Introduction

Nitinol, a remarkable alloy of nickel and titanium, is renowned for its unique shape memory and superelastic properties. This extraordinary material has revolutionized various industries, from medical devices to aerospace engineering. GEE SMA stands out as a leading manufacturer of nitinol, consistently pushing the boundaries of innovation in the field.

Understanding Nitinol

Nitinol, a metal alloy known for its shape-memory and superelastic properties, is revolutionizing various industries. Here's what makes nitinol so special:

- Shape Memory: Nitinol can be deformed and then "remember" its original shape when exposed to a specific temperature or external trigger. This allows for minimally invasive medical procedures, where stents and other devices can be compressed for delivery and then expand to their original form inside the body.

- Superelasticity: Nitinol can undergo significant deformation without permanent damage, returning to its original shape once the stress is removed. This makes it ideal for orthodontic wires, which can exert gentle yet constant pressure to correct teeth alignment.

- Biocompatibility and Corrosion Resistance: Nitinol is well-tolerated by the human body and resists corrosion, reducing the risk of rejection and infection. This is crucial for long-term implants like stents.

Nitinol's unique combination of properties makes it a valuable material with vast potential across various sectors. As research continues, we can expect even more innovative applications of this remarkable smart material.

GEE SMA: A Leader in Nitinol Manufacturing

GEE SMA has earned a stellar reputation as an industry leader in producing high-quality nitinol products. With state-of-the-art manufacturing facilities and a dedicated team of experts, GEE SMA continues to set the standard for excellence in nitinol production.

GEE SMA's commitment to innovation and continuous improvement has led to developing cutting-edge nitinol products that meet the evolving needs of various industries. By leveraging advanced technologies and materials, GEE SMA can produce nitinol components with exceptional shape memory and superelasticity, making them ideal for various applications. This dedication to pushing the boundaries of nitinol manufacturing has solidified GEE SMA's position as a frontrunner in the industry.

Exploring Nitinol's Fascinating Properties

Nitinol's properties are truly fascinating, from its ability to withstand extreme temperatures to its biocompatibility for medical implants. Its shape memory feature allows it to revert to its original form when heated, making it an invaluable material for various cutting-edge applications.

Nitinol's unique properties have also made it a game-changer in robotics. Its shape memory allows for creating self-repairing robots that can revert to their original form after being damaged. This opens up a world of possibilities for developing more resilient and durable robotic systems, paving the way for advancements in manufacturing, space exploration, and healthcare.

The Discovery of Nitinol

Nitinol, a unique nickel-titanium alloy with remarkable properties, was discovered by Buehler and Wang in 1961. Their serendipitous discovery occurred while conducting experiments on various metal alloys at the Naval Ordnance Laboratory. Upon heating a sample of the nickel-titanium alloy, they observed its extraordinary ability to return to its original shape after being deformed - a phenomenon known as shape memory.

The Story of Buehler and Wang's Serendipitous Discovery

Buehler and Wang's accidental discovery of nitinol's shape memory properties sparked immense interest in the scientific community. This unprecedented characteristic allowed the alloy to be bent or deformed and revert to its original form when subjected to heat, making it an incredibly valuable material for numerous applications.

The discovery of nitinol's shape memory properties revolutionized the field of materials science, leading to breakthroughs in engineering and technology. This unprecedented characteristic allowed for the development of innovative medical devices, such as stents and orthodontic wires, that could adapt to the body's natural movements. Furthermore, nitinol's ability to withstand repeated deformation without losing its original shape made it an ideal material for aerospace, automotive, and robotics applications.

Nitinol's Unique Shape Memory Properties

Nitinol's shape memory properties are rooted in its crystal structure, which reverses phase transformation when exposed to temperature changes. This enables the material to remember its original shape and return to it when heated, making it ideal for applications requiring precise and reliable movement or deformation.

Nitinol's unique shape memory properties have made it a popular choice in medical devices, such as stents and orthodontic wires, where precise movement and deformation are essential for successful treatment. The ability of Nitinol to return to its original shape when heated also makes it an ideal material for use in aerospace and automotive applications, where reliability and performance are paramount. Additionally, Nitinol's biocompatibility further enhances its appeal in the medical field, as it can safely remain within the human body without causing adverse reactions.

The Composition and Properties of Nitinol Alloys

Nitinol is composed of approximately equal parts nickel and titanium, with minor composition variations resulting in different nitinol alloys with varying properties. These alloys can exhibit superelasticity, biocompatibility, corrosion resistance, and durability, making them highly sought after for various applications across industries.

Nitinol alloys are known for their unique ability to exhibit superelasticity, allowing them to return to their original shape after deforming. This property makes nitinol ideal for applications in industries such as medical devices, where it can be used in stents and orthodontic wires that need to withstand deformation without permanent damage. Additionally, the biocompatibility of nitinol alloys makes them suitable for use in the human body, further expanding their potential applications in the medical field.

Nitinol's Remarkable Properties

Nitinol properties are truly remarkable, with its most famous characteristic being superelasticity. This unique feature allows nitinol wire to be bent and twisted without permanent deformation, making it a game-changing material for various applications. Whether in medical devices, aerospace engineering, or consumer electronics, we approach engineering challenges.

Nitinol's superelasticity has opened up a world of possibilities in the medical field, allowing for the development of innovative devices such as stents and orthodontic wires. The ability of nitinol to return to its original shape after being deformed makes it an ideal material for these applications, providing patients with more effective and comfortable treatments. Additionally, its biocompatibility and corrosion resistance make nitinol a top choice for medical device manufacturers looking to improve patient outcomes.

Superelasticity: A Game-Changing Feature

Nitinol's superelasticity allows it to be used in medical stents and orthodontic wires and in a wide range of other applications. For example, nitinol is used in eyeglass frames, where its ability to return to its original shape after being bent provides a durable and long-lasting option for consumers. Additionally, nitinol's superelasticity makes it an ideal material for actuators in robotics and aerospace engineering, where flexibility and resilience are essential for optimal performance.

Biocompatibility: Nitinol in Medical Devices

Another key aspect of nitinol properties is its biocompatibility, making it an ideal choice for medical devices. The nickel titanium alloy used in nitinol is non-toxic and well-tolerated by the human body, making it suitable for implants and surgical tools. Its ability to withstand the harsh environment of the human body while maintaining its shape memory properties has made it indispensable in modern medical technology.

In addition to its biocompatibility, nitinol also boasts impressive corrosion resistance and durability, making it a top choice for medical devices. The nickel titanium alloy is able to withstand the corrosive effects of bodily fluids and other environmental factors, ensuring its longevity and reliability in medical applications. This resistance to corrosion and wear makes nitinol an ideal material for implants and surgical tools that need to maintain their structural integrity over time.

Corrosion Resistance and Durability

Nitinol exhibits excellent corrosion resistance and durability, making it suitable for long-term applications. The nickel titanium alloy used in nitinol wire prevents rusting and degradation over time, ensuring that devices made from this material have a prolonged lifespan. This makes nitinol an ideal choice for applications that require long-term reliability and performance.

In addition to its resistance to corrosion, nitinol's durability also sets it apart as a superior material for long-term use. Its ability to withstand wear and tear over extended periods makes it an excellent choice for applications in industries such as medical devices, aerospace, and automotive engineering. This durability ensures that nitinol-based products maintain structural integrity and performance even under challenging conditions, providing peace of mind to manufacturers and end-users alike.

Applications of Nitinol

Nitinol in Biomedical Devices

Nitinol, a nickel-titanium alloy, has revolutionized various industries due to its remarkable properties.

- Shape Memory and Superelasticity: Nitinol can be deformed and then "remember" its original shape when heated or exhibit superelasticity, returning to its original shape after significant bending or twisting. This makes it ideal for medical devices like stents that expand within blood vessels or orthodontic wires that apply constant pressure.

- Biocompatibility and Corrosion Resistance: Nitinol is safe for implantation within the body and resists corrosion, making it perfect for medical implants and surgical tools.

- Shape Recovery and Resilience: Nitinol can withstand deformation and return to its original shape, along with being resistant to high temperatures and fatigue. This makes it valuable for aerospace components like actuators, sensors, deployable structures, and even adaptive wings, leading to lighter and more efficient designs.

Nitinol's unique combination of properties continues to push the boundaries of what's possible in medicine, aerospace, and beyond.

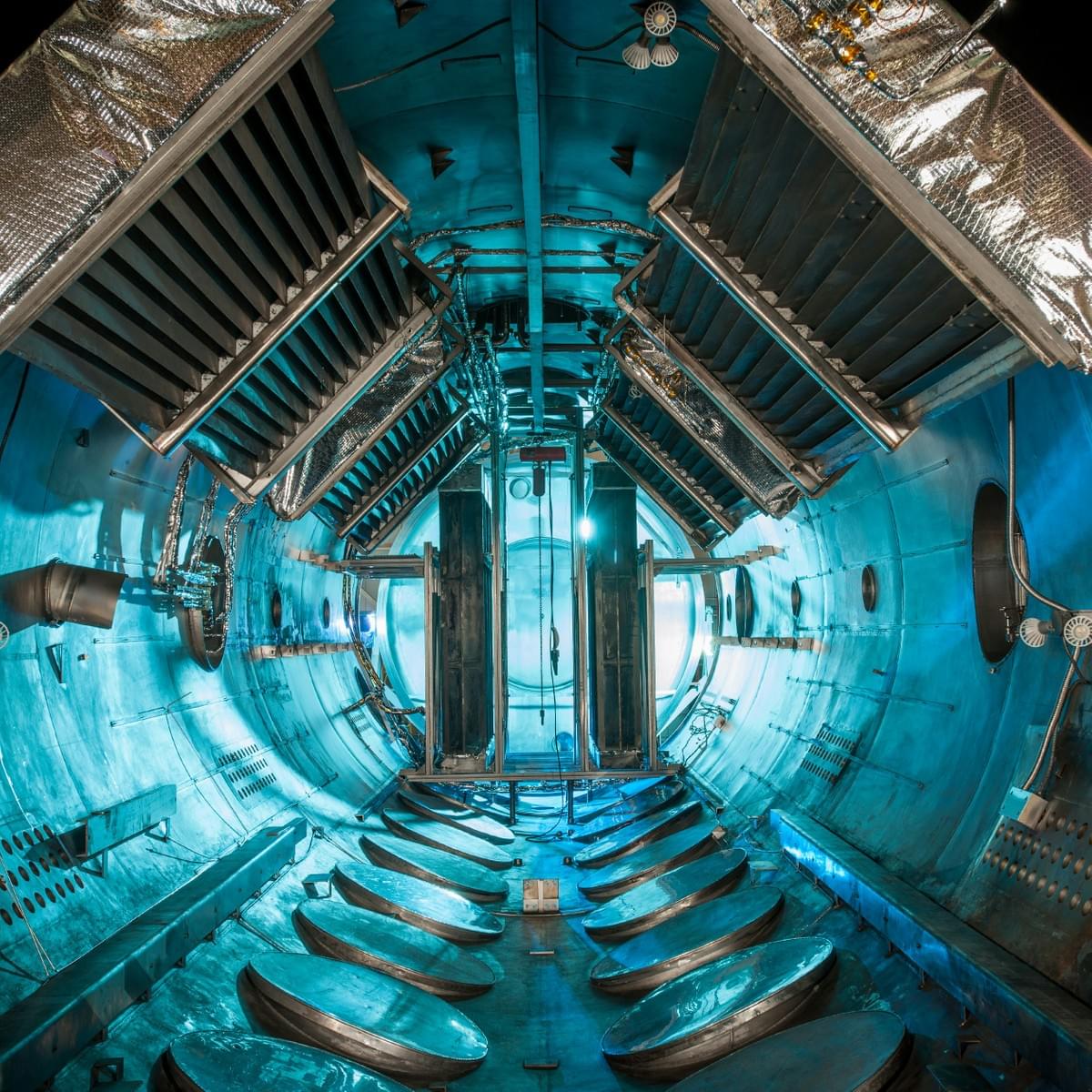

Nitinol in Aerospace Engineering

In aerospace engineering, nitinol's lightweight yet durable nature makes it an invaluable material for various applications. Nitinol wire is used in actuators for aircraft components, allowing for precise control and movement. Additionally, its shape memory properties are leveraged in deployable structures and mechanisms, contributing to the efficiency and reliability of aerospace systems.

Nitinol's unique properties also make it an ideal material for aerospace engineering due to its resistance to corrosion and high fatigue strength. This allows for the use of nitinol in critical components such as landing gear, where reliability and durability are paramount. The lightweight nature of nitinol further contributes to fuel efficiency in aircraft, making it a sought-after material for enhancing the performance of aerospace systems.

Nitinol in Consumer Electronics

Nitinol, a remarkable metal alloy, is making its mark in our everyday devices. Here are some ways this unique material is shaping the world of consumer electronics:

- Shape-Shifting Eyewear: Nitinol's shape memory allows eyeglass frames to return to their original form after bending or twisting, ensuring a perfect fit and lasting comfort.

- Durable Mobile Antennas: Nitinol wire's flexibility and resilience make it ideal for mobile phone antennas, withstanding bumps and drops without compromising signal strength.

- Comfy Tech Companions: Smartwatches and fitness trackers increasingly use nitinol components in their bands. This creates durable yet flexible straps that conform to your wrist and can handle the demands of an active life.

Nitinol's exceptional properties extend beyond consumer electronics, finding applications in various industries. With ongoing technological advancements, we can expect even more innovative uses for this versatile material in the future!

Advancements in Nitinol Technology

Innovative Nitinol Manufacturing Processes

Nitinol's unique properties have made it a valuable material in various fields. Advancements in manufacturing techniques have further unlocked its potential.

Here's how modern nitinol manufacturing has transformed the creation of nitinol alloys:

- Precise Control: Vacuum melting and controlled processing allow for near-perfect ratios of nickel and titanium, leading to consistent material properties.

- Shape Setting: Through heat treatment and specialized fixtures, nitinol can be formed into intricate shapes that "remember" their original form, enabling applications like self-expanding stents.

- Superelastic Processing: Specific heat treatments enhance nitinol's superelasticity, allowing it to absorb significant amounts of energy and return to its original shape, making it ideal for applications requiring flexibility under pressure.

By combining these techniques, manufacturers can create nitinol wires with exceptional performance, paving the way for advancements in medical devices, aerospace components, and more.

GEE SMA's Cutting-Edge Research and Development

GEE SMA has been at the forefront of cutting-edge research and development in nitinol technology. Their continuous efforts to improve nitinol properties and explore new applications have led to groundbreaking advancements, solidifying their position as a leader in the industry. Through collaborative partnerships and investment in state-of-the-art facilities, GEE SMA is driving innovation and shaping the future of nitinol technology.

Future Prospects for Nitinol Applications

The prospects for nitinol applications are promising, with ongoing research focused on expanding its use in emerging fields such as robotics, smart materials, and energy storage. As advancements in manufacturing processes continue to enhance nitinol properties, we expect to see even more innovative applications across diverse industries, cementing its status as a material of choice for next-generation technologies.

The Versatility of Nitinol in Modern Technology

With its remarkable properties and shape memory capabilities, Nitinol has become an indispensable material in modern technology. From biomedical devices to aerospace engineering, its versatility has revolutionized various industries. GEE SMA's unwavering commitment to excellence in nitinol manufacturing ensures that the potential of this incredible material continues to be harnessed for future innovations.

The unique properties of nitinol, such as superelasticity and biocompatibility, have made it a go-to material for many applications. Its ability to return to its original shape after deformation makes it ideal for medical stents, orthodontic wires, and even eyeglass frames. In addition, its corrosion resistance and durability have made it a popular choice in consumer electronics and automotive components.

GEE SMA's Commitment to Excellence in Nitinol Manufacturing

As a leader in nitinol manufacturing, GEE SMA has continuously pushed the boundaries of innovation and quality control. Their cutting-edge research and development have led to advancements in nitinol technology, resulting in improved manufacturing processes and superior product quality. Their dedication to excellence ensures that only the highest-standard nitinol products reach the market.

Embracing the Potential of Nitinol for Future Innovations

With ongoing advancements in nitinol technology, the potential for future innovations is limitless. As researchers continue to explore new applications for nitinol alloys, from robotics to smart materials, it is clear that this remarkable material will play a crucial role in shaping the future of technology. Embracing these possibilities will lead to groundbreaking developments that will benefit society.