Introduction

In the fascinating world of modern technology, shape memory actuators (SMAs) stand out as remarkable devices that blend science and innovation. These unique components are capable of returning to a predetermined shape when exposed to specific temperatures, making them invaluable in various applications. But what is a shape memory actuator? How does it work, and why should we care about it? Let’s delve into the science behind SMAs and their everyday uses.

Understanding Shape Memory Actuators

At its core, a shape memory actuator is a device that utilizes the unique properties of Shape Memory Alloys (SMAs) to create motion or force in response to temperature changes. This ingenious mechanism allows for precise control in various applications, from medical devices to robotics. But what is an SMA actuator exactly? It’s essentially a smart material that remembers its original shape and can revert back when heated or cooled.

The Science Behind SMAs

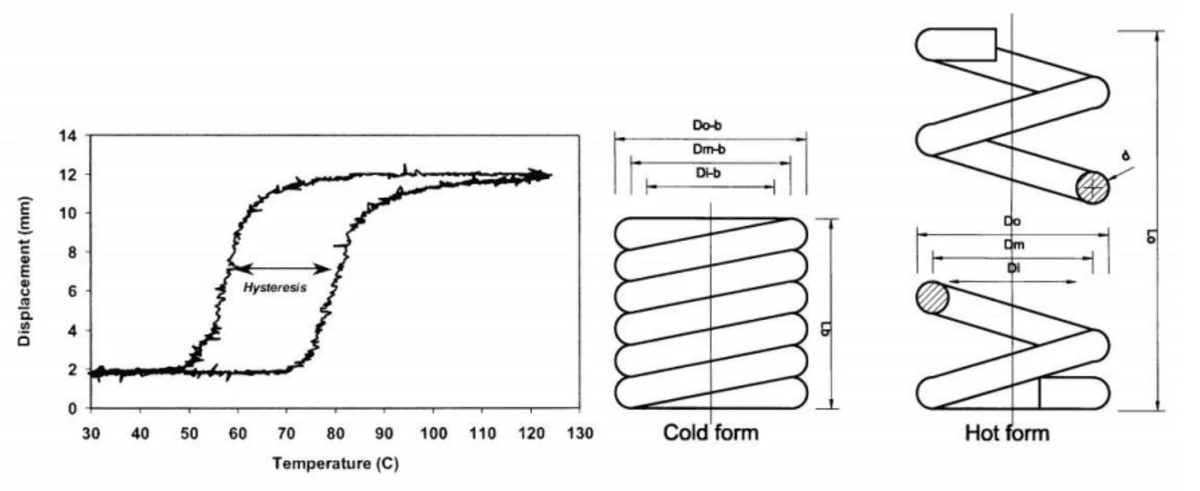

The science behind SMAs is rooted in their ability to undergo phase transformations at specific temperatures, which enables them to exhibit remarkable elasticity and strength. When an SMA wire is heated above its transformation temperature, it shifts from a martensitic phase (deformed state) to an austenitic phase (original state), resulting in motion. So how does SMA wire work? By harnessing this property, engineers can design actuators that respond dynamically to thermal stimuli.

Everyday Applications of SMAs

Shape Memory Alloy actuators have found their way into countless everyday applications, showcasing their versatility across different industries. From self-healing materials in construction to precision tools in medical surgeries, these actuators are revolutionizing how we think about motion and functionality. Moreover, understanding how nitinol is used in actuators opens up new possibilities for innovation—making our lives easier and more efficient than ever before.

What is a Shape Memory Actuator?

When diving into the world of engineering marvels, one cannot overlook the fascinating realm of shape memory actuators. These devices leverage the properties of shape memory alloys (SMAs) to create movement and force in a remarkably efficient manner. So, what exactly is a shape memory actuator? Simply put, it’s an actuator that utilizes the unique characteristics of SMAs to return to a predetermined shape when subjected to specific thermal conditions.

Definition and Principles

At its core, a shape memory actuator operates on the principle that certain materials can remember their original shapes after being deformed. This phenomenon occurs because SMAs transition between two distinct phases: martensite (the low-temperature phase) and austenite (the high-temperature phase). When you heat an SMA wire above its transformation temperature, it transforms back into its original shape, creating motion or force—voilà! That's how an SMA actuator works.

This remarkable ability makes SMAs ideal for various applications across industries—from robotics to medical devices. The beauty lies in their simplicity; with minimal energy input required for activation, these actuators are efficient and reliable. Understanding this fundamental principle lays the groundwork for exploring more about how these ingenious machines operate.

Types of Shape Memory Alloys

There are several types of shape memory alloys available today, each with its unique properties and applications. The most commonly used alloy is Nitinol, which is composed primarily of nickel and titanium; it’s renowned for its exceptional performance in medical devices and robotics. Other types include copper-based alloys like Cu-Al-Ni and Cu-Zn-Al, which also exhibit shape memory behavior but may not perform as well under certain conditions compared to Nitinol.

The choice of alloy significantly impacts the efficiency and effectiveness of a shape memory actuator; hence it's crucial to select one based on specific application needs. For example, if you’re looking at temperature sensitivity or biocompatibility for medical uses, Nitinol would be your go-to option. Understanding these different types can help engineers design better systems utilizing SMAs effectively.

Key Characteristics of SMAs

Shape Memory Alloys come with several key characteristics that make them stand out from conventional materials used in actuators. Firstly, they exhibit significant strain recovery—meaning they can undergo considerable deformation while still returning to their original shapes upon heating. This property enables compact designs without sacrificing performance or reliability; think about how much space that saves in intricate machinery!

Secondly, SMAs operate silently without any mechanical noise during actuation—ideal for applications where quiet operation is paramount such as in medical devices or consumer electronics like smartphones! Lastly, their versatility allows them to be integrated into various systems seamlessly; whether you’re designing sophisticated robotics or simple everyday gadgets like eyeglasses frames that adjust based on temperature changes.

In summary, understanding what is a shape memory actuator involves delving into the definition and principles behind them while recognizing the different types available along with their key characteristics ensures engineers can harness this technology effectively across numerous sectors.

How Does SMA Wire Work?

Understanding how SMA wire operates is key to grasping the broader concept of shape memory actuators. Essentially, SMA wire utilizes the unique properties of Shape Memory Alloys (SMAs) to convert thermal energy into mechanical motion. This transformation allows for a range of applications, from medical devices to robotics.

Mechanism of Action

The mechanism of action for SMA wire revolves around its ability to remember a specific shape. When heated above a certain temperature, the wire transitions from a low-energy state (martensite) to a high-energy state (austenite), allowing it to return to its pre-defined shape. This transformation is what makes it an effective component in various shape memory actuators, enabling precise and reliable movement.

Temperature Changes and Shape Memory

Temperature changes play a crucial role in how SMA wire works, as they trigger the transition between different phases of the alloy. When an SMA actuator is heated, it moves from its deformed state back to its original shape due to the heat-induced phase change. Conversely, when cooled, it can be reshaped or return to its lower-energy state—this cycle can be repeated multiple times without significant wear or degradation.

Practical Use Cases for SMA Wire

SMA wire finds itself in numerous practical use cases that highlight its versatility and efficiency as a shape memory actuator. In medical devices, it's often employed in stents that expand at body temperature, providing critical support without invasive procedures. Additionally, in robotics and automation systems, SMA actuators enable compact actuation solutions where traditional motors might be too bulky or power-hungry.

How is Nitinol Used in Actuators?

Nitinol, a specialized shape memory alloy (SMA), plays a pivotal role in the functionality of shape memory actuators. These remarkable materials exhibit unique properties that enable them to return to a predetermined shape when subjected to specific temperature changes. This intrinsic quality makes Nitinol particularly valuable across various fields, from medical devices to robotics.

Properties of Nitinol

Nitinol is renowned for its exceptional properties, which include high elasticity and the ability to undergo significant deformation without permanent damage. One of the most fascinating features of Nitinol is its shape memory effect; when heated above a certain temperature, it can revert to its original form after being deformed. Additionally, Nitinol boasts excellent fatigue resistance, making it an ideal candidate for applications requiring repeated motion—perfectly aligning with what is a shape memory actuator's demands.

The combination of these properties allows Nitinol to be both lightweight and strong, enhancing the overall performance of SMA actuators. With its biocompatibility and corrosion resistance, Nitinol also stands out as an optimal choice for medical applications where durability and safety are paramount. Understanding how does SMA wire work in conjunction with these properties helps clarify why Nitinol is so widely used in various actuator designs.

Nitinol in Medical Devices

In the realm of medical devices, nitinol's unique characteristics make it indispensable for numerous applications such as stents and guidewires. Stents made from nitinol can expand at body temperature after being inserted into arteries or veins, providing crucial support where it's needed most—this highlights what is an SMA actuator's significance in healthcare technology. The ability to compress during insertion yet expand upon reaching body temperature exemplifies how effective nitinol is at achieving desired outcomes with minimal invasiveness.

Moreover, nitinol’s flexibility allows for intricate designs that can navigate through complex anatomical structures while maintaining strength and reliability during use. As more innovations emerge within this sector, understanding how nitinol functions within these devices will further emphasize its role as a game-changer in modern medicine. It’s clear that when we discuss how is nitinol used in actuators, we’re really talking about transforming patient care through advanced technology.

Nitinol's Role in Robotics

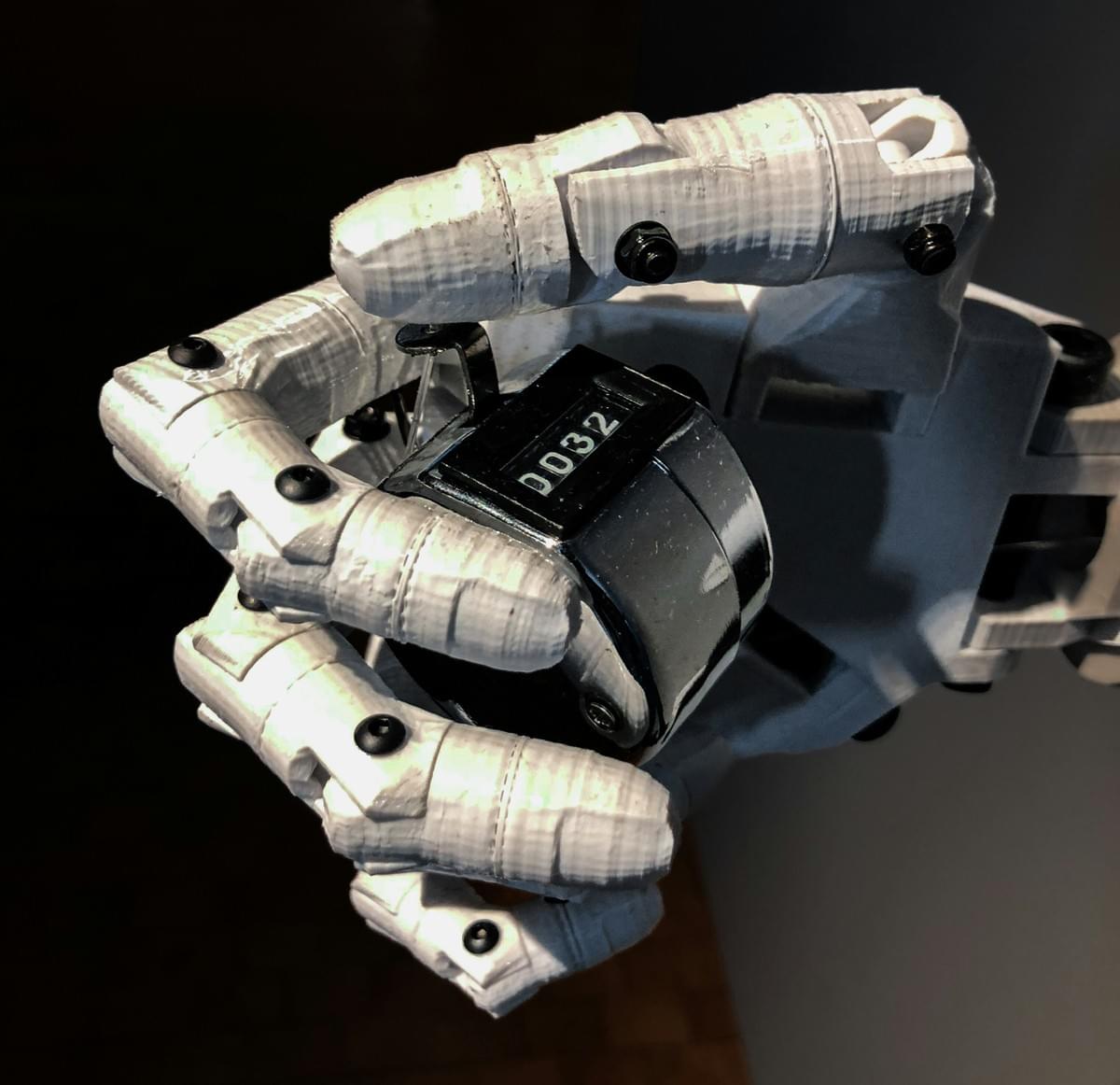

Nitinol significantly impacts the field of robotics by enabling sophisticated movements through shape memory actuators that mimic natural muscle action. Robots equipped with nitinol-based actuators can perform delicate tasks with greater precision due to their responsive nature—what is an SMA actuator if not a bridge between mechanical efficiency and biological inspiration? The lightweight yet robust characteristics allow robots to operate effectively without compromising on speed or power.

Furthermore, researchers are exploring innovative uses of nitinol actuators in soft robotics—where flexibility and adaptability are key components for success. These advancements illustrate not just how does SMA wire work but also highlight new possibilities for creating robots capable of interacting seamlessly with their environment. Ultimately, understanding how is nitinol used in actuators opens doors to revolutionary developments across industries reliant on automation and mechanization.

Benefits of Using Shape Memory Actuators

Shape memory actuators are revolutionizing the way we think about motion and control in various applications. These unique devices leverage the remarkable properties of Shape Memory Alloys (SMAs) to deliver enhanced performance, compact designs, and unmatched versatility across multiple industries. Understanding these benefits can shed light on why they are becoming increasingly popular in modern technology.

Enhanced Performance

When we ask, What is a shape memory actuator? it’s essential to highlight their superior performance capabilities. These actuators can exert significant force while converting thermal energy into mechanical motion, making them incredibly efficient for tasks requiring precision and reliability. The ability of SMAs to return to their original shape after deformation means that they can operate effectively under varying conditions without losing functionality.

Moreover, the response time of a shape memory actuator is impressive; they can activate within seconds when exposed to the appropriate temperature changes. This rapid response is particularly beneficial in applications such as robotics and medical devices, where timing is crucial for effectiveness. With enhanced performance characteristics like these, it's no wonder that many industries are turning to SMA actuators for their specific needs.

Compact Design Advantages

One of the standout features of an SMA actuator is its compact design. Unlike traditional motors or pneumatic systems that require extensive space for operation, shape memory actuators can fit into tight spaces while still delivering powerful results. This makes them ideal for applications where every millimeter counts—think small-scale robots or intricate medical devices.

Additionally, the lightweight nature of SMAs contributes significantly to overall system efficiency, allowing designers to create more streamlined products without sacrificing strength or functionality. This compactness not only reduces manufacturing costs but also enhances portability in consumer electronics and advanced machinery alike. When considering How does SMA wire work? it's clear that its ability to perform effectively in a small package presents numerous advantages in design flexibility.

Versatility Across Industries

The versatility of shape memory actuators cannot be overstated; they find applications across diverse fields ranging from aerospace engineering to biomedical innovations. For instance, understanding How is nitinol used in actuators? reveals its critical role in developing devices like stents that respond dynamically within the human body—opening up new avenues for minimally invasive surgeries.

In robotics and automation, SMAs enable precise movements and adaptive responses that traditional systems struggle with due to their bulkiness or rigidity. The adaptability offered by Shape Memory Alloy (SMA) actuators allows engineers from various sectors to innovate freely without being constrained by conventional mechanical systems' limitations. As industries continue exploring new possibilities with SMAs, we can expect even more groundbreaking applications on the horizon.

GEE SMA: Pioneers in Nitinol Manufacturing

In the realm of shape memory actuators, GEE SMA stands out as a leader in the manufacturing of Nitinol, a remarkable Shape Memory Alloy (SMA). Their dedication to quality ensures that every actuator meets stringent performance standards, making them a trusted choice for various industries. By focusing on innovation and excellence, GEE SMA continues to push the boundaries of what is possible with SMAs.

Commitment to Quality

At GEE SMA, commitment to quality is more than just a motto; it's woven into the very fabric of their operations. Each shape memory actuator undergoes rigorous testing and quality control measures to guarantee reliability and durability. This unwavering focus on excellence not only elevates their products but also instills confidence in customers who rely on these advanced technologies.

Custom Solutions for Unique Applications

Understanding that one size does not fit all, GEE SMA specializes in crafting custom solutions tailored to unique applications involving SMAs. Whether it's developing specialized actuators for medical devices or creating innovative designs for robotics, they embrace challenges head-on. Their ability to adapt and innovate ensures that clients receive shape memory actuators perfectly suited to their specific needs.

Key Contributions to the Industry

GEE SMA's influence extends beyond just product manufacturing; they have made significant contributions to advancing knowledge about how SMA wire works and its applications across various sectors. By pioneering research on how Nitinol can be utilized effectively in actuators, they are setting new benchmarks for performance and efficiency within the industry. Their efforts not only benefit their clients but also inspire further innovations in Shape Memory Alloy (SMA) actuators worldwide.

Conclusion

As we wrap up our exploration of shape memory actuators, it’s clear that these remarkable devices are not just a technological curiosity but a pivotal component in various industries. The future of shape memory technology looks promising, with ongoing research and development aimed at enhancing the capabilities and applications of SMAs. From medical devices to robotics, the potential for innovation is vast, making it an exciting time to be involved in this field.

The Future of Shape Memory Technology

The future of shape memory technology hinges on advancements in materials science and engineering techniques. Researchers are continually looking to improve the performance and efficiency of Shape Memory Alloy (SMA) actuators, which could lead to smaller, more powerful devices that can operate under a wider range of conditions. As we ask ourselves, What is a shape memory actuator? it's essential to recognize that these innovations will likely expand their use beyond current applications into new realms such as aerospace and wearable technology.

Innovations in SMA Applications

Innovations in SMA applications are already underway, with industries exploring unique uses for SMA wire that were previously unimaginable. For instance, the integration of SMAs into smart textiles offers exciting possibilities for adaptive clothing that can respond to temperature changes or user movements. Additionally, understanding How does SMA wire work? can inspire novel designs in automotive systems where lightweight and efficient actuation is crucial for performance enhancements.

Why You Should Care About SMAs

Understanding why you should care about SMAs goes beyond mere curiosity; it touches on how these technologies impact everyday life and industry efficiency. Whether you're interested in cutting-edge medical solutions or revolutionary robotics, knowing How is nitinol used in actuators? helps you appreciate the underlying mechanisms driving innovation today. Ultimately, Shape Memory Alloy (SMA) actuators symbolize a blend of science fiction becoming reality—making them integral not just for engineers but for anyone curious about the future.