Introduction

When it comes to cutting-edge medical technology, nitinol medical products are at the forefront of innovation. These advanced devices are made from a unique nickel-titanium alloy known for its remarkable properties, making it an ideal material for various medical applications. As the demand for nitinol medical devices continues to grow, the market is expanding rapidly, offering a wide range of solutions for healthcare professionals and patients.

Understanding Nitinol Medical Products

Nitinol medical devices are engineered with shape memory and superelasticity, allowing them to adapt to the body's natural movements while maintaining their original shape. This makes them highly versatile and suitable for various medical procedures, from cardiovascular interventions to orthodontic treatments.

Nitinol medical devices have revolutionized minimally invasive surgery, providing surgeons with the tools they need to perform delicate procedures with precision and ease. The unique properties of Nitinol allow for the creation of intricate medical devices that can be inserted into the body through small incisions, reducing the risk of complications and speeding up recovery times. As a result, Nitinol has become an essential material in the development of cutting-edge medical technologies.

Exploring Nitinol Medical Devices Market

The nitinol medical devices market is witnessing significant growth due to the increasing prevalence of chronic diseases and the rising demand for minimally invasive surgical procedures. With advancements in manufacturing techniques and design capabilities, nitinol-based implants and devices are becoming increasingly popular among healthcare providers and patients worldwide.

Nitinol medical devices are known for their versatility and unique properties, making them suitable for a wide range of applications in the healthcare industry. From orthopedic implants to cardiovascular stents, nitinol-based devices offer flexibility, shape memory, and superelasticity, allowing customized solutions that can adapt to the body's natural movements. This versatility has led to innovative medical devices that provide better patient outcomes and improved quality of life.

The Versatility of Nitinol Medical Devices

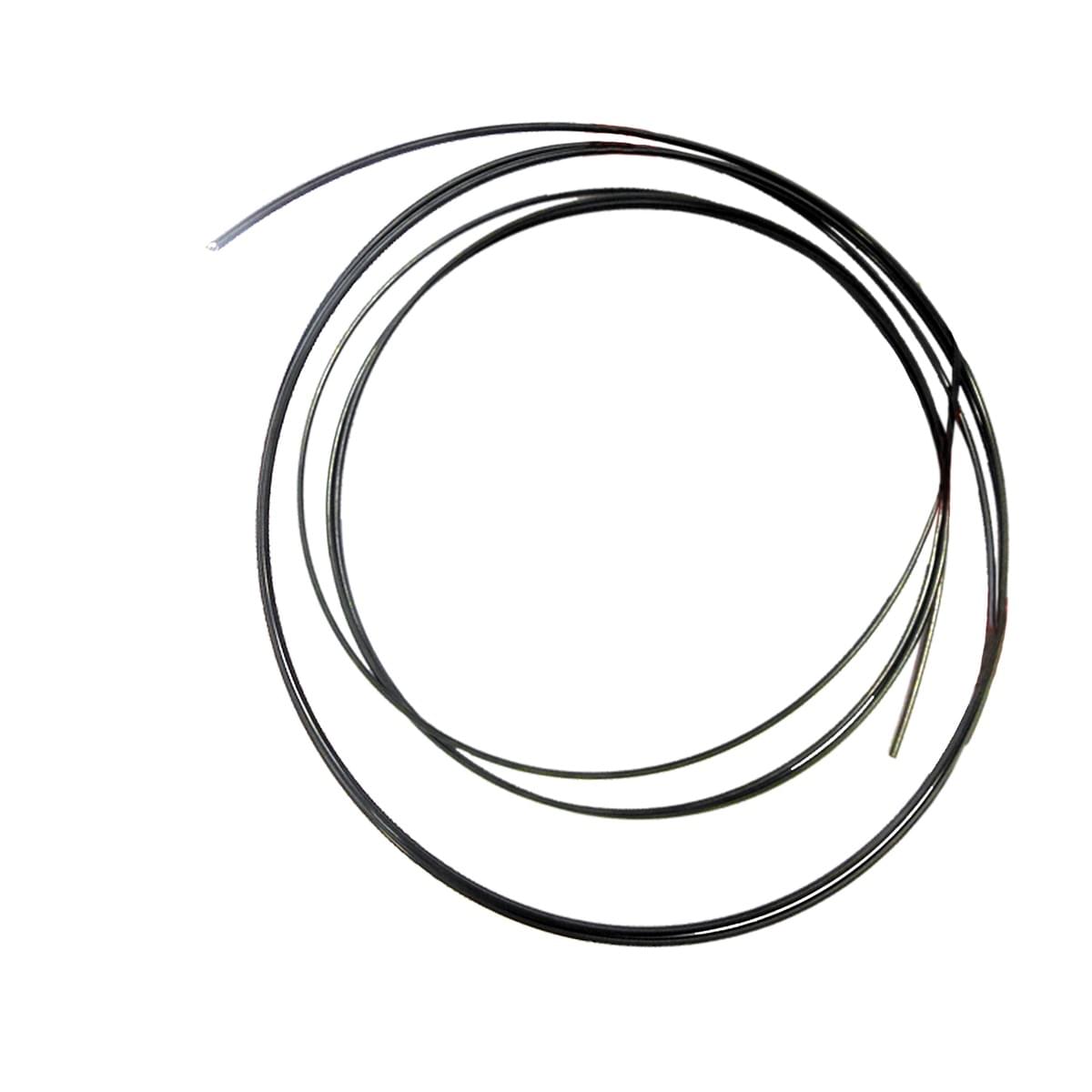

Nitinol medical devices offer unparalleled flexibility, durability, and biocompatibility, making them ideal for use in various applications. From cardiovascular stents and guidewires to neurovascular retrieval devices and surgical instruments, nitinol's unique properties make it an indispensable material in modern medicine.

Nitinol's flexibility and shape memory properties allow for the creation of medical devices that can be easily manipulated and inserted into the body through minimally invasive procedures. This reduces patient discomfort and recovery time and lowers the risk of complications associated with traditional open surgeries. Additionally, nitinol's ability to return to its original shape after deformation ensures that these devices maintain their effectiveness and structural integrity over time, providing long-term patient benefits.

Now that we have provided an overview of nitinol medical products and their market landscape, let's explore the advantages of these innovative devices in more detail.

The Advantages of Nitinol Medical Devices

1. Flexibility and Durability

Nitinol medical devices are known for their exceptional flexibility and durability, allowing them to withstand the rigors of medical procedures without losing their shape or integrity. This makes them ideal for applications such as cardiovascular stents and orthodontic braces, where they must adapt to the body's movements while providing reliable support.

2. Shape Memory Properties

One of the key advantages of nitinol medical devices is their unique shape memory properties. This allows them to be deformed at low temperatures and then return to their original shape when heated, making them perfect for minimally invasive procedures and implantation in challenging anatomical locations.

Additionally, the shape memory properties of nitinol medical devices allow for greater precision and control during procedures, as they can be manipulated into complex shapes and then return to their original form with ease. This flexibility makes nitinol devices ideal for delicate surgeries and interventions where traditional materials may not be suitable. Furthermore, the ability to withstand deformation and return to its intended shape reduces the risk of damage or failure during implantation, providing a reliable solution for medical practitioners.

3. Biocompatibility and Corrosion Resistance

In addition to their mechanical properties, nitinol medical devices offer excellent biocompatibility and corrosion resistance. This means that they can be safely implanted in the body without causing adverse reactions while also maintaining their structural integrity over time, leading to better patient outcomes and longer device lifespan.

Nitinol Medical Device Manufacturing Process

When it comes to the manufacturing process of nitinol medical devices, cold working and heat treatment are crucial steps. Cold working involves shaping the nitinol alloy at low temperatures, which enhances its strength and flexibility. Heat treatment allows the material to remember its original shape, making it ideal for medical applications such as stents and guidewires.

1. Cold Working and Heat Treatment

Cold working is achieved through drawing, rolling, or swaging, which deform the nitinol alloy at low temperatures. This increases its strength and elasticity, making it suitable for intricate medical devices and implants. Following this, heat treatment allows the material to regain its original shape when exposed to certain stimuli, such as temperature or stress.

Cold working is a crucial step in shaping nitinol alloy for medical devices, as it increases its strength and elasticity, making it ideal for intricate applications. This process involves deforming the alloy at low temperatures through drawing, rolling, or swaging. The resulting material is more durable and flexible, allowing for the creation of innovative and complex medical implants that can withstand the rigors of the human body.

2. Laser Cutting and Electrochemical Polishing

After cold working and heat treatment, nitinol undergoes laser cutting to achieve precise shapes for medical devices like stents or orthodontic braces. Electrochemical polishing is then used to smooth out any rough edges or surfaces, ensuring that the final product is biocompatible and safe for use within the human body.

3. Quality Control and Testing

Quality control measures are essential in ensuring that nitinol medical devices meet industry standards for safety and performance. Non-destructive testing methods such as X-ray inspection and ultrasound detect any defects or irregularities in the material. Additionally, thorough testing assesses factors like corrosion resistance and fatigue strength.

Furthermore, nitinol medical devices undergo rigorous testing to ensure their reliability and durability in real-world applications. This includes simulated stress testing to mimic the wear and tear the devices may experience. By subjecting the devices to extreme conditions, manufacturers can identify potential weaknesses and make necessary improvements to enhance their overall performance and longevity.

Applications of Nitinol Medical Devices

1. Cardiovascular Stents and Guidewires

Nitinol medical devices play a crucial role in cardiovascular treatments. Nitinol stents provide support to arteries and veins, preventing blockages and ensuring proper blood flow. Additionally, nitinol guidewires are used to navigate through blood vessels during minimally invasive procedures, showcasing the flexibility and durability of nitinol in critical medical applications.

2. Orthodontic Braces and Endodontic Files

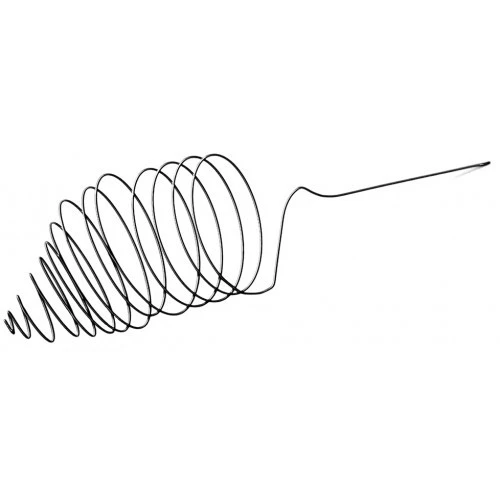

In dentistry, nitinol medical devices are widely used for orthodontic braces due to their shape memory properties, which allow them to apply constant pressure on teeth for effective realignment. Furthermore, endodontic files made from nitinol offer superior flexibility and resistance to fatigue during root canal procedures, making them essential tools for dental professionals.

In addition to their use in orthodontic braces and endodontic files, nitinol medical devices have also found applications in neurovascular retrieval devices. The shape memory properties of nitinol allow these devices to be easily maneuvered through the intricate pathways of blood vessels, making them invaluable for retrieving foreign bodies or treating aneurysms. The flexibility and durability of nitinol further enhance the effectiveness of these devices, providing medical professionals with reliable tools for neurovascular interventions.

3. Neurovascular Retrieval Devices and Surgical Instruments

Nitinol's biocompatibility and corrosion resistance make it an ideal material for neurovascular retrieval devices to remove brain blood clots. Moreover, surgical instruments made from nitinol exhibit exceptional strength and precision, enhancing the overall performance of various surgical procedures while ensuring patient safety.

Choosing high-quality nitinol medical devices is crucial for achieving successful patient outcomes across these diverse applications.

Where to Buy High-Quality Nitinol Medical Products

When sourcing top-notch nitinol medical devices and implants, look no further than GEE SMA. With a stellar reputation in the nitinol medical devices market, GEE SMA is known for its high-quality products and exceptional customer service. Their extensive range of thin film nitinol medical devices caters to various medical applications, making them a trusted choice for healthcare professionals worldwide.

GEE SMA: A Leader in Nitinol Shape Memory Alloys

GEE SMA stands out as a leader in producing nitinol medical devices and implants, offering innovative solutions for the healthcare industry. Their advanced manufacturing processes ensure the highest quality, reliability, and performance standards in their products. With a focus on precision engineering and cutting-edge technology, GEE SMA continues to set the bar for excellence in several other reputable suppliers in the market provideResearching and comparing different suppliers is essentialconsiderregardingchoosing medical devices, nitinol offers manyaccess, such as flexibility, durability, and shape memory properties, that make them ideal for various medical applications. From cardiovascular stents to neurovascular retrieval devices, nitinol's versatilitynitinol medical applications.

Other Reputable Nitinol Suppliers

In addition to GEE SMA, there are several other reputable suppliers in the market that provide high-quality nitinol medical devices. These suppliers offer a wide range of options for healthcare professionals seeking reliable solutions for their patients. It's essential to research and compare different suppliers to find the best fit for specific requirements and preferences.

When considering purchasing nitinol medical devices from other reputable suppliers, it's important to look for companies with a strong track record of delivering high-quality products. Additionally, healthcare professionals should take into account the supplier's customer service and support offerings, as having a reliable partner can make a significant difference in the long run. Furthermore, exploring the range of customization options available from different suppliers can help healthcare professionals find the best fit for their specific patient needs and treatment plans.

Considerations for Purchasing Nitinol Medical Devices

Nitinol's unique properties make it a valuable material for various medical devices. However, choosing the right supplier is essential to ensure quality and reliable performance. Here are some key factors to consider when purchasing nitinol medical devices:

- Product Quality and Certifications: Look for a supplier with a proven track record of producing high-quality nitinol devices that meet relevant regulatory standards. Ensure they hold necessary certifications, such as ISO 13485 for medical devices.

- Lead Times and Reliability: Timely delivery is critical in the medical field. Choose a supplier with established lead times and a reputation for on-time delivery. This ensures your devices are available when needed for patient care.

- Customizability: Medical device needs can vary. Consider a supplier offering customization options to tailor nitinol components to your requirements.

- Comprehensive Services: A single source supplier offering design, manufacturing, and potentially even sterilization services can streamline the procurement process and improve overall project efficiency.

- Customer Support: Responsive customer support is vital. Look for a supplier who provides clear communication throughout the process and readily addresses any questions or concerns you may have.

By choosing an established supplier like GEE SMA or other reputable companies with a strong track record in providing top-notch nitinol medical products, healthcare professionals can confidently meet their patients' needs with reliable and innovative solutions.

Conclusion

When it comes to choosing medical devices, nitinol offers a myriad of benefits, including its flexibility, durability, and shape memory properties. With GEE SMA as the ultimate nitinol supplier, you can have access to high-quality nitinol medical devices and implants that are biocompatible and corrosion-resistant. Building a successful partnership with a reputable nitinol supplier is crucial for ensuring the reliability and performance of your medical devices.

Benefits of Choosing Nitinol Medical Devices

Nitinol has revolutionized the field of medical devices due to its unique combination of properties. Here are some of the key advantages that make nitinol a highly sought-after material:

- Superior Flexibility: Nitinol devices can be designed to be incredibly flexible, allowing for easier insertion and navigation within narrow or delicate areas of the body. This minimally invasive approach minimizes patient discomfort and recovery time.

- Exceptional Durability: Nitinol is known for its remarkable strength and resistance to fatigue. This ensures long-lasting performance of medical implants, reducing the need for repeat procedures and improving patient outcomes.

- Shape Memory: Perhaps the most remarkable property of nitinol is its ability to "remember" its original shape. This allows for devices to be compressed for easier insertion and regain their intended form once inside the body, providing a secure fit and optimal functionality.

In conclusion, nitinol's versatility, durability, and shape memory properties make it a valuable asset in medical devices. These properties contribute to developing minimally invasive procedures, improved patient comfort, and long-lasting implants, ultimately leading to better patient care.

GEE SMA: The Ultimate Nitinol Supplier

GEE SMA is a leader in providing top-notch nitinol medical devices and implants. With their expertise in manufacturing thin film nitinol medical devices and their commitment to quality control, GEE SMA is the ultimate choice for healthcare professionals seeking reliable and innovative solutions.

GEE SMA's dedication to quality control sets them apart from other nitinol suppliers. Their meticulous attention to detail ensures that every medical device and implant meets the highest performance and reliability standards. Healthcare professionals can trust GEE SMA to deliver products that consistently exceed expectations, making them the ultimate partner in providing innovative solutions for patient care.

Building a Successful Partnership with a Nitinol Supplier

Establishing a strong partnership with a reputable nitinol supplier ensures consistent access to high-quality products. By collaborating closely with your supplier, you can leverage their expertise in nitinol medical device manufacturing to meet the specific needs of your practice or facility.

Remember that choosing the right supplier is crucial for obtaining reliable and high-quality nitinol medical devices that meet regulatory standards while offering innovative solutions for patient care.