Quality

With a commitment to innovation and continuous improvement, GEE SMA consistently enhances product quality through rigorous testing and refinement. Our dedication to staying at the forefront of shape memory alloy technologies ensures that our customers receive the highest-standard materials for their projects.

Now you can see how GEE SMA stands out in crafting high-quality superelastic shape memory alloy products that meet superior customer requirements while consistently enhancing product quality through tailored Nitinol functional materials.

Harness the Benefits of Super Elastic Shape Memory Alloys

Super elastic shape memory alloy materials have revolutionized various industries, offering unparalleled flexibility and resilience. These innovative materials are reshaping the future of engineering and design, providing endless possibilities for groundbreaking applications.

By harnessing the unique properties of superelastic shape memory alloys, engineers and designers can create products that are durable and adaptable to changing conditions. This remarkable material allows for developing cutting-edge technologies that can withstand extreme environments and deliver exceptional performance.

Meeting Unique Customer Needs with GEE SMA

GEE SMA is committed to meeting its customers' diverse needs by providing high-quality superelastic shape memory alloy products tailored to their specific requirements. Whether for medical devices, aerospace components, or automotive innovations, GEE SMA offers customized solutions that exceed expectations.

GEE SMA stays ahead of the curve by embracing the future of shape memory alloy technologies. With a dedicated team of experts and state-of-the-art facilities, we constantly research and develop new applications for our super elastic shape memory alloy products. This forward-thinking approach allows us to stay at the forefront of industry trends and offer our customers cutting-edge solutions for their needs.

Embracing the Future of Shape Memory Alloy Technologies

As we embrace the future of shape-memory alloy technologies, it's clear that superelastic alloys will continue to play a pivotal role in shaping our world. With ongoing advancements in material science and engineering, we can look forward to even more remarkable applications and breakthroughs in this exciting field. The potential for these alloys to revolutionize industries such as aerospace, automotive, and biomedical is immense, as their unique properties offer solutions to challenges previously thought insurmountable. From more fuel-efficient aircraft to minimally invasive medical devices, the impact of superelastic shape memory alloys is set to be genuinely transformative.

In conclusion, super elastic shape memory alloys are ushering in a new era of innovation and creativity across industries. With GEE SMA leading the way in producing top-quality materials, the potential for groundbreaking advancements is limitless.