Introduction

NiTiCu Shape Memory Alloys, also known as NiTiCu SMA, are a fascinating class of materials with unique properties that make them incredibly versatile and valuable in various industries. The History and Development of NiTiCu SMA has been a journey of innovation and discovery, leading to its widespread use in diverse Applications such as medical nitinol devices, fishing NiTi alloy tools, and nitinol springs for consumer electronics.

What is NiTiCu Shape Memory Alloys?

NiTiCu SMA is a ternary alloy consisting of Nickel (Ni), Titanium (Ti), and Copper (Cu). This combination results in a material that exhibits shape memory effect, superelasticity, and excellent biocompatibility. These properties make it ideal for medical applications such as medical NiTi implants and devices used in minimally invasive surgeries.

The History and Development of NiTiCu SMA

The development of NiTiCu SMA can be traced back to the 1960s when researchers at the Naval Ordnance Laboratory discovered the unique properties of Nitinol - a similar alloy made from Nickel (Ni) and Titanium (Ti). Over the years, advancements in metallurgy led to the addition of Copper (Cu) to create NiTiCuCr and other variations like NiTiNb, expanding the range of applications for these alloys.

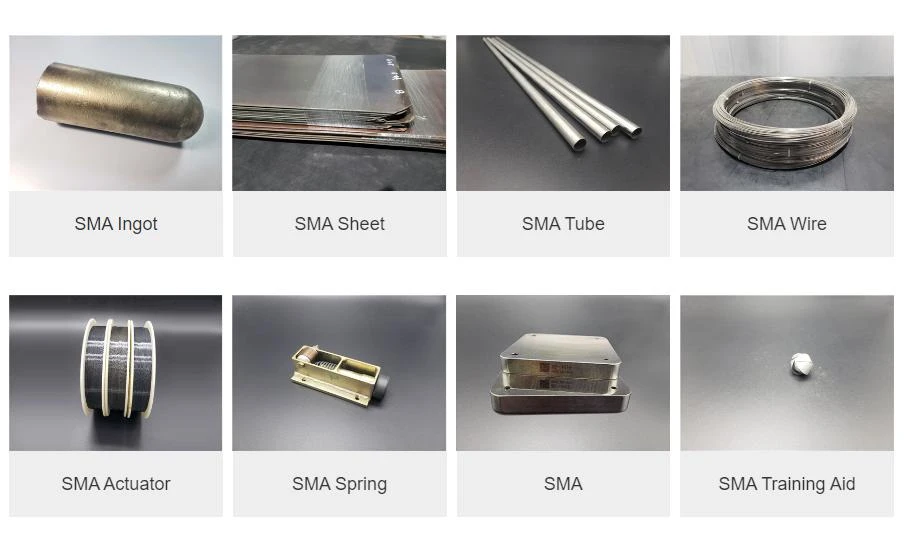

Applications of NiTiCu SMA

The versatility of NiTiCu SMA has led to its widespread use across various industries. In the medical field, it is used for manufacturing medical nitinol implants such as stents, orthodontic wires, and surgical instruments. It is also utilized in fishing tools like fishing Nitinol hooks due to its corrosion resistance and shape memory properties.

Now, let's move on to understanding the composition and unique properties of NiTiCu Shape Memory Alloys.

Understanding NiTiCu Shape Memory Alloys

Composition of NiTiCu SMA

NiTiCu shape memory alloys are composed of nickel (Ni), titanium (Ti), and copper (Cu). Copper's addition to the traditional NiTi alloy enhances its mechanical properties, making it more suitable for various applications in different industries.

NiTiCu shape memory alloys exhibit unique properties that make them highly desirable for various applications. The addition of copper to the traditional NiTi alloy enhances its mechanical properties. It improves its resistance to corrosion, making it suitable for use in harsh environments such as marine and aerospace applications. Furthermore, the unique combination of nickel, titanium, and copper in NiTiCu SMA results in excellent biocompatibility, making it ideal for medical devices and implants.

Unique Properties of NiTiCu SMA

One of NiTiCu SMA's unique properties is its shape memory effect, where the material can remember its original shape and return to it after deformation. Additionally, it exhibits superelasticity, allowing it to recover large strains without permanent deformation. These properties make it ideal for applications requiring precise and reliable actuation.

Furthermore, NiTiCu SMA offers excellent corrosion resistance, making it suitable for use in harsh environments where other materials may degrade over time. This property extends the lifespan of components made from NiTiCu SMA and reduces maintenance requirements, adding to its overall cost-effectiveness. In addition, its biocompatibility makes it an attractive option for medical devices and implants, where it can provide long-term performance without adverse effects on the human body.

Differences between NiTiCu SMA and other Shape Memory Alloys

NiTiCu, a shape memory alloy (SMA) type, stands out from its competitors due to its exceptional properties. Here's a breakdown of its key advantages:

- Enhanced Durability and Biocompatibility: NiTiCu offers superior fatigue resistance compared to other SMAs like NiTiCr and NiTiNb. This and its improved biocompatibility make it a prime choice for medical devices crafted from Nitinol, a nickel-titanium alloy.

- Ideal for Demanding Applications: NiTiCu SMA's improved mechanical properties make it perfect for applications where durability is paramount, such as fishing equipment made from Nitinol.

- Excellent Shape Memory Effect: In addition to its superior fatigue resistance and biocompatibility, NiTiCu exhibits an exceptional shape memory effect. This allows it to return to its original form after deformation, making it ideal for applications requiring precise and reliable actuation, like stents or orthodontic wires.

- Enhanced Thermal Conductivity: The addition of copper to NiTiCu boosts its thermal conductivity, making it a valuable material for heat transfer applications in various industries, including automotive and aerospace.

NiTiCu SMA's unique properties offer a compelling alternative to traditional SMAs, opening doors for its use in diverse fields requiring durability, biocompatibility, precise actuation, and efficient heat transfer.

Manufacturing Process of NiTiCu SMA

NiTiCu Shape Memory Alloys are manufactured through a complex process that involves precise mixing and heat treatment. The first step is melting and mixing the NiTiCu alloy, which involves carefully combining nickel, titanium, and copper to achieve the desired composition. This process requires strict adherence to specific ratios to optimize the alloy's shape memory properties.

Melting and Mixing of Alloy

The melting and mixing of NiTiCu SMA is crucial in ensuring the alloy's desired properties. The raw materials are melted together at high temperatures in a controlled environment to form a homogenous mixture. The precise combination of nickel, titanium, and copper is essential for achieving the unique shape memory characteristics that make NiTiCu SMA so valuable in various applications.

Heat Treatment Process

After the alloy has been mixed, it undergoes a heat treatment process to set its shape memory properties. This involves subjecting the material to specific temperature cycles that allow it to develop its unique crystalline structure, enabling it to remember its original shape even after deforming. The heat treatment process is critical in determining the functionality and reliability of NiTiCu SMA for different applications.

Quality Control and Testing

Quality control and testing play a significant role in ensuring that NiTiCu SMA meets stringent industry standards. Advanced testing methods such as X-ray diffraction and differential scanning calorimetry verify the material's composition and shape memory properties. Quality control measures are implemented throughout the manufacturing process to guarantee that each batch of NiTiCu SMA meets precise specifications before being used in various industries.

With careful attention to detail during melting, mixing, heat treatment, quality control, and testing processes, manufacturers can produce high-quality NiTiCu SMA with exceptional shape memory properties for diverse applications across industries.

Advantages and Disadvantages of NiTiCu SMA

NiTiCu Shape Memory Alloys (SMA) offer various advantages in engineering applications. These alloys are known for their exceptional shape memory properties, superelasticity, and high damping capacity, making them ideal for use in various industries such as aerospace, automotive, and medical.

Advantages of using NiTiCu SMA in Engineering

NiTiCu shape memory alloys (SMAs) offer several advantages, making them valuable materials in engineering applications. Here are some key benefits:

- Shape Memory Effect: NiTiCu can return to its original form after deforming, making it ideal for applications requiring precise movements and positioning, such as deployable antennas, microgrippers, and self-repairing mechanisms.

- Excellent Durability: These alloys are highly resistant to fatigue and corrosion. This ensures reliable performance over extended periods, even in harsh environments like pipelines and biomedical implants.

- Compact and Lightweight Design: NiTiCu's unique properties enable the creation of smaller and lighter components. This translates to increased efficiency in systems where weight and size are critical factors, such as aerospace and robotics.

In conclusion, NiTiCu SMAs present a unique combination of shape memory, durability, and compactness, making them versatile materials for innovative engineering solutions.

Limitations and Challenges of NiTiCu SMA

NiTiCu shape memory alloys (SMAs) offer a unique combination of properties that make them valuable for various applications. However, some limitations and challenges must also be considered when working with these materials.

Here are some of the key limitations to consider:

- Cost: NiTiCu SMAs are generally more expensive than traditional materials, such as steel or plastic. This can significantly impact the affordability of products that utilize them.

- Manufacturing complexity: The manufacturing process for NiTiCu SMAs is intricate and requires specialized equipment and expertise. The raw material supply chain is also limited, which can further complicate production.

while NiTiCu SMAs hold great promise for various applications, addressing these limitations is crucial for their wider adoption and cost-effective integration into next-generation technologies. By developing more efficient manufacturing processes and exploring alternative material sources, researchers can help to make NiTiCu SMAs a more practical and accessible material for a wider range of applications.

Overcoming the Challenges with NiTiCu SMA

To address these challenges, ongoing research efforts are focused on developing cost-effective production methods for NiTiCu SMAs without compromising their quality and performance. Additionally, advancements in material sourcing and recycling technology aim to create a more sustainable supply chain for these alloys. Overcoming these obstacles can facilitate the widespread adoption of NiTiCu SMAs in various engineering applications.

Stay tuned for more exciting information on the diverse applications and future developments of NiTiCu Shape Memory Alloys!

Applications of NiTiCu Shape Memory Alloys

1. Medical and Healthcare Applications

Due to their unique properties, NiTiCu shape memory alloys are widely used in the medical and healthcare industry. Medical nitinol, a type of NiTiCu alloy, is commonly used in surgical instruments, dental braces, stents, and catheters. NiTiCu's biocompatibility and corrosion resistance make it an ideal material for implants and medical devices.

2. Aerospace and Defense Applications

In the aerospace and defense sector, NiTiCuCr alloys are utilized for various applications such as actuators, aerospace components, missile systems, and armor-piercing projectiles. The exceptional strength-to-weight ratio and resistance to high temperatures make NiTiCuCr a preferred choice for critical components in aircraft and defense systems.

3. Consumer Electronics and Automotive Applications

The versatility of NiTiCu alloys extends to consumer electronics and automotive industries, where fishing nitinol or fishing NiTi alloy is commonly used for applications such as eyeglass frames, mobile phone antennas, orthodontic wires, and engine components. The flexibility, durability, and shape memory properties of nitinol spring make it an excellent choice for these applications.

By leveraging the exceptional properties of NiTiCu shape memory alloys across diverse industries such as medical, aerospace & defense, consumer electronics & automotive sectors, it's evident that this material holds immense potential for future advancements in technology and innovation.

Future Developments and Trends in NiTiCu SMA

Research and Innovation in NiTiCu SMA

As the demand for advanced materials grows, ongoing research and innovation in NiTiCu SMA continue to push the boundaries of what is possible. Scientists are constantly exploring new compositions, such as NiTiCuCr and NiTiNb, to enhance the properties of shape memory alloys for various applications. These developments open up exciting possibilities for the future of engineering and technology.

Potential New Applications and Markets for NiTiCu SMA

With its remarkable properties, NiTiCu SMA holds great potential for new applications and markets beyond its current uses in medical nitinol devices, fishing nitinol tools, and nitinol springs. Industries such as aerospace, automotive, and consumer electronics are beginning to recognize the benefits of using this versatile material in their products. NiTiCu SMA's versatility makes it a promising candidate for a wide range of innovative solutions.

Environmental and Sustainability Considerations

In an era where sustainability is at the forefront of design and manufacturing processes, NiTiCu SMA offers significant advantages. Its durability and ability to withstand repeated use make it an environmentally friendly choice compared to traditional materials. Additionally, the recyclability of NiTiCu SMA aligns with the growing emphasis on sustainable practices across industries, making it a valuable asset in creating eco-friendly products.

Furthermore, using NiTiCu SMA can reduce products and processes' carbon footprint. Its high strength-to-weight ratio means that less material is required to achieve the same level of performance, leading to lower energy consumption during manufacturing and transportation. This can result in significant cost savings and environmental benefits over the lifecycle of products, making NiTiCu SMA a smart choice for sustainable design and production.

Embrace the Advantages of NiTiCu SMA

NiTiCu Shape Memory Alloys are remarkable materials with incredible versatility and potential. From medical nitinol devices to fishing nitinol tools, NiTiCu SMA's applications are diverse and exciting. As we look to the future, it's clear that NiTiCu SMA will continue to revolutionize various industries, offering innovative solutions and pushing the boundaries of what's possible.

The Versatility and Potential of NiTiCu SMA

NiTiCu SMA's versatility extends beyond its physical properties. It also offers the potential for cost-effective and sustainable solutions in various industries. Its shape memory effect and superelasticity make it an attractive option for applications requiring repeated use and durability. As research continues to uncover new ways to manipulate and enhance its properties, the potential for NiTiCu SMA to revolutionize industries such as aerospace, automotive, and consumer electronics is becoming increasingly evident.

The Exciting Future of NiTiCu SMA

As technology advances, so too does the potential for further innovation in NiTiCu SMA. With alloys like NiTiCuCr and NiTiNb on the horizon, we can expect even more tailored materials with enhanced properties for specific applications. The future holds endless possibilities for this incredible material, paving the way for groundbreaking developments across various industries.

It's clear that embracing NiTiCu SMA's advantages is key to unlocking its full potential. While there are limitations and challenges to overcome, ongoing research and development efforts are focused on addressing these issues. By harnessing NiTiCu SMA's unique properties and leveraging its advantages in engineering and design, we can continue to push boundaries and create innovative solutions that benefit society as a whole.

With its remarkable properties and diverse applications, NiTiCu Shape Memory Alloys have a bright future ahead. As we continue to explore new possibilities and overcome challenges, these alloys will undoubtedly play a significant role in shaping our world for years to come. Let's embrace the potential of NiTiCu SMA as we look forward to an exciting future filled with groundbreaking innovations!