Introduction

In the world of industrial materials, few elements have proven as versatile and essential as copper. Among its many forms, copper nitric wire stands out for its unique properties and applications across various sectors. Understanding what copper NiTi wire is and how it differs from other types of wire can significantly impact your choice in projects that require reliability and performance.

A Dive into Copper Nitric Wire

Copper nitric wire is a specialized alloy that combines the excellent conductivity of copper with enhanced resistance to corrosion and heat. This makes it an ideal choice for applications where durability is paramount. By exploring what copper NiTi wire can offer, you’ll uncover a world of possibilities for enhancing efficiency in your work.

The Importance of Copper in Industries

Copper has long been hailed as a backbone material in numerous industries, from electrical engineering to plumbing and construction. Its superior conductivity allows for efficient energy transmission, while its malleability ensures ease of use in various applications. As industries evolve, understanding the importance of copper—and specifically copper tracer wire—becomes crucial for maintaining operational excellence.

What Makes Copper Nitric Wire Unique

What sets copper nitric wire apart from other materials? Its unique composition not only provides exceptional electrical conductivity but also offers resistance to oxidation and wear over time. This combination means that choosing the right type of wire—like copper NiTi wire—can lead to longer-lasting installations with fewer maintenance requirements.

What is Copper Nitric Wire?

Copper nitric wire, often referred to as copper NiTi wire, is a specialized type of wire made from a unique alloy that combines copper with nickel and titanium. This combination provides enhanced properties, making it suitable for various applications across multiple industries. With its remarkable strength and flexibility, copper nitric wire is becoming increasingly popular in fields ranging from electronics to automotive manufacturing.

Definition and Composition

What is copper NiTi wire? At its core, it’s an alloy composed primarily of copper, nickel, and titanium elements. The specific ratios of these metals can be tailored to achieve desired mechanical properties such as tensile strength and ductility. This carefully engineered composition not only enhances the performance characteristics of the wire but also ensures that it can withstand demanding environments without compromising its integrity.

Applications in Various Industries

Copper nitric wire finds its way into numerous applications across diverse sectors due to its unique properties. In the electronics industry, it’s often used for wiring in devices requiring high conductivity and reliability. Additionally, industries like aerospace, automotive, and telecommunications leverage this versatile material for components that demand exceptional durability and resistance to corrosion.

Key Advantages of Using Copper Nitric Wire

One of the key advantages of using copper nitric wire is its superior conductivity compared to many other materials; this makes it ideal for electrical applications where efficiency matters most. Furthermore, the alloy's resistance to wear and tear translates into longer-lasting products that require less frequent replacements or repairs—ultimately saving both time and money in maintenance costs. Lastly, customized options are available for those seeking tailored solutions; understanding customized Copper NiTi wire price factors can help businesses make informed decisions about their procurement needs.

What is Copper Tracer Wire Used For?

Copper tracer wire is an essential tool in the utility industry, primarily used for locating and identifying underground utilities. This specialized wire helps prevent costly accidents during excavation by allowing workers to pinpoint the location of buried pipes and cables accurately. Understanding its role can significantly enhance safety and efficiency in utility management.

Understanding Its Role in Locating Utilities

The primary function of copper tracer wire is to provide a reliable means of detecting underground utilities without the need for extensive digging or invasive techniques. When installed alongside utility lines, it sends signals that can be detected by specialized equipment, allowing workers to map out the precise locations of various services like water, gas, and electricity. This capability reduces the risk of accidental damage during construction or repair work, making it an invaluable asset for contractors and utility companies alike.

Benefits of Using Copper Tracer Wire

One major benefit of using copper tracer wire is its high conductivity, which ensures strong signals can be transmitted over long distances without significant loss. Additionally, copper's durability makes it resistant to corrosion and environmental factors, enhancing its lifespan compared to other materials. The use of copper tracer wire not only improves safety but also saves time and money by minimizing the chances of damaging existing utilities during excavation projects.

Common Applications and Use Cases

Copper tracer wire finds applications across various sectors including construction, telecommunications, water supply systems, and electrical installations. In construction projects where multiple utilities are present underground, this wire helps create accurate maps that guide excavators safely around existing infrastructure. Furthermore, municipalities often employ copper tracer wire for routine maintenance checks on their utility networks to ensure everything remains functional without unnecessary disruptions.

Comparing Copper Wire and Nichrome Wire

Differences in Composition and Properties

Copper wire is primarily composed of pure copper, which boasts excellent electrical conductivity. In contrast, nichrome wire consists of a nickel-chromium alloy that offers different thermal and electrical characteristics. The distinct compositions lead to varying properties; for instance, while copper is known for its high conductivity, nichrome excels in resistance to oxidation and heat.

Understanding what is the difference between copper wire and nichrome wire can help you make informed choices based on your needs. For example, if you're looking for a material that conducts electricity efficiently, copper niticr wire would be your go-to option. However, if heat resistance is a priority—like in heating elements—nichrome would be the better choice.

Heat Resistance and Conductivity

One of the standout features of nichrome wire is its exceptional heat resistance; it can handle high temperatures without significant degradation or loss of performance. This makes it ideal for applications such as heating elements in toasters or industrial furnaces where sustained heat exposure occurs regularly. On the other hand, while copper niticr wire does conduct electricity exceptionally well due to its low resistivity, it tends to lose efficiency at higher temperatures.

Conductivity plays a vital role when deciding between these two wires; copper's superior conductivity means it's often used in electrical wiring where efficiency is key. If you’re asking yourself what is the difference between copper wire and tungsten wire regarding conductivity and performance under temperature variations, know that tungsten also has impressive properties but differs significantly from both copper and nichrome when it comes to everyday applications.

Choosing the Right Wire for Your Needs

Selecting the right type of wire ultimately depends on your specific application requirements. If electrical conductivity tops your list—especially if you're dealing with wiring systems—copper niticr wire should be your first choice due to its outstanding performance characteristics. Conversely, if you need a material that can withstand extreme temperatures without losing integrity or function—think heating coils or high-temperature equipment—nichrome would serve you better.

Additionally, considering customized Copper Niti Wire price options may also influence your decision-making process when selecting wires tailored specifically for unique applications or environments. Ultimately understanding what each type brings to the table will empower you to choose wisely based on factors such as cost-efficiency, durability under stress conditions like temperature changes or corrosion resistance.

Understanding Copper Wire and Tungsten Wire Differences

Comparing Strength and Durability

Copper wire is renowned for its impressive ductility and malleability, making it easy to work with during installation or repair. While it offers great flexibility, tungsten wire stands out due to its exceptional strength; it's one of the hardest metals available. When considering what is copper NiTi wire?, it’s worth noting that this alloy combines copper’s excellent electrical properties with added strength from nickel and titanium—perfect for demanding applications.

Conductivity and Temperature Performance

When comparing conductivity between copper wire and tungsten wire, copper takes the lead with its superior electrical conductivity ratings. This makes it an ideal choice for applications requiring efficient energy transfer—think of those electrifying circuits! However, tungsten shines in high-temperature environments due to its ability to withstand extreme heat without losing structural integrity; thus, if you're looking at what is the difference between copper wire and tungsten wire?, remember that heat resistance plays a significant role in decision-making.

When to Use Copper vs. Tungsten Wire

Choosing between copper niticr wire and tungsten depends largely on your project's requirements. If you're focusing on electrical efficiency or need something lightweight yet durable for general wiring tasks, then copper is usually the go-to option. However, if you require a robust solution for high-temperature applications or scenarios where strength trumps everything else—like in certain aerospace components—tungsten will likely be your best bet.

Customized Copper Niti Wire Price Explained

When it comes to understanding the **Customized Copper Niti Wire Price**, several factors come into play that can influence the overall cost. First and foremost, the composition and quality of the copper niticr wire itself greatly impact pricing; higher purity levels often mean a higher price tag. Additionally, variations in diameter, length, and specific customization requests can also lead to fluctuations in cost, making it essential for buyers to communicate their needs clearly.

Factors Influencing the Price of Copper Niti Wire

Several key elements determine the price of **copper NiTi wire**. Market demand is a significant factor; when industries require more copper tracer wire for utility location or other applications, prices may rise due to increased demand. Furthermore, manufacturing processes play a role; custom orders that require specialized techniques or additional features will typically incur higher costs than standard products.

Another important aspect is sourcing materials. The availability of high-quality copper affects pricing directly—if suppliers face shortages or increased production costs, those expenses are likely passed on to consumers. Lastly, geographical location can influence prices due to shipping costs and local market conditions.

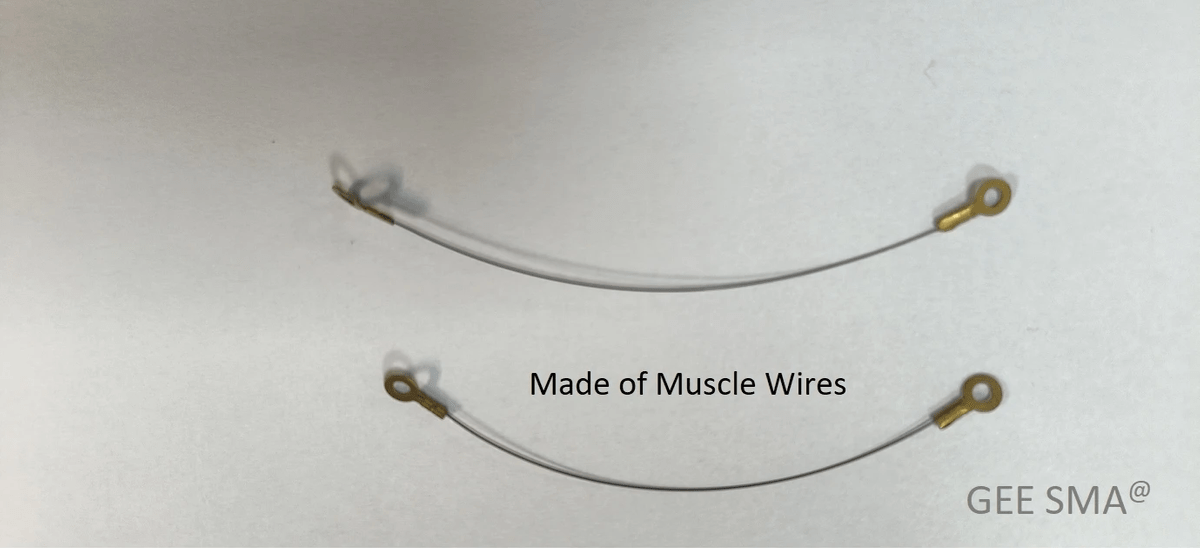

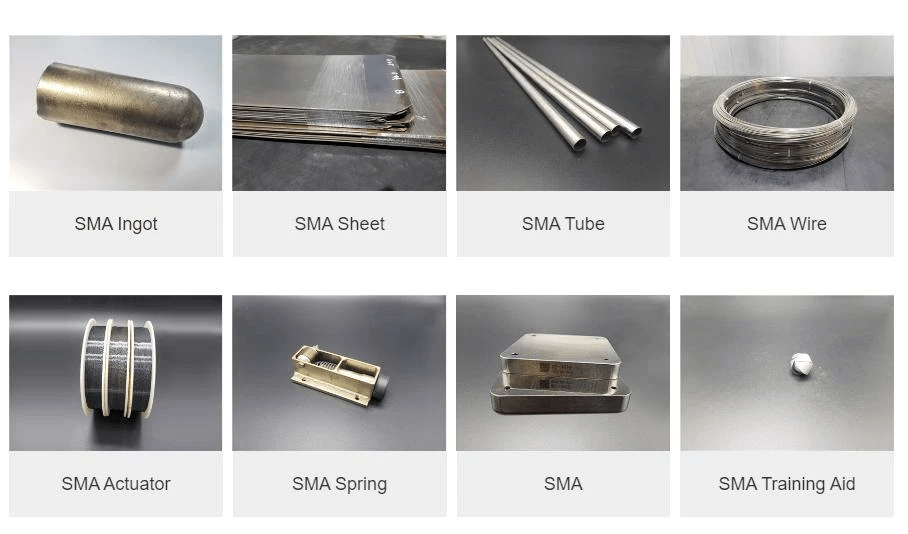

GEE SMA's Role in Custom Manufacturing

GEE SMA stands out in the realm of custom manufacturing by offering tailored solutions for **copper niticr wire** needs. Their expertise allows them to adapt their production processes efficiently based on client specifications while maintaining competitive pricing structures. By leveraging advanced technology and skilled labor forces, GEE SMA ensures that each order meets high standards without unnecessary markups.

Moreover, GEE SMA provides valuable insights into what is copper NiTi wire? This enables clients to make informed decisions about their purchases based on application requirements and budget constraints. With a commitment to customer satisfaction, they prioritize clear communication throughout the manufacturing process.

Maximizing Value with Customized Options

To maximize value when purchasing **copper NiTi wire**, it's crucial for buyers to explore all available customization options thoroughly. Tailoring specific characteristics such as gauge size or tensile strength can lead directly to enhanced performance in your intended application—be it electrical work or medical devices using copper tracer wire for locating utilities effectively.

Additionally, considering long-term benefits over short-term savings is wise; investing in high-quality customized wires may reduce maintenance costs and improve reliability over time compared with cheaper alternatives like Nichrome or tungsten wires. Understanding what is the difference between copper wire and Nichrome wire—or even tungsten—can help you choose wisely based on your project’s demands.

By focusing on quality rather than just price alone while working with manufacturers like GEE SMA ensures that you get not only what you pay for but also peace of mind knowing you’ve made an educated choice tailored specifically for your needs.

Conclusion

In summary, copper nitric wire stands out as a versatile and essential component in various industries, thanks to its unique properties and applications. The key advantages of this wire include its excellent conductivity, corrosion resistance, and adaptability for specialized tasks. Understanding what copper NiTi wire is can further enhance its application in fields requiring precision and reliability.

Key Takeaways on Copper Nitric Wire

Copper nitric wire is not just another metal; it's a powerhouse in the world of electrical wiring and industrial applications. Its composition allows it to excel in environments where other materials might falter, making it indispensable for many sectors. Remember that when considering what is copper NiTi wire?, you’re looking at an innovative solution that combines the best attributes of both copper and nickel-titanium alloys.

Applications of Copper Tracer Wire

When discussing what is copper tracer wire used for?, it’s crucial to highlight its role in utility location and infrastructure maintenance. This specialized wire helps professionals pinpoint underground utilities without disrupting surface structures, ensuring safety and efficiency during excavation projects. The benefits extend beyond mere location; they also include cost savings and reduced risk of damage to existing lines.

The Importance of Choosing the Right Wire

Choosing the right type of wire can make or break your project, whether you’re weighing the difference between copper wire and Nichrome wire or deciding between copper wire and tungsten wire for high-temperature applications. Each type has its unique strengths: while copper excels in conductivity, Nichrome offers superior heat resistance under extreme conditions. Ultimately, understanding customized Copper Niti Wire price factors will help you select the best option tailored to your specific needs without breaking the bank.