Introduction

Nitinol guide wires are crucial components in various medical procedures. They are known for their flexibility and shape memory properties. Understanding the unique characteristics of nitinol wire is essential for its effective use in biomedical applications. The science behind nitinol wire involves its composition of nickel and titanium, giving it remarkable properties.

Understanding Nitinol Guide Wires

Nitinol guide wires are commonly used in minimally invasive surgeries, allowing for precise navigation through blood vessels and other anatomical structures. Their superelasticity and kink resistance make them indispensable tools for medical professionals, ensuring patient safety and successful procedures.

Nitinol guide wires are also known for their shape memory, allowing them to return to their original form after being bent or deformed during use. This unique property ensures that the guide wire can maintain its intended shape and trajectory, providing medical professionals with reliable and consistent performance throughout the procedure. Additionally, the biocompatibility of Nitinol makes it suitable for prolonged contact with bodily tissues, minimizing the risk of adverse reactions and promoting healing post-surgery.

Exploring the Applications of Nitinol Wire

Nitinol wire's applications extend beyond the medical field, with uses in industries such as aerospace, automotive, and robotics. Its unique properties make it ideal for applications requiring shape memory, superelasticity, and biocompatibility.

Nitinol wire's unique properties have made it valuable in various industries. In the aerospace sector, nitinol wire is used in actuators and components that require shape memory and superelasticity, making it an essential material for advanced aircraft and spacecraft. In the automotive industry, nitinol wire is utilized in various applications such as engine components, sensors, and safety systems, where its biocompatibility and durability are highly advantageous. In robotics, nitinol wire's ability to return to its original shape after deformation makes it an ideal material for creating intricate and precise robotic mechanisms.

The Science Behind Nitinol Wire

Nitinol wire consists of nearly equal parts nickel and titanium, resulting in a material with exceptional flexibility and resilience. Understanding the phase transformation process that occurs in nitinol allows for its controlled use in various applications.

What is Nitinol Wire?

Nitinol wire is a type of shape memory alloy composed of nickel and titanium, known for its unique ability to return to a predetermined shape when heated. This composition gives nitinol wire its remarkable flexibility and resilience, making it an ideal material for various industry applications.

The Composition of Nitinol

Nitinol comprises approximately 50% nickel and 50% titanium, with small amounts of other elements such as iron or chromium. This specific combination of metals gives nitinol its exceptional properties, including superelasticity and shape memory.

Nitinol Wire Properties

Nitinol wire's properties make it highly desirable for a wide range of applications. It exhibits superelastic behavior, allowing it to withstand significant deformation without permanent damage. Additionally, nitinol wire has shape memory properties, enabling it to return to its original shape after deforming.

Applications of Nitinol in Various Industries

Nitinol wire has applications in various industries, including medical devices, automotive components, robotics, and aerospace technology. In the medical field, nitinol guide wires are commonly used for minimally invasive procedures due to their flexibility and ability to navigate intricate pathways within the body.

Now that we understand what nitinol wire is composed of and its unique properties, let's delve into how to train and use this remarkable material effectively.

Training and Using Nitinol Wire

Nitinol guide wires are crucial in various medical procedures, but proper training is essential to ensure safe and effective use. To train nitinol wire, start by familiarizing yourself with the material's unique properties, such as its shape memory and superelasticity. Then, practice bending and shaping the wire to understand how it responds to different stimuli. Finally, seek guidance from experienced professionals or attend specialized workshops to hone your skills in handling nitinol guide wires.

How to Train Nitinol Wire

To train nitinol guide wire effectively, starting with a solid understanding of its properties and behavior is important. Begin by studying the material composition of nitinol and how it transforms at specific temperatures. Next, practice using specialized tools and techniques to shape the wire into various forms. Finally, seek mentorship from seasoned practitioners who can provide valuable insights and hands-on training for using nitinol guide wires in real-world scenarios.

Tips for Using Nitinol Wire Safely

Nitinol wires are a valuable tool in many medical procedures, but prioritizing safety is crucial to avoid complications. Here are some key points to remember when handling nitinol guide wires:

- Proper Training is Essential: Before working with nitinol wires independently, ensure you have received thorough training on their handling and use. This ensures you understand their properties and can operate them effectively.

- Inspect Before Use: Always meticulously inspect the guide wire for any signs of damage or defects before each use. A compromised wire can malfunction and increase risks during procedures.

- Follow Established Protocols: Strictly adhere to established protocols and guidelines when using nitinol guide wires. These protocols are designed to minimize risks and ensure successful outcomes for patients.

By following these simple steps, you can contribute to a safe and effective environment for yourself and your patients when working with nitinol guide wires.

Common Mistakes When Handling Nitinol Wire

Despite its remarkable properties, mishandling nitinol wire can lead to costly errors or even pose risks to patient safety during medical interventions. One common mistake is applying excessive force when shaping the wire, which can lead to permanent deformation or breakage. Another error is neglecting proper sterilization protocols for nitinol guide wires before use in medical procedures, which can introduce infection risks. By being aware of these potential pitfalls and adhering to best practices, practitioners can avoid common mistakes when handling nitinol guide wires.

How Does Nitinol Wire Work?

Nitinol wire is a unique material with special properties that make it ideal for various applications, including biomedical devices. These properties, such as shape memory and superelasticity, allow nitinol to return to its original shape when heated or subjected to stress. This makes nitinol wire highly versatile and durable, making it an excellent choice for medical devices like stents and orthodontic wires.

The Unique Properties of Nitinol

Nitinol is a nickel-titanium alloy with two unique properties: shape memory and superelasticity. These properties allow nitinol wire to be bent or deformed at room temperature and then return to its original shape when heated above its transition temperature. This makes nitinol wire perfect for applications where precision and flexibility are essential.

Nitinol wire is widely used in medical devices such as stents, where its superelasticity allows it to be compressed and inserted into a blood vessel before expanding back to its original shape. This flexibility and resilience make nitinol ideal for applications requiring intricate movements and precise control. In addition, the shape memory property of nitinol allows it to be pre-programmed into a specific shape, which can then be activated by heat, making it invaluable in industries such as aerospace and robotics.

Nitinol Wire Transformation

Nitinol wire transforms due to the phase change between martensite and austenite structures within the material. When nitinol is deformed at low temperatures, it becomes martensitic; upon heating, it transforms back into the austenitic phase, regaining its original shape.

Nitinol Wire Applications in Biomedical Devices

The unique properties of nitinol wire make it indispensable in the medical field. It is commonly used in minimally invasive surgical procedures, such as guiding catheters through blood vessels or shaping stents for cardiovascular interventions. Its superelasticity also allows for less invasive procedures and quicker patient recovery times.

With a deeper understanding of how nitinol wire works, we can appreciate its value in various industries, particularly in biomedical applications where precision and flexibility are crucial. Whether shaping stents or guiding catheters through blood vessels, nitinol's unique properties make it an indispensable material in modern medicine.

Shaping Nitinol Wire

Nitinol wire is incredibly versatile and can be shaped using various techniques to meet specific application requirements. One common method is using heat to soften the wire, allowing it to be easily bent or formed into intricate shapes. Another technique involves applying mechanical force to the wire, allowing it to retain its new shape once cooled. These shaping techniques make nitinol wire an ideal choice for various applications, from medical devices to industrial components.

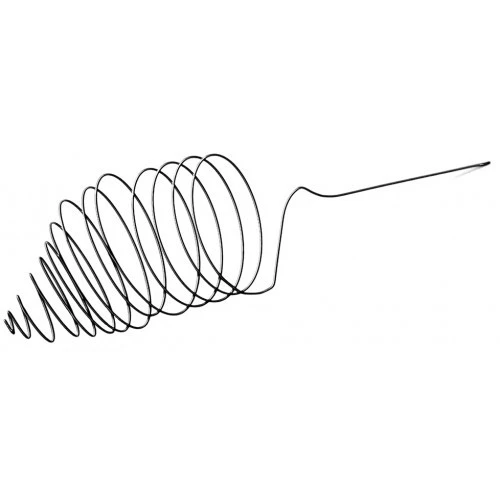

Techniques for Shaping Nitinol Wire

One popular technique for shaping nitinol wire is superelasticity, which allows the wire to be deformed and return to its original shape once the force is removed. This property makes nitinol wire highly resilient and capable of withstanding repeated use without permanent deformation. Additionally, nitinol wire can be shaped using conventional metalworking methods such as bending, twisting, and coiling, making it easy to create custom shapes for specific applications.

Shape Memory Properties of Nitinol

Nitinol exhibits shape memory properties, meaning it can remember its original shape and return to it when subjected to a specific stimulus, such as heat or stress. This unique characteristic allows nitinol wire to be pre-programmed with a specific shape and then revert when triggered by an external factor. As a result, nitinol wire is commonly used in medical devices that require precise positioning or deployment within the body.

Nitinol Wire Forming Processes

Forming nitinol wire typically involves a combination of heat treatment and mechanical shaping techniques. The wire is often subjected to controlled heating and cooling cycles during manufacturing to set its desired shape memory properties. Once shaped, the nitinol wire can undergo further processing, such as cutting or welding, before being incorporated into various products like stents, orthodontic wires, or actuators.

After the shaping process, nitinol wire can be further treated to enhance its performance characteristics. This may involve surface finishing or coating to improve the wire's corrosion resistance, biocompatibility, or wear resistance. These additional treatments can ensure that the nitinol wire meets the specific requirements of the intended application, whether for medical devices or industrial components.

Nitinol Wire in the Market

Researching Nitinol Wire Suppliers

When researching nitinol wire suppliers, consider their experience in the industry, the quality of their products, and their customer service. Look for suppliers who specialize in nitinol guide wires and have a proven track record of delivering reliable, high-quality materials for various applications.

Nitinol Wire Amazon Reviews

Before making a purchase, checking out nitinol wire Amazon reviews is always a good idea. Reading feedback from other customers can provide valuable insights into the performance and reliability of specific nitinol guide wires available on the market. Look for reviews that mention durability, ease of use, and overall satisfaction with the product.

Considerations When Purchasing Nitinol Guide Wires

Nitinol guide wires are essential tools in many medical procedures. Here's what to consider when choosing the perfect one for your needs:

- Application Needs: Identify your procedure's specific requirements. Consider factors like wire diameter, length, tip design, and flexibility.

- Customization Options: Look for suppliers that offer customization to ensure the wire perfectly fits your application.

- Additional Factors: When deciding, evaluate price, delivery time, and after-sales support.

- Beyond these considerations, a reliable supplier is key.

- Research the supplier's reputation: Look for reviews and testimonials to gauge their product quality, service, and on-time delivery.

Choosing a reputable supplier with high-quality nitinol wires and excellent support ensures a smooth and successful experience.

Conclusion

When choosing the right nitinol guide wire for your needs, consider size, shape, and intended application factors. Look for reputable suppliers like GEE SMA that offer high-quality nitinol materials and have a track record of reliability and customer satisfaction. Whether it's for medical devices or industrial applications, partnering with a trusted supplier is crucial.

Choosing the Right Nitinol Wire for Your Needs

When selecting a nitinol guide wire, it's essential to consider the specific requirements of your project or application. Whether you need a superelastic or shape memory wire, understanding the properties and capabilities of nitinol is essential. Look for suppliers that offer customization options to ensure you get the right wire for your needs. Additionally, consider the diameter and length of the wire and any special coatings or treatments that may be necessary for your application. These factors can significantly impact the performance and longevity of the nitinol wire in your project.

Exploring the Future of Nitinol Wire Applications

As technology advances, the future of nitinol wire applications looks promising. From minimally invasive medical procedures to innovative industrial solutions, nitinol's unique properties open up new possibilities in various industries. Stay updated on emerging trends and advancements in nitinol technology to explore new opportunities.

Partnering with GEE SMA for High-Quality Nitinol Materials

GEE SMA is a leading supplier of high-quality nitinol materials, offering various options for medical and industrial applications. Focusing on precision engineering and customer satisfaction, GEE SMA provides reliable solutions tailored to your specific needs. Trust GEE SMA for all your nitinol material requirements.