Introduction

Nitinol, a fascinating alloy primarily composed of nickel and titanium, is renowned for its unique properties that make it stand out in the world of materials science. This remarkable substance exhibits the shape memory effect, allowing it to return to a predetermined shape when heated. The nitinol melting point is a critical factor that influences its applications across various industries, from medical devices to robotics.

Overview of Nitinol and its Properties

Nitinol's defining characteristic is its ability to undergo significant structural changes based on temperature variations. When heated above its transition temperature, Nitinol can revert to a pre-set shape, making it an invaluable material in applications requiring precision and reliability. Additionally, understanding what happens when nitinol is heated helps engineers and designers maximize its potential in innovative products.

The Importance of Nitinol Melting Point

The nitinol melting point plays a pivotal role in determining how the material behaves under different conditions. Knowing what temperature does nitinol melt at allows manufacturers to optimize processes like welding and shaping without compromising the integrity of the alloy. Moreover, this melting point also influences thermal stability and performance, making it essential knowledge for anyone working with NiTi Shape Memory Alloys.

Common Applications of Nitinol

Nitinol finds itself at home in numerous applications due to its unique properties; from stents used in minimally invasive surgeries to actuators in robotics, this alloy's versatility knows no bounds. Its ability to return to a specific shape makes it ideal for use in medical devices where precision is paramount. Furthermore, understanding what is the boiling point of nitinol can provide insights into its behavior under extreme conditions, further expanding its potential uses across various fields.

What is Nitinol?

Nitinol, a remarkable alloy of nickel and titanium, is celebrated for its unique properties, most notably the shape memory effect and superelasticity. This fascinating material has garnered attention across various industries due to its ability to return to a predetermined shape when subjected to specific thermal conditions. With applications ranging from medical devices to robotics, understanding the composition and characteristics of Nitinol is essential for harnessing its full potential.

Definition and Composition

Nitinol stands for Nickel Titanium Naval Ordnance Laboratory, where it was first discovered in the 1960s. This alloy typically consists of approximately 55% nickel and 45% titanium, creating a material that exhibits extraordinary mechanical properties. Its unique composition allows Nitinol to undergo phase transformations that contribute significantly to its behavior under different temperatures.

Shape Memory Effect Explained

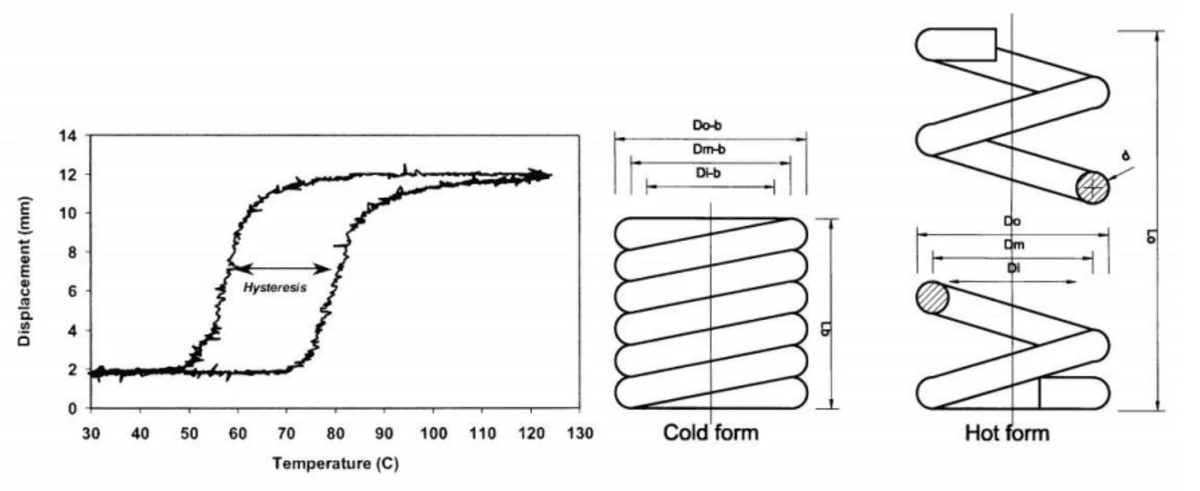

The shape memory effect is one of Nitinol's most intriguing features; it allows the material to remember a specific shape when heated above its transition temperature. When cooled below this temperature, the alloy can be deformed into another shape but will revert back when reheated. This phenomenon makes Nitinol particularly useful in applications where precise movements or adjustments are necessary, such as in stents or actuators.

Applications in Various Industries

The versatility of NiTi Shape Memory Alloy has led to its adoption across numerous fields including medicine, aerospace, and automotive engineering. In medical applications, for example, Nitinol's ability to expand at body temperature makes it ideal for stents that need to open up arteries effectively. In aerospace and robotics, components made from this alloy can provide lightweight solutions with enhanced performance due to their unique thermal properties.

Understanding the Nitinol Melting Point

When diving into the fascinating world of Nitinol, one cannot overlook its melting point, a crucial factor that influences its applications and performance. The nitinol melting point is typically around 1,400 degrees Fahrenheit (760 degrees Celsius), but this can vary based on the specific alloy composition and processing methods used. Understanding what temperature nitinol melts at is essential for engineers and manufacturers who work with this unique material.

What temperature does nitinol melt at?

So, what temperature does nitinol melt at? Generally, you’re looking at a melting point of approximately 1,400°F (760°C) for most NiTi alloys. This relatively high melting point allows Nitinol to maintain its structural integrity under various thermal conditions, making it suitable for applications where heat resistance is paramount.

Factors Affecting the Melting Point

The nitinol melting point isn’t set in stone; several factors can influence it significantly. Variations in alloy composition—such as the ratios of nickel to titanium—can lead to shifts in the melting temperature. Additionally, processing methods like heat treatment and work hardening can also play a role; these processes can either elevate or lower the melting point depending on how they alter the material's microstructure.

Differences between Nitinol and Other Metals

When comparing nitinol to other metals regarding their melting points, there are some notable differences that stand out. For instance, while aluminum has a much lower melting point of around 1,220°F (660°C), stainless steel typically melts between 2,500°F (1,370°C) and 2,800°F (1,540°C). These differences highlight why understanding the nitinol melting point is essential for selecting materials for specific applications where thermal stability is required.

What is the Transition Temperature of NiTi?

The transition temperature of NiTi, or Nitinol, is a critical concept that plays a significant role in its unique properties and applications. This temperature is where the alloy transitions between its two distinct phases: the austenite phase, which is stable at higher temperatures, and the martensite phase, which is stable at lower temperatures. Understanding this transition temperature helps us make sense of how Nitinol behaves under varying conditions and why it’s such a fascinating material in various fields.

Defining Transition Temperature

Transition temperature refers to the specific thermal threshold at which Nitinol changes its structural configuration from one phase to another. For NiTi Shape Memory Alloys (SMAs), this temperature can vary based on composition and processing methods. Typically, the transition temperature can range from -100°C to 100°C or higher, depending on how the alloy has been treated and engineered.

How Transition Temperature Affects Performance

The performance of Nitinol is heavily influenced by its transition temperature; it determines when the material will exhibit its remarkable shape memory effect and superelasticity. When heated above this threshold, Nitinol returns to its original shape after being deformed—this characteristic makes it invaluable for applications ranging from medical devices to actuators in robotics. Conversely, if it's cooled below this point, it can be easily manipulated into new shapes before returning to its original form upon reheating.

Real-world Applications of Transition Temperature

In real-world scenarios, understanding what happens when Nitinol is heated or cooled allows engineers and designers to harness these properties effectively. For example, in medical stents made from NiTi Shape Memory Alloys, knowing the transition temperature ensures they expand correctly within body vessels at body temperature while maintaining flexibility during insertion. Similarly, in robotics or aerospace engineering applications where precise movements are crucial, controlling the transition temperature allows for innovative designs that respond dynamically to thermal changes.

What Happens When Nitinol is Heated?

When nitinol is heated, it undergoes significant structural changes that are crucial to its unique properties. The NiTi shape memory alloy responds to temperature variations in ways that can be both fascinating and practical. Understanding these changes not only sheds light on what happens when nitinol is heated but also informs its diverse applications across industries.

Structural Changes During Heating

As the temperature rises, nitinol transitions from a martensitic phase to an austenitic phase, resulting in distinct structural transformations. This phase change occurs around the transition temperature of NiTi, which typically ranges between 30°C to 100°C depending on the specific alloy composition and treatment processes. When heated beyond its melting point (approximately 1310°C), nitinol will melt into a liquid state, losing its shape memory capabilities entirely.

These structural alterations are pivotal for applications like medical devices and actuators where controlled movement is essential. The ability of nitinol to return to its original shape after deformation—thanks to the shape memory effect—relies heavily on these heating-induced changes. Thus, understanding what happens when nitinol is heated not only highlights its unique characteristics but also sets the stage for innovative uses in various fields.

Practical Implications for Manufacturing

The heating process of nitinol has significant implications for manufacturing techniques and product design. Knowing what temperature does nitinol melt at helps engineers determine safe operating conditions during machining and processing. Furthermore, precise control over temperatures during production ensures that the desired mechanical properties are achieved without compromising the integrity of the material.

In addition, manufacturers must consider how heating affects not only the melting point but also other thermal properties such as thermal stability and fatigue resistance. By mastering these elements, companies can produce high-quality components that leverage nitinol's remarkable attributes effectively. This understanding ultimately leads to enhanced performance in real-world applications ranging from aerospace components to biomedical devices.

Case Studies of Nitinol in Action

To illustrate the practical implications of heating in nitinol’s applications, consider two case studies: stents used in cardiovascular procedures and robotic actuators in advanced machinery systems. In both instances, knowing how heat affects their functionality was crucial for successful implementation.

For instance, stents made from NiTi shape memory alloy expand at body temperature after being deployed through minimally invasive procedures due to their transition temperature characteristics; they revert back upon cooling if needed for adjustments or removals. Similarly, robotic systems utilize controlled heating mechanisms to trigger movements based on pre-set temperatures—demonstrating how what happens when nitinol is heated directly influences operational efficiency.

Through these examples, we see firsthand how understanding both the melting point and transition temperature of NiTi can lead to groundbreaking innovations across multiple sectors while showcasing just how versatile this remarkable alloy truly is.

Exploring the Boiling Point of Nitinol

Nitinol, a remarkable alloy primarily composed of nickel and titanium, exhibits unique properties that make it a favorite in various high-tech applications. While much attention is given to its melting point, understanding its boiling point is equally critical for industries that utilize NiTi Shape Memory Alloy (SMA). Knowing What is the boiling point of nitinol? allows engineers and designers to ensure that their applications can withstand extreme conditions without compromising performance.

What is the boiling point of nitinol?

The boiling point of nitinol is approximately 2,600 degrees Celsius (4,700 degrees Fahrenheit). This high boiling temperature underscores the thermal stability of this remarkable alloy, which enables it to maintain its structural integrity under intense heat. For those working with Nitinol in engineering or manufacturing contexts, knowing What temperature does nitinol melt at? becomes essential when considering operational limits; however, understanding its boiling point provides additional safety margins during high-temperature processes.

Thermal Stability and Its Importance

Thermal stability plays a pivotal role in determining how materials behave under varying temperatures. In applications where Nitinol may be subjected to substantial heat—like in medical devices or aerospace components—understanding both the melting and boiling points ensures reliability and safety. When discussing What happens when nitinol is heated?, it's crucial to note that while it can transition through various phases due to its shape memory effect, exceeding its thermal limits could lead to irreversible changes or failure.

Comparisons with Other Alloys

When comparing Nitinol’s thermal properties with those of other alloys, it becomes clear why NiTi SMAs are often preferred for demanding applications. Many traditional metals have lower melting and boiling points than Nitinol; for instance, aluminum melts at around 660 degrees Celsius (1,220 degrees Fahrenheit), which makes it less suitable for high-temperature environments. Understanding these differences not only highlights the advantages of using Nitinol but also reinforces why engineers must consider both melting and boiling points when selecting materials for their projects.

GEE SMA: Innovating with Nitinol

In the realm of advanced materials, GEE SMA stands out as a leader in the innovation and application of Nitinol. This company specializes in harnessing the unique properties of NiTi Shape Memory Alloy, which includes its impressive melting point and remarkable shape memory effect. By focusing on quality and customization, GEE SMA has carved a niche for itself in various industries that rely on this versatile alloy.

Overview of GEE SMA

GEE SMA is dedicated to pushing the boundaries of what is possible with Nitinol. Their expertise lies not only in understanding what temperature does nitinol melt at but also in maximizing its performance across diverse applications. With a strong emphasis on research and development, GEE SMA continuously seeks to improve the functionality of NiTi Shape Memory Alloy for innovative uses.

Commitment to Quality and Customization

At GEE SMA, quality isn't just a buzzword; it’s a core value that permeates every aspect of their operations. They understand that knowing what is the boiling point of nitinol or its transition temperature can significantly impact product performance and reliability. This commitment extends to customizing solutions tailored specifically to client needs, ensuring that each application benefits from optimal properties such as thermal stability and shape recovery.

Case Studies of Successful Nitinol Applications

GEE SMA has successfully implemented Nitinol in numerous real-world scenarios, showcasing its versatility and effectiveness. For instance, one case study highlighted how understanding what happens when nitinol is heated allowed engineers to design medical devices that utilize the shape memory effect for minimally invasive surgeries. Another example involved aerospace components where knowledge about both the melting point and transition temperature of NiTi was crucial for ensuring safety and performance under extreme conditions.

Conclusion

In summary, the unique properties of Nitinol, particularly its melting point and transition temperature, play a crucial role in its application across various industries. Understanding What temperature does nitinol melt at? is vital for engineers and designers who utilize this remarkable NiTi Shape Memory Alloy in their projects. The ability of Nitinol to change shape upon heating or cooling makes it an invaluable material for innovative solutions.

Key Takeaways on Nitinol Melting Point

The nitinol melting point is typically around 1310°C (2400°F), which is significantly higher than many other metals but essential for applications requiring thermal stability. Knowing What happens when nitinol is heated? reveals that the alloy undergoes structural changes that enhance its shape memory capabilities, making it ideal for medical devices and robotics. Additionally, understanding the relationship between the melting point and transition temperature of NiTi allows manufacturers to tailor products to meet specific performance requirements.

Future Trends in Nitinol Applications

As technology advances, so too does the potential for Nitinol applications across various fields such as aerospace, automotive, and healthcare. The question What is the boiling point of nitinol? becomes increasingly relevant as researchers explore high-temperature environments where this alloy can thrive. Future trends indicate a growing interest in customizing NiTi Shape Memory Alloys to create more efficient systems that leverage their unique thermal properties.

How to Choose the Right Nitinol for Your Needs

When selecting Nitinol for your project, consider factors like melting point, transition temperature of NiTi, and specific application requirements. It's essential to ask yourself: What happens when nitinol is heated? This understanding will guide you in choosing an alloy that meets your performance criteria while ensuring safety and reliability. By evaluating these aspects carefully, you can make informed decisions about which type of Nitinol best suits your needs.