Introduction

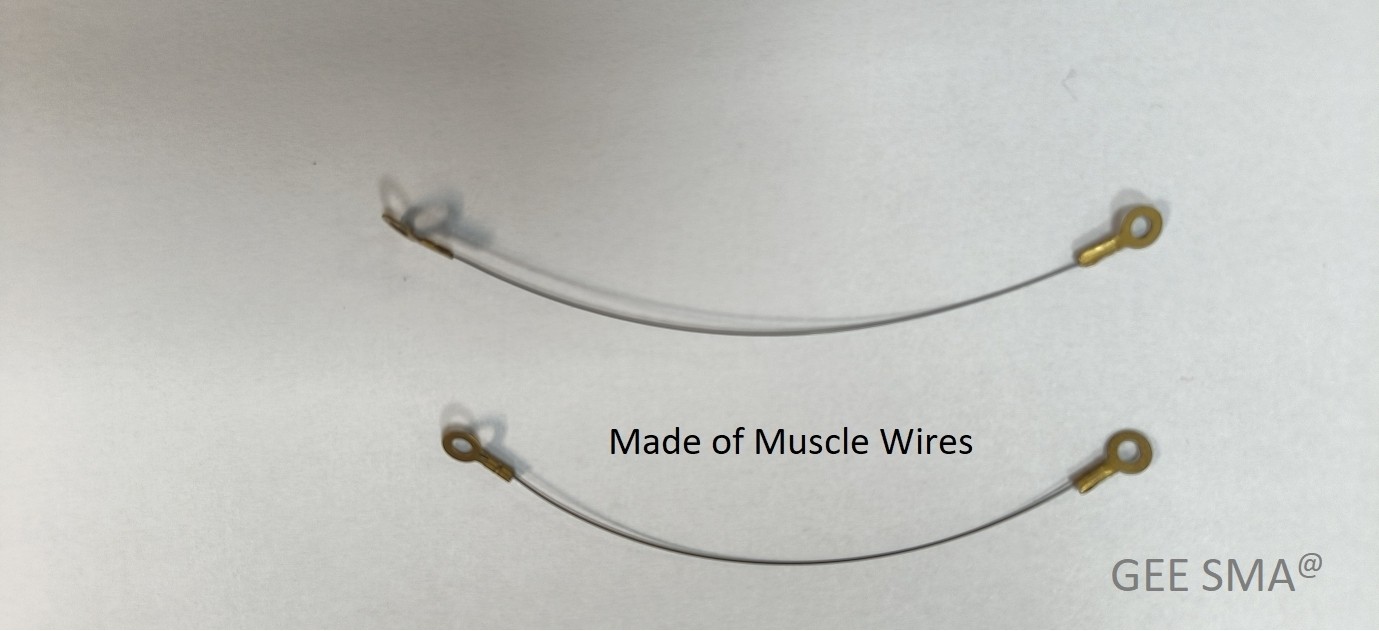

Nitinol muscle wire is a remarkable material with a wide range of applications across various industries. Its unique properties make it an ideal choice for innovative technologies and engineering solutions. Understanding the mechanics of nitinol muscle wire actuation is crucial in unleashing its full potential.

Exploring the Versatility of Nitinol Muscle Wire

Nitinol muscle wire, also known as shape memory nitinol, is a shape memory alloy that can remember its original shape and return to it when heated. This remarkable property allows it to be used in a wide range of applications, from medical devices to robotics and aerospace technologies.

Understanding the Mechanics of Nitinol Muscle Wire Actuation

The actuation of nitinol muscle wire involves the application of heat to induce a phase change in the material, causing it to contract or expand. This makes it an ideal component for actuators, which are used to control motion in various mechanical systems.

Unleashing the Potential of Nitinol Muscle Wire

The potential of nitinol muscle wire is vast, with ongoing research and development expanding its applications in cutting-edge technologies. From medical devices like guidewires to advanced engineering components, nitinol muscle wire offers unparalleled versatility and performance.

What is Nitinol Muscle Wire?

The Science Behind Nitinol Muscle Wire

Nitinol muscle wire, also known as shape memory nitinol, is a type of smart material that has the ability to remember its original shape and return to it when heated. This unique property is due to its composition of nickel and titanium, which allows it to undergo significant deformation and then recover its initial form when subjected to heat.

Nitinol muscle wire has found a wide range of applications in various industries due to its unique shape memory property. In the medical field, it is used in minimally invasive surgery to create self-expanding stents that can be inserted into blood vessels and then return to their original shape once inside the body. Additionally, this smart material is utilized in orthodontic braces to apply gentle, continuous force to shift teeth into proper alignment, providing a more comfortable and efficient treatment option for patients.

Applications of Nitinol Muscle Wire in Various Industries

Nitinol muscle wire is widely used in various industries for its remarkable properties. In the medical field, it is utilized as a nitinol guidewire for minimally invasive surgeries, where its flexibility and shape memory enable precise navigation through blood vessels and other pathways within the body. Additionally, it is employed in orthodontic braces, robotics, aerospace engineering, and even consumer electronics.

Nitinol muscle wire's unique properties have also found applications in the field of robotics, where its shape memory and superelasticity are leveraged to create robotic actuators and sensors. The ability of nitinol muscle wire to contract and expand with changes in temperature or electrical current makes it an ideal material for creating responsive and adaptable robotic components. As a result, nitinol muscle wire has become an essential material in the development of advanced robotic systems for various industries, including manufacturing, healthcare, and exploration.

Advantages of Using Nitinol Muscle Wire

The use of nitinol muscle wire offers several advantages across different applications. Its shape memory allows for intricate movements in medical devices such as stents and catheters, providing enhanced patient care with minimal invasiveness. Furthermore, its superelasticity makes it highly durable and resistant to fatigue failure, ensuring longevity in various engineering solutions.

In addition, nitinol muscle wire's biocompatibility makes it an ideal choice for medical implants, reducing the risk of rejection and promoting better integration with the body. This characteristic is particularly advantageous in orthopedic applications, where implants made from nitinol muscle wire can provide superior support and flexibility for patients. Moreover, its ability to withstand repeated deformation without permanent damage makes it a reliable option for long-term medical use, contributing to improved patient outcomes and satisfaction.

Nitinol Muscle Wire Actuator

Nitinol muscle wire actuators are innovative devices that utilize the unique properties of nitinol muscle wire to produce mechanical motion. When an electric current is passed through the nitinol wire, it undergoes a phase transformation, causing it to contract or expand with great force, making it ideal for various actuation applications.

How Nitinol Muscle Wire Actuators Work

Nitinol muscle wire actuators work based on the shape memory effect of nitinol. When heated, the wire returns to its original shape, allowing it to act as a powerful actuator. This makes it suitable for applications such as robotics, medical devices, and aerospace technology where precise and reliable motion control is essential.

Innovations in Nitinol Muscle Wire Actuator Technology

In recent years, there have been significant advancements in nitinol muscle wire actuator technology, leading to more efficient and compact designs. These innovations have expanded the potential applications of nitinol muscle wire actuators across a wide range of industries, from automotive engineering to consumer electronics.

Future Potential of Nitinol Muscle Wire Actuators

The future potential of nitinol muscle wire actuators is vast and promising. As research and development in smart materials continue to evolve, we can expect to see even more sophisticated and versatile applications for these actuators. From advanced prosthetics to adaptive structures in architecture, the possibilities for leveraging the unique capabilities of nitinol muscle wire are endless.

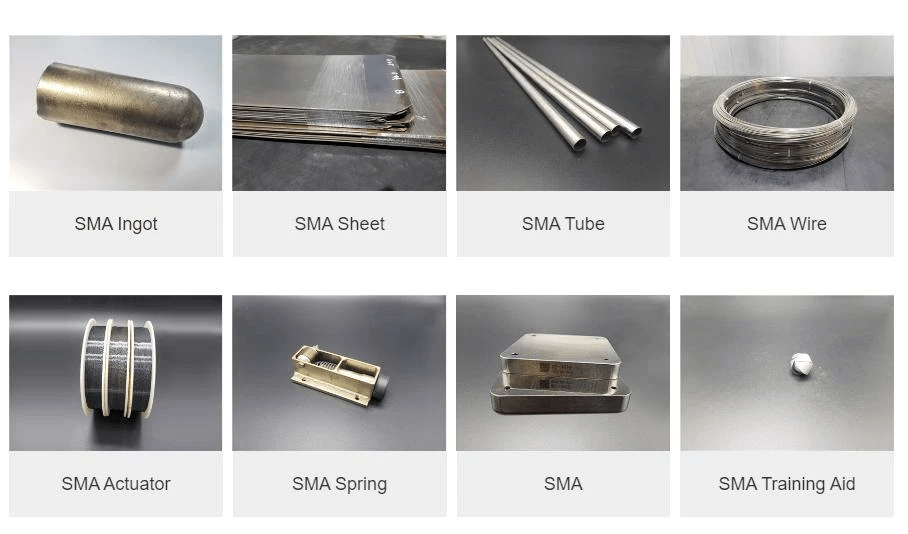

Nitinol Components

Nitinol components are integral to a wide range of engineering applications, offering unique shape memory and superelastic properties. These components, made from Shape Memory Nitinol (COM-11900), are used in industries such as aerospace, automotive, and medical devices for their ability to return to a predetermined shape when heated. This makes them ideal for complex mechanisms and precise instruments.

Diving into the World of Nitinol Components

From intricate surgical tools to innovative robotics, nitinol components play a crucial role in shaping the future of engineering. Their remarkable flexibility and durability make them suitable for use in minimally invasive medical procedures, where precision and reliability are paramount. In addition, their ability to withstand extreme conditions makes them indispensable in demanding industrial settings.

Benefits of Using Nitinol Components in Engineering

The benefits of using nitinol components in engineering are manifold. Their shape memory properties allow for compact designs with complex functionalities, making them ideal for space-constrained applications. Furthermore, their superelasticity enables them to absorb energy and return to their original shape without permanent deformation, ensuring longevity and reliability in critical systems.

Additionally, nitinol components offer excellent corrosion resistance, making them suitable for use in harsh environments such as aerospace and medical devices. Their biocompatibility also makes them an ideal choice for implantable medical devices, ensuring minimal risk of rejection or adverse reactions within the body. This unique combination of properties makes nitinol components a versatile and reliable option for a wide range of engineering applications.

GEE SMA's Superior Nitinol Component Offerings

GEE SMA stands out as a premier provider of nitinol components, offering a diverse range of high-quality products tailored to meet the unique needs of various industries. With a focus on precision engineering and cutting-edge technology, GEE SMA delivers superior nitinol components that empower innovation and drive technological advancements across different sectors.

GEE SMA's commitment to excellence extends beyond just delivering high-quality nitinol components. The company also prides itself on providing exceptional customer service, ensuring that clients receive personalized attention and support throughout the entire process. Whether it's collaborating on custom designs or providing technical assistance, GEE SMA goes above and beyond to ensure client satisfaction and project success.

Remember that you can always rely on GEE SMA's expertise and commitment to excellence when it comes to harnessing the full potential of nitinol components in your engineering projects!

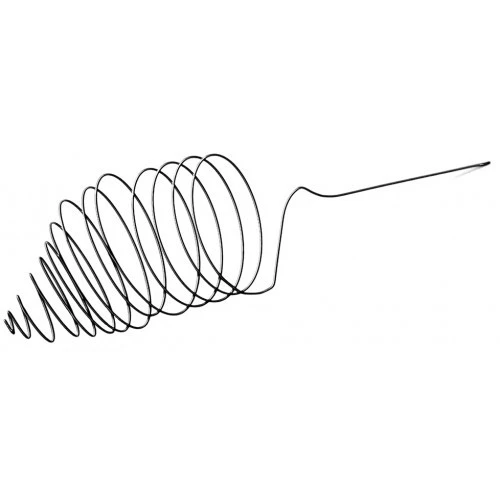

Nitinol Spring

Nitinol springs are renowned for their unique properties, including shape memory and superelasticity. These springs have the ability to return to their original shape after being deformed, making them ideal for a wide range of applications.

The Unique Properties of Nitinol Springs

Nitinol springs exhibit shape memory, allowing them to revert to their original shape when heated. This property makes them invaluable in industries such as medical devices, automotive engineering, and aerospace technology. Additionally, nitinol springs possess superelasticity, enabling them to withstand significant deformation without permanent damage.

Applications of Nitinol Springs in Various Industries

The versatility of nitinol springs lends itself to diverse applications across various industries. From minimally invasive surgical tools and orthodontic braces to actuators and sensors in robotics and aerospace technology, nitinol springs are a critical component in many cutting-edge innovations.

Nitinol springs are also widely used in the automotive industry, where they play a crucial role in fuel injection systems, exhaust systems, and various other components. Their ability to withstand high temperatures and repetitive motion makes them an ideal choice for these applications. Additionally, nitinol springs are being increasingly utilized in the field of consumer electronics, where their shape memory properties are leveraged for applications such as self-adjusting eyeglass frames and smartwatch bands.

GEE SMA's High-Quality Nitinol Spring Production

GEE SMA is a leading manufacturer of high-quality nitinol springs designed for precision and reliability. With a focus on innovation and advanced manufacturing techniques, GEE SMA produces nitinol springs that meet the stringent demands of modern engineering applications.

Memory Wire Applications

Nitinol Memory Wire in Cutting-Edge Technologies

Nitinol memory wire is revolutionizing cutting-edge technologies with its unique shape memory and superelastic properties. From medical devices to aerospace applications, nitinol memory wire is being used to create innovative solutions that require precise and reliable actuation, making it a crucial component in the advancement of various industries.

The versatility of nitinol memory wire is evident in its ability to be used in a wide range of applications, from minimally invasive medical devices to intricate aerospace mechanisms. Its shape memory allows it to return to its original shape after being deformed, making it ideal for applications that require precise and repeatable movements. Furthermore, its superelastic properties enable it to withstand significant deformation without permanent damage, providing reliability in critical operations.

Exploring Diverse Applications of Nitinol Memory Wire

The versatility of nitinol memory wire extends to a wide range of applications, including minimally invasive surgical tools, robotics, automotive components, and consumer electronics. Its ability to return to a predetermined shape after being deformed makes it ideal for intricate mechanisms that demand consistent performance and durability.

Nitinol memory wire's unique properties also make it an excellent choice for medical devices such as stents and guidewires. Its flexibility and biocompatibility allow for easy insertion and reliable performance within the human body. This has revolutionized the field of minimally invasive surgery, offering patients faster recovery times and reduced risk of complications.

GEE SMA: Your Trusted Source for Nitinol Memory Wire Solutions

When it comes to sourcing high-quality nitinol memory wire solutions, GEE SMA stands out as a trusted provider with a proven track record of delivering superior products tailored to meet specific industry requirements. With a focus on precision engineering and cutting-edge technology, GEE SMA offers customized nitinol memory wire solutions that empower innovation and drive progress across diverse sectors.

By leveraging the unique properties of nitinol memory wire, industries can unlock new possibilities for enhancing performance and efficiency in their products and processes. Whether it's enabling groundbreaking advancements in healthcare or pushing the boundaries of technological innovation, nitinol memory wire continues to play an essential role in shaping the future of various fields.

Conclusion

In conclusion, the potential of nitinol muscle wire technology is truly remarkable. Its versatility and unique properties make it an invaluable resource across various industries. From actuators to components and memory wire applications, nitinol muscle wire continues to revolutionize the way we approach engineering challenges.

Harnessing the Power of Nitinol Muscle Wire Technology

Nitinol muscle wire is a game-changer in engineering, offering unparalleled flexibility and strength for actuation purposes. Its ability to remember and return to a predetermined shape makes it ideal for applications such as robotics, medical devices, and aerospace technology. With GEE SMA's expertise in nitinol muscle wire technology, the possibilities are endless.

Leveraging the Versatility of Nitinol Components

The use of nitinol components presents numerous advantages in engineering, including its superelasticity and shape memory properties. From medical devices to automotive applications, nitinol components offer durability and precision that traditional materials cannot match. GEE SMA's superior nitinol component offerings ensure high-quality solutions for any project.

Embracing Innovation with Nitinol Memory Wire

Nitinol memory wire has opened up new frontiers in cutting-edge technologies, from minimally invasive surgical tools to advanced sensors and actuators. GEE SMA provides trusted sources for nitinol memory wire solutions that meet the demands of modern innovation across various industries.

The versatility of nitinol memory wire makes it an ideal choice for a wide range of applications, including robotics, aerospace, and automotive industries. With its unique shape memory and superelastic properties, nitinol wire can be tailored to specific project requirements, offering unparalleled performance and reliability. Whether you're looking to improve the precision of surgical tools or enhance the responsiveness of sensors and actuators, embracing nitinol technology can give your innovations a competitive edge in today's fast-paced market.

Remember, whether it's muscle wire actuators or high-quality components you're seeking, embracing the power of nitinol technology can take your projects to new heights!