Introduction

Smart Material Alloys (SMA) have revolutionized the tech industry with their unique properties and versatility. From Nitinol muscles to SMA actuators, these alloys are at the forefront of innovation, offering many benefits for smart technology applications.

Understanding SMA Alloys

SMA alloys, or superelastic alloys, exhibit remarkable shape memory and superelasticity. These properties allow them to return to their original shape after being deformed, making them ideal for various applications in smart technology.

SMA alloys are highly versatile in various smart technology applications, including biomedical devices, aerospace components, and consumer electronics. Their ability to withstand repeated deformation without losing their original shape makes them an ideal choice for devices that require durability and reliability. Additionally, SMA alloys can be easily integrated into complex systems, making them a popular choice for engineers and designers looking to create innovative and efficient products.

Benefits of Using SMA Alloys in Smart Tech

Shape memory alloys (SMAs) are revolutionizing smart technology due to their unique properties:

- Lightweight and Durable: SMA components are strong and can withstand repeated use without bending or breaking.

- Adaptive to Temperature and Stress: Their ability to react to temperature or stress changes makes them ideal for technologies that need to adjust automatically.

- Superelastic and Resilient: SMAs can deform significantly and bounce back to their original shape, perfect for applications requiring flexibility and durability like medical devices, robotics, and aerospace.

- Excellent Corrosion Resistance: SMAs resist corrosion, ensuring long-lasting performance in various smart tech products.

SMAs offer a powerful combination of strength, adaptability, and resilience, making them a game-changer for the future of smart technology.

Overview of Nitinol Muscles

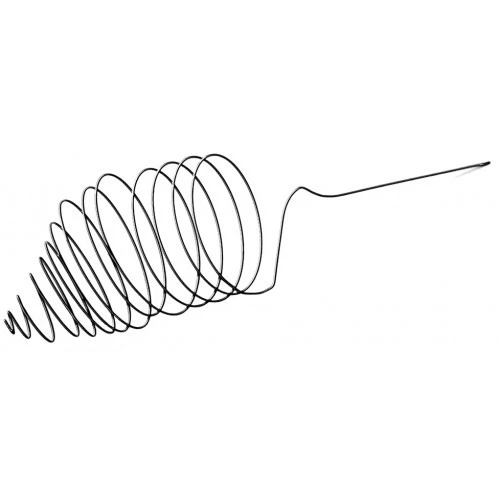

Nitinol muscles, a type of SMA actuator made from Nitinol wire, can mimic the movements of natural muscles when subjected to temperature changes or electrical currents. This unique feature has led to their widespread use in robotics and medical devices.

Now, let's delve deeper into the science behind these remarkable materials and explore their potential applications in shaping the future of smart technology.

The Science Behind SMA Alloys

Nitinol, a type of SMA alloy, is renowned for its superelasticity and shape memory properties. When subjected to stress, it can undergo significant deformation and return to its original shape when removed. This unique characteristic makes it ideal for applications in smart technology, such as Nitinol muscles that mimic human movement in robotics.

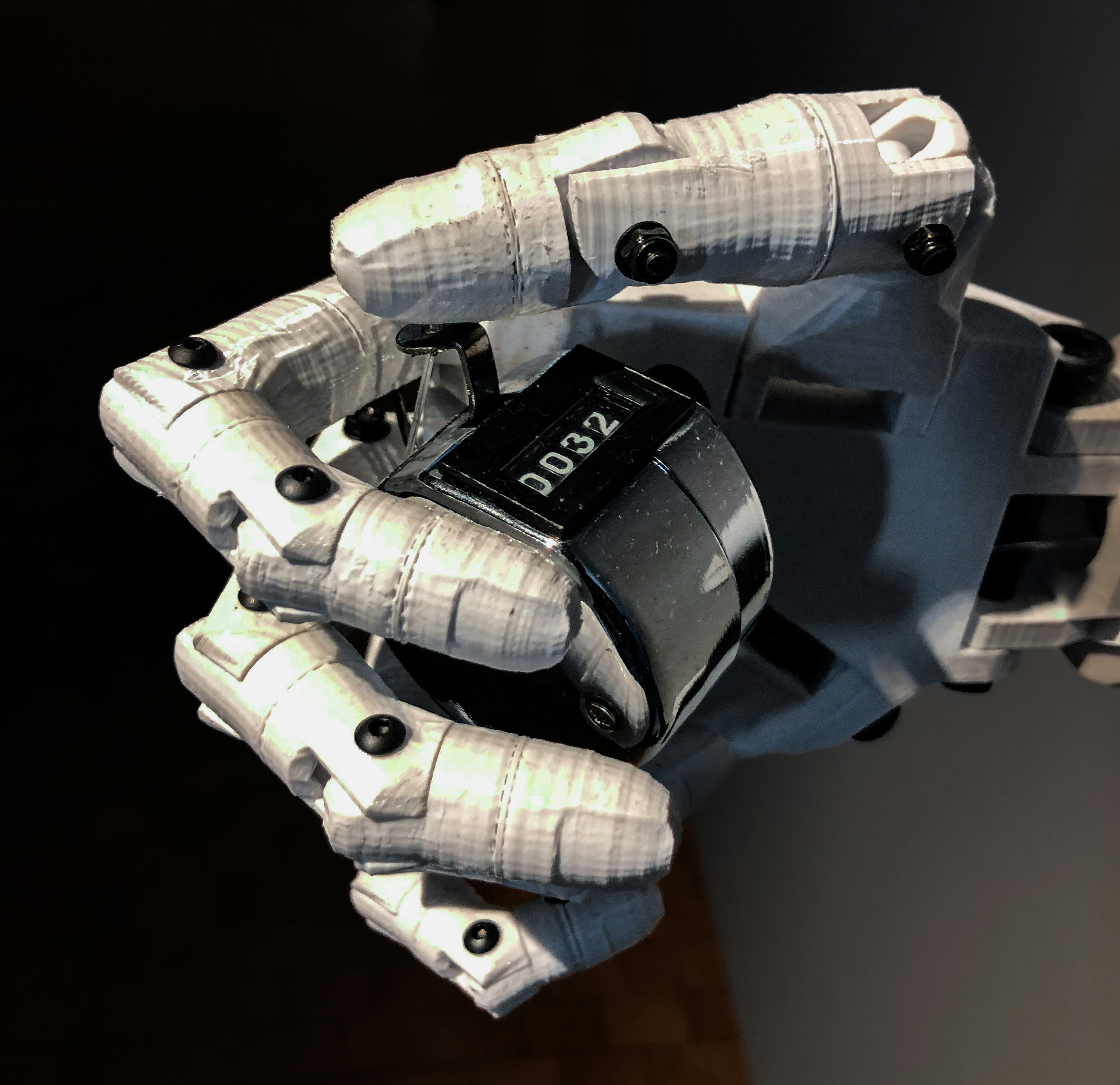

SMA alloys like Nitinol are widely used in smart tech applications due to their remarkable properties. They are commonly found in SMA actuators, pivotal components in robotics and automation. These actuators provide precise and efficient movement, making them invaluable in developing advanced robotic systems.

The advantages of SMA alloys over traditional materials are evident in their exceptional durability and resilience. Unlike conventional materials that may deform or break under stress, Nitinol's superelastic alloy can withstand repeated use without compromising its structural integrity. This makes it a superior choice for long-lasting and reliable smart tech components.

GEE SMA's Role in SMA Alloys

GEE SMA is pivotal in producing high-quality Nitinol materials, utilizing state-of-the-art technology to ensure superior performance and reliability. Our team is dedicated to tailoring components to meet the specific needs of our customers, providing bespoke solutions that deliver exceptional results. Our commitment to swift customer response and product enhancement ensures that our clients receive the best possible support and continuously improved products.

Crafting High-Quality Nitinol Materials

At GEE SMA, we pride ourselves on crafting high-quality Nitinol materials that exhibit remarkable superelasticity and shape memory properties. Our advanced manufacturing processes enable us to produce SMA wires and components with unparalleled precision and consistency, ensuring optimal application performance.

Furthermore, our team of experienced engineers and materials scientists is dedicated to pushing the boundaries of Nitinol technology. Through continuous research and development, we can tailor our components to meet the specific needs of our customers, whether it's for medical devices, aerospace applications, or industrial machinery. This commitment to customization ensures that our Nitinol materials deliver exceptional performance and reliability in any given application.

Tailoring Components to Meet Customer Needs

We understand that each customer has unique requirements, so we specialize in tailoring SMA components to meet specific application needs. Whether designing custom SMA actuators for robotics or creating specialized SMA coils for medical devices, our team works closely with clients to deliver tailored solutions that exceed expectations.

Our commitment to tailoring SMA components to meet customer needs extends beyond the initial design phase. We also provide swift customer response and product enhancement to ensure that our solutions continue to meet evolving requirements. By staying in close communication with our clients, we can quickly address any issues or concerns and proactively improve our products based on their feedback. This dedication to ongoing support and improvement sets us apart as a partner who is genuinely invested in the success of our customers' applications.

Swift Customer Response and Product Enhancement

Our commitment to swift customer response sets us apart. We prioritize open communication channels and rapid assistance for all inquiries. Additionally, we are dedicated to continuous product enhancement, leveraging cutting-edge research and development to improve the capabilities of our SMA alloys and meet evolving industry demands.

In addition to our commitment to swift customer response and continuous product enhancement, we prioritize proactive problem-solving and anticipate potential issues before they arise. By staying ahead of the curve, we can provide our customers with solutions that meet their current needs and anticipate their future requirements. This proactive approach allows us to maintain a competitive edge in the industry and ensures that our customers always receive the best possible service and products.

Innovative Applications of SMA Alloys

SMA alloys have revolutionized the field of robotics with their use in SMA actuators, providing precise and efficient movement in robotic limbs and joints. These super-elastic alloys allow seamless integration into advanced robotic systems, enhancing their agility and dexterity.

SMA Actuators in Robotics

The flexibility and durability of SMA wires make them ideal for use in medical devices, particularly in SMA coils for stents and catheters. These super-elastic alloys provide a reliable and responsive solution for medical applications, ensuring patient comfort and safety during procedures. In addition to their applications in the medical field, SMA actuators are also finding increasing use in robotics. The unique ability of SMA wires to contract or expand in response to changes in temperature or electrical current makes them perfect for creating small, efficient actuators that can be used in robotic systems.

SMA Coils in Medical Devices

In aerospace technology, SMA springs' lightweight yet robust nature has proven invaluable. From landing gear to wing flaps, these shape memory alloy springs offer a reliable and efficient solution for critical components in aircraft, ensuring smooth operation at high altitudes. Furthermore, SMA coils are also used in medical devices such as stents and orthodontic braces. The biocompatibility and flexibility of SMA coils make them an ideal choice for such applications, providing patients with durable and comfortable medical implants that can adapt to their body's movements.

SMA Springs in Aerospace Technology

Shape Memory Alloys (SMAs), particularly Nitinol, are revolutionizing various industries with their unique properties. Their potential for further advancements seems limitless. The aerospace industry, in particular, has greatly benefited from SMAs.

Here are some key applications of SMAs in aerospace:

- Actuators and control surfaces: SMAs can adjust wing shapes for optimal performance during flight phases.

- Landing gear: Their shape memory effect allows for compact storage and self-deployment upon landing.

- Engine components: SMAs can be used for vibration damping and active flow control, improving engine efficiency.

These lightweight, high-strength materials offer exciting possibilities for the future of aerospace engineering, creating more efficient and reliable aircraft. With continued research and development, SMAs promise to play an even more significant role in shaping the future of flight.

Future of Smart Tech with SMA Alloys

The potential for advancement in wearable tech using SMA alloys is immense. With the ability to create lightweight and flexible materials, SMA wires can be integrated into clothing and accessories to provide personalized comfort and support. Imagine a future where smart garments adjust their fit based on body temperature or movement, all thanks to the power of superelastic alloys.

Potential for Advancement in Wearable Tech

SMA alloys, particularly nitinol muscles, have the potential to revolutionize the wearable tech industry. These smart materials can create responsive and adaptable fabrics that adjust to the wearer's needs. From self-adjusting waistbands to temperature-regulating clothing, the possibilities for integrating SMA alloys into everyday wearables are endless.

Additionally, SMA alloys have the potential to enhance the performance of renewable energy systems. By incorporating nitinol muscles into solar panels, for example, these smart materials can enable the panels to adjust their orientation throughout the day to maximize sunlight absorption. This could significantly improve the efficiency of solar energy generation and contribute to a more sustainable energy infrastructure. Furthermore, integrating SMA alloys into wind turbine blades could allow for greater flexibility and responsiveness to changing wind conditions, ultimately increasing the overall output of wind energy systems.

Impact on Renewable Energy Systems

SMA coils are crucial in enhancing efficiency and reliability in renewable energy systems. These coils, made from superelastic alloys, offer unique advantages:

- Durability: Composed of shape-memory alloys, SMA coils can withstand repeated stress and strain, making them ideal for the demanding conditions of renewable energy sources.

- Energy Harvesting: Their elasticity allows them to be incorporated into devices like vibration-powered generators or wave energy converters, effectively capturing energy from the environment.

- Smart Home Integration: Beyond harvesting, SMA coils can be integrated into smart home systems for optimized energy use. For instance, they can be used in heating and cooling systems to regulate energy consumption based on temperature and pressure changes.

Combining these capabilities, SMA coils contribute significantly to advancing sustainable and efficient renewable energy solutions.

Integration Into Smart Home Devices

As smart home technology continues to evolve, SMA springs are poised to play a significant role in creating responsive and energy-efficient devices. Whether it's improving the functionality of automated window shades or enhancing the precision of HVAC systems, SMA springs offer a reliable and durable solution for integrating intelligence into household appliances.

SMA springs can also be integrated into smart home security systems, providing a reliable and efficient way to control and monitor access points. By incorporating SMA springs into door locks and surveillance cameras, homeowners can enjoy added peace of mind, knowing that their smart home devices are equipped with durable and responsive technology. This integration not only enhances the home's security features but also contributes to the overall energy efficiency of the system.

By harnessing the potential of SMA alloys in these key areas, we are paving the way for a future where smart technology seamlessly integrates with our daily lives, offering enhanced comfort, efficiency, and sustainability.

Conclusion

SMA Alloys, particularly Nitinol muscles, have revolutionized the world of smart technology with their remarkable properties. As these alloys continue to gain traction, it's essential to harness their potential to create innovative solutions for a wide range of applications.

Adapting to meet evolving tech demands is crucial in maximizing the benefits of SMA Alloys. With GEE SMA's expertise in crafting high-quality Nitinol materials, the industry can stay ahead of the curve by tailoring components to meet specific customer needs and swiftly responding to market demands.

Embracing the versatility of Nitinol technology opens up endless possibilities for future advancements in smart tech. From wearable devices and renewable energy systems to smart home appliances, SMA Alloys are poised to play a pivotal role in shaping the technology landscape. With its unique shape memory and superelastic properties, Nitinol has the potential to revolutionize the medical field, enabling the development of advanced implantable devices and minimally invasive surgical tools. Furthermore, as research and development in Nitinol technology continues to expand, we can anticipate breakthroughs in aerospace engineering, where SMA Alloys can be utilized to create more efficient and lightweight components for aircraft and spacecraft.

With SMA actuators, coils, springs, and wires at the forefront of innovation, these super elastic alloys are set to redefine the future of smart technology as we know it. With SMA alloys leading the charge, the potential for growth and advancement is limitless.