Introduction

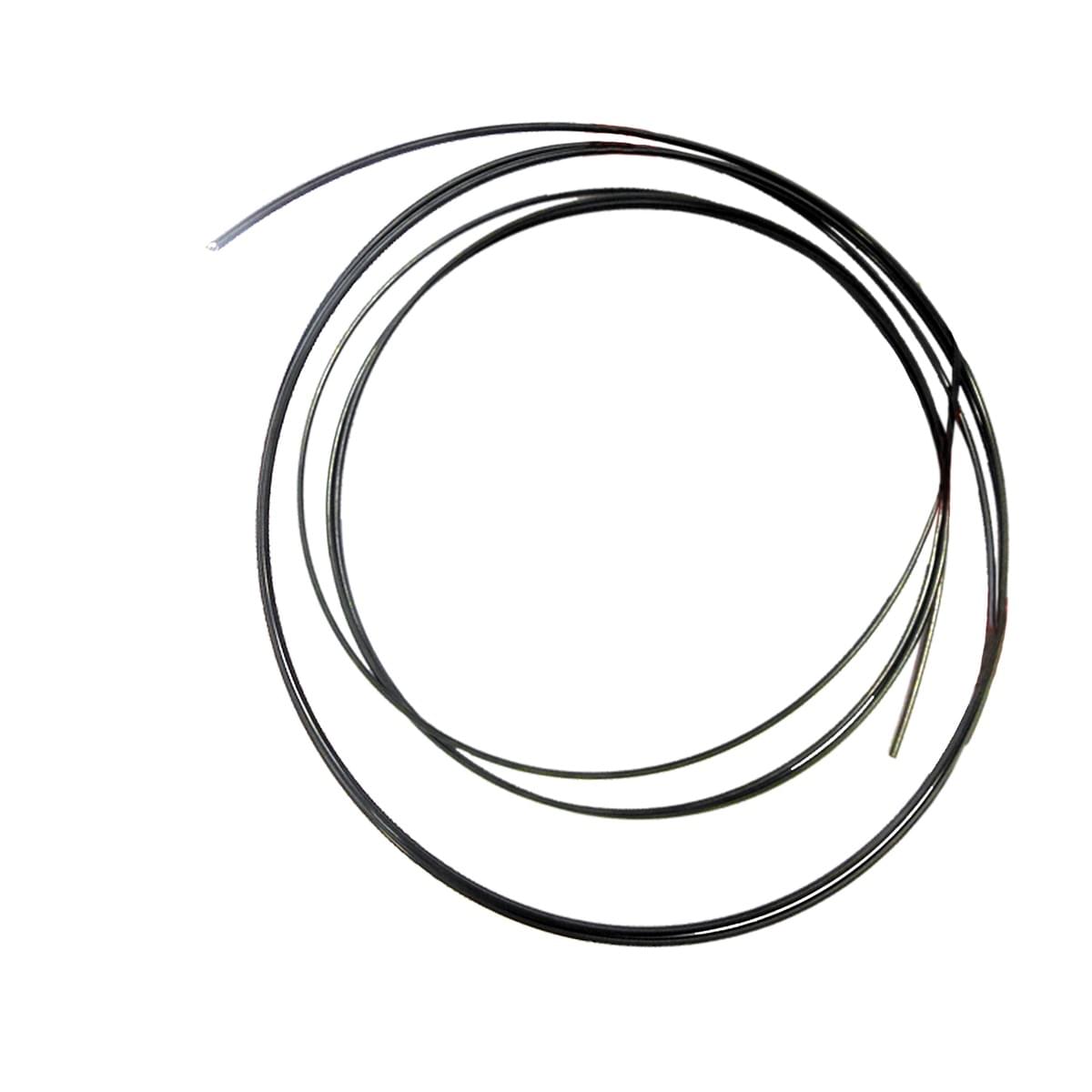

Niti alloy wire for guide wire applications has revolutionized the medical and industrial fields with its unique properties. Nitinol wire, also known as NiTi wire, offers remarkable versatility and adaptability, making it an ideal material for various applications. From CoNiCr-Nitinol composite wire to shape memory alloy (SMA) wire, the potential of nitinol in guidewire manufacturing is truly endless.

Understanding Niti Alloy Wire for Guide Wire Applications

Nitinol guidewires are made of a unique nickel-titanium alloy known for its shape memory and superelasticity. This allows the guide wire to navigate through complex anatomical pathways with ease and precision. The flexibility and resilience of nitinol wire make it an indispensable tool in minimally invasive medical procedures and industrial applications alike.

Nitinol wire's unique properties also make it an ideal material for applications in industries such as aerospace and automotive engineering. Its shape memory allows it to return to its original form after being deformed, making it suitable for use in actuators, sensors, and other components that require precise and reliable performance. Additionally, the superelasticity of nitinol wire enables it to withstand repeated bending and twisting without permanent deformation, making it a durable and cost-effective choice for a wide range of industrial applications.

Exploring the Versatility of Nitinol Wire

Nitinol wire can be used for a wide range of applications, including cardiovascular interventions, neurovascular procedures, aerospace engineering, automotive technologies, and robotics. Its ability to return to a predetermined shape after deformation makes it highly sought after in industries where precision and reliability are paramount.

Nitinol wire's unique properties also make it an ideal material for manufacturing medical guidewires. Its superelasticity and shape memory allow for precise navigation through the body's intricate pathways, providing doctors with the control and flexibility needed for delicate procedures. This has revolutionized minimally invasive surgeries, enabling faster recovery times and reduced risk for patients.

Applications of Nitinol Alloy in Guidewire Manufacturing

The applications of nitinol alloy extend beyond medical devices to include industrial tools and components that require high performance under extreme conditions. From intricate surgical instruments to advanced aerospace components, nitinol's unique properties have paved the way for innovative solutions in diverse fields.

Nitinol alloy's exceptional flexibility and shape memory make it an ideal material for manufacturing guidewires used in minimally invasive medical procedures. The ability to navigate through tortuous pathways within the body while maintaining its original shape allows for precise and safe guidance during surgeries. This unique property of nitinol alloy has revolutionized the field of interventional medicine, enabling healthcare professionals to perform complex procedures with minimal trauma to the patient.

What is Nitinol?

Nitinol, a nickel-titanium (NiTi) alloy, is renowned for its unique properties and characteristics that make it a valuable material for various applications. With its shape memory and superelasticity, Nitinol wire can undergo significant deformation and still return to its original shape when subjected to heat or stress. This makes it an ideal material for guide wire manufacturing, as it can navigate through complex pathways in the body without losing its shape or functionality.

Properties and Characteristics of Nitinol Alloy

Nitinol alloy exhibits excellent biocompatibility, corrosion resistance, and radiopacity, making it suitable for medical devices such as guide wires used in minimally invasive procedures. Its unique combination of properties allows for precise control and maneuverability during medical interventions, ensuring patient safety and successful outcomes.

Shape Memory and Superelasticity of Niti Alloy Wire

The remarkable ability of Nitinol wire to remember its original shape after deformation enables it to adapt to the anatomical structures within the body during medical procedures. This feature is crucial in guide wire applications, where flexibility and resilience are essential for navigating through blood vessels or other intricate pathways.

Structure and Composition of CoNiCr-Nitinol Composite Wire

CoNiCr-Nitinol composite wire is a variation of Nitinol that offers enhanced mechanical properties such as increased strength and durability. The addition of cobalt, nickel, chromium, and other elements further improves the performance of Nitinol wire in demanding applications like cardiovascular interventions or industrial settings.

With its exceptional properties and versatile composition, Nitinol alloy has become indispensable in various industries including healthcare, aerospace, automotive, robotics, and more. Its widespread use underscores the significance of this innovative material in shaping the future of functional materials across different sectors.

Guide Wire Manufacturing

Utilizing Nitinol Wire in Medical Devices

Nitinol wire is extensively used in the manufacturing of medical devices, particularly in the production of guide wires for various medical procedures. Its unique shape memory and superelastic properties make it an ideal material for creating flexible and durable guide wires that can navigate through complex anatomical structures with ease.

Advantages of Using Nitinol Wire for Guidewire Production

The use of nitinol wire in guidewire production offers several advantages, including its ability to withstand repeated bending and flexing without losing its shape or structural integrity. This makes nitinol guidewires highly reliable and long-lasting, ensuring optimal performance during minimally invasive procedures.

Precision Engineering of Nitinol Wire for Guide Wire Applications

The precision engineering of nitinol wire for guide wire applications involves meticulous attention to detail in shaping, cutting, and forming the wire to meet specific design requirements. This ensures that each guidewire is manufactured with the highest level of accuracy and consistency, guaranteeing superior performance in clinical settings.

Medical Applications

Nitinol Guidewires in Minimally Invasive Procedures

Nitinol guidewires are commonly used in minimally invasive procedures such as angioplasty and stent placement. The flexibility and shape memory properties of nitinol wire make it ideal for navigating through intricate blood vessels with minimal trauma to the patient. This allows for more precise and efficient medical interventions, reducing recovery times and improving patient outcomes.

Additionally, nitinol guidewires are extremely durable, allowing for repeated use without compromising their performance. This not only reduces the cost of medical procedures but also minimizes waste and environmental impact. Furthermore, the enhanced visibility of nitinol wire under fluoroscopy enables healthcare professionals to accurately track the movement of the wire within the body, ensuring greater precision during delicate procedures.

Nitinol Wire in Cardiovascular and Neurovascular Interventions

In cardiovascular and neurovascular interventions, nitinol wire plays a crucial role in delivering catheters to targeted areas within the body. The superelasticity of nitinol allows for easy navigation through tortuous blood vessels, while its shape memory properties ensure that the wire returns to its original shape after being bent or deformed during the procedure. This makes nitinol wire an indispensable tool for treating complex conditions such as aneurysms and blocked arteries.

Nitinol guide wires are designed to provide enhanced performance and durability during cardiovascular and neurovascular interventions. The unique properties of nitinol, such as its high tensile strength and resistance to corrosion, make it an ideal material for guide wires that need to withstand the rigors of medical procedures. Additionally, the flexibility of nitinol allows for precise control and maneuverability, ensuring that physicians can navigate through intricate vascular pathways with ease. As a result, nitinol guide wires have become the go-to choice for delivering catheters to targeted areas within the body, ultimately improving patient outcomes.

Enhanced Performance and Durability of Nitinol Guide Wires

The use of nitinol guide wires offers enhanced performance and durability compared to traditional guide wires made from materials like stainless steel. Nitinol's ability to withstand repeated bending without permanent deformation ensures that guide wires maintain their integrity throughout a procedure, reducing the risk of complications or injury to patients. Additionally, the biocompatibility of nitinol minimizes the risk of adverse reactions, making it a safe choice for medical applications.

Furthermore, nitinol guide wires are known for their superelasticity, allowing them to return to their original shape after being bent or deformed. This property makes them ideal for navigating through complex and tortuous anatomical structures with minimal resistance, improving the overall efficiency of medical procedures. Moreover, nitinol's unique shape memory capabilities enable guide wires to adapt to various conditions within the body, providing physicians with greater control and precision during interventions.

Industrial Applications

Nitinol Wire in Aerospace and Automotive Industries

Nitinol wire is widely utilized in the aerospace and automotive industries due to its unique properties such as superelasticity and shape memory. It is used in various applications including actuators, sensors, and components for aircraft, spacecraft, and automotive engines. The ability of nitinol wire to withstand extreme conditions makes it an ideal material for critical components in these industries.

Nitinol SMA Shape Memory Alloy Wire in Robotics

The shape memory properties of nitinol SMA wire make it an excellent choice for robotics applications. It allows for the creation of compact and efficient robotic components that can change shape or revert to their original form when subjected to different stimuli. This makes nitinol SMA wire a valuable material for the development of advanced robotic systems with enhanced flexibility and adaptability.

Customized Solutions for Diverse Nitinol Wire Applications

Nitinol wire offers customized solutions for a wide range of industrial applications beyond aerospace, automotive, and robotics. Its versatility allows for tailored designs to meet specific requirements in industries such as manufacturing, engineering, and consumer electronics. From intricate components to complex mechanisms, nitinol wire provides endless possibilities for innovative solutions across diverse industrial sectors.

Future Trends

As the demand for advanced medical devices continues to rise, there is a growing focus on innovations and advancements in nitinol wire technology. Researchers and manufacturers are exploring new techniques to enhance the properties of nitinol alloy wire for guide wire applications, such as improving flexibility and fatigue resistance. These developments aim to further elevate the performance and reliability of nitinol guidewires in various medical procedures.

Innovations and Advancements in Nitinol Wire Technology

Innovations in nitinol wire technology are paving the way for enhanced precision and control in medical procedures. With ongoing research into shape memory and superelasticity, there is potential for the development of more intricate designs that can navigate complex anatomical structures with ease. This could lead to the creation of next-generation nitinol guidewires that offer unprecedented maneuverability and support during minimally invasive interventions.

Potential Growth and Expansion of Nitinol Alloy Applications

The potential for growth and expansion of nitinol alloy applications extends beyond the medical field. Industries such as aerospace, automotive, and robotics are increasingly recognizing the value of nitinol wire due to its unique properties, including its ability to return to a predetermined shape after deformation. This opens up opportunities for utilizing nitinol SMA shape memory alloy wire in a wide range of industrial applications, from actuators in aircraft components to adaptive mechanisms in robotic systems.

GEE SMA's Role in Shaping the Future of Nitinol Functional Materials

GEE SMA (Shape Memory Alloys) plays a pivotal role in shaping the future of nitinol functional materials by driving advancements in manufacturing processes and material design. Their expertise contributes to refining the performance characteristics of CoNiCr-Nitinol composite wire, ensuring that it meets stringent quality standards for guide wire production. As GEE SMA continues to push boundaries with their cutting-edge solutions, they are instrumental in unlocking new possibilities for utilizing nitinol wire (NiTi wire) across diverse industries.

Conclusion

Nitinol wire, particularly Niti alloy wire for guide wire applications, has proven to be a game-changer in various industries. Its unique properties, such as shape memory and superelasticity, make it an ideal material for manufacturing guide wires used in medical procedures and industrial applications. The versatility and durability of CoNiCr-Nitinol Composite Wire further enhance its potential for a wide range of uses.

The Enduring Significance of Nitinol Wire in Various Industries

From medical devices to aerospace and automotive industries, the enduring significance of nitinol wire cannot be overstated. Its ability to withstand extreme conditions and maintain its shape makes it invaluable in critical applications where precision and reliability are paramount.

Harnessing the Potential of Nitinol Shape Memory Alloy Wire

The potential of nitinol SMA shape memory alloy wire is limitless. As technology continues to advance, so does the potential for innovative uses of this remarkable material. From robotics to minimally invasive medical procedures, harnessing the full potential of nitinol wire opens up a world of possibilities.

Exploring Endless Possibilities with Nitinol Wire (NiTi Wire)

As we look to the future, the endless possibilities with nitinol wire continue to unfold. With ongoing innovations and advancements in nitinol wire technology, we can expect to see even more diverse applications across various industries. The future is bright for NiTi wire as it continues to shape the landscape of functional materials.