Introduction

Are you ready to dive into the fascinating world of Nitinol? This incredible shape memory alloy has captured the imagination of engineers and scientists alike, and for good reason! From its remarkable properties to its wide range of applications, Nitinol is truly a magical material that continues to amaze and inspire. Join us as we unravel the mysteries of this extraordinary alloy and explore its potential in the world of actuators.

Exploring the Magic of Nitinol

Nitinol is a unique alloy that exhibits remarkable shape memory effect, superelasticity, and temperature sensitivity. These properties make it a perfect candidate for use in actuators, where precise control and reliable performance are essential. The ability of Nitinol to remember its original shape after deformation sets it apart from conventional materials, opening up a world of possibilities for innovative engineering solutions.

Understanding the Power of Nitinol Actuators

So, why is Nitinol used in actuators? The answer lies in its exceptional performance and versatility. Nitinol actuators offer rapid response times, high force output, and exceptional durability, making them ideal for a wide range of applications across various industries. Whether it's in biomedical devices, robotics, or aerospace technology, Nitinol actuators continue to revolutionize the way we approach engineering challenges.

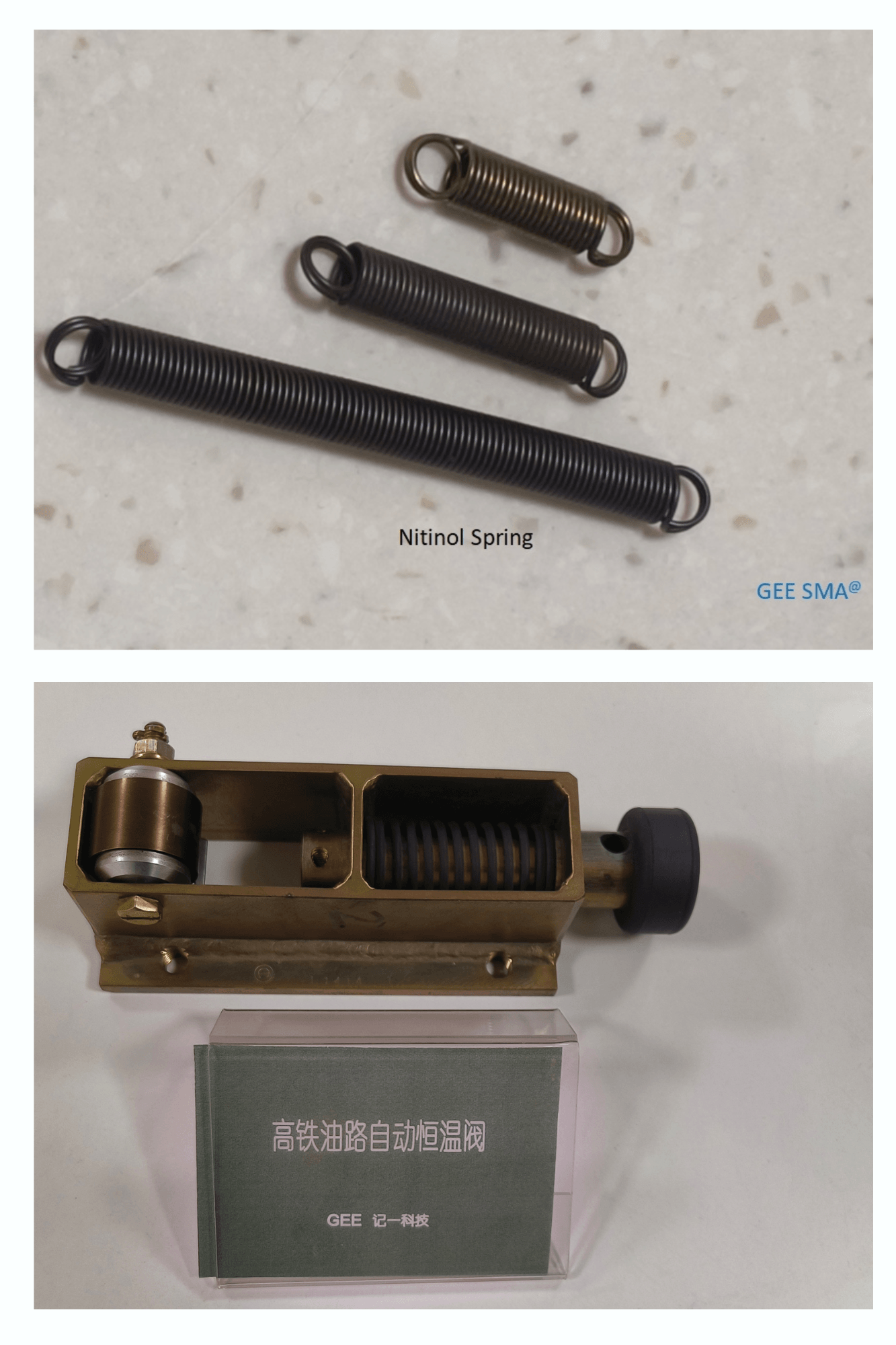

Unveiling the Secrets of GEE SMA

At the forefront of Nitinol technology is GEE SMA – your trusted partner in unlocking the full potential of this incredible material. With expertise in developing cutting-edge Nitinol linear actuators that deliver unparalleled speed and precision, GEE SMA is paving the way for groundbreaking advancements in engineering and technology.

The Fascinating Properties of Nitinol

Nitinol, a unique shape memory alloy, is widely used in actuators due to its remarkable properties. The shape memory effect allows Nitinol to return to its original shape after being deformed, making it perfect for actuators that require precise movements and positioning. Additionally, Nitinol exhibits superelasticity, enabling it to withstand large amounts of strain without permanent deformation, making it an ideal material for high-performance actuators. Furthermore, Nitinol's temperature sensitivity allows for precise control and responsiveness in various applications.

Shape Memory Effect

Nitinol's shape memory effect is a remarkable property that sets it apart from other materials used in actuators. When heated above its transformation temperature, Nitinol can recover its original shape after being deformed, making it an excellent choice for actuators that require accurate and repeatable motion control. This unique ability makes Nitinol actuators highly reliable and efficient in various industries such as robotics and aerospace technology.

Superelasticity

The superelasticity of Nitinol makes it an ideal material for actuators that require resilience and durability. This property allows Nitinol to withstand large amounts of strain without undergoing permanent deformation, ensuring the longevity and reliability of the actuator in demanding applications such as biomedical devices and aerospace technology.

Temperature Sensitivity

Nitinol's temperature sensitivity is a key factor in its use as an actuator material. This property enables precise control over the actuator's movements based on changes in temperature, making it suitable for applications where accuracy and responsiveness are crucial. Whether used in robotics or biomedical devices, the temperature sensitivity of Nitinol ensures optimal performance and efficiency.

Applications of Nitinol Actuators

Nitinol actuators are widely used in various industries due to their unique properties and performance. Biomedical devices, such as stents and guidewires, benefit from the precise control and shape memory effect of nitinol actuators, ensuring accurate placement and deployment within the human body. In robotics, nitinol actuators enable smooth and efficient movement in robotic arms and grippers, enhancing their dexterity and flexibility. Additionally, aerospace technology leverages the lightweight yet durable nature of nitinol actuators for applications like aircraft wing morphing and space exploration mechanisms.

Biomedical Devices

Nitinol actuators play a crucial role in biomedical devices by providing exceptional control and responsiveness. The shape memory effect allows these actuators to adapt to specific conditions inside the body, making them ideal for applications like minimally invasive surgery tools and drug delivery systems. With the ability to change shape based on temperature variations, nitinol actuators ensure precise movements that are essential in medical procedures.

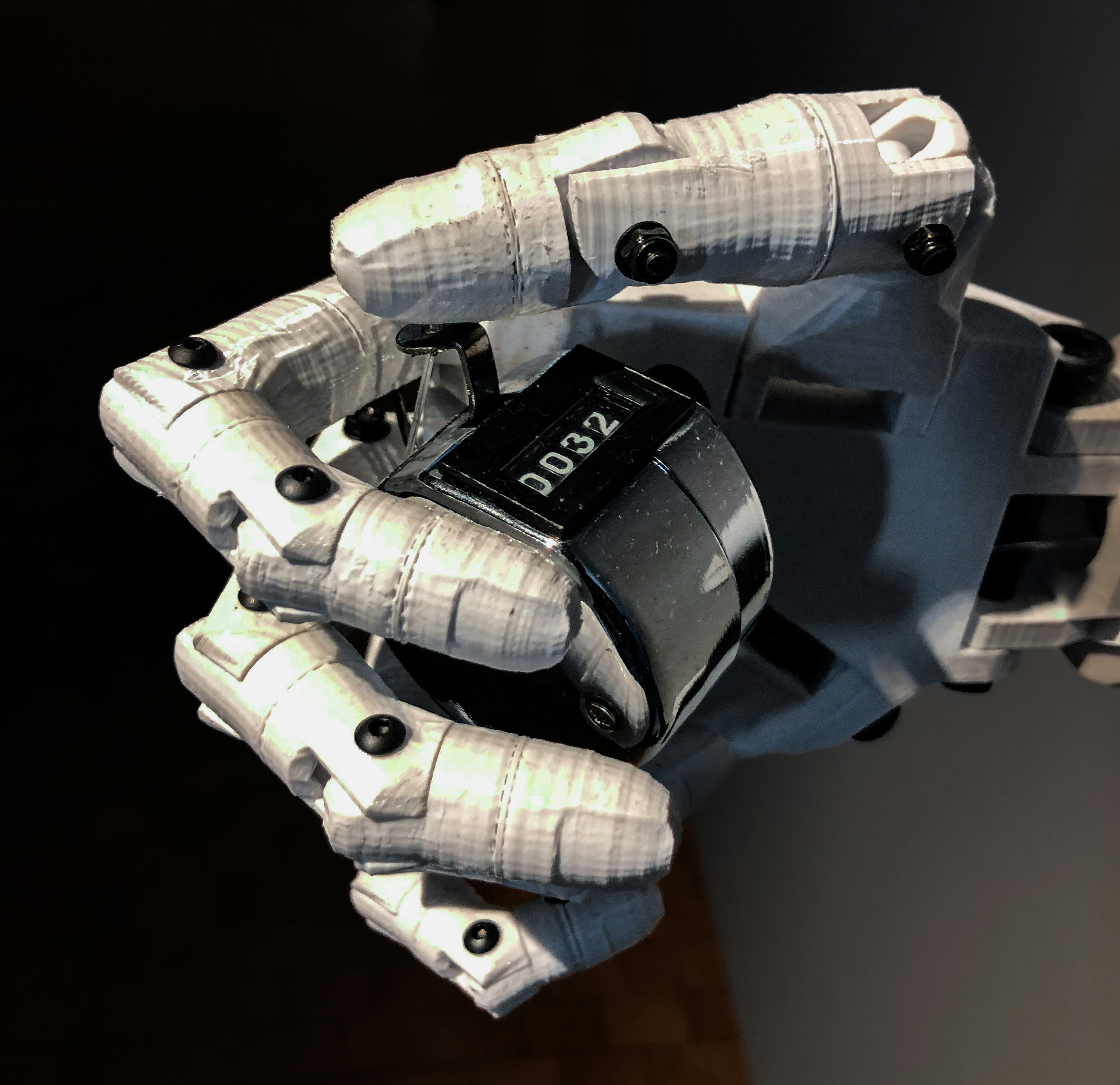

Robotics

In robotics, nitinol actuators offer unparalleled advantages in terms of speed, durability, and energy efficiency. These actuators enable robots to perform intricate tasks with accuracy while consuming minimal power. From surgical robots performing delicate operations to industrial robots handling complex manufacturing processes, nitinol actuators enhance overall performance and reliability.

Aerospace Technology

Aerospace technology relies on nitinol linear actuators for various critical functions such as aircraft wing morphing and satellite deployment mechanisms. The superelasticity of nitinol allows these actuators to withstand extreme conditions while maintaining their structural integrity. This makes them well-suited for aerospace applications where precision control and resilience are paramount.

With their versatility and reliability across different industries, it's clear that nitinol linear actuators are revolutionizing the way we approach technological advancements.

Advantages of Using Nitinol in Actuators

Nitinol actuators offer a multitude of advantages that make them a popular choice in various industries. Firstly, they are lightweight and durable, making them ideal for applications where weight and space are crucial factors. This allows for more compact and efficient designs without sacrificing performance or reliability. Additionally, Nitinol actuators are highly energy efficient, consuming minimal power while delivering impressive force and motion. This not only reduces operational costs but also contributes to environmental sustainability. Furthermore, their precise control enables fine-tuned movements, making them suitable for intricate tasks that demand accuracy and consistency.

Lightweight and Durable

Nitinol's exceptional combination of strength and flexibility makes it an ideal material for actuators that need to withstand repeated use and harsh conditions without succumbing to wear or damage. Its lightweight nature allows for the creation of compact and portable devices, while its durability ensures long-lasting performance in demanding environments. Whether used in medical devices or aerospace technology, the lightweight and durable properties of Nitinol actuators provide a competitive edge in various applications.

Energy Efficiency

One of the standout features of Nitinol actuators is their remarkable energy efficiency. By utilizing the unique properties of Nitinol, these actuators can convert thermal energy into mechanical work with high efficiency, minimizing power consumption while maximizing output performance. This makes them an attractive choice for applications where energy conservation is a priority, such as in portable medical devices or battery-powered robotics.

Precise Control

Nitinol actuators offer unparalleled precision and control over movement due to their ability to respond to subtle changes in temperature or stress with predictable behavior. This level of control is essential for applications that require accurate positioning or delicate manipulation, such as surgical tools or micro-scale robotics. The precise control offered by Nitinol actuators ensures reliable operation in critical scenarios where accuracy is paramount.

Comparison with Other Actuators

When it comes to comparing nitinol actuators with other types of actuators, one common comparison is with DC linear actuators. DC linear actuators are typically powered by direct current and are known for their simplicity and ease of use. However, they lack the unique properties of nitinol, such as shape memory effect and superelasticity, which make nitinol actuators highly desirable in various applications.

DC Linear Actuators

DC linear actuators operate using a simple mechanism where the motor turns a screw that drives the piston rod in and out. This linear motion is used to push or pull loads in a straight line. While DC linear actuators are reliable and cost-effective, they lack the temperature sensitivity and precise control offered by nitinol actuators. This makes them less suitable for applications that require intricate movements and responsiveness to changes in temperature.

DC linear actuators are commonly used in applications such as automotive, home automation, and industrial machinery. Their simple design and reliable performance make them a popular choice for tasks that require linear motion. However, their limitations in temperature sensitivity and precise control mean that they may not be the best option for more advanced or intricate movements.

Two Types of Linear Actuators

There are two main types of linear actuators: mechanical and electro-mechanical. Mechanical linear actuators use gears, belts, or chains to convert rotary motion into linear motion, while electro-mechanical linear actuators utilize electric motors to achieve the same result. Both types have their own advantages, but neither can match the speed, energy efficiency, and lightweight nature of nitinol linear actuators.

With its unparalleled properties such as shape memory effect, superelasticity, temperature sensitivity, and precise control capabilities, it's clear why nitinol is used in actuators across various industries. When compared to other types of linear actuators like DC linear ones or mechanical/electro-mechanical ones, it's evident that nitinol offers unmatched performance and versatility.

How Fast is a Nitinol Actuator?

Nitinol actuators are known for their impressive speed and performance, making them ideal for a wide range of applications. Due to their unique shape memory effect and superelasticity, Nitinol actuators can respond rapidly to changes in temperature or stress, allowing for quick and precise movements in various devices and systems.

Speed and Performance

The speed of a Nitinol actuator is determined by its ability to undergo rapid shape changes in response to external stimuli. This allows for swift and efficient mechanical motion, making Nitinol actuators highly sought after in industries where speed and precision are critical. Whether it's in medical devices, robotics, or aerospace technology, Nitinol actuators deliver exceptional performance that meets the demands of modern engineering.

Nitinol actuators are also known for their durability and longevity, making them a cost-effective solution for industries that require high-speed performance over extended periods of time. This reliability is particularly important in medical devices where precision and consistency are crucial for successful procedures. Additionally, the ability of Nitinol actuators to operate in extreme conditions, such as those found in aerospace technology, further demonstrates their exceptional performance and versatility.

Real-life Applications

In real-life applications, the speed of Nitinol actuators translates into tangible benefits across numerous industries. In the field of biomedical devices, Nitinol actuators enable quick and accurate adjustments in surgical tools or implantable devices, improving patient outcomes and surgical efficiency. In robotics, the rapid response of Nitinol actuators allows for agile and precise movements in robotic arms or grippers, enhancing automation capabilities. Similarly, in aerospace technology, the high-speed performance of Nitinol actuators contributes to improved control and maneuverability in aircraft components.

With its impressive speed and performance capabilities, it's no wonder that Nitinol is used extensively in advanced technologies where swift and accurate motion is essential for success. Whether it's enhancing medical procedures, powering cutting-edge robots, or propelling aerospace innovations forward, Nitinol actuators continue to revolutionize industries with their remarkable speed and efficiency.

Conclusion

Nitinol actuators are revolutionizing industries with their incredible properties and applications. From biomedical devices to aerospace technology, the versatility of nitinol actuators is changing the game. GEE SMA is your trusted partner in nitinol technology, providing cutting-edge solutions for various industries. With our expertise, we are unlocking the full potential of nitinol linear actuators, pushing boundaries and driving innovation.

Revolutionizing Industries with Nitinol Actuators

Nitinol actuators have become a game-changer in various industries due to their remarkable properties such as shape memory effect and superelasticity. The ability to recover their original shape after deformation makes them ideal for applications requiring precise control and reliable performance.

GEE SMA: Your Trusted Partner in Nitinol Technology

As a leading provider of nitinol technology, GEE SMA offers state-of-the-art solutions for diverse industries. Our expertise in developing advanced nitinol actuators ensures that our clients receive top-notch products that meet their specific needs and requirements.

With a focus on innovation and quality, GEE SMA is committed to pushing the boundaries of nitinol technology. Our team of experts continuously strives to develop cutting-edge solutions that deliver superior performance and reliability. By leveraging our in-depth knowledge and experience, we ensure that our nitinol linear actuators set new standards in the industry.

Unlocking the Potential of Nitinol Linear Actuators

With our innovative approach and deep understanding of nitinol technology, GEE SMA is unlocking the full potential of nitinol linear actuators. Our commitment to pushing boundaries and driving innovation allows us to create cutting-edge solutions that elevate performance and efficiency across various applications. Furthermore, our team of experts continuously explores new possibilities for nitinol linear actuators, ensuring that we stay ahead of the curve in this rapidly evolving field. By harnessing the unique properties of nitinol, we are able to develop actuators with unmatched precision and reliability, setting a new standard for the industry.